Mitsubishi Fuso FE User manual

13EB-18

P31533

Electronic Governor

1Housing

2Control rack position sensor

3Cover

4Coil assembly

5Linear DC motor

6Link

7Emergency engine stop lever

8Sensing gear

● Linear DC motor

The linear DC motor 5moves the coil assembly 4vertically

in accordance with signals from the electronic governor con-

trol unit. Via the link 6, this movement is transmitted to the

control rack A, which moves longitudinally to increase and

decrease the fuel quantity.

●Control rack position sensor

The control rack position sensor 2senses whether the con-

trol rack Ais moved to the correct position by the linear DC

motor 5. In the event of a discrepancy between the actual

control rack position and the target control rack position (this

is determined by the electronic governor control unit), the

control unit instructs the linear DC motor to perform a correc-

tive movement.

P31532

3

4

5

86

12

A2

4

5

6

7

STRUCTURE AND OPERATION

13EB-19

13EB

15722

B

8

● Emergency engine stop lever

The emergency engine stop lever 7is connected to the link 6. Via a

cable, it enables the link to be moved from the driver’s seat. In the event

of a system fault that prevents the engine from being stopped normally,

operation of the emergency engine stop lever forces the control rack A

to move to the position at which fuel injection is terminated. This opera-

tion takes place irrespective of the position of the linear DC motor 5.

●Backup engine speed sensor

The backup engine speed sensor Bis fitted inside the governor. It

converts the rotation speed of the sensing gear 8into electric signals

and feeds the signals to the electronic governor control unit to provide

an indication of the engine speed.

13EB-20

1. INSPECTION PROCEDURES

Diagnostic Function

• Whenever the starter switch is placed at ON, the diagnostic function is activated to check all the sensors, etc. If any of

them is found faulty, the warning lamp in the meter cluster is lit to alert the driver. At the same time, the fault location is

stored in memory, and the system enters the backup mode.

Warning Lamp Indications

)deR()rebmA(

rorrelacitirc-ytefaS )nevirdebtontsumelciheV( NOFFO

rorrelacitirc-ytefas-noN )gnileeflortnocroopetipsednevirdebnacelciheV( FFONO

•The stored fault location can be read as a diagnostic trouble code by the Multi-Use Tester II or the diagnosis switch.

CAUTION –

• Check to ensure that the battery voltage is within the specified range.

• Check all the harness and device connectors for looseness. Always remove a connector at least 20 seconds

after placing the starter switch at the LOCK position.

• Do not forget to clear the diagnostic trouble code by the Multi-UseTester II or memory clear switch after a fault

has been rectified.

• As a rule, inspection operations should be performed with the starter switch at the LOCK position. Some

checks, however, may have to be made with the starter switch at the ON position. In such a case, use care to

make sure that no short circuit develops between pins of the connectors or with the body.

• The resistance value of each component is affected by the temperature and the accuracy of the tester. The

reading, therefore, does not always fall within the standard limits. Note that the check values shown in the text

are the values obtained at normal temperature (10 to 35°C {58 to 95°F}).

• Whether or not the system automatically returns to normal from the backup mode after a fault has been re-

moved depends on the diagnostic trouble code (fault location). When the system returns to normal, the

warning lamp will be OFF.

• Even when the fault has been removed and the system has been automatically returned to the normal mode,

the diagnostic trouble code of the fault remains stored in the engine control unit.

• When a fault occurs at a point where the system is not automatically reset, perform the memory clear proce-

dure to let the system exit from the backup mode. P13EB-25

TROUBLESHOOTING

13EB-21

13EB

Inspection Flowchart

The system inspection can be performed effectively by use of theMulti-Use Tester II. The types of system inspections may

be broadly divided as shown below in accordance with the trouble symptoms and diagnostic trouble code outputs.

•Inspections based on diagnostic trouble codes stored in the engine control unit

•Inspections of intermittent troubles

Vehicle brought into workshop

Read diagnostic trouble codes

Trouble code output No communications can be made

with Multi-Use Tester II.

Normal code

output

Identify cause for diagnostic

trouble code issue and

rectify

Normal code output

after erasure

Check for

intermittent troubles

If no communications can be made with all the other systems,

it is highly likely that the diagnostic circuit is faulty.

If no communications can be made with this system only, an open

circuit in the diagnostic output circuit or power supply circuit

(including the ground circuit) of this system is suspected.

Driving test

If the same diagnostic trouble code is issued during test driving, reexamine the cause for the

diagnostic trouble code issue and rectify.

If none of the diagnostic trouble codes stored in the engine control unit before the test driving

is issued, perform the checks on intermittent troubles in addition to the checks based on the

diagnostic trouble codes.

Erase the diagnostic trouble codes.

