10

www.mizarimaging.com

Tilt User’s Guide

How to Image

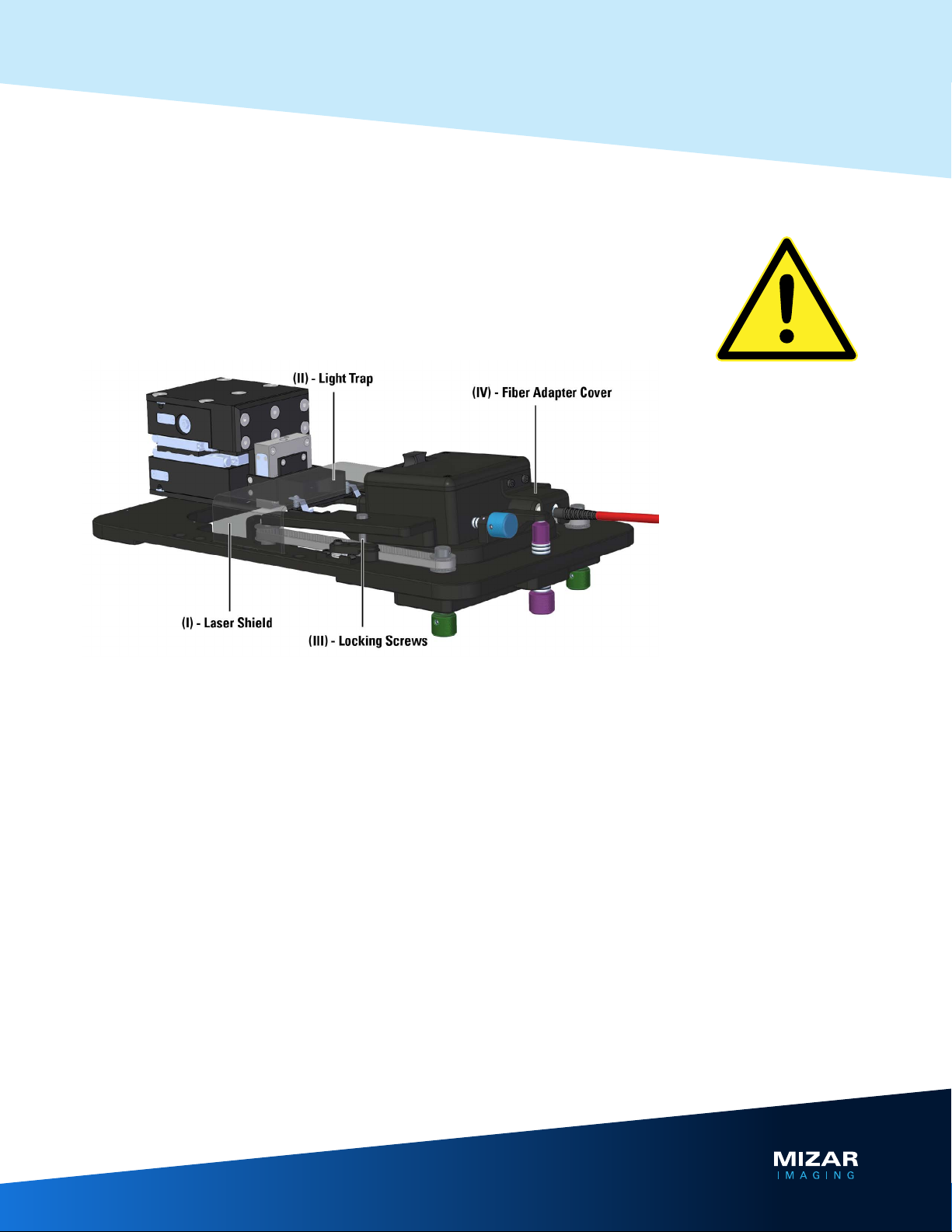

1. Check the LIGHTSHEET

Your Tilt was properly aligned when installed and should not need to be realigned if undis-

turbed. However, it is good practice to verify that everything looks good prior to imaging,

and only takes a few seconds:

