Technical Documentation

KFG-P 2000

mk North America, Inc. |105 Highland Park Drive | Bloomfi eld, CT 06002 | (860) 769-5500 |www.mknorthamerica.com

©2022 | Page 6

mk North America, Inc. |105 Highland Park Drive | Bloomfi eld, CT 06002 | (860) 769-5500 |www.mknorthamerica.com

©2022 | Page 7

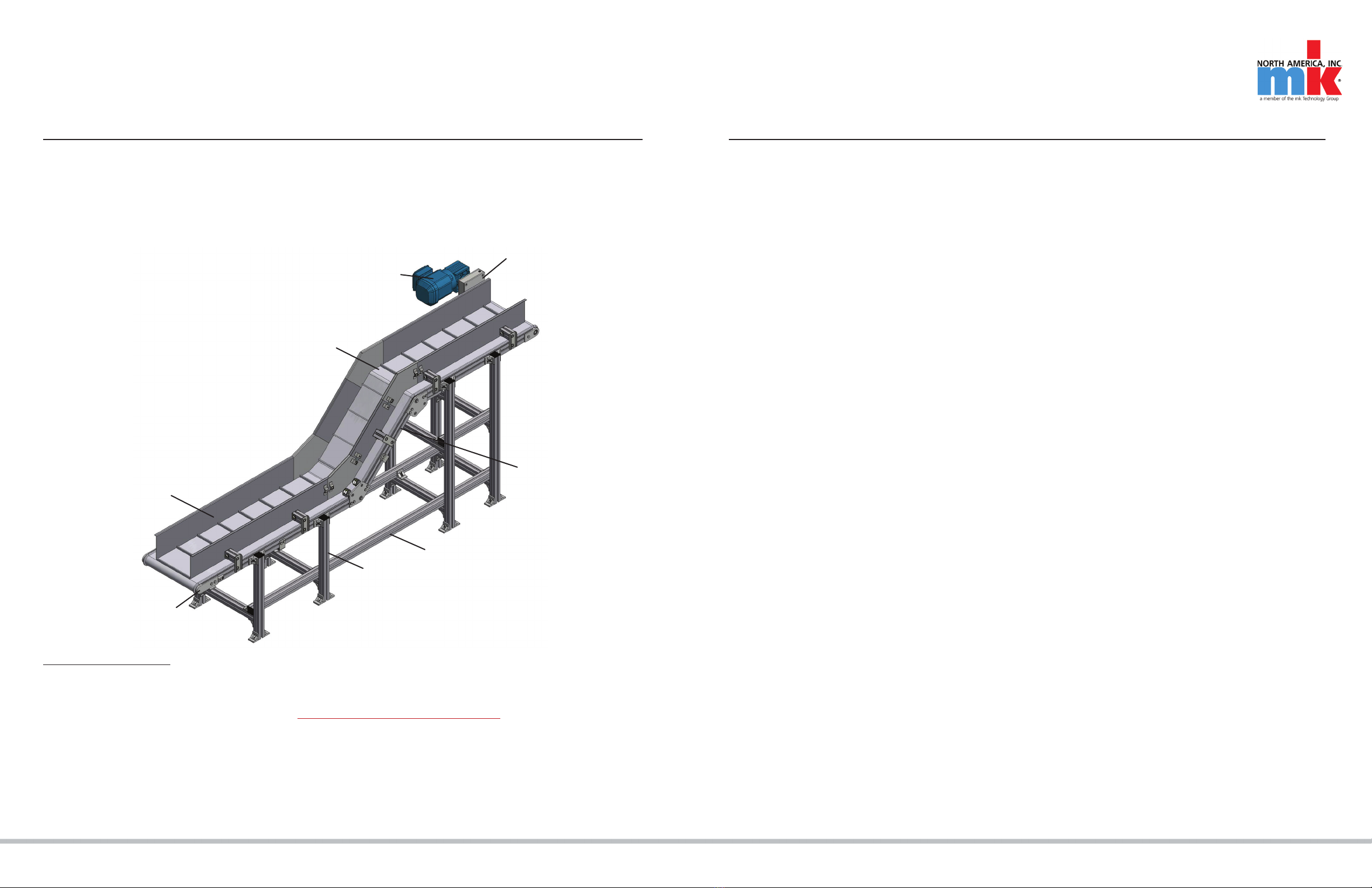

Typical Components

1) Conveyor Frame

2) Idler End

3) Gearmotor Mount/Drive Assembly - serial number plate mounted here

4) Gearmotor

5) Speed Control (Not Shown)

