Siemens Energy SpecTRON 8 User manual

Unrestricted

siemens-energy.com

SpecTRON 8

Installation, Operation Manual

Document No: DOC0075

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

2 of 63

Unrestricted

Foreword

Thank you for purchasing a Siemens Energy Subsea Connectors SpecTRON 8 product. The

information that follows is an overview of the protection, storage, shipment, unpacking,

deployment and maintenance instructions for SpecTRON 8 products.

Siemens Subsea Connectors recommend the termination and installation of all equipment only be

undertaken by suitably trained and qualified personnel.

Revision Summary

This page records the revision status of the entire document and its authorisation for issue. When a

page or pages of the document are revised, the number of the page(s) affected will be entered in the

Page(s) Affected/Remarks column and a vertical margin line will appear against the latest amended

text.

Rev

Compiled by

Approved by

Issue Date

Page(s) Affected/Remarks

See TeamCenter revision history for earlier revision history

13

S.Hargreaves

M.Earnshaw

12/09/2019

Section 5.1 - Figure 8 updated to include central

slinging position on the Dual Penetrator Assembly

and added note about inboard termination.

Updated whole document to latest Siemens template

format.

Section 3.3.3 –Added cable OD, MBR, Weight in Air

and Weight in Water for both 35mm2and 4mm2.

Created Section 3.3.4 to include test connector cable

information.

Changed Rev 12 Sections 10.2, 10.3, 10.5 and 10.6

into sub sections of 10.1 and 10.2 as 10.1 and 10.2

didn’t have any content underneath their titles.

Created Section 11 to describe connection points etc.

for test connectors.

Section 5.1 Figures 4, 5, 6 & 7 –Corrected positions

of arrows.

Document Control Page –Removed Tronic reference

and replaced with Siemens.

14

C. Plant

N. Williamson

20/12/2021

Updated to Siemens Energy template and product

safety focused layout

Aligned contents with SpecTRON 10, 10+ and 45 IoM

for consistency

Added hose management/routing information

Added cleaning/drying instructions (Section 8.1)

