10

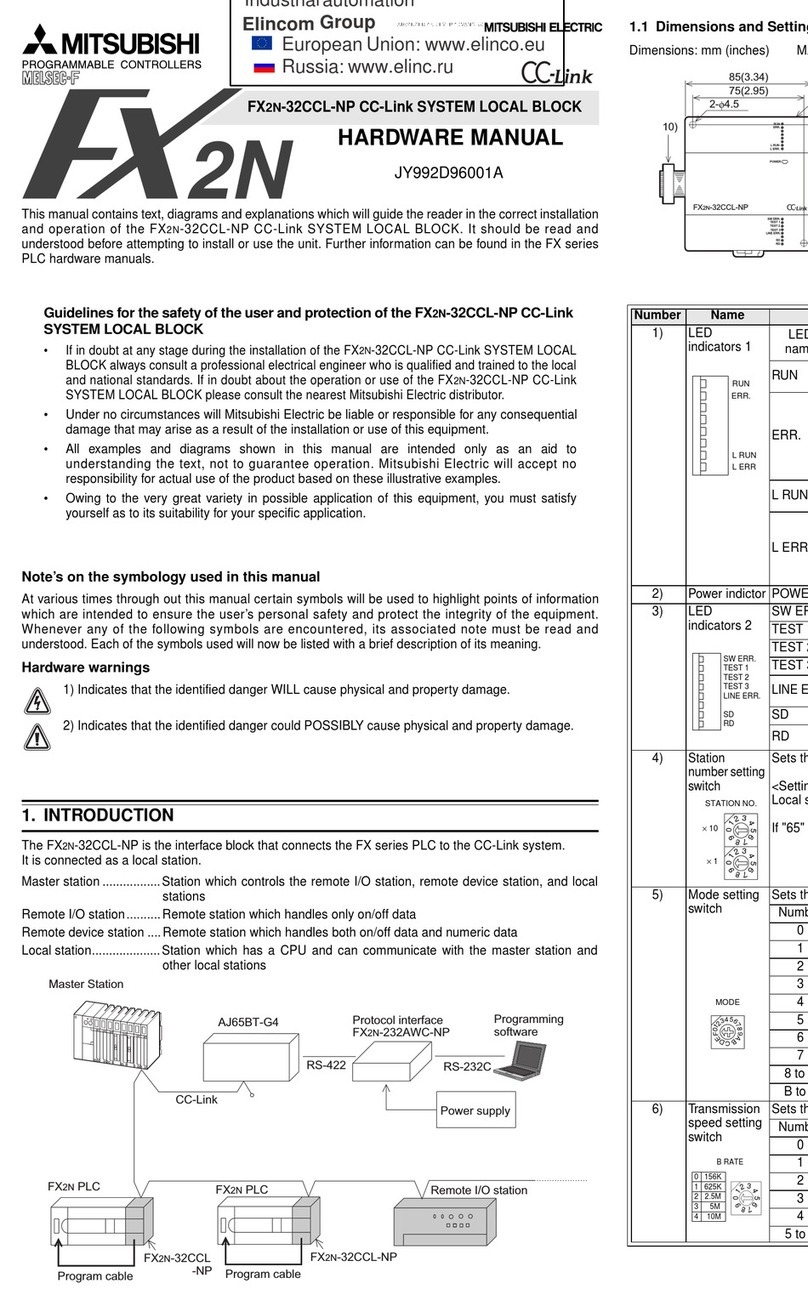

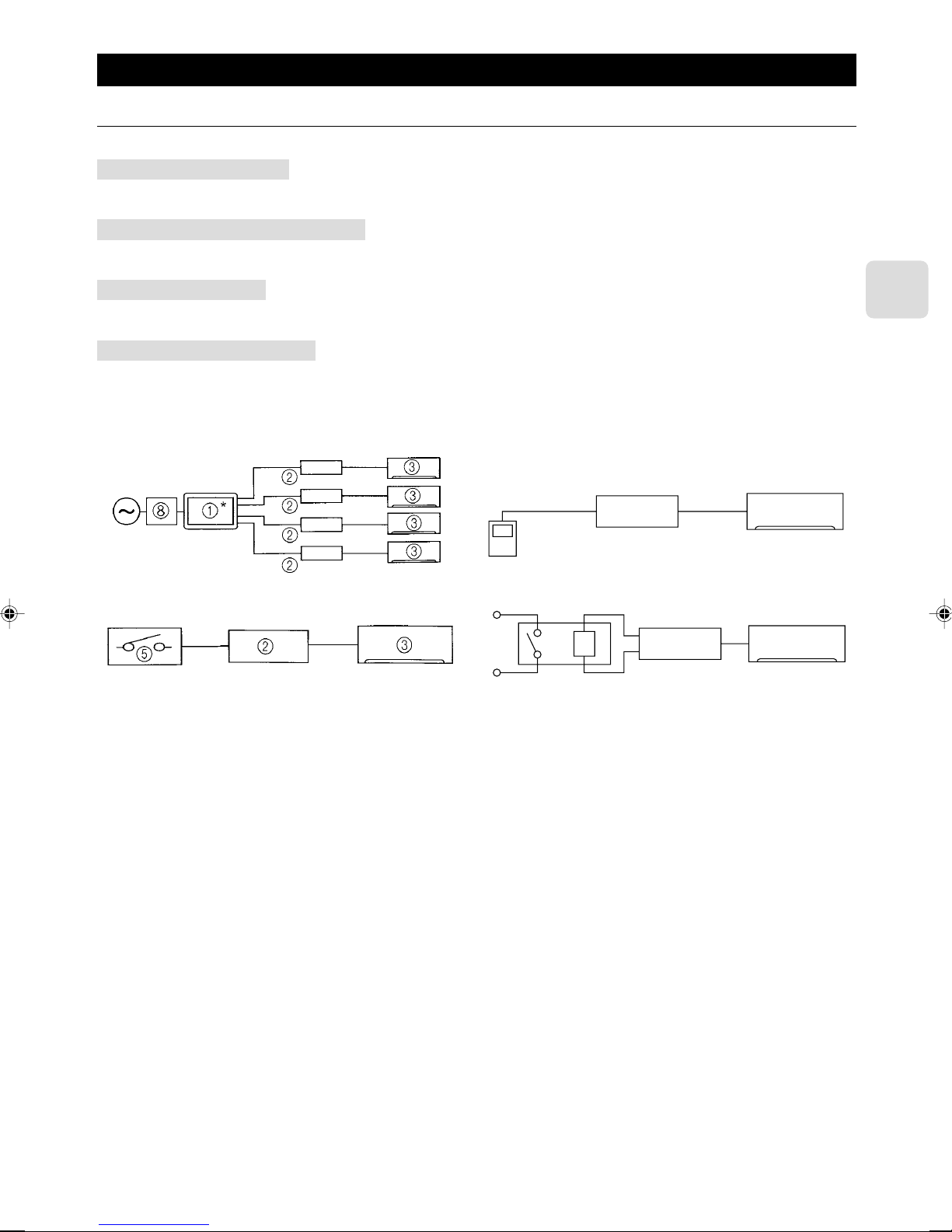

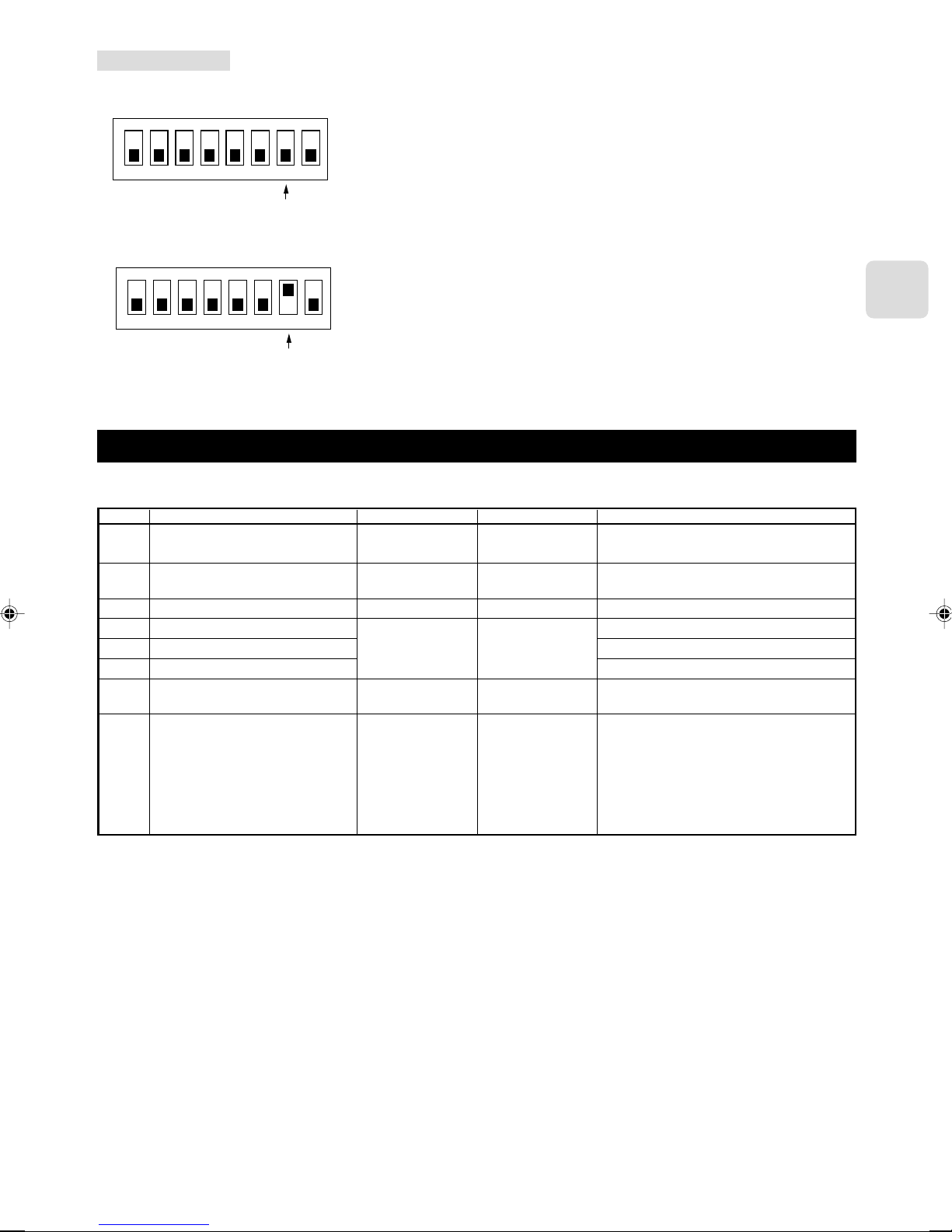

Remote control (CN591) mode switch

SW 500 Functions

Do not use the CN591 remote control

ON/OFF Prohibited/Allowed mode 1

ON/OFF Prohibited/Allowed mode 2

(level input)

ON/OFF Prohibited/Allowed mode 3

(pulse input)

Coin timer mode 1 (for a no-voltage

contact point a)

Coin timer mode 2 (for a no-voltage

contact point b)

