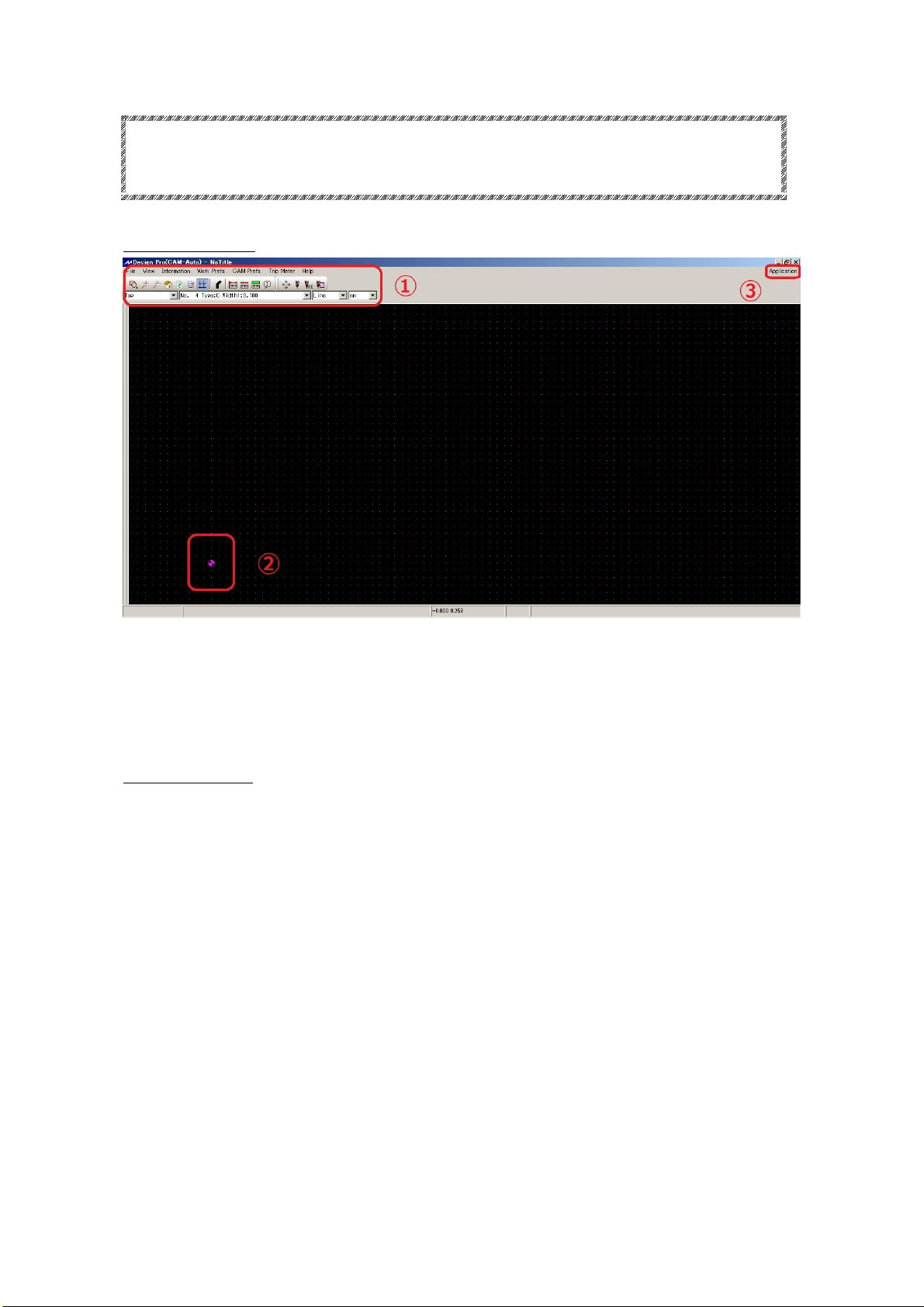

◆CAD with Dongle Key

Make sure to remove Dongle key when you are using the prototyping machine.

Connection error may occur and prototyping machine may be unable to use.

◆Tools and RPM

For processing, set the RPM to 30~40. The unit in the software is x 1000RPM.

To drill 0.3~0.4mm size holes, set the Lower2 3~4mm/sec.

IMPORTANT

To drill 0.3~0.4mm size holes, go to CAM Pref. →Board Maker and set

the Lower2 3~4mm/sec. After setting the Lower2 speed slower, make sure

to set Drill Wait and Before Cutting longer than the default setting. If

not, there is a possibility of spindle head moving too early before the

drilling is completely penetrated.