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

3 of 63

Unrestricted

Contents

1PRODUCT SCOPE........................................................................................... 6

1.1 Product Certification............................................................................. 6

1.2 Contact details...................................................................................... 6

1.3 Product advice label ............................................................................. 7

1.4 Product marking ................................................................................... 8

1.5 CE label/marking................................................................................... 8

2PRODUCT SAFETY......................................................................................... 9

2.1 Action-related warnings....................................................................... 9

2.2 Intended use......................................................................................... 9

2.3 General safety information ................................................................ 10

2.4 Related documents............................................................................. 13

3ABBREVIATIONS ......................................................................................... 15

4SPECIFICATION AND RESIDUAL HAZARDS .................................................. 17

4.1 Connector General Specification........................................................ 17

4.2 Misalignment capability of wet mate stab connectors....................... 18

4.3 Hose Specifications ............................................................................ 18

4.4 Cable Specifications ........................................................................... 19

4.5 Other specifications............................................................................ 20

4.6 Environmental, disposal and recycling............................................... 21

4.7 Personal protective equipment (PPE) ................................................. 21

5PREPARING PRODUCT FOR USE................................................................... 22

5.1 Safety precautions before installation ............................................... 22

5.2 Unpacking .......................................................................................... 24

5.3 Safe disposal of packaging................................................................. 27

5.4 Lifting ................................................................................................. 27

5.5 Installation and assembly................................................................... 30

5.6 Storage and protection....................................................................... 30

5.7 Repackaging to prevent damage in transport .................................... 32

6OPERATION OF PRODUCT ........................................................................... 33

6.1 Energising Wet Mate Pair ................................................................... 33

6.2 Deployment........................................................................................ 33

6.3 Retrieval ............................................................................................. 33

6.4 Hose Management and Routing......................................................... 34

6.5 Hose Buoyancy Subsea....................................................................... 39

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

4 of 63

Unrestricted

6.6 ROV Manipulator ................................................................................ 39

6.7 Connecting ROV Wet Mate Pair Subsea.............................................. 42

6.8 Disconnecting ROV Wet Mate Pair Subsea ......................................... 46

6.9 Connecting ROV Wet Mate Pair Manually/Topside ............................. 48

6.10 Disconnecting ROV Wet Mate Pair Manually/Topside......................... 50

6.11 Test Connectors.................................................................................. 51

6.12 Testing................................................................................................ 54

6.13 Quick references................................................................................. 55

6.14 Disposal of waste products................................................................. 55

7USER INFORMATION................................................................................... 56

7.1 Normal and faulty/dangerous operation ............................................ 56

7.2 Cathodic Protection ............................................................................ 56

7.3 Troubleshooting (FAQ’s)..................................................................... 57

8PRODUCT MAINTENANCE........................................................................... 58

8.1 Connector Cleaning and Drying ......................................................... 58

8.2 Product maintenance (skilled persons) .............................................. 60

9CUSTOMER COMMENTS/FEEDBACK............................................................ 62

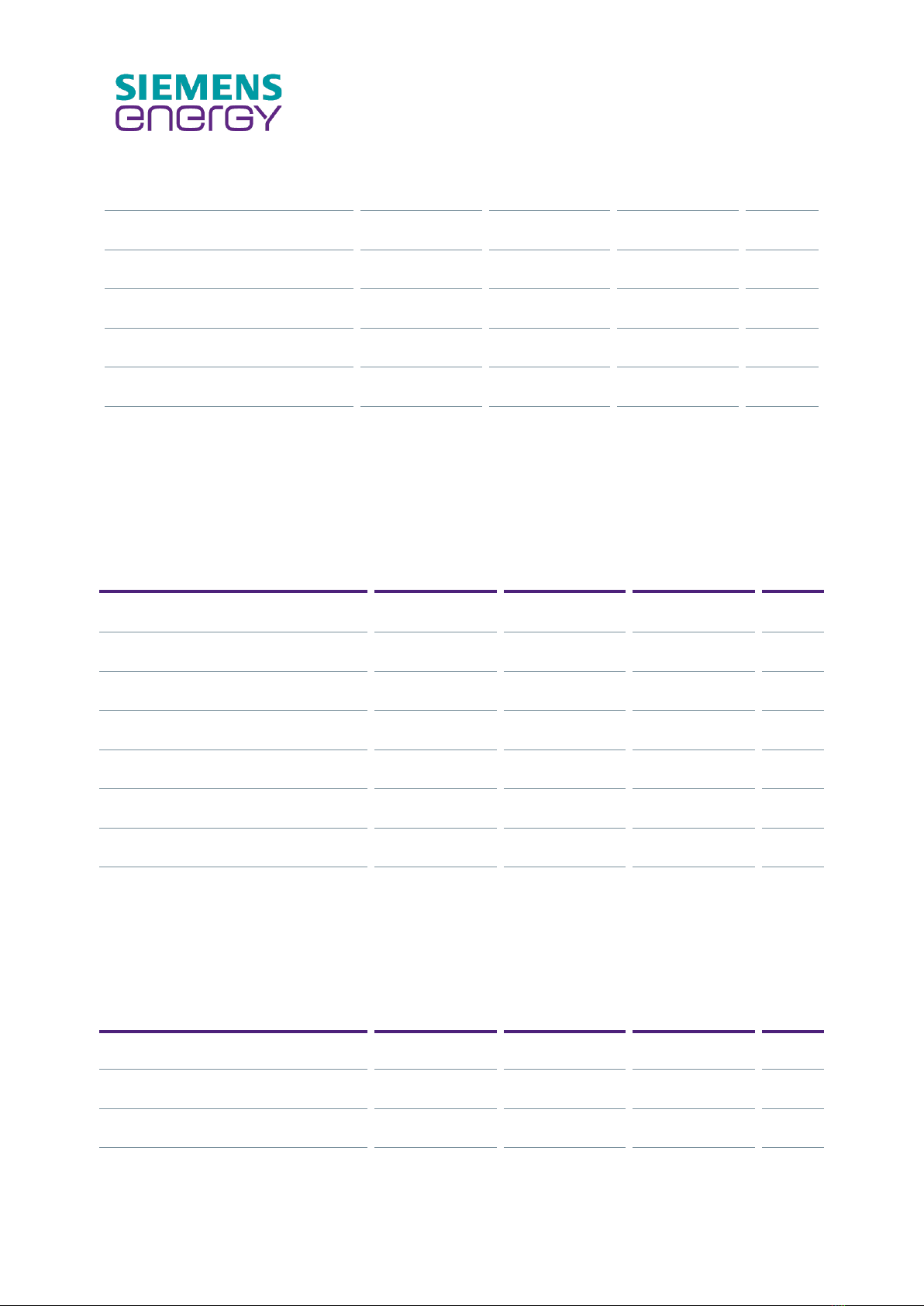

Tables

Table 1 - SpecTRON 8 Product Certification........................................................................6

Table 2 - Contact Details.....................................................................................................6

Table 3 - SpecTRON 8 Connectors General Specification..................................................17

Table 4 - SpecTRON 8 Hose Specifications........................................................................19

Table 5 - SpecTRON 8 Cable Specifications (4 –16 mm sq.) ............................................. 19

Table 6 - SpecTRON 8 Cable Specifications (35 mm sq.)................................................... 20

