FX

2N

-32CCL-NP CC-Link SYSTEM LOCAL BLOCK

HARDWARE MANUAL

JY992D96001A

This manual contains text, diagrams and explanations which will guide the reader in the correct installation

and operation of the FX2N-32CCL-NP CC-Link SYSTEM LOCAL BLOCK. It should be read and

understood before attempting to install or use the unit. Further information can be found in the FX series

PLC hardware manuals.

Note’s on the symbology used in this manual

At various times through out this manual certain symbols will be used to highlight points of information

which are intended to ensure the user’s personal safety and protect the integrity of the equipment.

Whenever any of the following symbols are encountered, its associated note must be read and

understood. Each of the symbols used will now be listed with a brief description of its meaning.

Hardware warnings

1) Indicates that the identified danger WILL cause physical and property damage.

2) Indicates that the identified danger could POSSIBLY cause physical and property damage.

1. INTRODUCTION

The FX2N-32CCL-NP is the interface block that connects the FX series PLC to the CC-Link system.

It is connected as a local station.

Master station .................Station which controls the remote I/O station, remote device station, and local

stations

Remote I/O station..........Remote station which handles only on/off data

Remote device station ....Remote station which handles both on/off data and numeric data

Local station....................Station which has a CPU and can communicate with the master station and

other local stations

Protocolinterface

FX

2N

-232AW C-NP

R e m o te I/O s ta tio n

FX

2N

PLC

M asterStation

AJ65BT-G4

RS-422 RS-232C

Program m ing

softw are

Powersupply

FX

2N

PLC

C C -Link

FX

2N

-3 2 C C L

-N P

FX

2N

-3 2 C C L -N P

Program cable Program cable

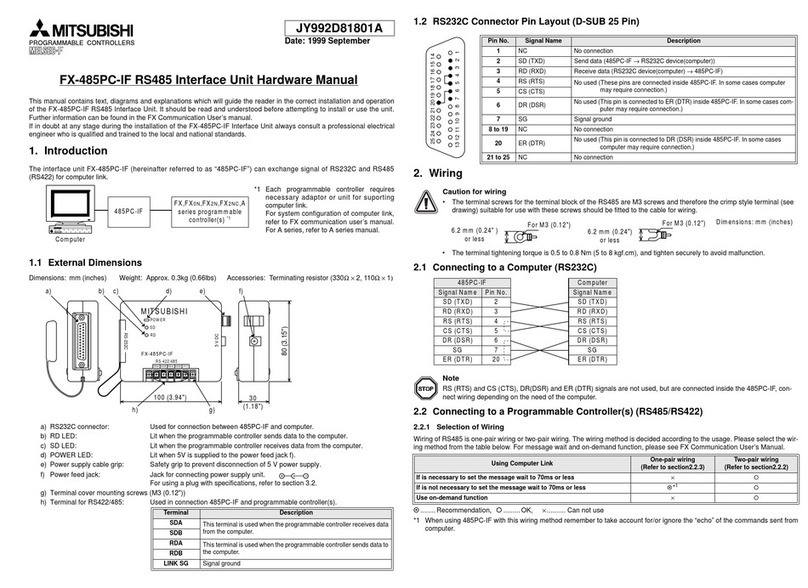

1.1 Dimensions and Setting

Dimensions: mm (inches) MASS (Weight): 0.4 kg (0.88 lbs)

Number Name Description

1) LED

indicators 1 LED

name Description LED status

Normal Error

RUN ON : Module is normal.

OFF: Watchdog timer error has occurred. ON OFF

ERR.

Indicates the communication status with

the stations set in the parameters.

ON : Communication error has

occurred in all stations.

Flashing : Communication error has

occurred in some stations.

OFF ON or

flashing

L RUN ON : Data link is being executed

(host station). ON OFF

L ERR.

ON : Communication error has

occurred (host station).

Flashing : The settings of the switches 4)

to 7) are changed while the

power is ON.

OFF ON or

flashing

2) Power indictor POWER ON : 24V DC is supplied from the outside. ON OFF

3) LED

indicators 2 SW ERR. ON : Switch setting error has occurred. OFF ON

TEST 1 Test result indication OFF except during testTEST 2

TEST 3

LINE ERR.

