T9901075-2-3 UK Page 6 of 38

NB. The defrost cycle auxiliary heater should not be site enabled during commissioning on

R2, WY and WR2 systems. On R2 systems the LEV in the air curtain closes during system

defrost and defrost does not occur on WY and WR2 systems.

Point of Information: If used, an auxiliary defrost heater may seem counter-productive for

a heat pump system. When put into context, however, the auxiliary heater fitted is of low

output for the size of the air curtain, it will just temper the discharge air and is only used for

a few minutes a day during a small period of the year. Tests at the Building Research

Establishment (BRE) test house on the heat pump air curtain system showed that even

with the auxiliary heater cutting in during defrost, as it has to during their EN14511

performance test, the annual seasonal COP was hardly affected.

The air curtain is supplied with an integral condensate drain tray fitted inside the unit so it

could be used in cooling mode during warm weather, if so desired. This should be decided

at the design stage as a condensate drain system will need to be installed if cooling is

required and extended to a suitable drain by the installer. The condensate can be drained

by gravity by connecting suitable condensate hose onto the 15mm drain pipe on the

condensate drain tray inside the air curtain. If a gravity condensate drain is not visually

suitable it will be necessary to remove condensate using a condensate pump, supplied

and fitted by the installer. The condensate pump can be located inside the right hand end

of the air curtain or in a remote location outside of the unit if required. It must be of

sufficient capacity, see Page 22, self priming and capable of providing the appropriate

suction head so the pump will lift condensate out of the air curtain, particularly if it is in a

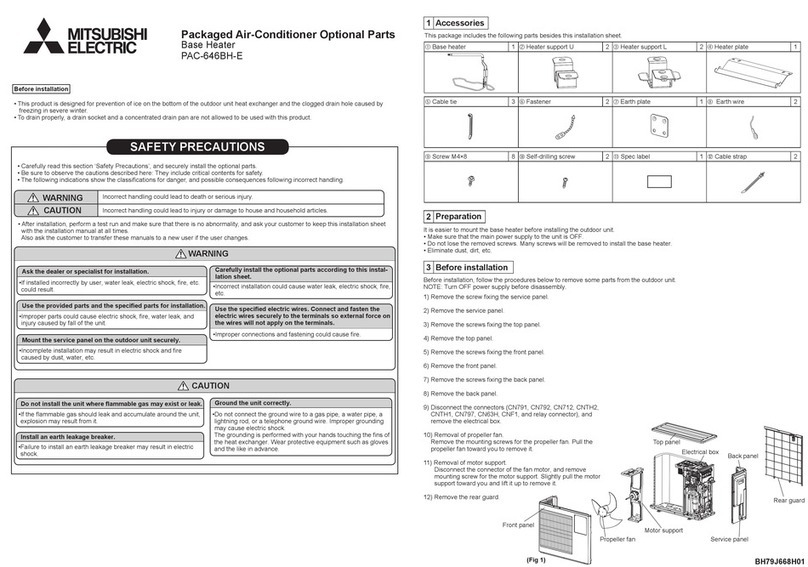

remote location. There are two hole penetrations at the right hand end of the air curtain for

condensate pipework to pass through, see Figure 1, Page 11. Suitable condensate pumps

are Peristaltic or Rotary Diaphragm type. We recommend the Blue Diamond rotary

diaphragm type with cooling signal sensor (drainStik) manufactured by Charles Austen

Pumps Ltd. (www.miniblue.co.uk).

If using a condensate pump it is recommended that it has the facility so it only operates

when the air curtain is in cooling mode by detection of water in the drain tray or by

detecting a cooling differential in the airflow. It should also have a pump overrun feature to

empty the drain tray as much as possible when the air curtain is switched off. It should

have an alarm system with appropriate sensor fitted in the drain tray that will give a volt-

free signal (open circuit = alarm) and stop the air curtain cooling if the condensate drain

tray is in danger of flooding (air curtain fans will continue to operate). Other indoor units on

the same City Multi system are unaffected if the air curtain condensate alarm occurs.

There is a fixing bracket with 8mm diameter hole attached to the drain tray inside the air

curtain so a condensate sensor can be fixed in the tray by the installer. The hole can be

enlarged, if necessary, to suit the type of sensor used so it is located in the tray at the

appropriate position, see the manufacturer’s instructions that come with the condensate

pump for further information. A 230V AC, single phase electrical supply is provided inside

the air curtain to power a condensate pump and a condensate alarm connection is

provided for the condensate pump alarm circuit.

Warning: The air curtain condensate collection system is designed to remove condensate

with the air curtain operating in cooling mode during normal summer weather conditions in

countries with a temperate climate. In case of extreme weather conditions, drain tray

blockage or condensate pump failure, which can occur, it is vital that the design of the floor

beneath the air curtain and its surface is such that it will not become slippery or damaged if

it became wet. This is similar to the conditions that might be experienced with heavy