P13EB-23

P13EB-25

P13EB-26

P13EB-23

^Gr 00

13EB-22

2. CONNECTION OF MULTI-USETESTER II

0SpecialTools

19492

19141

19493

20538

20536

P41125

A

2

1

3

B

C

TROUBLESHOOTING

-acoL noit looTlaicepSfoepahSdnaemaN.oNtraPnoitacilppA

–IIretseTesU-itluM 694199BMmetsysfonoitcepsnI

–ssenrahIIretseTesU-itluM )snoitacinummocrof( 106723KM IIretseTesU-itluMotrewopylppusoT elcihevhtiwetacinummocdnareporp secivedlacirtceleedis

–yromemylno-daeR )8.1E-TRM(kcap MH063580 folortnocdnanoitcepsnirofataD tinulortnocenigne

–dracyromeM esU-itluMnites( )reporpIIretseT 005199BMatadetirwoT

–IIretseTesU-itluM ssenrah 994199BM tiucricasaIIretseTesU-itluMesuoT retset

•Place the starter switch at the LOCK position.

•Connect the 1Multi-Use Tester II harness to 2Multi-Use Tester II

and insert the 3read-only memory in the tester.

•Connect the connector Ato the cigar lighter socket.

•Connect the Multi-Use Tester II connector C(16 pins) to the data link

connector B(16 pins).

NOTE

For the operating procedures for the Multi-Use Tester II, refer to

the instruction manual for the Multi-Use Tester II.

13EB-23

13EB

3. READING AND ERASING DIAGNOSTICTROUBLE CODES

Two types of methods are available for reading or erasing a diagnostic trouble code; one using the Multi-Use Tester II and

one using the vehicle side diagnostic functions.

(1) Method using Multi-Use Tester II

●Current Diagnostic Trouble Code

•Check to see that the memory clear switch 1 is connected.

•Set the starter switch to ON.

•Operatethe Multi-UseTester II to read the current diagnostic trouble

code and determine the fault location.

●Past Diagnostic Trouble Code

•Set the starter switch to ON.

•Disconnect the memory clear switch 1.

•Operate the Multi-Use Tester II to read the past registered diagnos-

tic trouble codes and determine the fault location.

●Erasing Diagnostic Trouble Codes

•Set the starter switch to ON.

•Operate the Multi-Use Tester II to erase all of the diagnostic trouble

codes stored in the engine control unit.

(2) Method Not Using Multi-UseTester II (Method Using

Diagnostic Switch and Memory Clear Switch)

●Current Diagnostic Trouble Code

•Set the starter switch to ON.

•Disconnect the diagnostic switch 2.

•The diagnostic trouble code is displayed by flashes of the red warn-

ing lamp 3.

P41117

P41118

MEMORY

CLEAR

1

DIAG

CHECK

2

3

13EB-24

MEMORY

CLEAR

DIAG

CHECK

1

2

3

●Reading DiagnosticTrouble Code

•Diagnostic trouble codes are indicated by the number of times the red

warning lamp 3 flashes and their duration.

•The flashing intervals also differ between the 10s digit and the units

digit.

•10s digit: 1.2 second interval

•Units digit: 0.4 second interval

•Eachdiagnostic trouble code is displayed from the10s digitfollowed

bythe unitsdigit. As for a code which has no10s digit, the units digit

only is displayed.

•Each diagnostic trouble code is displayed three times in succession.

•If there is no additional codes stored, the sequence is then repeated

from the beginning with each code indicated three times.

•When the diagnostic switch 2 is connected, the engine control unit will

immediately stop displaying codes.

●Past Diagnostic Trouble Codes

•After reading the current diagnostic trouble codes (with the diagnostic

switch 2disconnected), disconnect the memory clear switch 1. Then

the warning lamp 3will restart flashing.

•Thistime, thewarning lampdisplays the past diagnostic trouble codes.

Determine the fault locations based on the indicated codes.

●Erasing Diagnostic Trouble Codes

Disconnect the memory clear switch 1 and the diagnostic switch 2 then

reconnect them. Then all the diagnostic trouble codes stored in the en-

gine control unit will be cleared.

CAUTION –

• If the contents of memory are not to be cleared after display of the

stored codes,set the starter switch to OFF with the memory clear

switch 1 disconnected. Thereafter, connect the memory clear

switch.

• When you change the combination of the injection pump and en-

gine control unit, you must rewrite the pump data stored in the

engine control unit.For this purpose,be sure to perform the diag-

nostic trouble code erasing procedure.

• Whenever the engine control unit has been replaced with a new

one,be sure to erase the diagnostic trouble codes by disconnect-

ing the memory clear switch 1 and diagnostic switch 2 after con-

necting all the connectors. Upon completing the procedure, con-

firm that no diagnostic trouble codes is stored.