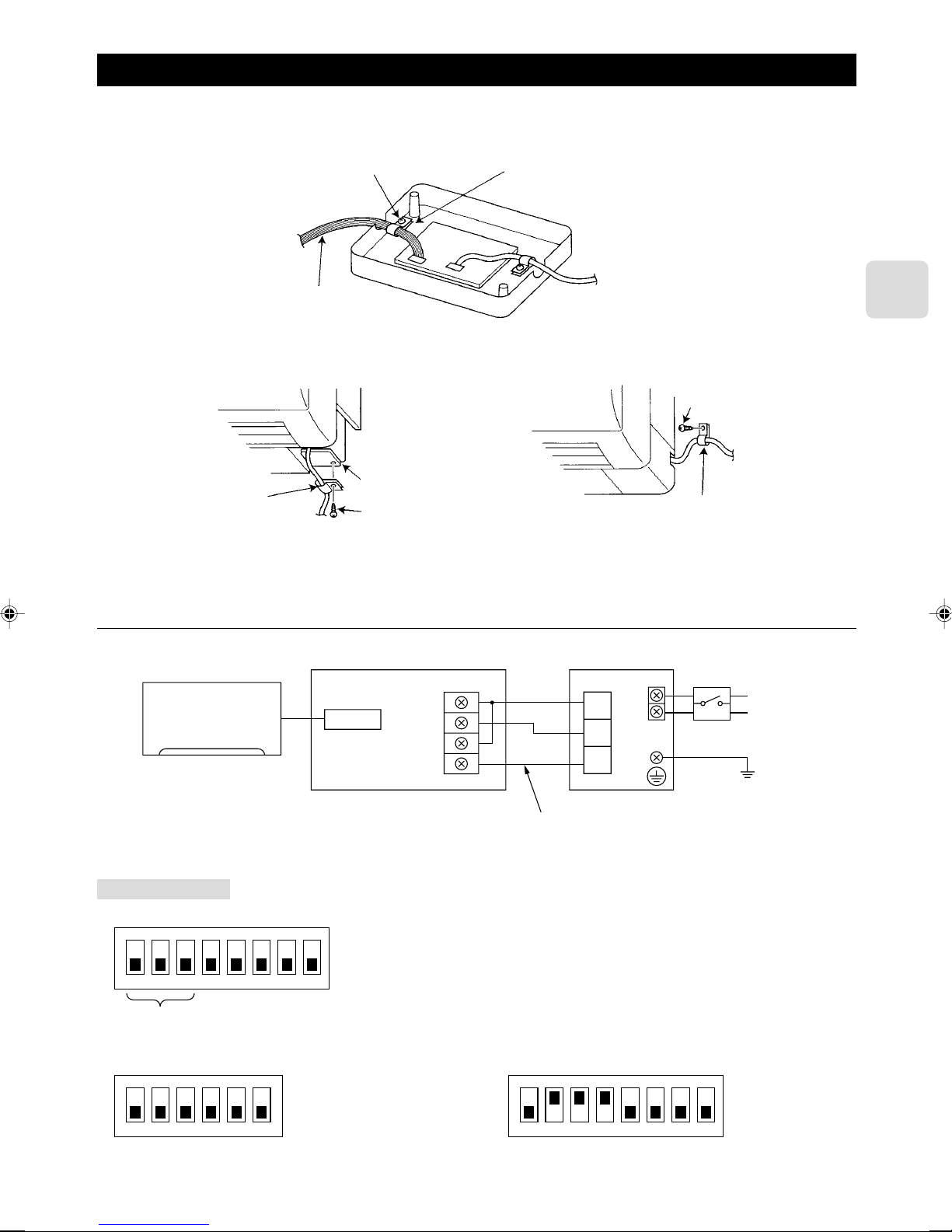

Cooling-Heating/Temperature settings

mode 1 (3 temperature patterns)

Cooling-Heating/Temperature settings

mode 2 (8 temperature patterns)

Operating Details

–

Manual operations prohibited when CN591 No. 1 and No. 3 are closed, permitted

when open.

Only when No. 1 and No. 3 are closed and manual operations are prohibited.

On when CN591 No. 1 and No. 2 are closed, off when open.

(Cannot be operated from the remote control when manual operations are pro-

hibited. Only valid when operated from the CN591.)

On when CN591 No. 1 and No. 2 are closed, off when open.

Manual operations prohibited when No. 1 and No. 3 are closed, permitted when

open.

(Cannot be operated from the remote control when manual operations are pro-

hibited. Only valid when operated from the CN591.)

On when CN591 No. 1 and No. 2 are closed, off when No. 1 and No. 3 are closed.

Manual operations prohibited when No. 1 and No. 4 are closed, and permitted

when No. 1 and No. 5 are closed.

(Same as when they are open.)

