mk North America, Inc. |105-125 Highland Park Drive |Bloomfield, CT 06002 |(860) 769-5500 |www.mknorthamerica.com

©2020 |Page 7

4 WARRANTYINFORMATION

Warranty

mkNorthAmerica,Inc.(MKNA)offersaCOMPLETEONEYEARWARRANTYfromthedateofdelivery,totheoriginalpurchaserofthe

MKNAequipment(CUSTOMER),tobefreefromdefectsinmaterialandworkmanship;undernormaluseandwithproperinstallation,

maintenanceandcleaning.

AdditionallyMKNAoffersaLIMITED10YEARWARRANTYonallequipmentthatMKNAistheoriginalmanufacturerof,tobe

freefromdefectandworkmanship.1.

ThiswarrantyisextendedbyMKNAonlytoCUSTOMER,andisnon-transferable.AllwarrantyrequestsshallbemadebyCUSTOMER.

MKNAwillreplaceorrepair,atourfactoryoranyotherlocationwedesignate2.,anydefectivepartwithinthewarrantyperiodandwithout

charge.ItisatMKNA’ssolediscretionwhethertorepairorreplace.CUSTOMERwillprovideMKNAwithapromptwrittennoticeofthe

defect,includingtheserialnumberoftheunit(whenapplicable)andthedateofdelivery.

AtMKNA’srequestCUSTOMERwillreturnalldefectivepartsforevaluationatMKNA.MKNAwillprovideCUSTOMERwithareturngoods

authorizationnumber(RGA#).NopartswillbereturnedwithoutaRGA#.TheRGA#mustclearlybemarkedonalllabels,packagesand

packingslips.

CUSTOMER shall pay all costs for packaging, shipping, duties and/or any other related costs in the sending or receiving of parts.

CUSTOMERisresponsibleforalllaborassociatedwithsendingorreceivingofparts.

MKNAPROVIDESNOWARRANTYOFMERCHANTABILITYORFITNESSFORAPARTICULARPURPOSE;UNLESSITISAGREEDTOBY

MKNAANDCUSTOMERINWRITINGPRIORTOPLACEMENTOFORDER.SuchagreementrequiresapprovalofMKNAManagement.

UNDERNOCIRCUMSTANCESSHALL MKNA BE HELDLIABLE FOR DAMAGES ORLIABILITYFOR LOSSOF PRODUCTION,PRODUCT,

EQUIPMENT OR PROFITS OR LIABILITY FOR DIRECT, INCIDENTAL, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES OR ANY

DAMAGESTOPERSONSORPROPERTY,WHATSOEVER.CUSTOMERagreesthatitistheirsoleremedyforliabilityofanykind,including

negligencewithrespecttotheequipmentandservicesfurnishedbyMKNAshallbelimitedtotheremediesprovidedherein.Thiswarranty