P02739

13705

10s digit Units digit

ON

OFF

Diagnostic switch

disconnected

ON

OFF

First diagnostic trouble code dis-

played (Diagnostic trouble code 12)

Second

dagnostic

trouble

code

displayed

1.2 1.2

0.4

0.4

0.4

2.4 2.4 2.82.4

P41119

A second

or more 3 seconds

Connected

Released Memory cleared

at this point

TROUBLESHOOTING

13EB-25

13EB

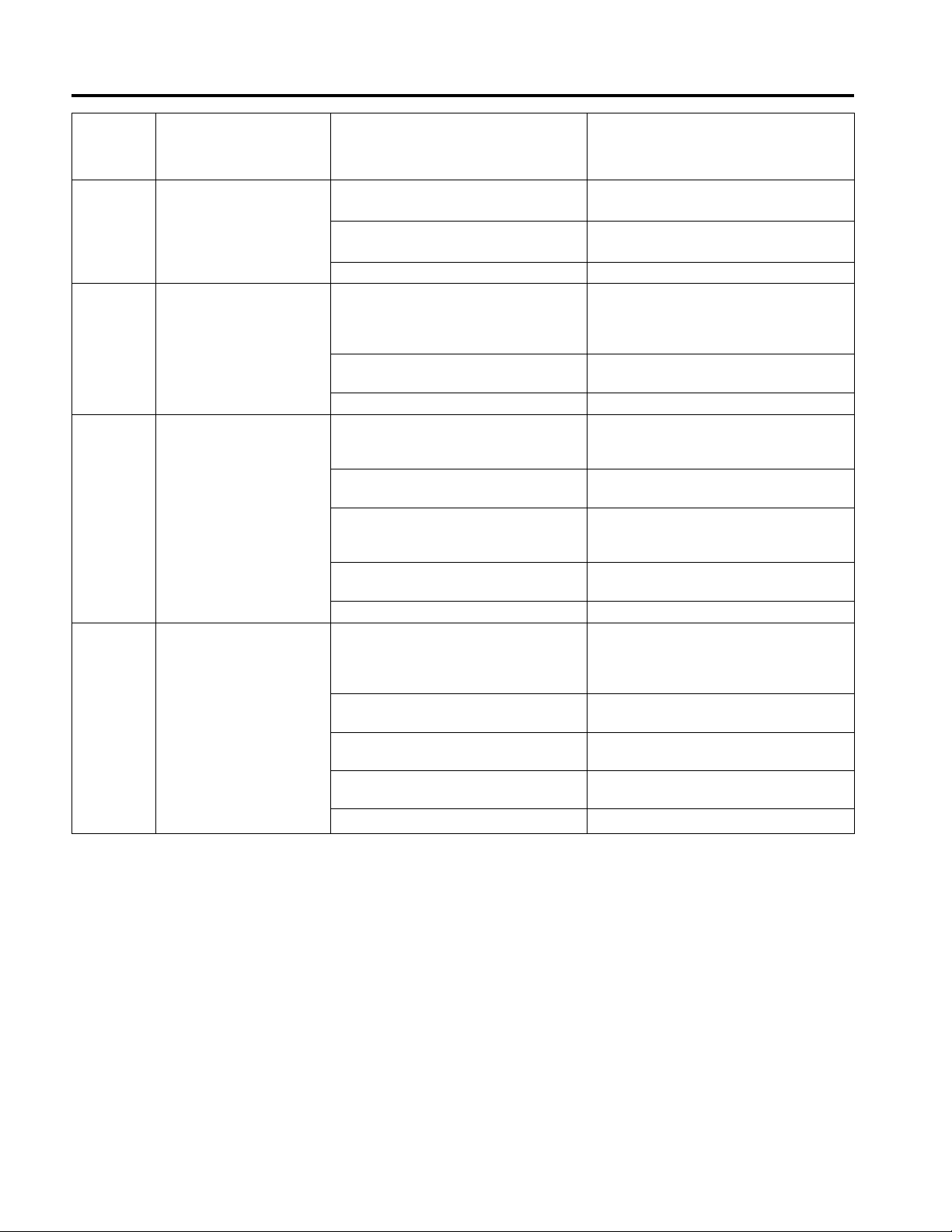

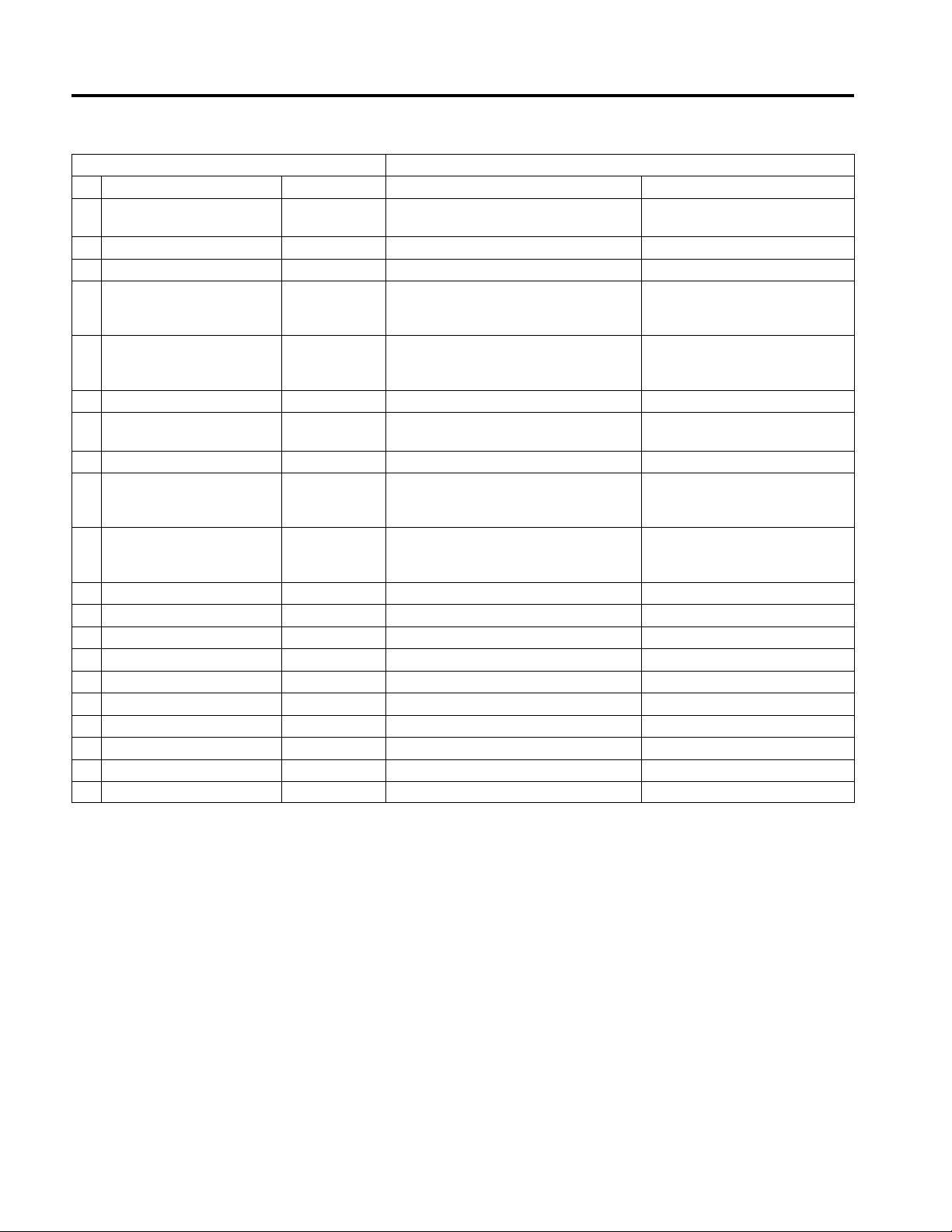

4. DIAGNOSTIC TROUBLE AND CHECK ITEMS

Diagnosis Warning Electronic control unit countermeasure(s) in the case of

code Fault location lamp failure (back-up mode) Drive ability

01 Normal — — ●

03 Pre-stroke actuator Amber Provides control with “0” as correction value. ●

learning function

Sub-control rack position Amber Normal control using the main control rack position sensor ●

06 sensor

11 Governor servo Red *1 Engine stopped by the pull-down function. ×

Pre-stroke control stop engine revolution speed limit (approx-

12 Pre-stroke servo Amber imately 1800 rpm) ▲

Pre-stroke control stop engine revolution speed limit (approx-

13 Pre-stroke sensor Amber imately 1800 rpm) ▲

Back-up engine speed Amber Control using the main engine speed sensor

14 sensor ●

Calculate the engine revolution speed from the pulse count of

15 Engine speed sensor Amber the back-up engine speed sensor. ●

Both the back-up engine

14+15 sensor and the main Red Can not start the engine. ×

engine speed sensors

