Table of Contents

1Introduction...............................................................................................................................................3

1.1 Analogue/Digital Inputs .....................................................................................................................3

1.2 Frequency Inputs...............................................................................................................................3

2System Requirements ..............................................................................................................................3

3Safety........................................................................................................................................................4

3.1 Before installation:.............................................................................................................................4

4Installation.................................................................................................................................................8

4.1 Installation Requirements..................................................................................................................8

4.2 Summary of Installation Steps...........................................................................................................8

4.3 Overview............................................................................................................................................9

4.4 Tools and inspection .........................................................................................................................9

4.5 Connection ......................................................................................................................................10

4.6 Inserting of SIM card .......................................................................................................................13

4.7 Beep and flash codes......................................................................................................................13

5Harness Installation................................................................................................................................17

5.1 Description of connectors................................................................................................................17

5.2 Connector the Main harness wires according to the following table:..............................................18

5.3 Connect the Auxiliary harness wires according to the following table: ...........................................19

5.4 Connect the Code plug harness wires according to the following table:.........................................19

5.5 Connect the Serial harness wires according to the following table:................................................20

6Starter Interruption..................................................................................................................................21

6.1 Code Plug Socket Installation .........................................................................................................22

6.2 Positioning the FM 3617i/FM 3717i/FM 3817i Unit .........................................................................22

6.3 Signal Inputs....................................................................................................................................23

6.4 Power Outputs.................................................................................................................................24

6.5 Serial Communication .....................................................................................................................25

6.6 Loading Device Drivers ...................................................................................................................25

6.7 Configuring Vehicle Properties........................................................................................................26

6.8 Setting the Real Time Clock............................................................................................................26

6.9 Speed and RPM Calibration............................................................................................................27

6.10 Testing Installation.......................................................................................................................29

6.11 Voice / Hands-free connection....................................................................................................29

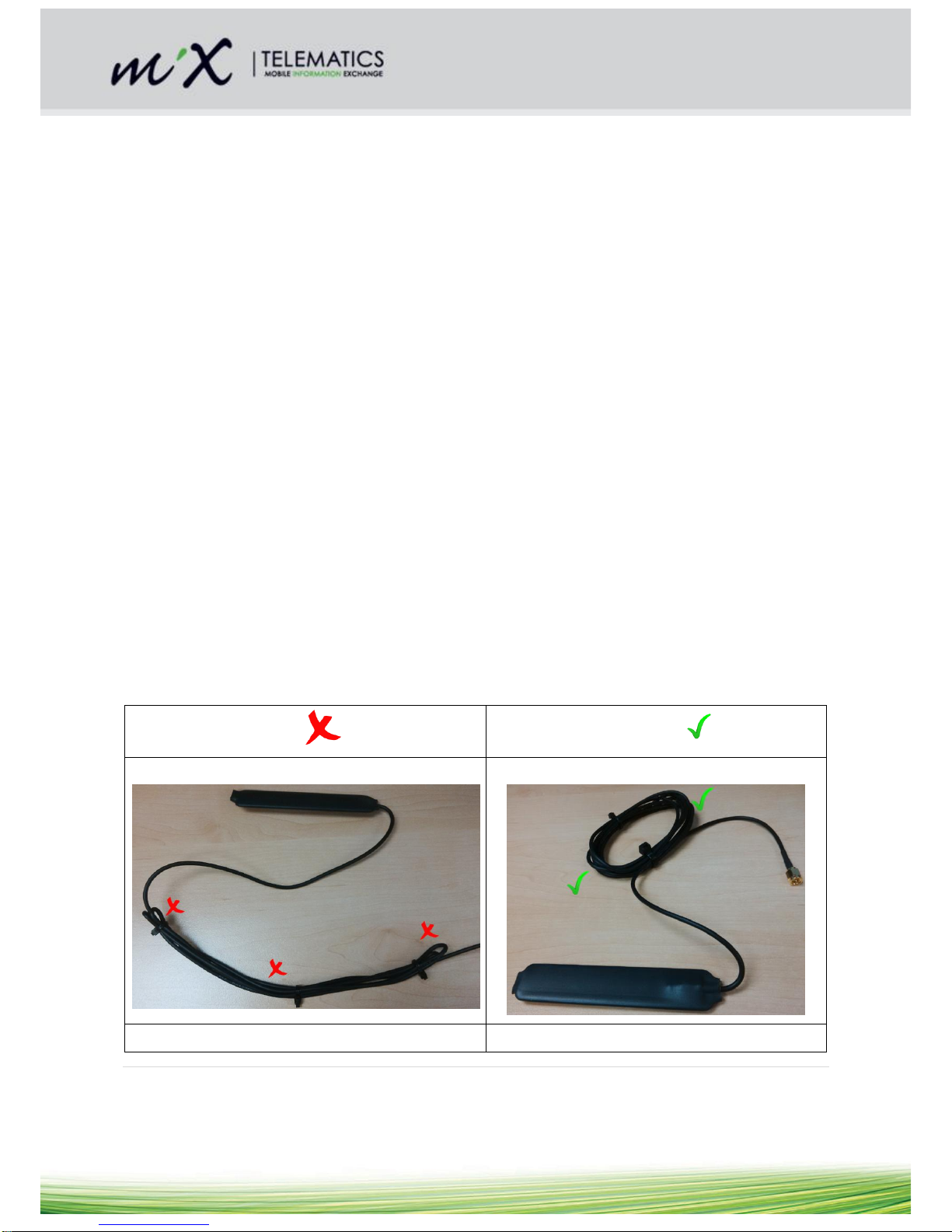

6.12 GPS antenna connection ............................................................................................................29

6.13 GSM Antenna connection ...........................................................................................................29

7Troubleshooting......................................................................................................................................30

8Maintenance ...........................................................................................................................................30

9FM 3617i/FM 3717i/FM 3817i Specifications .........................................................................................31

9.1 Technical description.......................................................................................................................31

9.2 Technical specifications ..................................................................................................................32

9.3 Auxiliary inputs/outputs ...................................................................................................................36

9.4 Look up table for installers to determine Speed and RPM FM Dealer Sensitivity Settings ............37

10 Statutory and Regulatory Compliance ............................................................................................39