Table 7 - Troubleshooting product contact details........................................................... 57

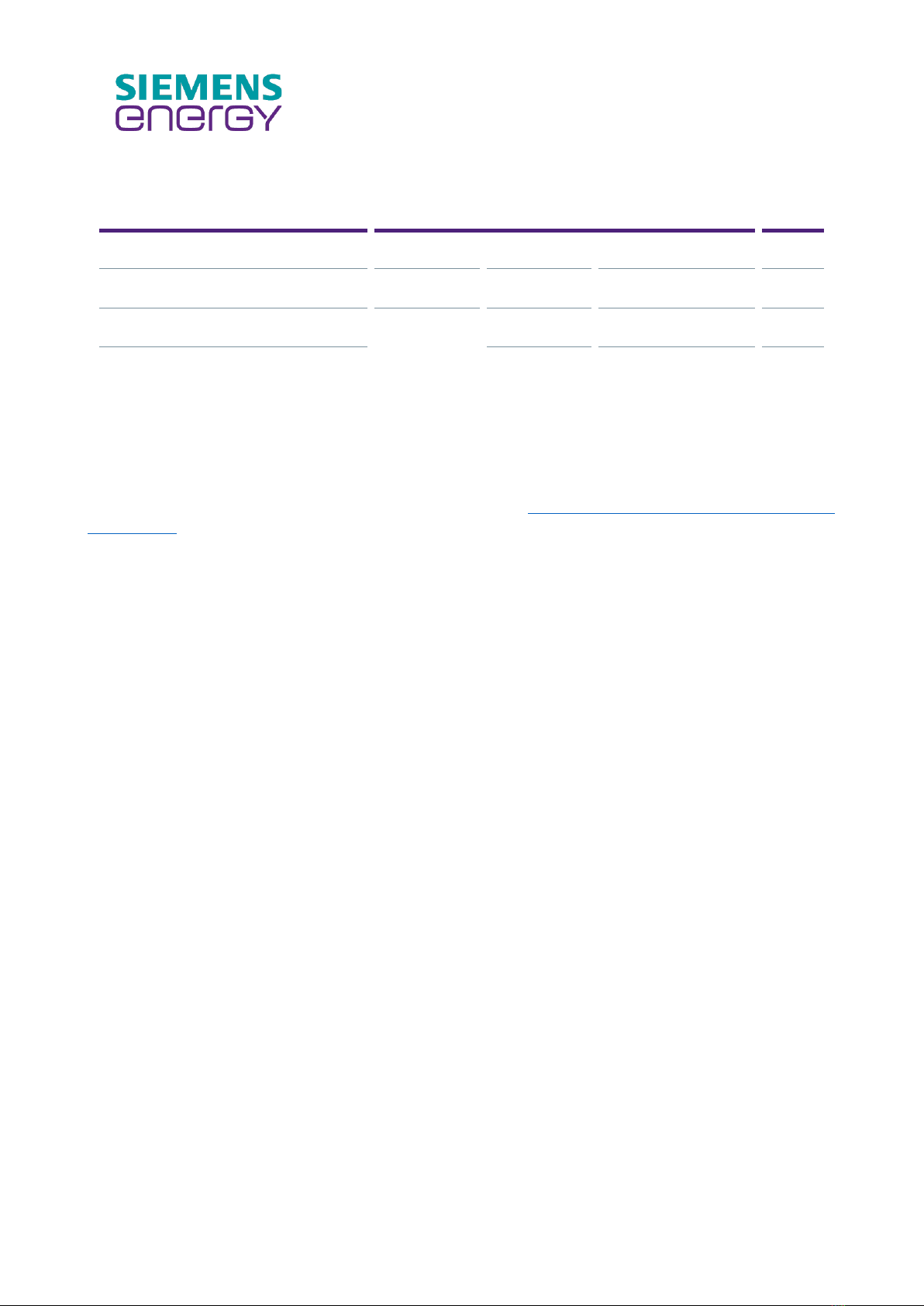

Illustrations

Figure 1 - Product Advice Label ..........................................................................................7

Figure 2 - Example Etching for SpecTRON 8 Products ........................................................8

Figure 3 - Example harness marking ..................................................................................8

Figure 4 - SpecTRON 8 Current Rating ..............................................................................18

Figure 5 - SpecTRON 8 Stab Connector Misalignment Capability.....................................18

Figure 6 - SpecTRON 8 harness typical packaging............................................................22

Figure 7 - Optional polyethylene plastic packaging .........................................................23

Figure 8 - ROV Plug Cap ....................................................................................................24

Figure 9 - ROV Receptacle Cap..........................................................................................25