are faulty upon start-up.

Accelerator pedal position Control using the accelerator pedal sensor I

16 sensor II Amber ●

21 Water temperature sensor Amber Set the water temperature to 80 °C {176°F}. ●

Control rack position Switch to the sub-control rack position sensor control.

22 sensor Amber ▲

Accelerator pedal position Control using the accelerator pedal position sensor II.

24 sensor I Amber ●

Both accelerator pedal

24+16

position

sensor I and Red Set the maximum accelerator depression angle to 30 degrees ▲

accelerator pedal

position

even if the accelerator pedal is depressed

.

sensor II are faulty

31 Idling adjustment volume Amber Set to auto idling. ●

32 Boost pressure sensor Amber Set the boost pressure to 0 kpa {0 mmHg, 0 in. Hg}. ▲*2

33 RAM (ECU internal Red Do not start the engine. ×

memory circuit)

Boost temperature sensor Amber Normal control assuming the boost temperature is

41 80 °C {176 °F}. ●

45 Reverse engine Amber *1 Engine stopped by the pull-down function. ×*2

operation

65 Accelerator switch Amber Limited accelerator depressing angle (Approximately 30%) ●

*1:The pull-down function indicates the rack pull-back action. In the event

of an engine over-run or severe accident, the rack is pulled back

immediately to the no-injection direction in order to protect the engine.

●: Driveable

▲: Back-up mode driving possible

×: Undriveable

*2:Driveable if the starter switch is turned OFF once and then restarted

again.