ON : The cable is broken the transmission

route is affected by noise, etc. OFF ON

SD ON : Data is being transmitted. ON OFF

RD ON : Data is being received. ON OFF

4)

Station

numbersetting

switch

Sets the station number of the module. (Default setting at shipment: 00)

<Setting range>

Local station : 1 to 64

If "65" or larger number is set, the "SW" and "L ERR." LED indicators turn ON.

5) Mode setting

switch Sets the operation status of the module. (Default setting at shipment: 0)

Number Name Description

0 Online Sets connection to data link.

1 (Unusable)

2 Offline Sets disconnection from data link.

3 (Unusable)

4 (Unusable)

5 (Unusable)

6 Hardware test

7 (Unusable) Setting error (The SW LED indicator turns ON.)

8 to A (Unusable) Used in PLC internal operations.

B to F (Unusable) Setting error (The SW LED indicator turns ON.)

6) Transmission

speed setting

switch

Sets the transmission speed of the module. (Default setting at shipment: 0)

Number Setting contents

0 156 kbps

1 625 kbps

2 2.5 Mbps

3 5 Mbps

4 10 Mbps

5 to 9 Setting error (The SW and L ERR. LED indicators turn ON.)

RUN

ERR.

L E R R .

L R U N

POW ER

SW ERR.

TEST 1

TEST 2

TEST 3

LIN E ER R .

SD

RD

×10

×1

STATION

NO.

MODE

B RATE

1

3

2

4

156K

625K

2.5M

5M

10M

0

HLD

41

ONOFF

SW

1

2

3

--

-

-

-

-

4

5

6

7

8

-

-

--

-

-

CLR

FX

2N

-3 2 C C L -N P

0

1

2

3

4

5

6

7

8

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

12345678

ON

RUN

ERR.

L R U N

L E R R .

POW ER

SW ERR.

TEST 1

TEST 2

TEST 3

LIN E ER R .

SD

RD

85(3.34)

90(3.5)

87(3.43)

9(0.35)

FX2N -3 2 C C L -N P

2-

φ4.5

80(3.15)

75(2.95)

MITSUBISHI

1)

2)

3)

4)

5)

6)

8)

7)

9)

10)

11)

13)

Inside oftop cover

24+

24-

FG

SLD D G DA DB

12)

RUN

ERR.

L RUN

L ERR

SW ERR.

TEST 1

TEST 2

TEST 3

LINE ERR.

SD

RD

STATION NO.

×10

×1

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

MODE

12

3

4

5

6

7

8

9

0

A

B

C

D

E

F

B RATE

0

2

1

3

4

156K

625K

2.5M

5M

10M

1

2

3

4

5

6

7

8

9

0

2. Installation and wiring

INSTALLATION PRECAUTIONS

• Use the module in the environment described in the HARDWARE MANUAL General Specification.

Do not use the PLC in a place with dust, soot, conductive dust, corrosive gas or combustible gas,

place exposed to high temperature, condensation, wind or rain or place with vibration or impact.

Using the module outside the range of the general specification may result in electrical shock, fire,

malfunctions, or may damage the PLC.

• When drilling screw holes or performing wiring, make sure that cutting chips, wire chips or

other foreign matter does not enter the ventilation window of the module.

Such matter may cause fire, failure or malfunction.

• When the installation work is completed, remove the dust protection sheet from the ventilation

window of the PLC.

If the sheet remains attached, it may cause fire, failure or malfunction.

• Securely connect extension cables to specified connectors.

Poor contact may cause malfunction.

WIRING PRECAUTIONS

• Before beginning any installation or wiring work, make sure all phases of the power supply

have been shut down from the outside.

Incomplete shutdown of thepower supply phases may cause electrical shock or damage in the

module.

• Following an installation or wiring work, when turning on the power supply and operating the

PLC, make sure that the terminal cover provided as an accessory has been attached to the

module.

A missing cover may cause electrical shock.

• For the CC-Link system, use dedicated cables specified by the manufacturer.