Figure 10 - Tree Cap Penetrator / Plug Removal of Keyed Cap .........................................25

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

5 of 63

Unrestricted

Figure 11 - Tree Cap Penetrator / Plug Protective Cap Removal .......................................26

Figure 12 - Tree Cap Penetrator / Plug Split Sleeve Removal............................................26

Figure 13 - ROV Receptacle - Penetrator - Tree Cap Plug Jumper .....................................27

Figure 14 - Recommended lift position - ROV Receptacle ................................................ 28

Figure 15 - Recommended lift positions - ROV Plug (Without / with locking mechanism)

28

Figure 16 –Recommended lift positions - Tree Cap Penetrator / Plug (Version 1) ...........29

Figure 17 - Recommended lift positions Tree Cap Penetrator / Plug (Version 2).............. 29

Figure 18 - Recommended Lift Positions - Dual Penetrator ..............................................29

Figure 19 - AquaTRON (left) and Gorilla (right) hoses at to minimum bend radius .........34

Figure 20 - Incorrectly bent AquaTRON (orange) and Gorilla (yellow) Hose ....................35

Figure 21 - Immediate fall in routing................................................................................35

Figure 22 - Hose kink due to immediate fall in routing and weight application ..............35

Figure 23 - Plate Former ................................................................................................... 36

Figure 24 - ‘U’ Former .......................................................................................................36

Figure 25 - ‘L’ Former .......................................................................................................36

Figure 26 - Permanent fixed ‘U’ former ............................................................................37

Figure 27 - Potential Clamping of Hose on Compliant Connector ....................................37

Figure 28 - Example of temporary hose support during SIT .............................................38

Figure 29 - Example of support for immediate fall in hose routing ................................. 38

Figure 30 - Fabricated stand with former used for hose support .....................................39

Figure 31 - Recommended ROV Manipulator Jaw for T Bar Handle..................................39

Figure 32 - ROV Connector Handling (without and with locking mechanism).................40

Figure 33 - Recommended ROV Manipulator Jaw for Fishtail Handle.............................. 40

Figure 34 - ROV Connector Handling................................................................................ 41

Figure 35 - Visual alignment indicators on plug and receptacle (coated connectors) .....42

Figure 36 - Physical alignment keyway relative to visual indicator (uncoated connectors)

43

Figure 37 - Final Push with open jaw................................................................................43

Figure 38 - Alignment Indicators (Connectors with Locking Mechanism) .......................44

Figure 39 - Mating Check - Fully Mated. (NB: Small Gap between Flanges)..................... 44

Figure 40 - Mating Check - Locking Mechanism Engaged. ............................................... 45

Figure 41 - Locking Mechanism Disengaged ....................................................................47

Figure 42 - Mate using ROV Handle..................................................................................49

Figure 43 - Check Connectors are Mated.......................................................................... 49

Figure 44 - Tailed Test Harness Connection Points...........................................................52

Figure 45 - Alignment Indicators (Topside Test Connectors) ...........................................52

Figure 46 - SpecTRON 8 Test Receptacle with collar, stud, and nuts................................53

Figure 47 –Receptacle Components for drying and cleaning..........................................58

Figure 48 - Receptacle Pin tip ..........................................................................................59

Figure 49 - Receptacle pin contact area as supplied ........................................................59

Figure 50 - SpecTRON 8 Plug Power Washing Locations .................................................. 60

Figure 51 - SpecTRON 8 Receptacle Power Washing Locations ........................................61

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

6 of 63

Unrestricted

1PRODUCT SCOPE

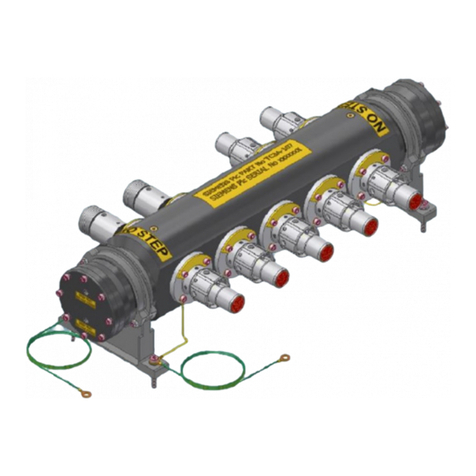

This manual includes information on the following SpecTRON 8 connector types:

- SpecTRON 8 ROV Wet Mate Plug

- SpecTRON 8 ROV Wet Mate Receptacle

- SpecTRON 8 Stab Wet Mate Plug

- SpecTRON 8 Stab Wet Mate Receptacle

- SpecTRON 8 Penetrator

- SpecTRON 8 Dual Penetrator

- SpecTRON 8 Single Feed-through

oTree Cap Penetrator and Plug

oTubing Hanger Receptacle

- SpecTRON 8 Dual Feed-through

oTree Cap Penetrator and Plug

oTubing Hanger Receptacle

- SpecTRON 8 ROV Dummy Connectors

- SpecTRON 8 ROV Parking Receptacle

1.1 Product Certification

Standard

Description

SEPS SP-1001

Power connectors,penetrators and jumper assemblies with rated voltage

from 3 kV (Umax = 3,6 kV) to 30 kV (umax = 36 kV)

Note: Self-certified via in-house testing.