13EB-26

TROUBLESHOOTING

Diagnosis Diagnosis code

code display Cause Remedy

condition (s)

03 Faulty timing rod, timing sleeve or other Repair or replace the injection pump

parts in the injection pump assembly. assembly. *

Faulty adjusment or pre-stroke position Repair or replace the injection pump

sensor assembly. *

Faulty engine control unit Replace the engine control unit

06 Open or short in harness wire or poor Inspect the harness and the connector

connector contact between the ÕP13EB-41

sub-control rack position sensor and the

engine control unit

Open, short, or poor connector contact in Inspect the sub-control rack position sensor

the sub-control rack position sensor ÕP13EB-35

Faulty engine control unit Replace the engine control unit

11 Open or short in harness wire or poor Inspect the harness and the connector

connector contact between the linear DC ÕP13EB-41

motor and the engine control unit

Open or shorted wire in the linear DC Inspect the linear DC motor ÕP13EB-32

motor connector

Poor adjustment of the emergency Inspect the emergency engine stop button

engine stop cable (The lever is pulled in ÕP13EB-31

the stop direction)

Faulty injection pump assembly rack Repair or replace the injection pump

movement or poor governor actuator link assembly. *

Faulty engine control unit Replace the engine control unit

12 Open or short in harness wire or poor Inspect the harness and the connector

connector contact between the pre-stroke ÕP13EB-41

actuator, pre-stroke cut relay, and

engine control unit

Open or shorted wire in the pre-stroke cut Inspect the pre-stroke cut relay

relay ÕP13EB-34

Faulty pre-stroke actuator Repair or replace the injection pump

assembly. *

Faulty timing rod, timing sleeve, etc. in Repair or replace the injection pump

the injection pump assembly assembly. *

Faulty engine control unit Replace the engine control unit

Displayed if the output

voltage of the control rack

position sensor is less

than 0.06 V or more than

3.5 V.

Displayed if the difference

between the target control

rackposition and the actual

control rack position is

± 1mm {0.039 in.}.

Displayed if the difference

between the target timing

rod angle and the actual

timing rod angle is ± 2°.

*: Contact your MFTA representative for current injection pump repair and replacement procedures.

Indicates that pre-stroke

learning function has not

been executed.

13EB-27

13EB

Displayed if the pulse

count of the main engine

speed sensor is less than

that of the back-up engine

speed sensor.

Diagnosis Diagnosis code

code display Cause Remedy

condition (s)

13 Open or short in harness wire or poor Inspect the harness and the connector

connector contact between the pre-stroke ÕP13EB-41

position sensor and the engine control

unit

Open or shorted pre-stroke position Inspect the pre-stroke actuator

sensor coil ÕP13EB-32

Faulty engine control unit Replace the engine control unit

14 Open or short in harness wire or poor Inspect the harness and the connector

connector contact between the back-up ÕP13EB-41

engine speed sensor and the engine

control unit

Faulty back-up engine speed sensor Repair or replace the injection pump

assembly. *

Faulty engine control unit Replace the engine control unit

15 Open or short in harness wire or poor Inspect the harness and the connector

connector contact between the speed ÕP13EB-41

sensor and the engine control unit

Open or shorted wire or improperly Inspect the engine speed sensor main unit

assembled coil in the engine speed ÕP13EB-33

sensor main unit

Faulty engine control unit Replace the engine control unit

16 Open or short in harness wire or poor • Inspect the accelerator position sensor

connector contact between the using Multi-Use Tester-II ÕP13EB-30

accelerator pedal position sensor II and • Inspect the harness and the connector

the engine control unit ÕP13EB-41

Internal malfunction or faulty adjustment • Inspect the accelerator pedal position

of the lever portion of the accelerator sensor ÕP13EB-30

pedal position sensor II • Inspect the accelerator pedal position

sensor using Multi-Use Tester-II

ÕP13EB-30

Faulty engine control unit Replace the engine control unit

21 Open or short in harness wire or poor Inspect the harness and the connector

— connector contact between the coolant ÕP13EB-41

temperature sensor and the engine

control unit

Faulty coolant temperature sensor • Inspect the coolant temperature sensor

ÕP13EB-35

• Inspect the coolant temperature sensor

using Multi-Use Tester-II ÕP13EB-30

Faulty engine control unit Replace the engine control unit

Displayed if the output

voltage of the pre-stroke

position sensor is less

than 0.9 V or more than

3.4 V.

Displayed if the pulse

count of the back-up

engine speed sensor is

less than that of the main

engine speed sensor.

Displayed if the output

voltage of the accelerator

pedal position sensor is

less than 0.5 V or more

than 4.5 V.

*: Contact your MFTA representative for current injection pump repair and replacement procedures.

13EB-28

TROUBLESHOOTING

Diagnosis Diagnosis code

code display Cause Remedy

condition (s)

22 Open or short in harness wire or poor Inspect the harness and the connector

connector contact between the control ÕP13EB-41

rack position sensor and the engine

control unit

Open or shorted wire in the coil or poor • Inspect the control rack position sensor

control rack position sensor contact ÕP13EB-32

• Inspect the control rack position sensor

using Multi-Use Tester-II ÕP13EB-30

Faulty movement of the injection pump Repair or replace the injection pump

assembly control hook or poor governor assembly. *

actuator link.

