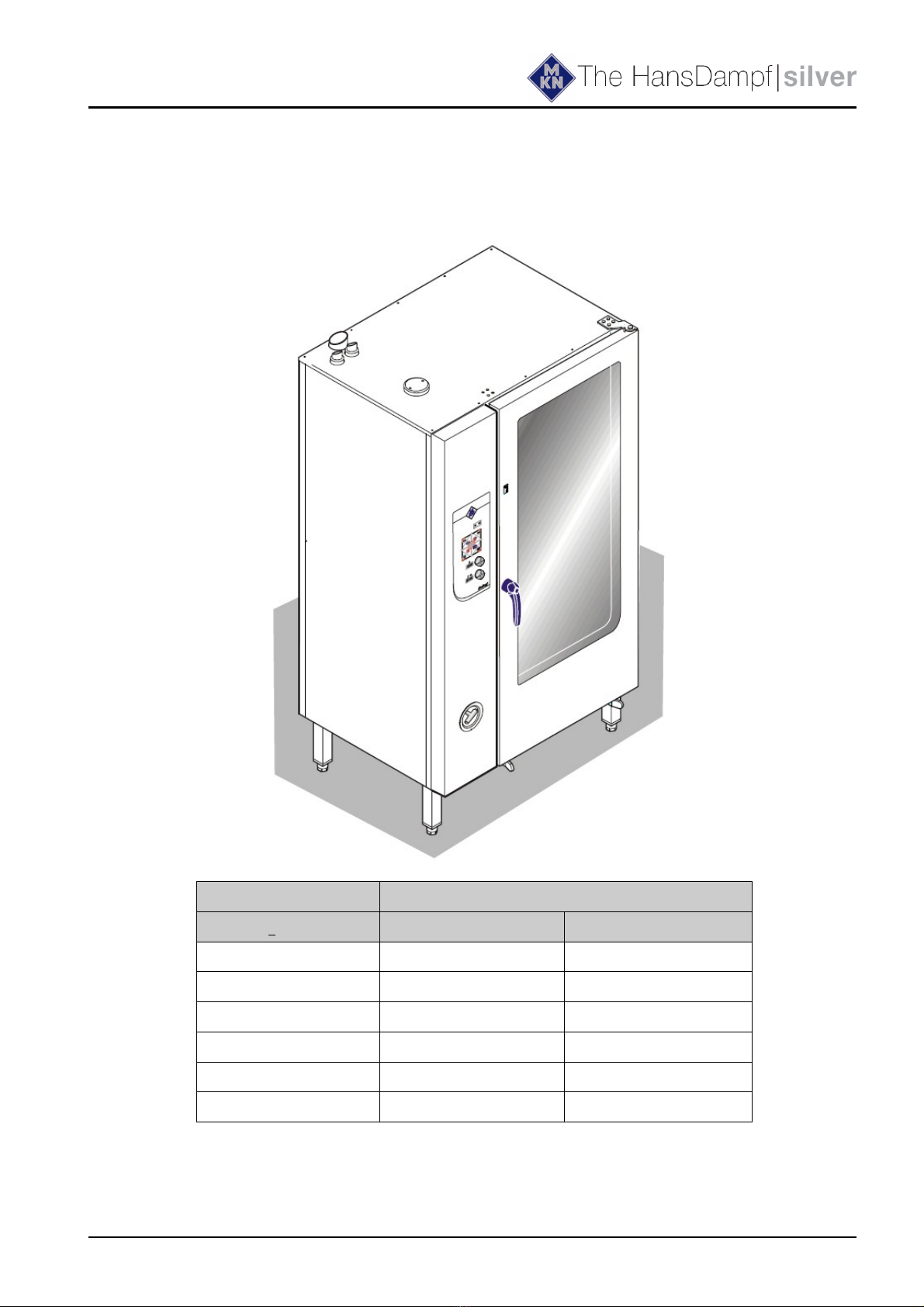

Service manual

DynaSteam Features

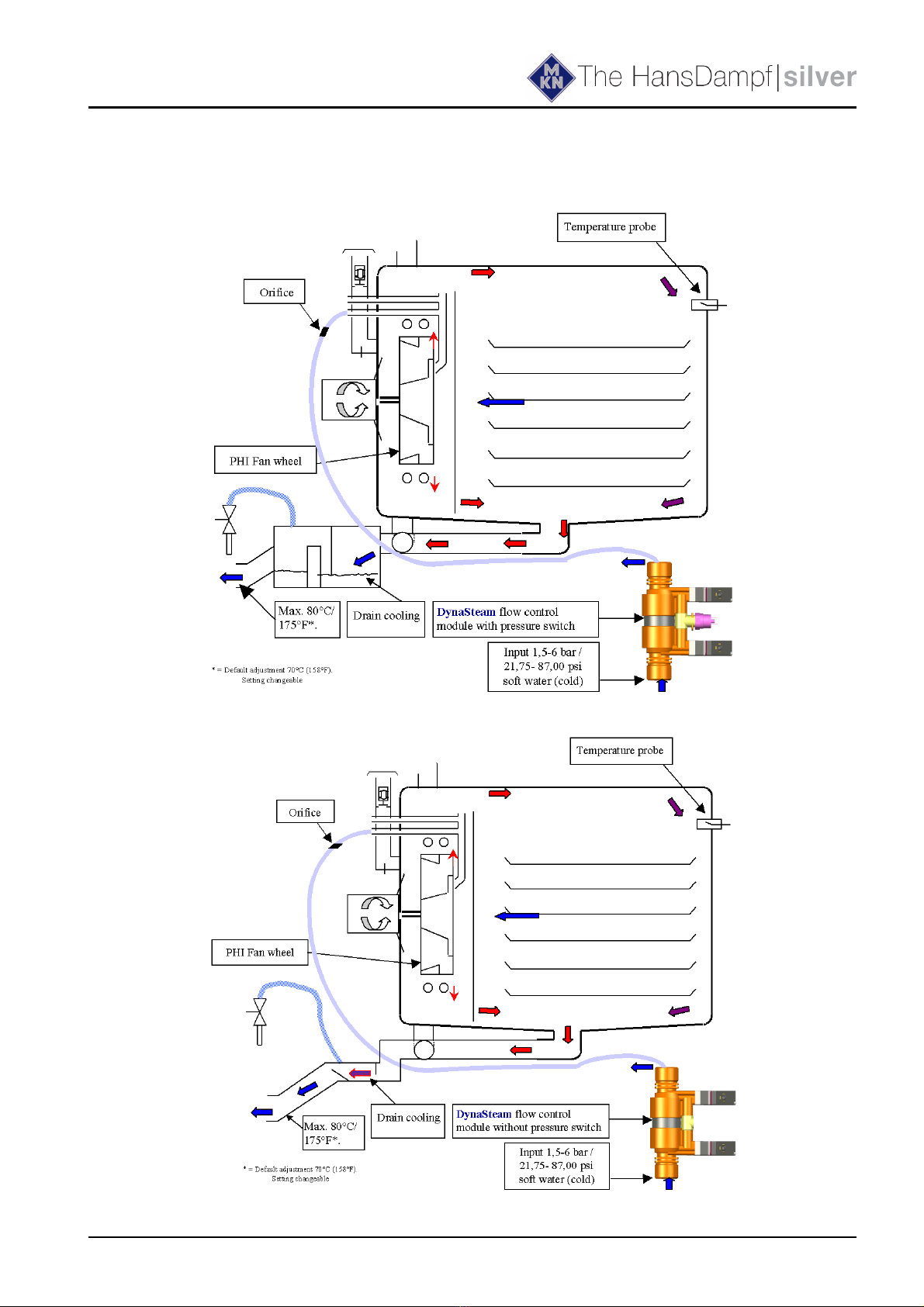

➢The pcb controls the DynaSteam unit which is responsible for the amount of injected water

The incoming water flow pressure must be between 1,5 (21,75 psi) and 6 bar (87,00 psi) The

pressure switch controls the availability and the pressure of water (Only at units with

WaveClean)

➢The water runs now through a hose to the water supply pipe located in the chamber Inside the

hose is an orifice to stabilize the pulsed water flow from the DynaSteam unit

➢The water supply pipe injects the water on an centrifuge at the PHI fan wheel The heating

elements surround the fan wheel heats it up The water gets to steam now and by the speed of

the fan wheel tiny drops are flung against the chamber Surplus water runs into the drain

➢During heat up and after opening / closing the door during operation the steaming unit

increases the amount of water to speed up the steam production (controlled by the electronic)

➢At a temperature of more than 107°C (225°F) the steaming unit decreases the amount of water

(electronic controlled)

Average water consumption

during permanently steaming:

unit / type 6 23 6 1 6 2 10 1 10 2 20 1 20 2

steam water

volume in ml/h

7500 16000 21000 18000 24000 18000

18000

24000

24000

The automatic cleaning system WaveClean

Option

Selecting cleaning level and starting WaveClean

➢Press the "FLEXI" button after switching on the Combisteamer or

when a cooking process is complete

➢The upper display shows CL

➢The bottom display remains dark

➢Press the START/STOP button

➢ CL1 is displayed in the top display for the first WaveClean

cleaning stage

Select the cleaning stage with the adjustment knob:

CL1 -> WaveClean, short : approx 1,0 Std

CL2 ->WaveClean, normal: approx 2,0 Std

CL3 -> WaveClean, extra: approx 3,0 Std

Staring WaveClean Press the "START/STOP" button after selecting the

8