Table 1 - SpecTRON 8 Product Certification

1.2 Contact details

For additional information or questions regards the products visit the Siemens Energy website

www.siemens-energy.com/subsea or contact the following:

Department

E-mail address

Product Safety Officer

subsea.connectors.productsafety.gb@siemens-energy.com

Technical Support

connectortechnicalsupport.gb@siemens-energy.com

Service (Site Team)

susultlcmsupport.gb@siemens-energy.com

Sales

connectorsales.gb@siemens-energy.com

Table 2 - Contact Details

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

7 of 63

Unrestricted

1.3 Product advice label

The following product advice label is supplied with all Siemens Energy subsea products.

Figure 1 - Product Advice Label

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

8 of 63

Unrestricted

1.4 Product marking

1.4.1 Connectors and Penetrators

Figure 2 - Example Etching for SpecTRON 8 Products

Siemens Energy Subsea SpecTRON 8 connectors and penetrators are laser marked on the gland body

with the Siemens Energy Subsea part number, unique serial number, and product rating information.

Additionally, connector front-ends are also marked with their part number and unique serial number

to aide traceability during manufacturing.

1.4.2 Harnesses

Harnesses are also marked with the Siemens Energy Subsea part number and unique serial number

as shown in Figure 3. Client and project specific information is also usually added to these labels.

Labels are typically black text on a yellow background underneath clear heat shrink. Typically, labels

are located at each end of the harness and centrally.

Figure 3 - Example harness marking

1.5 CE label/marking

SpecTRON 8 is exempt from any current requirement for CE marking. Siemens Energy continue to

monitor European and International requirements for applicability to the SpecTRON 8 product range.

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

9 of 63

Unrestricted

2PRODUCT SAFETY

Siemens Energy Subsea recommends the termination of all equipment shall only be undertaken by

trained, suitably qualified and experienced personnel (SQEP) i.e. competent person.

2.1 Action-related warnings

Classification of action-related warnings

The action related warnings are classified in accordance with the severity of the possible danger using

the following warning signs and signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental damage

2.2 Intended use

Following installation, commissioning, and deployment of product, please complete and return the

Customer Comments/Feedback form (Section 9). Please e-mail completed form to the Product Safety

Officer at subsea.connectors.productsafety.gb@siemens-energy.com.

There is a risk of injury or death to the user or others, or of damage to the product and other property

in the event of improper use or use for which it is not intended.

The product is intended as a subsea high voltage electrical connector, for use by suitably trained

personnel in industrial applications only.

Intended use includes the following:

- observance of the installation and operating instructions included for the product and any other

system components.

- compliance with all inspection and maintenance conditions listed in the instructions.

- Use of all recommended tooling appropriate for specific tasks.

- All activities to be undertaken by a competent person (see 2.3.1 for definition).

Any other use that is not specified in this document or covered in installation and operating

instructions, or beyond that specified in this document shall be considered improper use.

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

10 of 63

Unrestricted

2.3 General safety information

2.3.1 Installation by competent persons only

The installation, inspection, maintenance and repair of the product shall be undertaken by trained,

suitably qualified and experienced personnel (SQEP) i.e. competent person, to carry out a specified

activity. Installation, inspection, maintenance and repair of products by untrained and deemed non-

competent persons could invalidate the product warranty.

For further information contact Service (Site Team) susultlcmsupport.gb@siemens-energy.com.

2.3.2 Danger caused by improper operation and foreseeable misuse

Improper operation and foreseeable misuse may present a danger to you and others and cause

material damage. Carefully read the enclosed instructions and all other applicable documents,

particularly the “Safety” section and the warnings.

Danger! Risk of death from electric shock if user dismantles/incorrectly re-

assembles/incorrectly re-terminates product (foreseeable misuse).

- Maintenance, disassembly, re-assembly and termination activities must only be carried

out by a competent person.

Danger! Risk of death from electric shock if shuttle pins are depressed e.g. with a

screwdriver when plug is live.

- Maintenance and testing activities must only be carried out by a competent person.

- Correct tools must always be used.