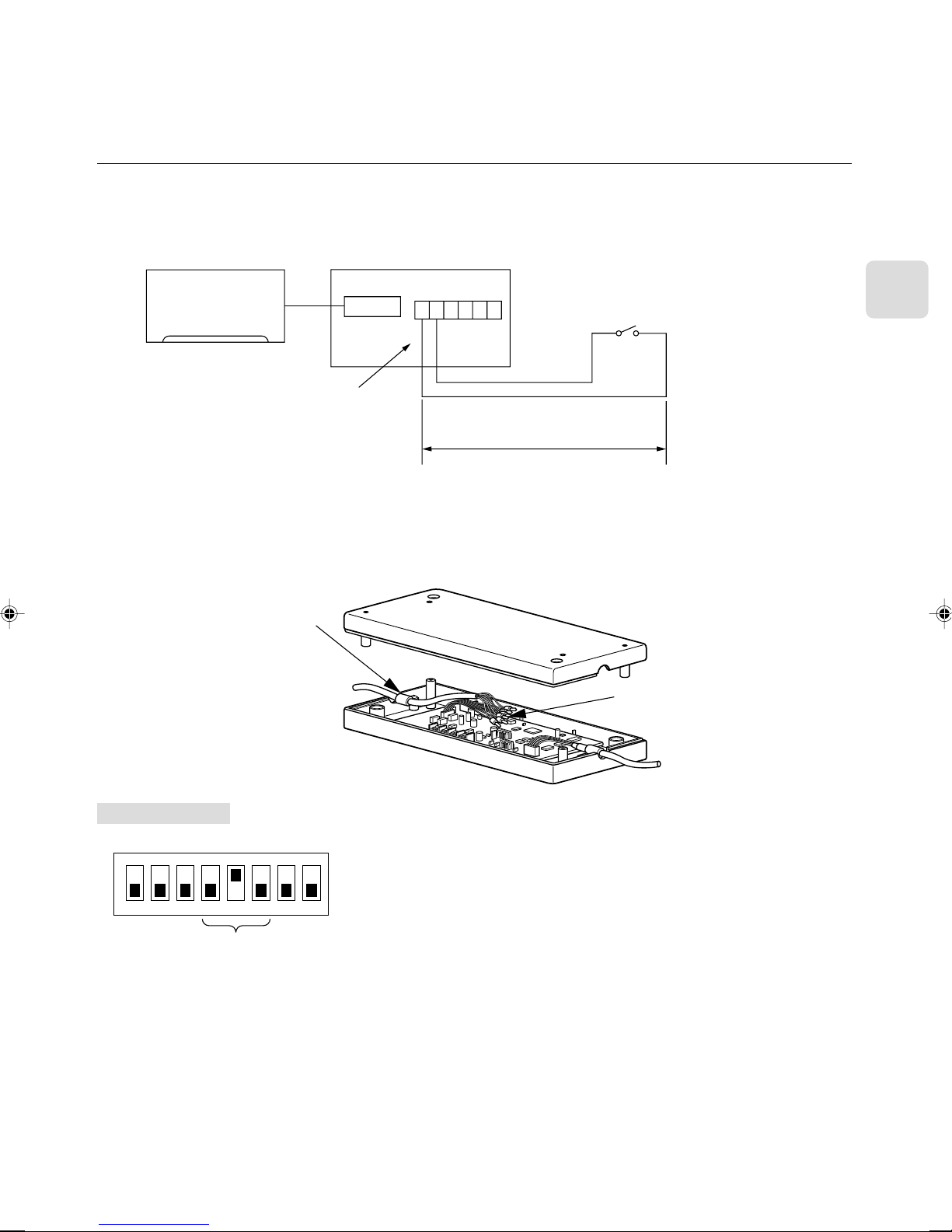

Permitted and on when CN591 No. 1 and No. 2 are closed, manual operations

prohibited and off when open.

(When permitted, the unit can be operated from the remote control.)

Manual operations prohibited and off when CN591 No. 1 and No. 2 are closed,

permitted and on when open.

(When permitted, the unit can be operated from the remote control.)

On when CN591 No. 1 and No. 2 are closed, off when open.

When No. 1 and No. 3 are closed 20 °C

When No. 1 and No. 4 are closed 24 °C

When No. 1 and No. 5 are closed 28 °C

(When multiple switches No. 3, 4, and 5 are closed, the highest temperature will

be selected.)

Heat when No. 1 and No. 6 are closed, cool when open.

(Remote control operations are valid as always.)

