Modco Industries LLC, 10650 FM 1484 Conroe, TX 77301 / Phone: 936-539-9222 / FAX: 936-622-6818

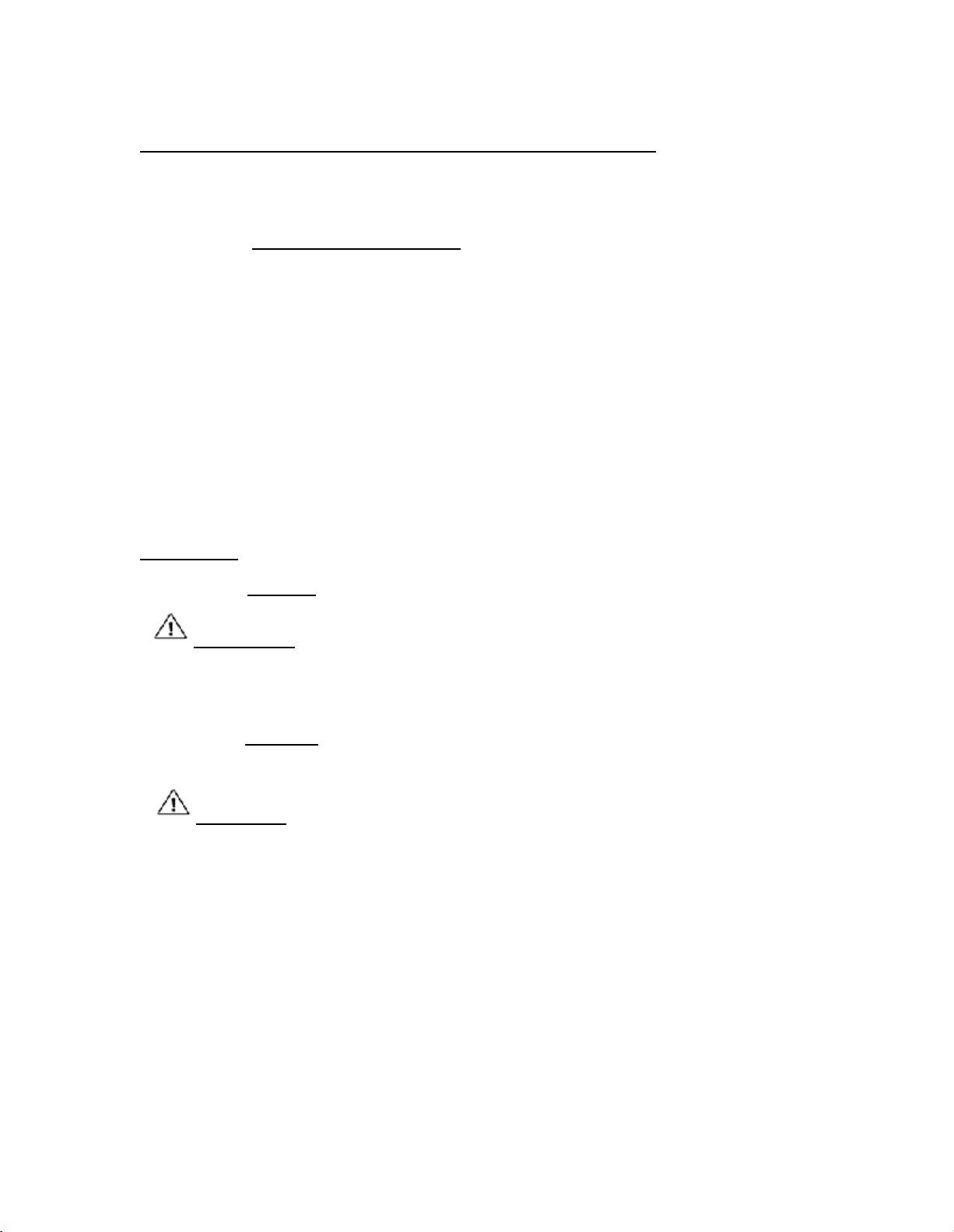

MODCO FIGURE 500 HORIZONTAL CLOSURES

OPERATION AND MAINTENANCE INSTRUCTIONS

PROPER HINGE ADJUSTMENT ON THE MODCO FIG. 500 CLOSURE IS NECESSARY TO INSURE THE

CLOSURE HINGE PROVIDES PROPER ALIGNMENT OF CAP AND SUB, AND AFFORDS BALANCE OF

CAP TO ELIMINATE THREAD DRAG DURING MAKE-UP AND ALLOW PORPER METAL TO METAL

CONTACT OF CAP SEALING FACE AND O-RING GROOVE LANDS.