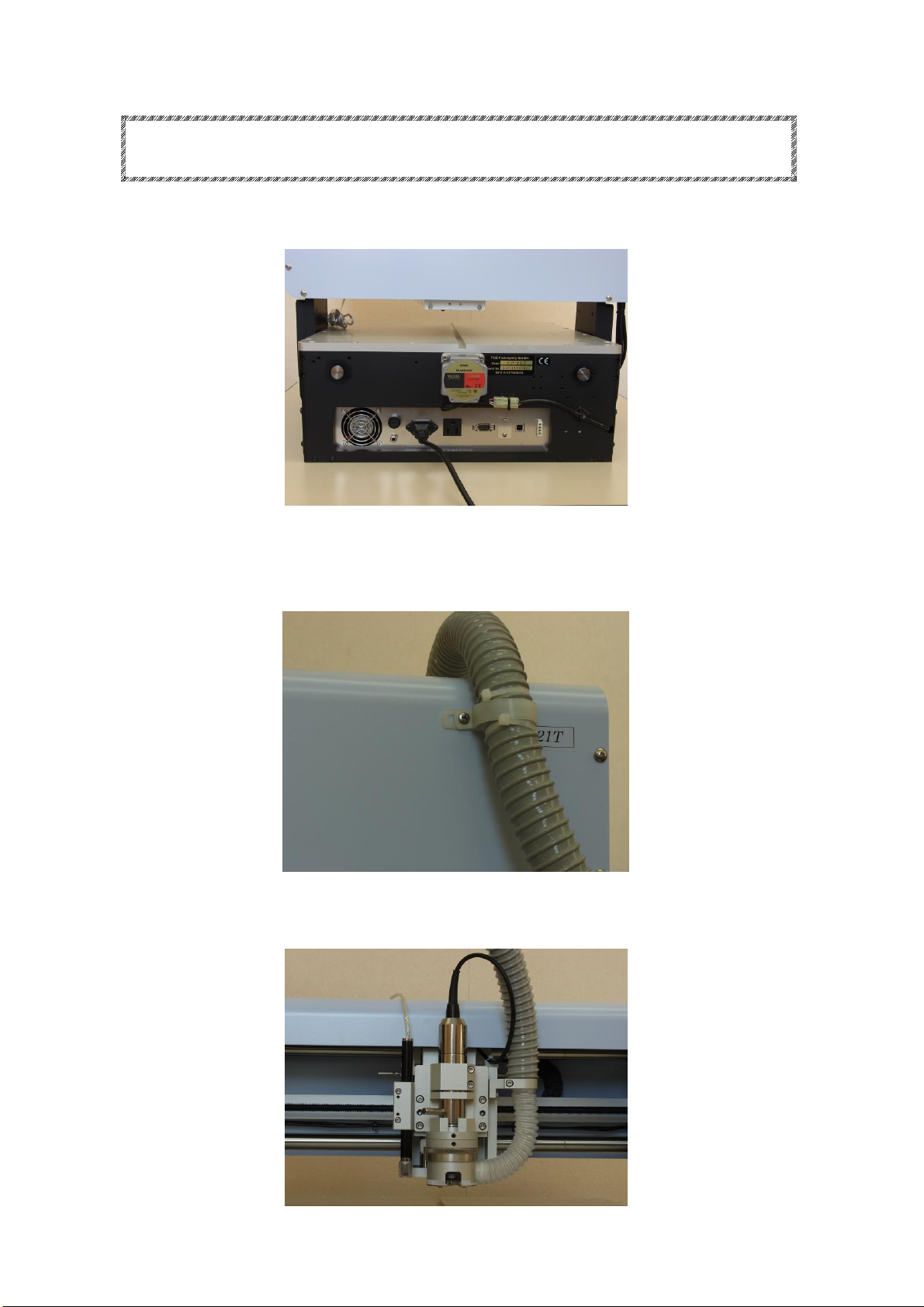

◆Transportation

Since the Auto Lab precision machine, use the container box which was used

for shipping. For long distant transportation using carrier, make sure to

select carrier with great handle care with the transportation.

Do not apply any force to the shaft, lead screw, spindle head while

transportation. It could result to have the accuracy to drop.

◆Spindle Motor Cleaning

Note that spindle motor and collet are ultra-precision component. In order

to keep the machine performance well, daily checkup and cleaning is necessary.

