100DP/300DP DUAL PULSE RESISTANCE WELDING POWER SUPPLY

990-295 iii

CONTENTS

Page

Revision Record ........................................................................................................................................ ii

Contact Us .........................................................................................................................................v

Safety Notes ....................................................................................................................................... vi

Chapter 1. Description

Section I: Features .................................................................................................................................. 1-1

Features ..................................................................................................................................... 1-1

Description ..................................................................................................................................... 1-2

Section III: Major Components ............................................................................................................. 1-4

Major Components ........................................................................................................................... 1-3

Front Panel Display and Display Controls ............................................................................... 1-3

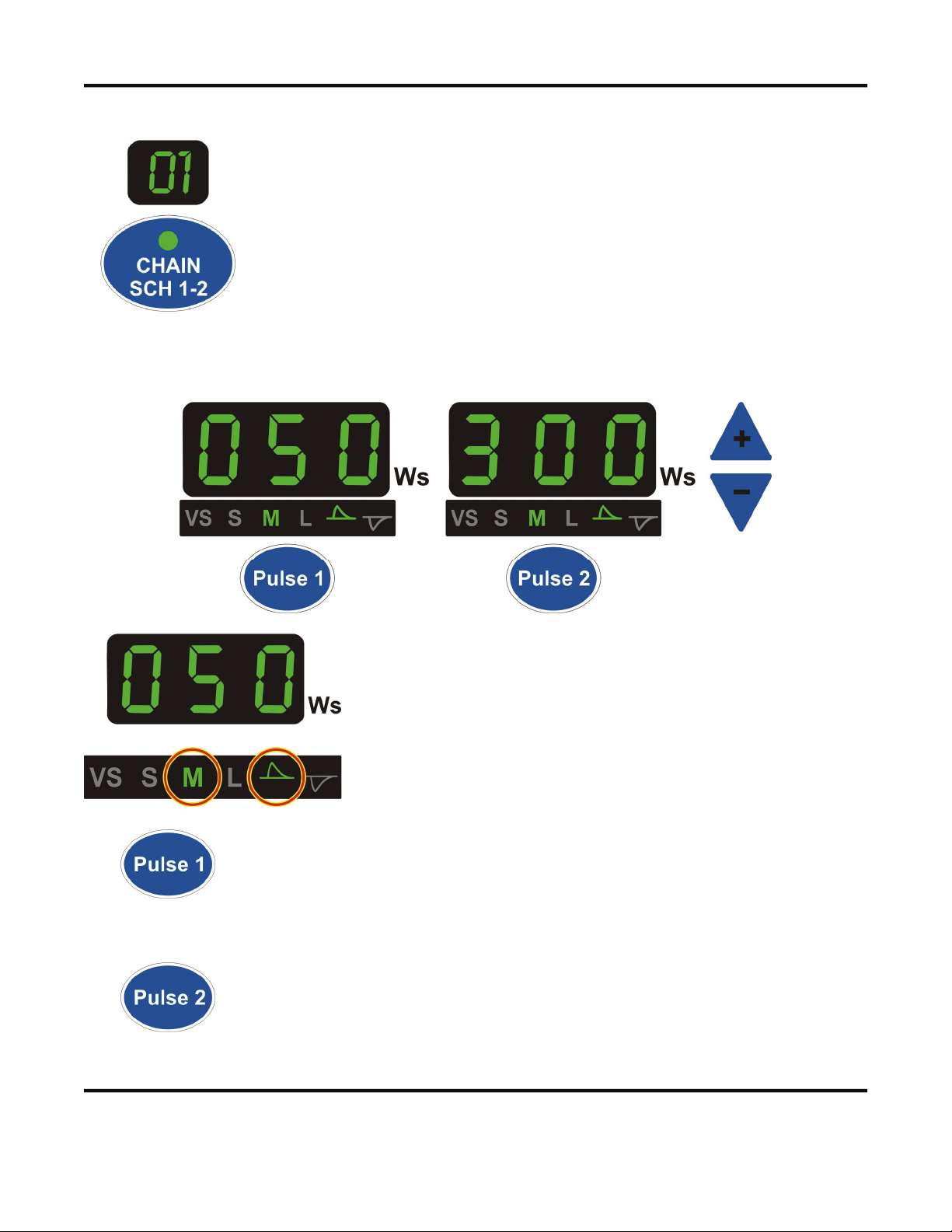

Schedule Number and Chain Switch ........................................................................................ 1-4

Energy and Pulse Indicators, Pulse Edit Buttons, Up/Down Buttons ...................................... 1-4

Polarity Select ........................................................................................................................... 1-7

Charge Monitor ........................................................................................................................ 1-7

WELD/NO WELD Switch ....................................................................................................... 1-7

Emergency Stop Switch Operation .................................................................................................. 1-7

Chapter 2. Installation and Setup

Section I: Installation ............................................................................................................................. 2-1

Unpacking ..................................................................................................................................... 2-1

Space Requirements ......................................................................................................................... 2-1

Utilities ..................................................................................................................................... 2-2

Power ..................................................................................................................................... 2-2

Compressed Air and Cooling Water ......................................................................................... 2-2

Input Logic Configuration ............................................................................................................... 2-2

Section II: Setup ..................................................................................................................................... 2-3

Connections to External Equipment ................................................................................................ 2-3

Weld Head Connections .................................................................................................................. 2-4

Foot Pedal-Actuated Weld Head Connection .................................................................................. 2-5

EZ-AIR Weld Head Connections ..................................................................................................... 2-6

Chapter 3. Operation

Section I: Introduction ........................................................................................................................... 3-1

Before You Start .............................................................................................................................. 3-1

Pre-Operational Checks ................................................................................................................... 3-1

Connections .............................................................................................................................. 3-1

Power ..................................................................................................................................... 3-1

Compressed Air ........................................................................................................................ 3-1

Adjust Buzzer Loudness .................................................................................................................. 3-1