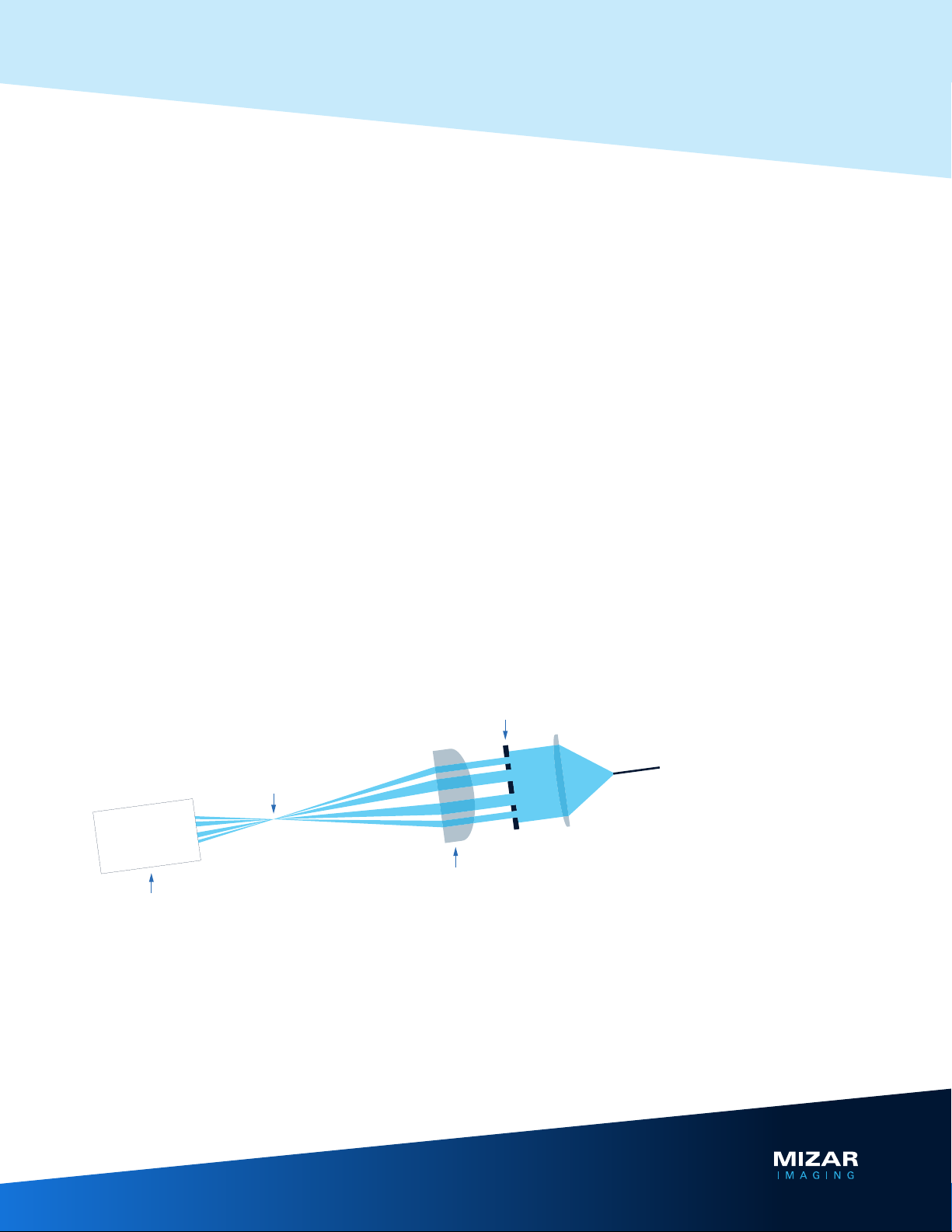

• With the laser on low power (~2 mW) take a piece of lens paper (or a lint-free wipe) and

hold it over the front lens cover where the four light sheets emerge from the Tilt optic

assembly.

• Check to see that the light sheet is evenly illuminated side-to-side, i.e., that one side is

not brighter than the other.

• Check also that the top pair is equal in brightness to the bottom pair.

Sheet not looking good? See Aligning Tilt Optical Components on pages 12-16.

Or call us for support at +1.508.939.7500.

2. Load your sample

Mount your specimens in a suitable sample chamber, and place sample chamber onto the

sample holder platform.

For detailed tips on mounting samples seeTips for Mounting Samples on page 17.

See also Recommended Specimen Chambers on page 18.