Danger! Risk of imminent danger to life, risk of severe personal injury caused by a shuttle

pin projectile due to damage caused to shuttle pins e.g. with a screwdriver (foreseeable

misuse).

- Maintenance and testing activities must only be carried out by a competent person.

- Correct tools must always be used.

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

11 of 63

Unrestricted

2.3.3 Risk of death due to electrocution

Danger! Risk of death from electric shock due to exposed live pins, e.g. factory or top-side

system test and unmated receptacle is energised, e.g. by diver subsea.

- Ensure all test procedures are followed.

- Receptacles must be mated to a wet mate or test plug before energisation

- Communication channels and protocols are observed.

Danger! Risk of death from electric shock from any exposed conductors due to stored

electrical energy, e.g. capacitance of cable or elsewhere in the system.

- Ensure all procedures are followed.

- Allow sufficient time for discharging of items after testing

Danger! Risk of death from electric shock from test connectors. Live parts can be exposed

by disassembly without a tool (e.g. termination sleeves are accessible and can be removed).

Also exposed cable conductors at free end of test connectors, and unscreened cables in

some terminations.

- Ensure all test procedures are followed.

- Receptacles must be mated to a wet mate or test plug before energisation

- Communication channels and protocols must be observed.

Danger! Risk of death from electric shock if product is terminated incorrectly by 3rd party

e.g. loose conductor touching metal body, or live wire terminated to metal body in error.

- Installation/termination activities must be carried out by a competent person

Danger! Risk of death from electric shock due to metal body of connector not being earthed

during test and connector having earth fault (e.g. conductor touching metalwork) during

electrical testing.

- Ensure all testing of products both factory and deployed in-field have been completed

by competent persons.

Danger! Risk of death from electric shock or severe personal injury through burning from

de-mating live conductors by hand.

- Ensure all procedures are followed for mating/de-mating connectors.

2.3.4 Risk of injury and material damage due to maintenance and repairs carried out

incorrectly or not at all

Maintenance work or repairs on the products should only be carried out by a competent person.

Faults and damage should be immediately rectified by a competent person. Adhere to the

maintenance intervals specified.

Danger! Risk of imminent danger to life, risk of severe personal injury from burning and

material damage from ohmic heating in short-circuit condition or high over-currents.

- Ensure all testing of products both factory and deployed in-field have been completed

by competent persons.

Danger! Risk of imminent danger to life, risk of severe personal injury caused by released

pressure and or projectile due to incorrectly installed pressure retaining product, e.g.

during system pressure test (e.g. SpecTRON 8 penetrator fitted with wrong/insufficient

screws or seals).

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

12 of 63

Unrestricted

- Ensure all product assembly and testing activities are completed by competent persons.

Danger! Risk of imminent danger to life, risk of severe personal injury to persons with

pacemakers or implantable cardioverter-defibrillators (ICDS) from electromagnetic

interference (EMI) e.g. high frequency testing with large load currents.

- Ensure all testing of products both factory and topside are not conducted by or in the

presence of persons with pacemakers or ICDS.

Danger! Risk of severe personal eye injury due to pressurised oil squirting out of damaged

hose or removal of fill/vent screw.

Ensure all testing of products both factory and deployed in-field have been completed by

competent persons.

Warning. Risk of eye/bodily injury caused by released pressure during product disassembly,

in the event of retrieval from subsea with a fault that causes depth pressure to be trapped

inside the product.

- Ensure all product disassembly activities are completed by competent persons in

accordance with relevant procedures and using relevant personal protective equipment

(PPE).

Warning. Risk of bodily injury caused by pressure retaining parts becoming projectile due

to user over-pressurising the system, e.g. during Site Installation Test (SIT).

- Ensure all product SIT activities are completed by competent persons in accordance

with relevant procedures.

- All pressure testing of SpecTRON 8 products must be undertaken by a competent

person.

- Installation of SpecTRON 8 penetrators, and bulkhead connectors must be undertaken

by a competent person.

2.3.5 Risk of injury and material damage due to manual handling

Manual handling, lifting and carrying are known to be one of the largest contributors to occupational

ill-health. Ensure mechanical handling aids are used wherever possible to avoid manual handling.

Where manual handling is considered appropriate for the task, safe lifting guidelines must be

followed, e.g. adopt correct posture, consider team lifting, employ safe lifting technique, etc. Only

competent persons are permitted to perform tasks without supervision, if in doubt, ask.

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

13 of 63

Unrestricted

Warning. Risk of musculoskeletal injury from hand-mating connectors with high mate/de-

mate force and/or connector rapidly fires out during de-mate due to high shuttle spring

force, e.g. factory/topside testing.

- Ensure all product testing activities are completed by competent persons in accordance

with relevant procedures.

