Getting Started......................................................................................................................27

Adding & Calibrating Maps..................................................................................................27

1) To Add and Calibrate a Map......................................................................................28

2) To Recalibrate a Map ................................................................................................28

3) To Remove A Map From the Database......................................................................29

4) To Display a Different Map.......................................................................................29

Creating a Flight Plan............................................................................................................29

1) Map...........................................................................................................................30

2) Adding Waypoints.....................................................................................................30

3) Return To Home Mode..............................................................................................31

Editing Waypoints ................................................................................................................32

1) Waypoint Action .......................................................................................................32

2) Camera Action...........................................................................................................33

3) Altitude .....................................................................................................................34

4) Airspeed....................................................................................................................34

5) Waypoint Location....................................................................................................34

Using and Editing Existing Flight Plans................................................................................35

Image Mosaic Flight Plan......................................................................................................36

Initializing the Aircraft..........................................................................................................37

Re-tasking Aircraft................................................................................................................40

Reviewing the Aircraft’s Course ...........................................................................................41

Shut down Aircraft................................................................................................................41

Saving and Loading Flight Data............................................................................................42

Flight data format..................................................................................................................42

Flight Plan Format ................................................................................................................43

Configuration file format.......................................................................................................44

Autonomous takeoff procedures............................................................................................45

Autonomous landing procedures...........................................................................................45

Voice Error Messages ...........................................................................................................46

Tutorial 1 (Creating a flight plan)..........................................................................................46

1) Getting started...........................................................................................................46

2) Add a Map.................................................................................................................46

3) Create a Flight Plan ...................................................................................................46

OPERATING INSTRUCTIONS...............................................................................................49

Advanced Preparation...........................................................................................................49

Flight Operations ..................................................................................................................49

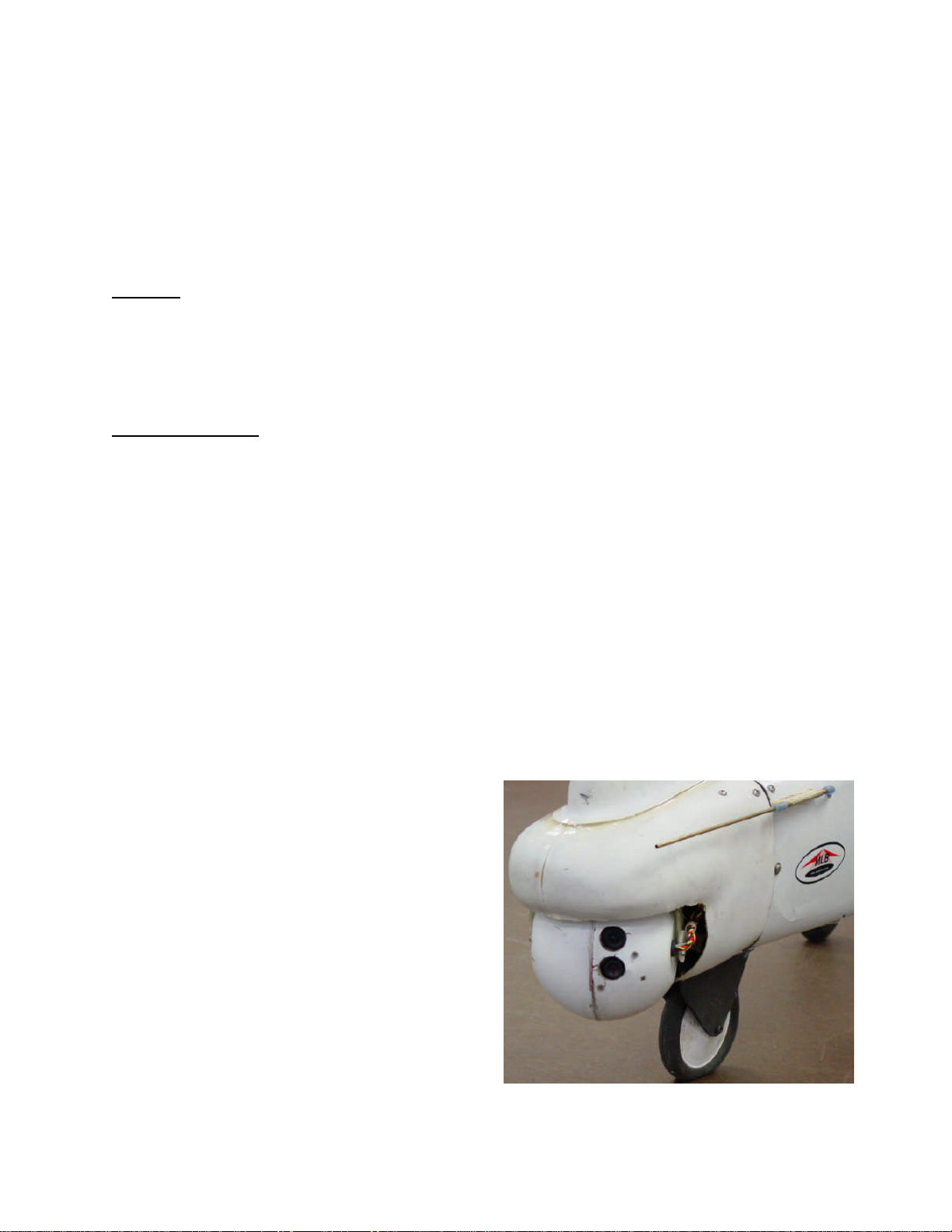

1) Airplane Setup...........................................................................................................50