Faulty engine control unit Replace the engine control unit

24 Open or short in harness wire or poor • Inspect the accelerator position

connector contact between the sensor using Multi-Use Tester-II

accelerator pedal position sensor and ÕP13EB-30

the engine control unit • Inspect the harness and the connector

ÕP13EB-41

Internal malfunction or poor adjustment • Inspect the accelerator position sensor I

of the accelerator pedal position sensor I ÕP13EB-30

lever

Faulty engine control unit Replace the engine control unit

31 Stuck idling speed adjustment potentio- Reset the knob to PUSH or PULL

meter knob (between PUSH and PULL)

Open or short in harness wire or poor Inspect the harness and the connector

connector contact between the idling ÕP13EB-41

speed adjustment potentiometer and the

engine control unit

Open wire in the switch portion of the Inspect the idling speed adjustment

idling speed adjustment potentiometer potentiometer ÕP13EB-34

or faulty internal movement

Faulty engine control unit Replace the engine control unit

32 Open or short in harness wire or poor Inspect the harness and the connector

connector contact between the boost ÕP13EB-41

pressure sensor and the engine

control unit

Internal malfunction of boost pressure • Inspect the boost pressure sensor using

sensor Multi-Use Tester-II ÕP13EB-30

• Inspect the boost pressure sensor

ÕP13EB-36

Clogged boost hose or faulty assembly Inspect the boost hose

Faulty engine control unit Replace the engine control unit

Displayed if the output

voltage of the control rack

position sensor I is less

than 0.5 V or more than

4.5 V.

Displayed if the output

voltage of the accelerator

pedal position sensor I is

less than 0.5 V or more

than 4.5 V.

Displayed if the output

voltage of the idling

adjustment volume is less

than 0.6 V or mor than

4.6 V.

Displayed if the output

voltage of the boost

pressure sensor is less

than 0.5 V or more than

4.8 V.

*: Contact your MFTA representative for current injection pumprepair and replacement procedures.

13EB-29

13EB

Diagnosis Diagnosis code

code display Cause Remedy

condition (s)

33 Faulty engine control main unit In order to reset the engine control unit,

temporarily turn the starter switch OFF and

erase the diagnostic codes by opening the

memory clear switch Õ P13EB-24

Replace the engine control unit if the

diagnostic codes persist after performing

the above procedure

41 Open or short in harness wire and poor Inspect the harness and the connector

connector contact between the boost ÕP13EB-41

temperature sensor and the engine

control unit

Open or shorted wire or poor assembly • Inspect the boost temperature sensor

of the boost temperature sensor coil ÕP13EB-37

• Inspect the boost temperature sensor

using Multi-Use Tester-II ÕP13EB-30

Faulty engine control unit Replace the engine control unit

45 Faulty phase of engine speed sensor • Inspect the engine speed sensor

— and backup engine speed sensor ÕP13EB-33

• Repair or replace the injection pump

assembly. *

65 Faulty accelerator switch Open or short in harness wire or poor Inspect the harness and the connector

connector contact between the accelera- ÕP13EB-41

tor switch and the engine control unit

Open or shorted wire in the accelerator Inspect the accelerator switch

switch (Accelerator switch is built in the accelerator

pedal position switch.) ÕP13EB-31

Faulty engine control unit Replace the engine control unit

Displayed if the engine

control unit is faulty.

Displayed if the output

voltage of the boost

temperature sensor is

more than 4.9 V.

*: Contact your MFTA representative for current injection pump repair and replacement procedures.

13EB-30

TROUBLESHOOTING

5. Service of Multi-Use Tester II

Multi-Use Tester-II display Inspection procedure

No. Data signal Type of data Inspection condition Evaluation criterion

11 ENGINE SPEED ❙❙❙❙. rpm Gradual acceleration (during engine Synchronization with tachometer

operation)