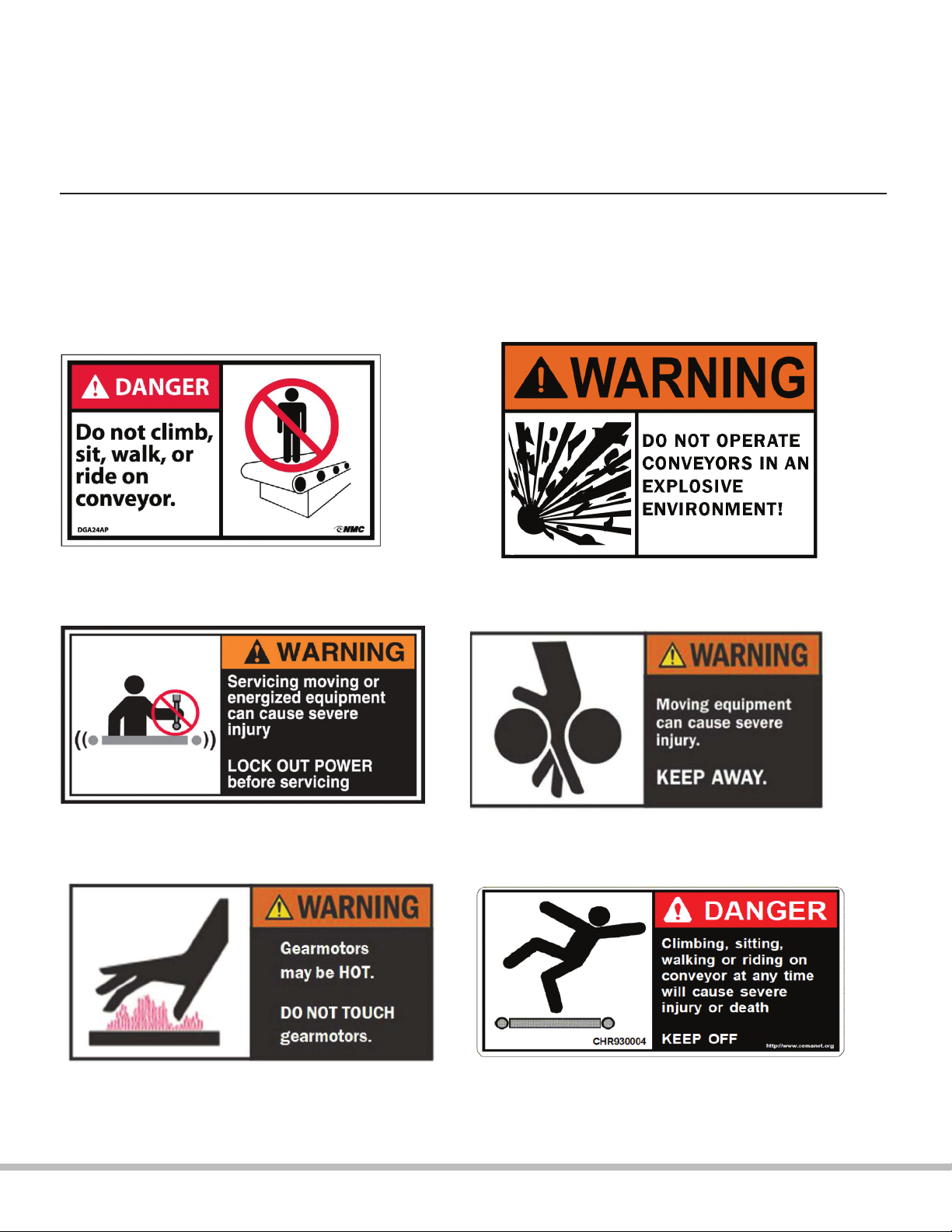

shall not apply to any failure of the unit or its components caused by lack of maintenance and/or improper maintenance, incorrect

adjustments,misuseorunreasonableuseorexposuretochemicalsand/orenvironmentswhichtheunitisnotdesignedfor.Unauthorized

modificationoftheunitortheuseofnon-MKNAreplacementpartsandbuildingcomponentsvoidsthiswarranty.

1.Thelimited10yearwarrantydoesnotapplytoequipmentandcomponentsmanufacturedbyothers.Suchequipmentandcomponents

aresubjecttoanylimitationcontainedintheoriginalmanufacturer’swarrantyandinclude,butarenotlimitedto:bearings,belts,casters,

controllers,motorsandpneumaticdevices.

2.NoworkwillbeperformedbyMKNAoranMKNAfactoryauthorizedservicerepresentativeatthesiteofinstallationunlessinMKNA’s

opinionitisimpracticalforCustomertoremoveandreturnthedefectiveparttoMKNA’sfactory.

EXCEPT AS EXPRESSLY STATED HEREIN, THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, BY OPERATION OF LAW OR

OTHERWISE,OFTHEEQUIPMENTORSERVICESFURNISHEDBYMKNAORFACTORYAUTHORIZEDSERVICEREPRESENTATIVE.THERE

ARENOWARRANTIESWHICHEXTENDBEYONDTHEDESCRIPTIONONTHEFACEHEREOF.

mkNorthAmerica,Inc.reservestherighttochange,modifyordiscontinueproductsand/orspecificationswithorwithoutnotice.

AllofmkNorthAmerica,Inc.productsarecoveredbythiswarranty.

Your model will vary.