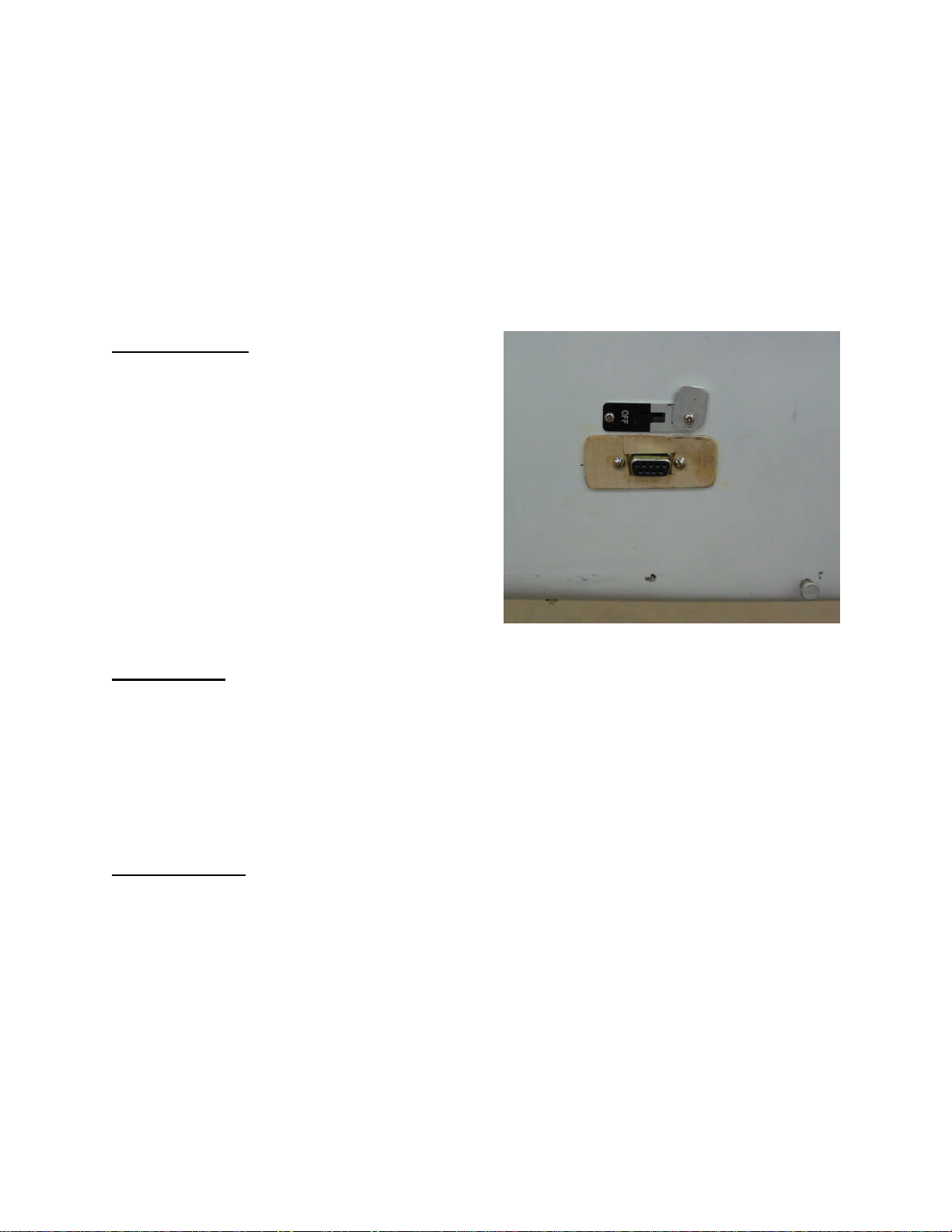

2) Ground Station ..........................................................................................................50

3) Takeoff......................................................................................................................51

4) Landing.....................................................................................................................53

5) Post-flight Operations................................................................................................53

SPECIFICATIONS...................................................................................................................54

CHECK LISTS.........................................................................................................................55

Advanced Preparation...........................................................................................................55

Flight Operations ..................................................................................................................56

FLIGHT TRAINING................................................................................................................58