Mitsubishi S4S User manual

Other Mitsubishi Engine manuals

Mitsubishi

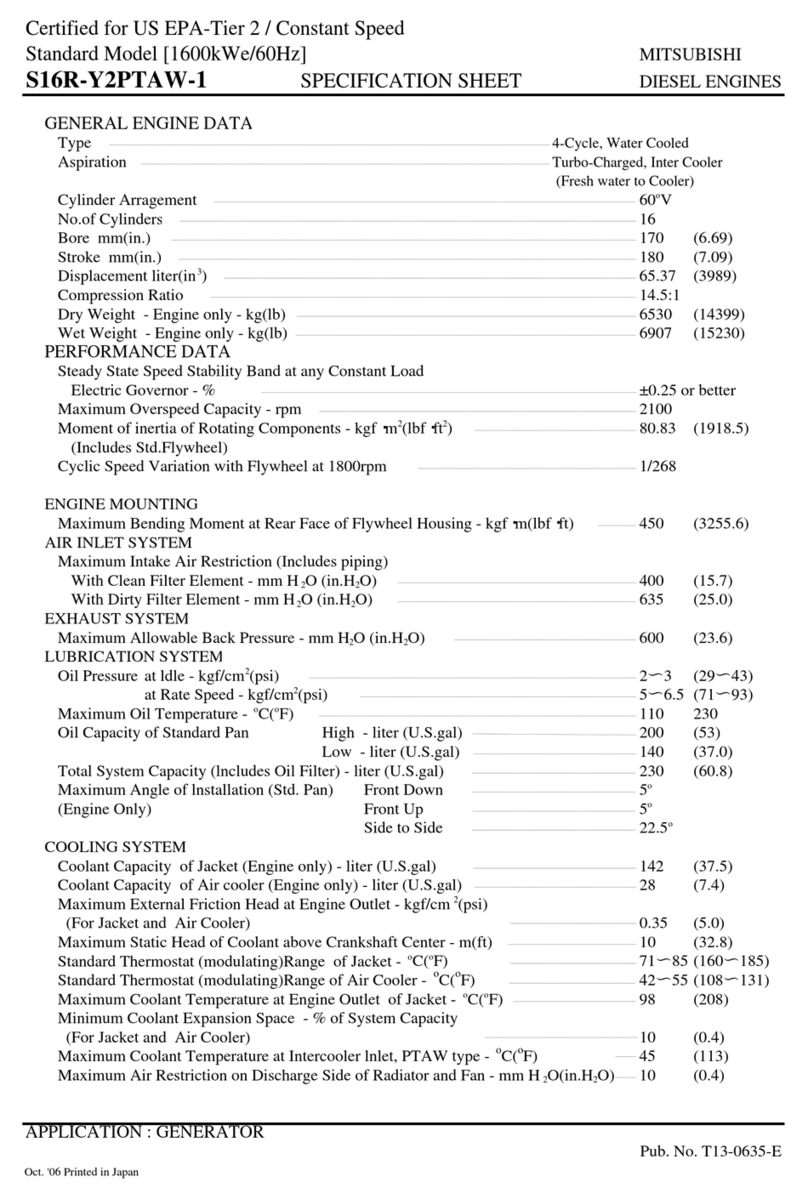

Mitsubishi Diesel Engines S16R-Y2PTAW-1 User manual

Mitsubishi

Mitsubishi 4D68 Instruction manual

Mitsubishi

Mitsubishi GB290 User manual

Mitsubishi

Mitsubishi K3G User manual

Mitsubishi

Mitsubishi 4G6 Series 1991 Instruction manual

Mitsubishi

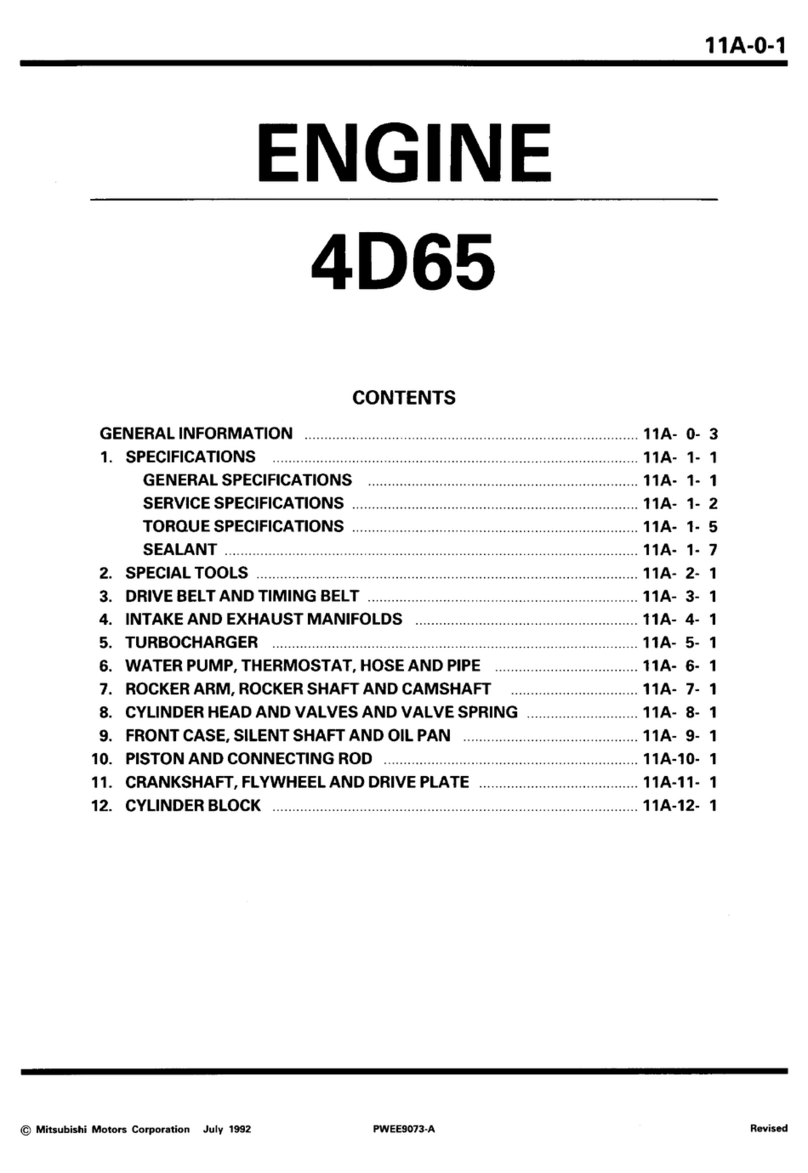

Mitsubishi 4D65 Instruction manual

Mitsubishi

Mitsubishi GB101 User manual

Mitsubishi

Mitsubishi S4Q User manual

Mitsubishi

Mitsubishi S16R Manual

Mitsubishi

Mitsubishi S3Q2 User manual

Mitsubishi

Mitsubishi Evolution EVOMITS User manual

Mitsubishi

Mitsubishi 4G1 series Instruction manual

Mitsubishi

Mitsubishi 4D56 User manual

Mitsubishi

Mitsubishi TUE Series User manual

Mitsubishi

Mitsubishi diesel engines User manual

Mitsubishi

Mitsubishi L3E User manual

Mitsubishi

Mitsubishi GB30G User manual

Mitsubishi

Mitsubishi 4D68 Instruction manual

Mitsubishi

Mitsubishi 4M41 User manual

Mitsubishi

Mitsubishi F8QT Instruction manual