12 TARGET RACK ❙❙.❙❙ mm Starter switch ON 3 mm

13 REAL RACK ❙❙.❙❙ mm Starter switch ON 3 mm

Accelerator pedal gradually depressed

14 ACCEL. VOLT ❙.❙❙❙ V from throttle-fully-closed to throttle-fully- 1 to 3 V

open position

Engine cold Same as ambient temperature

15 WATER TEMP ❙❙❙.❙ °F Engine warming up Gradual increase

Engine stopped after warmup Gradual decrease

16 BOOST PRESS ❙❙❙❙. mmHg Engine running at high idling speed 270 mmHg or higher

17 PS ANG. DIFF. ❙❙.❙❙ deg 400 < Ne 2,000 –5.5° or greater

Ne: Engine speed 5.5° or smaller

18 SUPPLY VOLT ❙❙.❙❙ V Starter switch ON 7 to 14 V

Throttle completely closed 0 %

19 ACCEL. STROKE ❙❙❙.❙% Pedal gradually depressed Gradual increase

Throttle completely open 100 %

Engine cold Same as ambient temperature

20 BOOST TEMP ❙❙❙.❙ °F Engine warming up Gradual increase

Engine stopped after warmup Gradual decrease

21 START SIG ON/OFF Engine cranked using starter switch ON

33 ACCEL. SW ON/OFF Accelerator pedal depressed OFF

34 DIAGNOSIS SW ON/OFF Diagnosis switch turned ON/OFF ON/OFF

35 DIAG. RESET SW ON/OFF Memory clear switch turned ON/OFF ON/OFF

37 CLUTCH SW ON/OFF Clutch pedal depressed ON

38 NEUTRAL SW ON/OFF Transmission in neutral OFF

42 EXH. BRAKE SW ON/OFF Switch ON ON

51 A/C SW ON/OFF Air conditioner switch turned ON or OFF ON/OFF

61 EXH. BRAKE SIG ON/OFF Exhaust brake operating ON

75 IDLE UP CNCL ON/OFF Idle up prohibited (other than N range) ON

VII

13EB-31

13EB

1Idling speed adjustment potentiometer

2Relay box

3Exhaust brake cut relay < A/T >

Transmission neutral relay < M/T >

4Pre-stroke cut relay

5Exhaust brake relay < M/T >

6Sub control rack position sensor

7Engine coolant temperature sensor

8Pre-stroke actuator

9Boost pressure sensor

10 Control rack position sensor

11 Backup engine speed sensor

12 Linear DC motor

13 Engine speed sensor

14 Exhaust brake 3-way magnetic valve

15 Transmission neutral switch < M/T >

16 Boost temperature sensor

17 Emergency engine stop button

18 Clutch pedal switch

19 Fuel injection rate adjustment resistor

*a: Electronic governor

*b: Injection pump

M/T : Manual transmission

A/T : Automatic transmission

31550

9*a

*b

< Left side of engine >

2

INSPECTION OF ELECTRICAL EQUIPMENT

13EB-32

INSPECTION OF ELECTRICAL EQUIPMENT

Location Maintenance item Standard value Limit Remedy

Output voltage of idling

speed adjustment Knob pulled 1 to 3 V —

potentiometer

1

2

–

3

Replace

Knob 3.6 to 4.3 V —

pushed

1

–

4

92.5 to 101.5 Ω—

6Resistances of sub control

1

–

3

92.5 to 101.5 Ω—

rack position sensor

3

–

4

185 to 203 Ω—

Engine coolant Between terminal 20°C {68°F} (3.25 kΩ)—

7temperature sensor and body 40°C {104°F} (1.5 kΩ) — Replace

60°C {140°F} (620±62 Ω) —

Resistance of

2

–

3

5.5 to 6.1Ω—

8pre-stroke actuator

1

–

3

11.0 to 12.2 Ω—

(measured at

1

–

2

5.5 to 6.1Ω—

connector)

4

–

5

0.9 to 1.3 Ω

< Connector: 3 pin >

3

(3 pin) –

4

(10 pin)

3

(10 pin) –

4

(10 pin) 31.5 to 36.5 Ω—

< Connector: 10 pin > G–C

3

(3 pin) –

9

(10 pin)

3

(10 pin) – 18.0 to 21.0 Ω

< Governor actuator >

9

(10 pin) —

10

G–F

4

(10 pin) –

9

(10 pin)

13.5 to 15.5 Ω—

C–F

Service standards Unit : mm {in.}

Resistances

of control

rack position

sensor

24816

16165

16160

13725

13714

A

B

E

D

FG

C

16184

Repair or replace

the injection pump

assembly. *

Repair or replace

the injection pump

assembly. *

Repair or replace

the injection pump

assembly. *

The values in ( ) are reference values

*: Contact your MFTA representative for current injection pump repair and replacement procedures.

13EB-33

13EB

Location Maintenance item Standard value Limit Remedy

< Connector: 3 pin >

< Connector: 10 pin >

12 < Governor actuator >

Resistance of

13 engine speed sensor

1

–

2

2.1 to 2.5 Ω— Replace

(at 25°C {77°F})

14 Minimum operating voltage of 11 V or more — Replace

3-way magnetic valve

Resistance valve of boost 0°C {32°F} 5880±588 Ω—

16 temperature sensor 20°C {68°F} 2455±245 Ω— Replace

80°C {176°F} 322±32 Ω—

ÊTightening torque Unit : N·m {ft.lbs, kgf·m}

Location Parts to be tightened Tightening torque Remarks

7Coolant temperature sensor 34 ± 6.9 {25±5, 3.5±0.7} —

13 Lock nut of engine speed sensor 24 to 35 {17 to 26, 2.4 to 3.6} —

24816

16165

16160

G

A

B

F

C

D

E

Resistances

of linear DC

motor 9.0 to 9.8 Ω—

321

14013

14318

Unit : mm {in.}

Repair or

replace the in-

jection pump

assembly. *

*: Contact your MFTA representative for current injection pump repair and replacement procedures.

