Zeus200 Installation manual

V 1.0.7 - 12/10/2020 Page 2 of 28

SUMMARY

1 Introduction ................................................................................................................. 3

1.1 Security information.................................................................................................. 3

1.1.1 Destination of use (intended purpose) .................................................................. 3

1.1.2 Safety and correct mounting................................................................................ 3

1.1.3 General rules ..................................................................................................... 4

1.1.3.1 Positioning of the display / control panel ........................................................ 4

1.1.3.2 Generator placement ................................................................................... 4

1.1.3.3 Fuel supply ................................................................................................. 4

1.1.3.4 Fuel quality................................................................................................. 4

1.1.3.5 Exhaust gas ................................................................................................ 5

1.1.3.6 Combustion air inlet..................................................................................... 5

1.1.3.7 General notes ............................................................................................. 5

1.1.3.8 Danger of injury, fire and intoxication ............................................................ 5

1.1.3.9 Safety rules for assembly and operation ......................................................... 5

1.1.3.10 Exemptions from safety and accident prevention requirements ......................... 6

1.2 Certifications and approvals ....................................................................................... 6

1.3 Package contents ...................................................................................................... 7

1.4 Unpacking and preparations ....................................................................................... 7

2 Mounting ...................................................................................................................... 8

2.1 Generator ................................................................................................................ 8

2.1.1 Components list ................................................................................................. 8

2.1.2 Mounting instruction ........................................................................................... 9

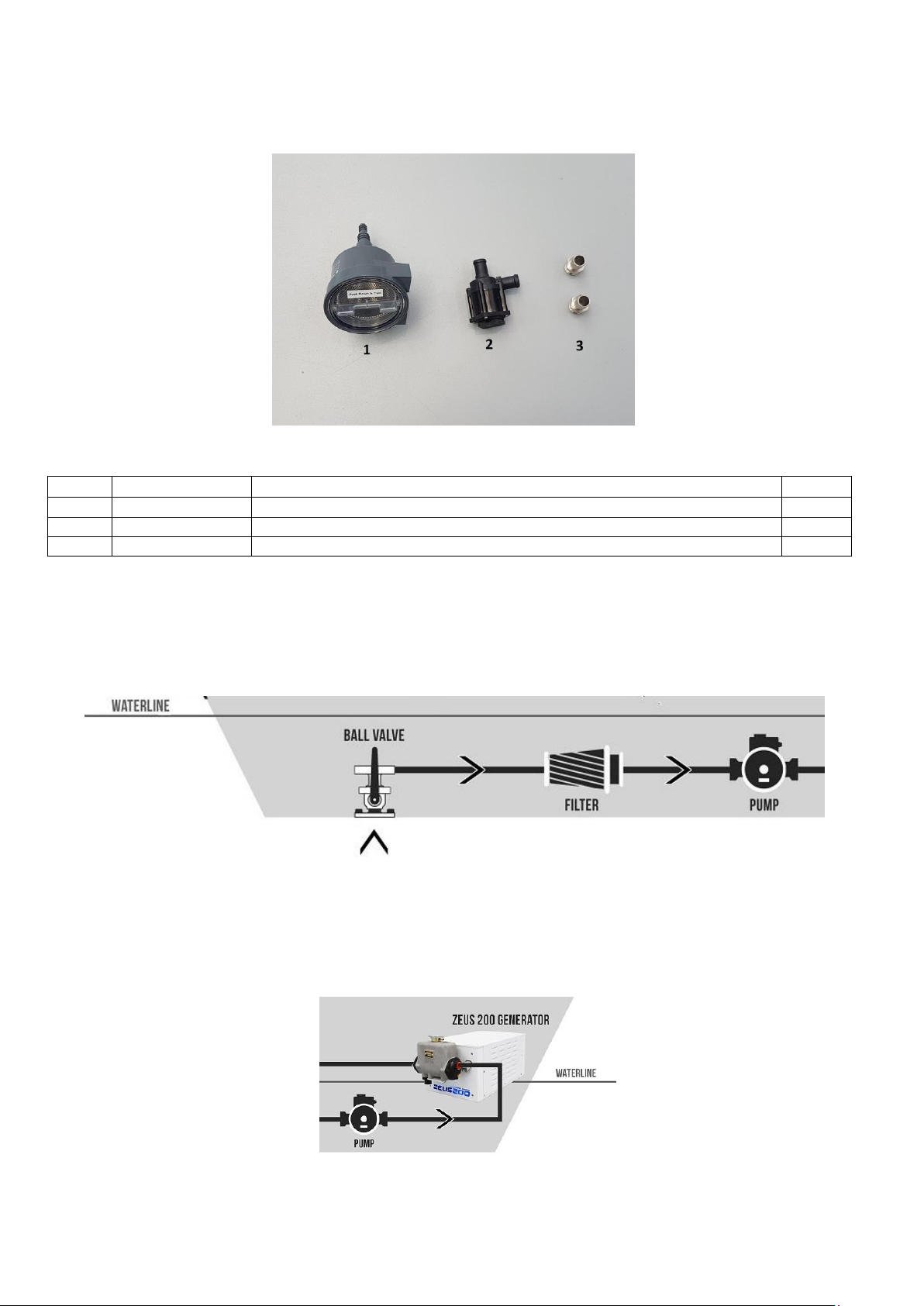

2.2 Filter and external pump.......................................................................................... 10

2.2.1 Components list ............................................................................................... 10

2.2.2 Mounting instruction ......................................................................................... 10

2.3 Exhaust gas line ..................................................................................................... 12

2.3.1 Components list ............................................................................................... 12

2.3.2 Mounting instruction ......................................................................................... 12

2.4 Fuel supply line ...................................................................................................... 13

2.4.1 Components list ............................................................................................... 13

2.4.2 Mounting instruction ......................................................................................... 13

2.5 Electrical system..................................................................................................... 15

2.5.1 Components list ............................................................................................... 15

2.5.2 Element identification ....................................................................................... 16

2.5.3 Electrical diagram............................................................................................. 17

2.5.4 Generator connections ...................................................................................... 18

2.5.5 External water pump connection, coolant sensor and provision for flow switch ......... 18

2.5.6 Display unit connections.................................................................................... 19

2.5.7 Temperature sensor connections ........................................................................ 19

2.5.8 Solar panel / Wind generator connections (optional) ............................................. 19

2.5.9 Secondary battery connections 12V/24V (optional)............................................... 20

2.5.10 Primary battery connections ........................................................................... 20

2.5.11 Connection of the D + / + 15 subkey .............................................................. 20

2.6 First start-up .......................................................................................................... 21

2.6.1 Loading of the cooling system............................................................................ 21

2.6.2 Loading of fuel system ...................................................................................... 21

2.6.3 Battery type selection ....................................................................................... 22

3 Installer Menu ............................................................................................................ 24

3.1 Menu activation ...................................................................................................... 24

3.2 Alarm pop-up reset ................................................................................................. 25

3.3 Historical of alarms ................................................................................................. 25

4 Fault or malfunctions.................................................................................................. 26

5 Technical data ............................................................................................................ 28

6 Warranty .................................................................................................................... 28

7 References ................................................................................................................. 28