Spindle motor may result to malfunction when dust or debris are caught between

tool and collet, decreasing the holding power of the tools. Make sure to check

and clean the spindle motor before using.

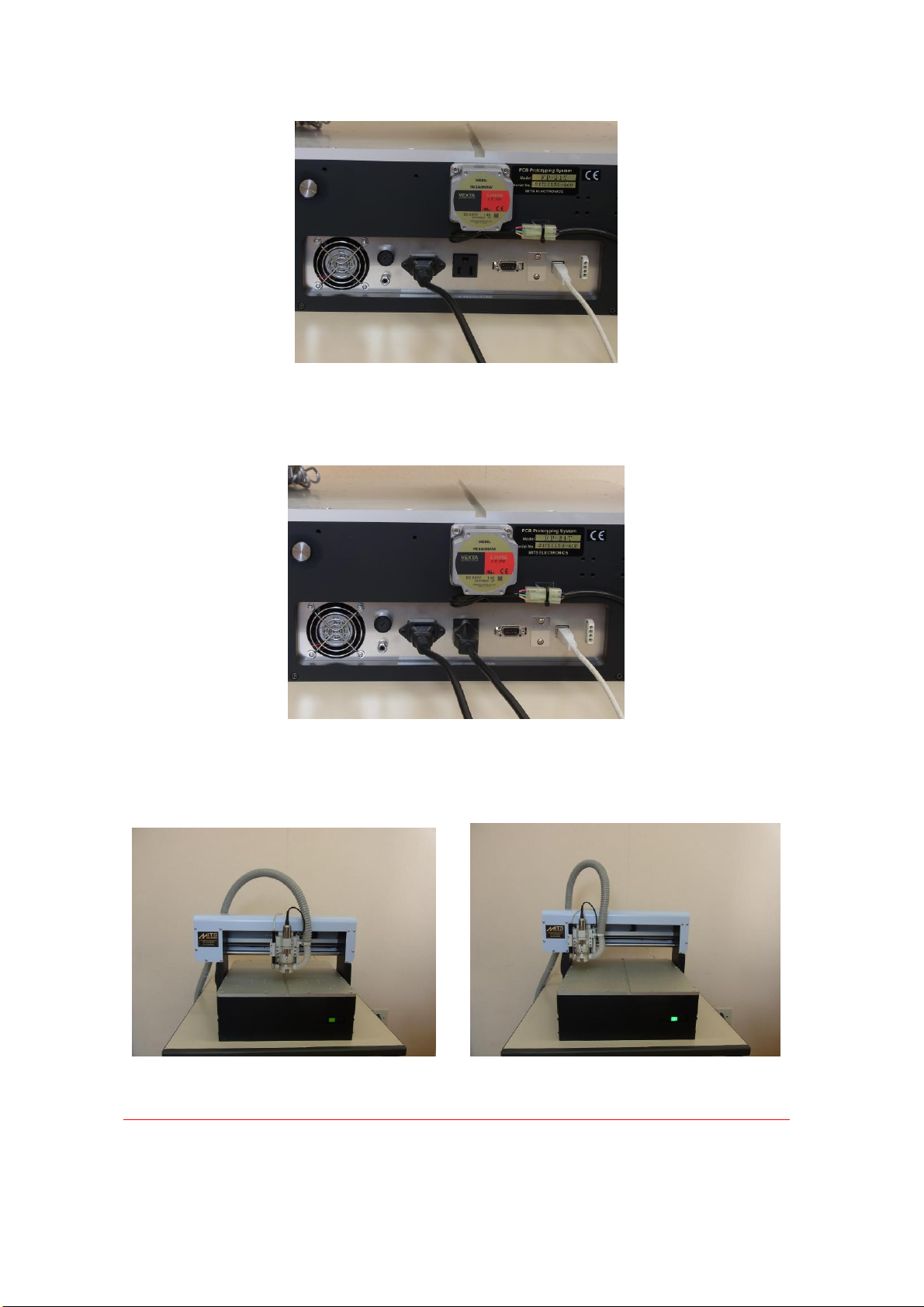

◆Warranty

The term of warranty for PCB Prototyping Machine is 1 year with the intended

use. Note that spindle motor and consumable supplies are not included in the

warranty. Also note that even within the warranty period, below circumstances

will be considered as charged repair. Improper use, inappropriate assembly,

damage/breakage by carelessness, natural disaster, abrasion, modification,

use of non-genuine components/parts, use in undesignated voltage. Please

operate with great care when you are using the machine without any training.