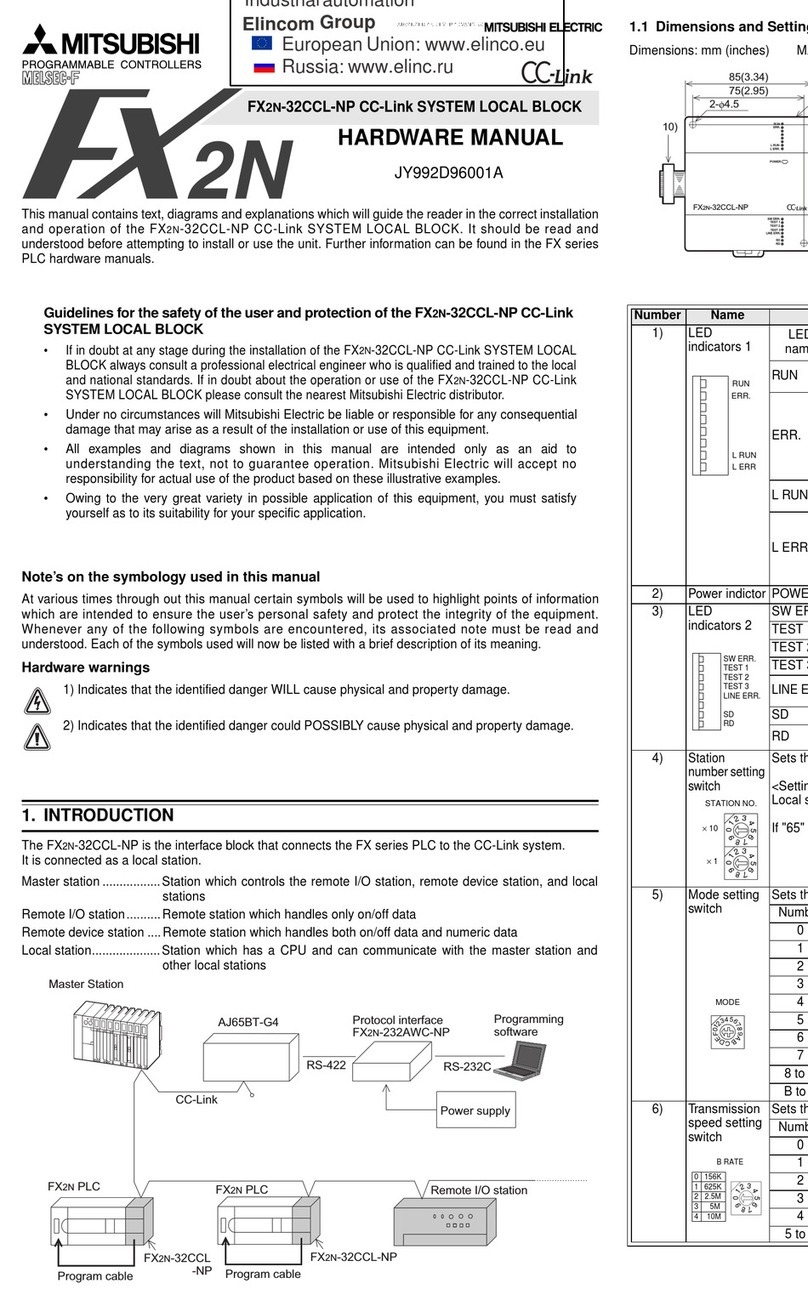

5. Wiring

5.1 Data Link

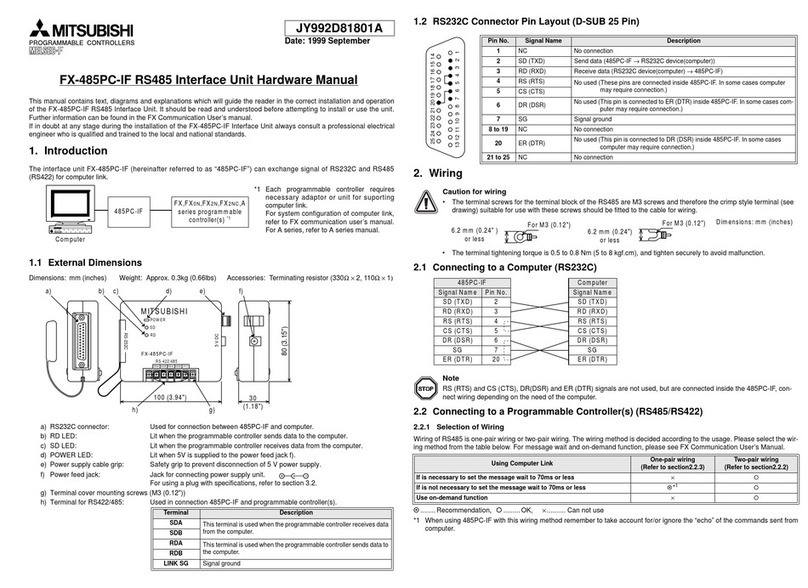

The method of connecting the AJ65BT-R2, master module and remote

module with a CC-Link dedicated cable is shown below.

CC-Link dedicated

cable

Terminator Terminato

Master module AJ65BT-R2 Remote module

CC-Link dedicated

cable

DA

DB

DG

SLD

FG

DA

DB

DG

SLD

FG

24V

24G

DA

DB

DG

SLD

FG

24V

24G

(B)

(W)

(Y)

POIN

T

Always connect the modules on both ends of the data link with the

"terminator" enclosed with the master module. (Connect across DA-DB)

5.2 Connection with external device

The method of connecting the AJ65BT-R2 and external device with

RS-232C is show below.

Pin

No. Name Signal

abbrev.

Signal direction

AJ65BT-R2

external device

1 Reception carrier

detection CD

2 Reception data RD(RXD)

3 Transmission data SD(TXD)

4 Data terminal ready ER(DTR)

5 Signal ground SG

6 Data set ready DR(DSR)

7 Transmission request RS(RTS)

8 Transmission enable CS(CTS)

9 Not used – –

6

12345

789

The following type of

connector is mounted on

the AJ65BT-R2 side, so

use a mate connector

that matches this type.

9-pin D-SUB (female)

screw-fixed type

DDK Ltd.

17L-10090-27-D9AC

Figure 5.1 RS-232C interface specifications

(1) Example of connection for DC code control and DTR/DSR signal

control

AJ65BT-R2 side (DTE) External device (DTE)

Signal abbrev. Pin No.

Cable connection and signal

method Signal abbrev.