The performance of the CC-Link system cannot be guaranteed with any cable other than the

ones specified by the manufacturer.

With wiring outside the specification range, normal data transfer cannot be guaranteed.

• Make sure to fix communication cables and power cables connected to the module by placing

them in the duct or clamping them.

Cables not placed in duct or not clamped may hang or shift, allowing them to be accidentally

pulled, which may result in malfunction or damage to the module and the cables.

• The number of times to disconnect/connect the program cable for FX2N-32CCL-NP should be

kept to a minimum.

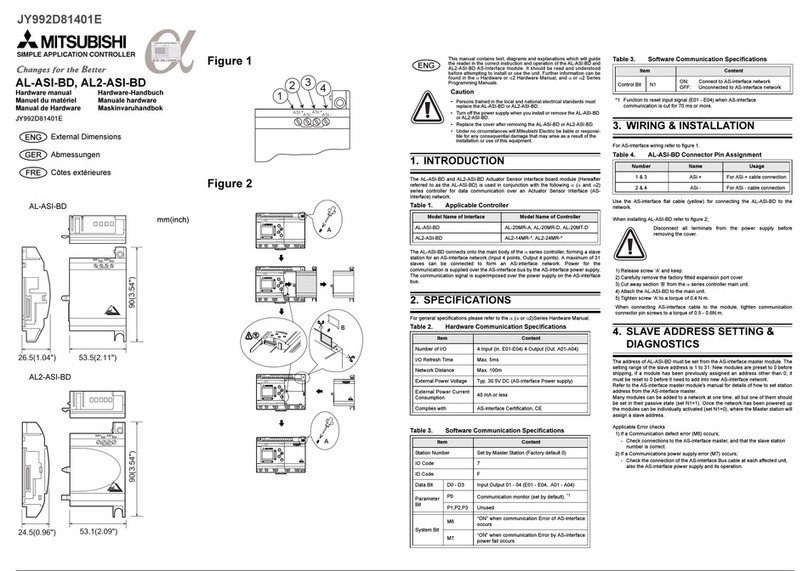

7) Condition

setting switch Sets the operation condition. (Default setting at shipment: All OFF)

Number Setting description Switch status

ON OFF

SW1 to

SW3 (Unusable) Always OFF

SW4 Input data status in data link faulty station Keep

(HLD) Clear

(CLR)

SW5 Number of occupied stations 4 1

SW6 to

SW8 (Unusable) Always OFF

8) Terminal block Connects dedicated CC-Link cables to enable data link. For the connection

method, refer to Section 2.3.

The terminals SLD and FG are connected inside.

9) Terminal block Connects the power supply to operate the master block.

10) Extensionbus

cable Connects the PLC.

11) Expansion

bus port Connects an extension equipment.

12) Program

port A connector for program cable

13) DIN rail

mounting

groove DIN46277: DIN rail mounting groove of 35 mm (1.38") in width

Number Name Description

HLD

1

SW

ON

CLR 4

OFF ON

12345678

2

1

3

4

6

5

7

8

SLD DG DA DB

24+

24-

FG

Guidelines for the safety of the user and protection of the FX

2N

-32CCL-NP CC-Link

SYSTEM LOCAL BLOCK

• If in doubt at any stage during the installation of the FX

2N

-32CCL-NP CC-Link SYSTEM LOCAL

BLOCK always consult a professional electrical engineer who is qualified and trained to the local

and national standards. If in doubt about the operation or use of the FX

2N

-32CCL-NP CC-Link

SYSTEM LOCAL BLOCK please consult the nearest Mitsubishi Electric distributor.

• Under no circumstances will Mitsubishi Electric be liable or responsible for any consequential

damage that may arise as a result of the installation or use of this equipment.

• All examples and diagrams shown in this manual are intended only as an aid to

understanding the text, not to guarantee operation. Mitsubishi Electric will accept no

responsibility for actual use of the product based on these illustrative examples.

• Owing to the very great variety in possible application of this equipment, you must satisfy

yourself as to its suitability for your specific application.

Industrialautomation

Elincom Group

EuropeanUnion: www.elinco.eu

Russia:www.elinc.ru