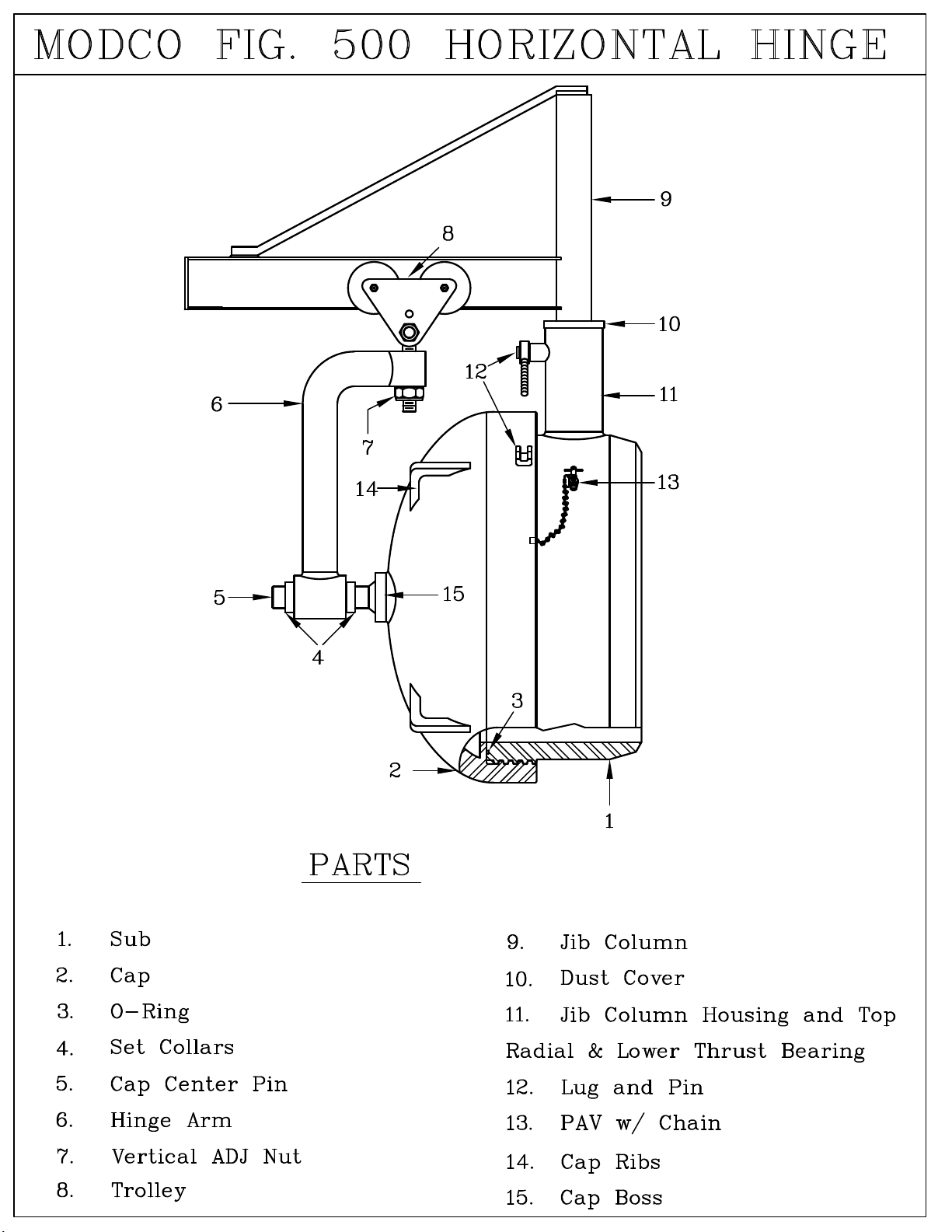

VERY IMPORTANT: TO PREVENT SUB WARPAGE, THE WELDING INSTRUCTIONS

ATTACHED TO EACH CLOSURE SHOULD BE FOLLOWED BY THOSE

FABRICATING THE CLOSURE.

A. PRIOR SERVICE HINGE ADJUSTMENTS:

IF ANY DIFFICULTY IS ENCOUNTERED DURING MAKE-UP OF CAP ONTO SUB OR IF EXCESSIVE

THREAD DRAG IS NOTICED, THE FOLLOWING ADJUSTMENTS SHOULD BE MADE:

1. TO CHECK “PARALLEL” ALIGNMENT OF CAP TO SUB – UNSCREW CAP FROM

SUB AND PULL CAP BACK A FEW INCHES TO CHECK FOR “PARALLEL”

ALIGNMENT OF CAP TO SUB. TO ADJUST THE “PARALLEL” ALIGNMENT,

LOOSEN THE SET COLLARS LOCATED ON THE CAP CENTER PIN EITHER SIDE OF

HINGE ARM. IF CAP TILTS INWARD AT TOP OF SUB, MOVE THE HINGE ARM

ALONG THE CAP CENTER PIN TOWARD THE CAP. IF CAP TILTS OUTWARD AT

TOP OF SUB, MOVE THE HINGE ARM AWAY FROM THE CAP. AFTER PROPER

ADJUSTMENT IS MADE, TIGHTEN THE ALLEN SET SCREWS WHICH HOLD SET

COLLARS IN PLACE.

WARNING: ALWAYS TIGHTEN OUTBOARD SET COLLAR TIGHT, TO ELIMINATE CAP FROM

SLIDING OFF OF THE CAP CENTER PIN AND DROPPING FREE. INJURY COULD

RESULT.

2. “VERTICAL” ADJUSTMENT OF THE CAP – IS MADE BY TIGHTENING OR

LOOSENING THE ADJUSTING NUT ON THE VERTICAL ADJUSTING PIN. PROPER

ADJUSTMENT WILL PROVIDE BALANCE OF CAP ON THE HINE, AND ALL

WEIGHT OF THE CAP WILL TRANSFER TO THE HINGE AND THEREBY

ELIMINATE WEIGHT OF CAP ONTO SUB THREADS DURING MAKE-UP OF CAP

ONTO SUB.