SD 3 SD

RD 2 RD

RS 7 RS

CS 8 CS

DR 6 DR

SG 5 SG

CD 1 CD

ER 4 ER

(2) Example of connection for only DC code control

AJ65BT-R2 side (DTE) External device (DTE)

Signal abbrev. Pin No.

Cable connection and signal

method Signal abbrev.

SD 3 SD

RD 2 RD

RS 7 RS

CS 8 CS

DR 6 DR

SG 5 SG

CD 1 CD

ER 4 ER

6. External Dimensions

63.5 (2.50)

9.5

(0.37)

161 (6.33)

170 (6.68)

4.5

(0.18)

71 (2.79)

80 (3.14)

4.5

(0.18)

2-φ4.5 installation hole

Unit: mm (inch)

Warranty

Mitsubishi will not be held liable for damage caused by factors found not to be

the cause of Mitsubishi; machine damage or lost profits caused by faults in the

Mitsubishi products; damage, secondary damage, accident compensation

caused by special factors unpredictable by Mitsubishi; damages to products

other than Mitsubishi products; and to other duties.

For safe use

yThis product has been manufactured as a general-purpose part for general

industries, and has not been designed or manufactured to be incorporated in a

device or system used in purposes related to human life.

yBefore using the product for special purposes such as nuclear power, electric

power, aerospace, medicine or passenger movement vehicles, consult with

Mitsubishi.

yThis product has been manufactured under strict quality control. However,

when installing the product where major accidents or losses could occur if the

product fails, install appropriate backup or failsafe functions in the system.

