en

2

• Ater installation has been completed, check or rerigerant leaks. I reriger-

ant leaks into the room and comes into contact with the flame of a heater or

portable cooking range, poisonous gases will be released.

• Do not use means to accelerate the derosting process or to clean, other

than those recommended by the manuacturer.

• The appliance shall be stored in a room without continuously operating igni-

tion sources (or eample: open lames, an operating gas appliance or an

operating electric heater).

• Do not pierce or burn.

• Be aware that refrigerants may not contain an odour.

/ Pipe-work shall be protected rom physical damage.

• The installation o pipe-work shall be kept to a minimum.

• Compliance with national gas regulations shall be observed.

• Keep any required ventilation openings clear o obstruction.

/ Do not use low temperature solder alloy in case o braing the rerigerant

pipes.

/ hen perorming braing work, be sure to ventilate the room suiciently.

Make sure that there are no haardous or lammable materials nearby.

When performing the work in a closed room, small room, or similar location,

make sure that there are no rerigerant leaks beore perorming the work.

If refrigerant leaks and accumulates, it may ignite or poisonous gases may

be released.

/ The appliance shall be stored in a well-ventilated area where the room sie

corresponds to the room area as specified for operation.

/ Keep gas-burning appliances, electric heaters, and other ire sources (igni-

tion sources) away from the location where installation, repair, and other air

conditioner work will be perormed.

I rerigerant comes into contact with a lame, poisonous gases will be

released.

/ Do not smoke during work and transportation.

1. Safety precautions

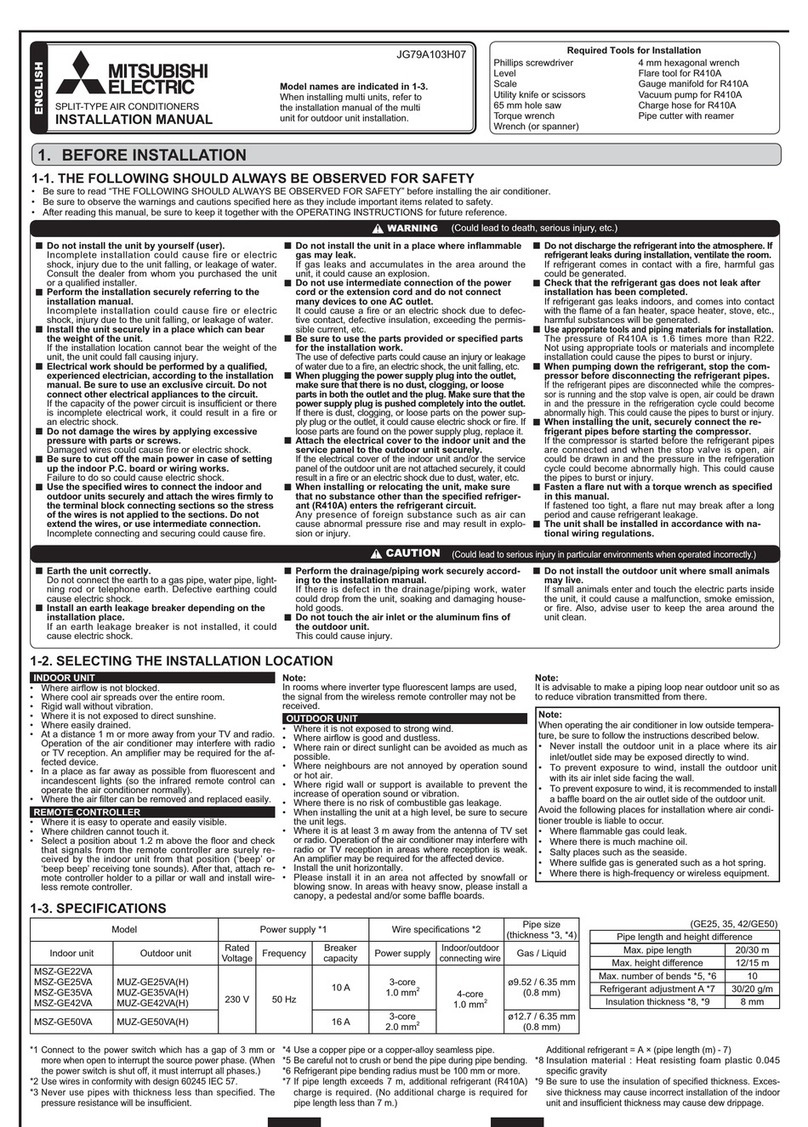

1.1. Before installation

Caution:

• Do not use the unit in an unusual environment. I the air conditioner is in-

stalled in areas eposed to steam, volatile oil (including machine oil), or

suluric gas, areas eposed to high salt content such as the seaside, or

areas where the unit will be covered by snow, the perormance can be sig-

nicantly reduced and the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced,

ow, or accumulate. I combustible gas accumulates around the unit, re or

eplosion may result.