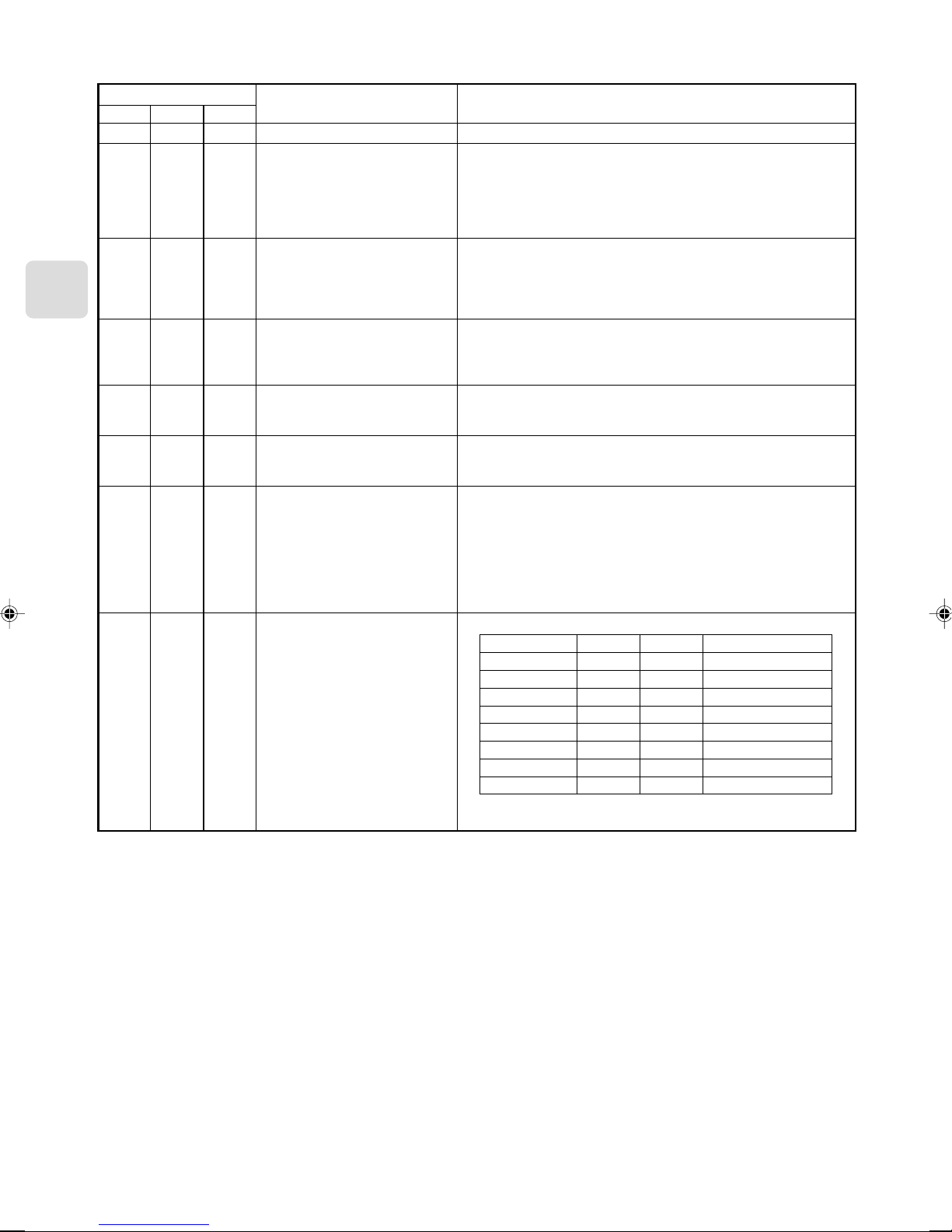

On when CN591 No. 1 and No. 2 are closed, off when open.

No. 1 and No. 3 No. 4 No. 5 Temperature settings

Open Open Open 16 °C

Closed Open Open 18 °C

Open Closed Open 20 °C

Closed Closed Open 22 °C

Open Open Closed 24 °C

Closed Open Closed 26 °C

Open Closed Closed 28 °C

Closed Closed Closed 30 °C

Heat when No. 1 and No. 6 are closed, cool when open.

(Remote control operations are valid as always.)

No. 5

OFF

OFF

ON

ON

OFF

OFF

ON

ON

No. 6

OFF

ON

OFF

ON

OFF

ON

OFF

ON

No. 4

OFF

OFF

OFF

OFF

ON

ON

ON

ON