- Ensure mechanical handling aids are used wherever possible to avoid manual handling.

- Where manual handling is considered appropriate for the task, safe lifting guidelines

must be followed, e.g. adopt correct posture, consider team lifting, employ safe lifting

technique, etc.

Warning. Risk of musculoskeletal injury from manual handling of heavy products.

- Ensure mechanical handling aids are used wherever possible to avoid manual handling.

- Where manual handling is considered appropriate for the task, safe lifting guidelines

must be followed, e.g. adopt correct posture, consider team lifting, employ safe lifting

technique, etc.

- Only competent persons are permitted to perform tasks without supervision, if in doubt

ask.

Warning. Risk of bodily injury from heavy product falling during lift with machinery.

- Ensure machinery/slings used have been tested and are within their expiry date.

- Safe lifting guidelines must be followed, e.g. lifting plan, banksman, etc.

- Correct lifting points must be identified and used.

- Only competent persons are permitted to perform tasks without supervision, if in doubt

ask.

Warning. Risk of minor personal injury to persons with sensitivities to mineral, silicone or

synthetic ester based oils.

- Wear appropriate hand protection when handling products, mineral, silicone or

synthetic ester based oils.

Warning. Risk of minor personal injury and material damage due to slips, trips and falls.

-Good housekeeping avoids slips, trips and falls, keep all work areas clean and tidy.

2.4 Related documents

Installers shall perform a full site risk assessment and put into place all necessary steps and

procedures to comply with applicable area, regional, national and international health and safety

legislation, e.g. The Health and Safety at Work Act (HASAWA) in the United Kingdom (UK) and ensure

safety of themselves and others regarding manual handling and working at height requirements.

During the product installation (and any subsequent work) it will be necessary to employ caution. All

installers and operatives involved from unloading the product until it is deployed in its final installed

location must exercise a full duty of care for themselves and others regarding safety. When lifting

and handling this product, operatives should employ assistance if required. In certain situations, it

may be necessary to use mechanical handling aids. Take care to avoid trip hazards, slippery or wet

surfaces.

Employers and installers should refer to the Health and Safety Executive (HSE) web site in the UK for

full advice and manual handling assessment charts (MAC) tool.

In addition, where no specific instructions are given then reference shall be made, but not restricted

to, where applicable, British Standards and codes of practice such as the following:

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

14 of 63

Unrestricted

- The Health and Safety at Work Act.

- COSHH Control of substances hazardous to health.

- BS 7671 Requirements for electrical installations. IEE Wiring Regulations.

- The Electricity at Work Regulations.

It is the operator’s and installers responsibility to comply with current Company, area, regional,

national and international health and safety legislation.

Following installation, commissioning and deployment of product, please complete and return the

Customer Comments/Feedback form (Section 9). Please e-mail completed form to the Product Safety

Officer at subsea.connectors.productsafety.gb@siemens-energy.com.

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

15 of 63

Unrestricted

3ABBREVIATIONS

A Ampere

ac Alternating Current

Assy Assembly

API American Petroleum Institute

AWG American Wire Gauge

BOM Bill of Material

°C Degree Celsius

CE Community European

Comms Communication Signal

COSHH Control of substances hazardous to health

CP Cathodic Protection

dc Direct Current

DWG Drawing

EFL Electrical Flying Leads

EMF Electrical Magnetic Field

EMI Electromagnetic Interference

FAT Factory Acceptance Test

IR Insulation Resistance

ICDS Implantable Cardioverter-Defibrillators

ISO International Organization for Standardization

ITP Inspection Test Plan

IWIS Intelligent Well Interface Standardisation

K Kelvin

LTC Long Term Cover

M Metres

Max. Maximum

MFG Manufacturer

Min. Minimum

NACE National Association of Corrosion Engineers

No. Number

PPE Personal Protective Equipment

ROV Remotely Operated Vehicle

SI Standard International

SIT Site Installation Test

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

16 of 63

Unrestricted

SRT Site Received Test

SST Stainless Steel

TBD To Be Defined

TSP Twisted Screened Pair

UNS Unified Numbering System for Metals and Alloys

V Volt

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

17 of 63

Unrestricted

4SPECIFICATION AND RESIDUAL HAZARDS

The following is the typical specification for SpecTRON 8 connectors with jumper cables offered by

Siemens Energy and will differ for connectors terminated to umbilical power cores or internal pigtails,

and in other situations. For connector specific information, please refer to product specific data

sheets. These are available via the Siemens Subsea website www.siemens-energy.com/subsea or

Siemens Subsea Connectors Technical Support connectortechnicalsupport.gb@siemens-energy.com.