2

(3 pin) –

1

(3 pin)

2

(3 pin) –

2

(10 pin)

1

(10 pin) –

2

(10 pin)

1

(10 pin) –

1

(3 pin)

A– B

13EB-34

INSPECTION OF ELECTRICAL EQUIPMENT

Connector terminal

Accelerator pedal position sensor

Item inspection harness

1

: Power

2

: GND (–)

3

: Output(+)

supply (+)

Output voltage with

knob pulled –+

Output voltage with

knob pushed

Output characteristics

02779

02778

1A

C

B

C

1

23

4.3

3.6

3

1

0300°

Angle of rotation

Output voltage (V)

PUSH

PULL

}

}

1

Inspection of idling speed adjustment potentiometer

• Disconnect the harness Aof the idling speed adjustment potentiometer

1from the cab-side harness B. Then, connect an inspection harness

Cbetween harnesses Aand B. (The inspection harness must be

made specially for this procedure.)

• Turn the starter switch to the ON position.

• Check the output voltages of the idling speed adjustment

potentiometer 1in accordance with the following table.

• If the output voltages are out of specification, replace the idling speed

adjustment potentiometer 1.

◆ Service procedure

07387 +–

+

2

1

3

4

4

3

1

2

–+

–

34

Inspection of pre-stroke cut relay and exhaust brake

cut relay (normally-closed type with 4-pin connector)

• Perform continuity checks in accordance with the following table.

1234

Not energized

Energized

:Continuity exists between terminals.

:Terminals across which 12 V DC is applied.

:Continuity no longer exists between terminals.

• Replace the relay if any abnormality is evident.

1.0 - 3.0

3.6 - 4.3

13EB-35

13EB

1234

No current

Current

07142

+–

+–

5

Inspection of exhaust brake relay (Open type 4 pin)

• Follow the table below to inspect continuity :

: There is continuity between terminal and .

: Indicates that 12 volts DC is applied to the line between

the terminals.

• If any fault is found, replace the relay.

2

1

3

4

–

+

431

2

13722

1

13799

21

43

6

6

Inspection of sub control rack position sensor

• Measure the resistances between the following terminals :

1

and

4

;

1

and

3

;

3

and

4

.

• If any resistance is out of specification, replace the sub control rack

position sensor 6.

• Have replacement performed by the nearest MFTA Dealer.

7

Inspection of engine water temperature sensor

• Put the engine water temperature sensor 7in a container of engine oil.

• Heat the oil to each of the specified temperatures. Stir the oil to ensure

that it heats up evenly.

• At each of the specified temperatures, measure the resistance be-

tween the terminal

1

and body of the engine water temperature

sensor 7.

• If the measurements are out of specification, replace the engine water

temperature sensor.

Item Standard value Limit Remedy

(reference values)

Engine coolant Between 20°C {68°F} (3.25 k) ohms —

temperature Terminal 40°C {104°F} (1.5k) ohms — Replace

sensor and body 60°C {140°F} (650±62k) ohms —

13EB-36

INSPECTION OF ELECTRICAL EQUIPMENT

P31493

F

Inspection of control rack position sensor

Perform the following inspections. If any abnormality is evident, have

inspection and repair performed by the nearest MFTA.

●Measurements on connectors

Measure resistances between terminals as specified in the standard

table.

13790

3

62

51

4

8

Inspection of pre-stroke actuator

Perform the following inspections. If any abnormality is evident, have

inspection and repair performed by the nearest MFTA Dealer.

CAUTION –

The pre-stroke actuator 8 must be inspected when the engine is

cold.

(1) Measurements on connectors

Measure the resistance between terminals

2

and

3

;

1

and

3

;

1

and

2

;

4

and

5

.

9

Inspection of boost pressure sensor

• Mount pressure gauge Afor boost pressure measurement as shown

in the diagram.

• Connect the Multi-Use Tester-II . Õ P13EB-22.

• Set the Multi-Use Tester-II for boost pressure measurement

• Start the engine. Compare the value displayed on the Multi-Use

Tester-II and the value indicated by pressure gauge A. If the values

are different, replace boost pressure sensor 9.

B: To inlet manifold.

20580

AB

6

H

Inspection of linear DC motor

Perform the following inspections. If any abnormality is evident, have

inspection and repair performed by the nearest MFTA Dealer.

(1) Measurements on connectors

Measure resistances between terminals as specified in the standard

table.

P31493

54321

10 9 8 7 6

21

3

54321

10 9 8 7 6

21

3

This manual suits for next models

4

Other Mitsubishi Fuso Truck manuals

Popular Truck manuals by other brands

Pfaff

Pfaff SILVERLINE I HU W-20 SL Translated Operating Instructions

Peterbilt

Peterbilt 579 Operator's manual

Navistar

Navistar ProStar+ Operation and maintenance manual

Chevrolet

Chevrolet 10-30 1967 Series Owner's and driver's manual

Hoppe

Hoppe AUDIO MINI Installation instructions & owner's manual

BorMann

BorMann PRO BWR2515 manual