•The outdoor unit produces condensation during the heating operation.

Make sure to provide drainage around the outdoor unit i such condensa-

tion is likely to cause damage.

• hen installing the unit in a hospital or communications oce, be prepared

or noise and electronic intererence. Inverters, home appliances, high-

frequency medical equipment, and radio communications equipment can

cause the air conditioner to malunction or breakdown. The air conditioner

may also aect medical equipment, disturbing medical care, and communi-

cations equipment, harming the screen display quality.

1.2. Beore installation (relocation)

Caution:

• Be etremely careul when transporting or installing the units. Two or more

persons are needed to handle the unit, as it weighs 20 kg or more. Do not

grasp the packaging bands. ear protective gloves to remove the unit rom

the packaging and to move it, as you can inure your hands on the ns or

the edge of other parts.

• Be sure to saely dispose o the packaging materials. Packaging materials,

such as nails and other metal or wooden parts may cause stabs or other

injuries.

• The base and attachments o the outdoor unit must be periodically checked

for looseness, cracks or other damage. If such defects are left uncorrected,

the unit may fall down and cause damage or injuries.

• Do not clean the air conditioner unit with water. Electric shock may result.

• Tighten all are nuts to specication using a torque wrench. I tightened too

much, the are nut can break ater an etended period and rerigerant can

leak out.

1.3. Beore electric work

Caution:

• Be sure to install circuit breakers. I not installed, electric shock may result.

• For the power lines, use standard cables o sucient capacity. Otherwise,

a short circuit, overheating, or re may result.

• hen installing the power lines, do not apply tension to the cables. I the

connections are loosened, the cables can snap or break and overheating or

re may result.

• Be sure to ground the unit. Do not connect the ground wire to gas or water

pipes, lightning rods, or telephone grounding lines. If the unit is not prop-

erly grounded, electric shock may result.

• Use circuit breakers (ground ault interrupter, isolating switch (B use),

and molded case circuit breaker) with the specied capacity. I the circuit

breaker capacity is larger than the specied capacity, breakdown or re

may result.

1.4. Beore starting the test run

Caution:

• Turn on the main power switch more than 12 hours beore starting opera-

tion. Starting operation ust ater turning on the power switch can severely

damage the internal parts. Keep the main power switch turned on during the

operation season.

• Beore starting operation, check that all panels, guards and other protective

parts are correctly installed. Rotating, hot, or high voltage parts can cause

injuries.

• Do not touch any switch with wet hands. Electric shock may result.

• Do not touch the rerigerant pipes with bare hands during operation. The

rerigerant pipes are hot or cold depending on the condition o the owing

rerigerant. I you touch the pipes, burns or rostbite may result.

• Ater stopping operation, be sure to wait at least ve minutes beore turn-

ing o the main power switch. Otherwise, water leakage or breakdown may

result.

1.5. Using R32 rerigerant air conditioners

Caution:

• Use C1220 copper phosphorus, or copper and copper alloy seamless

pipes, to connect the rerigerant pipes. Make sure the insides o the pipes

are clean and do not contain any harmful contaminants such as sulfuric

compounds, oidants, debris, or dust. Use pipes with the specied thick-

ness. (Reer to 4.1.) Note the ollowing i reusing eisting pipes that carried

R22 rerigerant.

- Replace the existing are nuts and are the ared sections again.

- Do not use thin pipes. (Refer to 4.1.)

• Store the pipes to be used during installation indoors and keep both ends

o the pipes sealed until ust beore braing. (Leave elbow oints, etc. in

their packaging.) I dust, debris, or moisture enters the rerigerant lines, oil

deterioration or compressor breakdown may result.

• Use ester oil, ether oil, alkylbenene oil (small amount) as the rerigeration

oil applied to the ared sections. I mineral oil is mied in the rerigeration

oil, oil deterioration may result.

• Servicing shall be perormed only as recommended by the manuacturer.

• Do not use rerigerant other than R32 rerigerant. I another rerigerant is

used, the chlorine will cause the oil to deteriorate.

• Use the ollowing tools specically designed or use with R32 rerigerant.

The ollowing tools are necessary to use R32 rerigerant. Contact your near-

est dealer for any questions.

Tools (for R32)

Gauge manifold Flare tool

Charge hose Size adjustment gauge

Gas leak detector Vacuum pump adapter

Torque wrench Electronic refrigerant charging scale

• Be sure to use the correct tools. I dust, debris, or moisture enters the rerig-

erant lines, refrigeration oil deterioration may result.

BH79D895W01_01en.indd 2 2020/08/24 17:30:32