Country/Region Sales office/Tel

When exported from Japan, this manual does not require application to the Ministry

of Economy, Trade and Industry for service transaction permission.

Specifications subject to change without notice.

Printed in Japan on recycled paper.

HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

NAGOYA WORKS : 1-14, YA DA-MIN AMI 5-CHOME, HIGASH I-KU, NAGOYA, JAP AN

Country/Region Sales office/Tel

U.S.A Mitsubishi Electric Automation Inc.

500 Corporate Woods Parkway Vernon

Hills, IL 60061, U.S.A.

Tel : +1-847-478-2100

Brazil MELCO-TEC Rep. Com.e Assessoria

Tecnica Ltda.

Rua Correia Dias, 184,

Edificio Paraiso Trade Center-8 andar

Paraiso, Sao Paulo, SP Brazil

Tel : +55-11-5908-8331

Germany Mitsubishi Electric Europe B.V. German

Branch

Gothaer Strasse 8 D-40880 Ratingen,

GERMANY

Tel : +49-2102-486-0

U.K Mitsubishi Electric Europe B.V. UK

Branch

Travellers Lane, Hatfield, Hertfordshire.,

AL10 8XB, U.K.

Tel : +44-1707-276100

Italy Mitsubishi Electric Europe B.V. Italian

Branch

Centro Dir. Colleoni, Pal. Perseo-Ingr.2

Via Paracelso 12, I-20041 Agrate Brianza.,

Milano, Italy

Tel : +39-039-60531

Spain Mitsubishi Electric Europe B.V. Spanish

Branch

Carretera de Rubi 76-80,

E-08190 Sant Cugat del Valles,

Barcelona, Spain

Tel : +34-93-565-3131

France Mitsubishi Electric Europe B.V. French

Branch

25, Boulevard des Bouvets, F-92741

Nanterre Cedex, France

TEL: +33-1-5568-5568

South Africa Circuit Breaker Industries Ltd.

Private Bag 2016, ZA-1600 Isando,

South Africa

Tel : +27-11-928-2000

Hong Kong Mitsubishi Electric Automation

(Hong Kong) Ltd.

10th Floor, Manulife Tower, 169 Electric

Road, North Point, Hong Kong

Tel : +852-2887-8870

China Mitsubishi Electric Automation

(Shanghai) Ltd.

4/F Zhi Fu Plazz, No.80 Xin Chang Road,

Shanghai 200003, China

Tel : +86-21-6120-0808

Taiwan Setsuyo Enterprise Co., Ltd.

6F No.105 Wu-Kung 3rd.Rd, Wu-Ku

Hsiang, Taipei Hsine, Taiwan

Tel : +886-2-2299-2499

Korea Mitsubishi Electric Automation Korea

Co., Ltd.

1480-6, Gayang-dong, Gangseo-ku

Seoul 157-200, Korea

Tel : +82-2-3660-9552

Singapore Mitsubishi Electric Asia Pte, Ltd.

307 Alexandra Road #05-01/02,

Mitsubishi Electric Building,

Singapore 159943

Tel : +65-6470-2460

Thailand Mitsubishi Electric Automation (Thailand)

Co., Ltd.

Bang-Chan Industrial Estate No.111

Moo 4, Serithai Rd, T.Kannayao,

A.Kannayao, Bangkok 10230 Thailand

Tel : +66-2-517-1326

Indonesia P.T. Autoteknindo Sumber Makmur

Muara Karang Selatan, Block A/Utara

No.1 Kav. No.11 Kawasan Industri

Pergudangan Jakarta - Utara 14440,

P.O.Box 5045 Jakarta, 11050 Indonesia

Tel : +62-21-6630833

India Messung Systems Pvt, Ltd.

Electronic Sadan NO:III Unit No15,

M.I.D.C Bhosari, Pune-411026, India

Tel : +91-20-2712-3130

Australia Mitsubishi Electric Australia Pty. Ltd.

348 Victoria Road, Rydalmere,

N.S.W 2116, Australia

Tel : +61-2-9684-7777