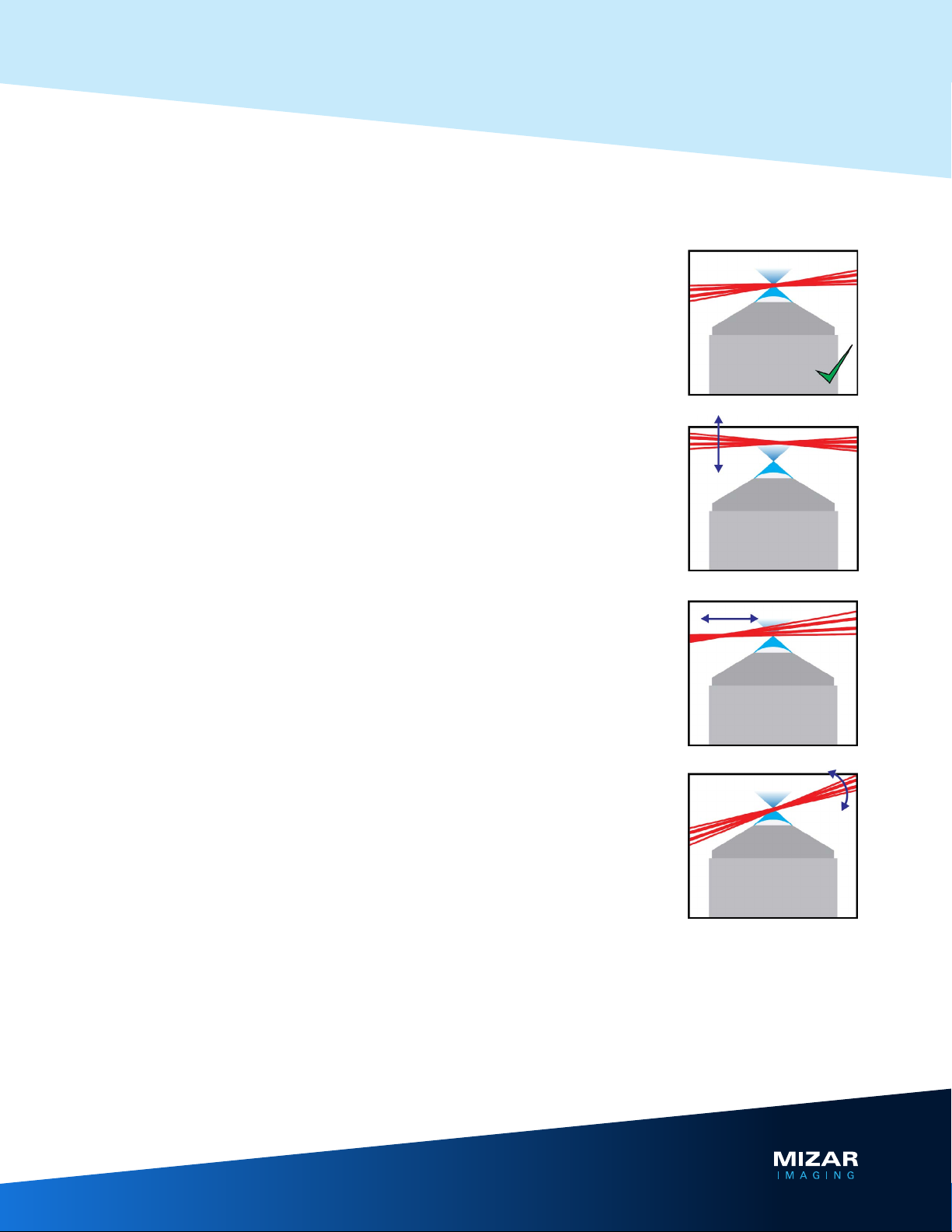

3. Coarse / Fine Focus the Lightsheet

3.1 Locate specimen and focal plane of interest.

With the laser off, use any type of transmitted light to find your sample. Focus on the ap-

proximate focal plane of interest.

3.2 Switch to live view on your computer.

Having located your sample and the focal plane of interest, turn off transmitted light and

direct 100% of the light path of your microscope to the camera. Switch to live mode in your

microscope’s software.

3.3 Coarse adjustment of the lightsheet.

• Set laser power to medium-low (10-30 mW) and open the shutter to the laser.

• Turn the (Green) Angle Adjustment knob on the bottom of the Tilt stage until you see

fluorescent signal from your sample. You may need to adjust your camera exposure or

perform a quick autoscale.

• With autoscaling off, adjust the (Green) knob until the image is as its brightest.