4.1 Connector General Specification

Value

Unit

Design Life

30

years

Number of ways / phases

3

-

Maximum Water Depth

3 000

m

Maximum Differential Pressure (Penetrator)

345

bar

Maximum Differential Pressure (Bulkhead Receptacle)

15

bar

Operating Temperature

-5 to 20

°C

Storage Temperature

-30 to 60

°C

Number of Mates (Wet Mate Pair)

100

-

Rated Voltage

5/8,7(10)

kV

Rated Current

See Graph

-

Rated Frequency

5 –200

Hz

Table 3 - SpecTRON 8 Connectors General Specification

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

18 of 63

Unrestricted

Figure 4 - SpecTRON 8 Current Rating

4.2 Misalignment capability of wet mate stab connectors

The table below summarises the maximum misalignment capabilities of the SpecTRON 8 stab wet

mate connectors. For full details, refer to Siemens Energy drawings T33259. For misalignment

capabilities of ROV wet mate connectors, tree-cap plugs and tubing hanger connectors, please

contact Siemens Energy Subsea Connectors Technical Support

connectortechnicalsupport.gb@siemens-energy.com.

Stab

Mate

Unit

Maximum Angular Misalignment (No radial or rotational)

2

°

Maximum Radial Misalignment (No angular or rotational)

3

mm

Maximum Rotational Misalignment (No radial or angular)

3

°

Under/Overstroke (Independent of other misalignments)

± 1,5

mm

Figure 5 - SpecTRON 8 Stab Connector Misalignment Capability

4.3 Hose Specifications

AquaTRON 200

Gorilla

AquaTRON 50

Unit

Outside Diameter

64,6 +4 / -2,8

51,8

25,2 ± 0,6 mm

mm

Minimum Bend Radius

375

250

125

mm

Storage Temperature Range

-40 to + 70

-25 to + 70

-40 to + 70

°C

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

19 of 63

Unrestricted

Min.Manipulation Temperature

-25

-25

-25

°C

Maximum Snag Load

5

2,5

5

kN

Weight in air

4,8

3,2

0,66

kg/m

Weight in water

1,45

1

0,14

kg/m

Max Length without coupler

45

N/A

80

m

Hose Coupler Weight in air

3,8

N/A

0,87

kg

Hose Coupler Weight in water

3,2

N/A

0,69

kg

Table 4 - SpecTRON 8 Hose Specifications

4.4 Cable Specifications

4 mm²

16 mm²

(Siwokul)

16 mm²

(S1U10510150)

Unit

Outside Diameter

8,95 ± 0,2

11,25 ± 0,3

10,9 ± 0.4

mm

Screen CSA

N/A

N/A

N/A

mm²

Minimum Bend Radius

55

61,8

75

mm

Storage Temperature Range

-40 to + 70

-40 to + 70

-40 to + 70

°C

Minimum Manipulation Temperature

-25

-25

-25

°C

Weight in air

0,11

0,23

0,29

kg/m

Weight in water

0,04

0,13

0,20

kg/m

Resistance @ 20 °C

13

1,24

1,24

mΩ/m

Table 5 - SpecTRON 8 Cable Specifications (4 –16 mm sq.)

35 mm²

(Sp. Siwokul)

35 mm²

(S1U10510151)

35 mm²

(Feltoflex)

Unit

Outside Diameter

18,10 ± 0,4

16,0 ± 0,2

24,5

mm

Screen CSA

N/A

N/A

16

mm²

Minimum Bend Radius

110

110

125

mm

Storage Temperature Range

-40 to + 70

-40 to + 70

-40 to + 70

°C

Document No:

DOC0075

Issue Date:

20/12/2021

Revision:

14

Page:

20 of 63

Unrestricted

35 mm²

(Sp. Siwokul)

35 mm²

(S1U10510151)

35 mm²

(Feltoflex)

Unit

Minimum Manipulation Temperature

-25

-25

-25

°C

Weight in air

0,55

0,63

1,04

kg/m

Weight in water

0,29

0,43

0,56

kg/m

Resistance @ 20 °C

0,565

0,565

0,565

mΩ/m

Table 6 - SpecTRON 8 Cable Specifications (35 mm sq.)

4.5 Other specifications

For all other specifications not included in the above tables, refer to product/project specific data

sheet(s), alternatively contact Technical Support connectortechnicalsupport.gb@Siemens-

energy.com.

Table of contents

Other Siemens Energy Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

HydraMaster

HydraMaster MAXX 450D manual

FlexArm

FlexArm GH-24 Installation & operation manual

Climax

Climax FF1200 operating manual

AirBench

AirBench BD Operation and maintenance manual

Chicago Dryer

Chicago Dryer Air Chicago Standard instruction manual

HISAKA

HISAKA UX Series Operation and maintenance manual