6) Belt

7) Side Rails

8) Support Stand

9) Stand Stringer

The KFG-P 2000 has many typical conveyor components. Below is a description of the basic parts and options

for the KFG-P 2000 conveyor. The items you receive will vary based on your actual purchase order. Items may

appear different on your model based on your particular order requirements. Consult your approval drawing for

specifi cs items included in your order.

Your model will vary.

3 CONVEYOR DESCRIPTION (CONT.) 4 WARRANTY INFORMATION

3.2 Conveyor Components

3

4

6

7

2

8

9

1

Warranty

mk North America, Inc. (MKNA) offers a COMPLETE ONE YEAR WARRANTY from the date of delivery, to the original purchaser of the

MKNA equipment (CUSTOMER), to be free from defects in material and workmanship; under normal use and with proper installation,

maintenance and cleaning.

Additionally MKNA offers a LIMITED 10 YEAR WARRANTY on all equipment that MKNA is the original manufacturer of, to be

free from defect and workmanship.1.

This warranty is extended by MKNA only to CUSTOMER, and is non-transferable. All warranty requests shall be made by CUSTOMER.

MKNA will replace or repair, at our factory or any other location we designate2., any defective part within the warranty period and without

charge. It is at MKNA’s sole discretion whether to repair or replace. CUSTOMER will provide MKNA with a prompt written notice of the

defect, including the serial number of the unit (when applicable) and the date of delivery.

At MKNA’s request CUSTOMER will return all defective parts for evaluation at MKNA. MKNA will provide CUSTOMER with a return goods

authorization number (RGA#). No parts will be returned without a RGA#. The RGA# must clearly be marked on all labels, packages and

packing slips.

CUSTOMER shall pay all costs for packaging, shipping, duties and/or any other related costs in the sending or receiving of parts.

CUSTOMER is responsible for all labor associated with sending or receiving of parts.

MKNA PROVIDES NO WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE; UNLESS IT IS AGREED TO BY

MKNA AND CUSTOMER IN WRITING PRIOR TO PLACEMENT OF ORDER. Such agreement requires approval of MKNA Management.

UNDER NO CIRCUMSTANCES SHALL MKNA BE HELD LIABLE FOR DAMAGES OR LIABILITY FOR LOSS OF PRODUCTION, PRODUCT,

EQUIPMENT OR PROFITS OR LIABILITY FOR DIRECT, INCIDENTAL, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES OR ANY

DAMAGES TO PERSONS OR PROPERTY, WHATSOEVER. CUSTOMER agrees that it is their sole remedy for liability of any kind, including

negligence with respect to the equipment and services furnished by MKNA shall be limited to the remedies provided herein. This warranty

shall not apply to any failure of the unit or its components caused by lack of maintenance and/or improper maintenance, incorrect

adjustments, misuse or unreasonable use or exposure to chemicals and/or environments which the unit is not designed for. Unauthorized

modification of the unit or the use of non-MKNA replacement parts and building components voids this warranty.

1. The limited 10 year warranty does not apply to equipment and components manufactured by others. Such equipment and components

are subject to any limitation contained in the original manufacturer’s warranty and include, but are not limited to: bearings, belts, casters,

controllers, motors and pneumatic devices.

2. No work will be performed by MKNA or an MKNA factory authorized service representative at the site of installation unless in MKNA’s

opinion it is impractical for Customer to remove and return the defective part to MKNA’s factory.

EXCEPT AS EXPRESSLY STATED HEREIN, THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, BY OPERATION OF LAW OR

OTHERWISE, OF THE EQUIPMENT OR SERVICES FURNISHED BY MKNA OR FACTORY AUTHORIZED SERVICE REPRESENTATIVE. THERE

ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.

mk North America, Inc. reserves the right to change, modify or discontinue products and/or specifications with or without notice.

All of mk North America, Inc. products are covered by this warranty.