Increasing/decreasingpantographspring

tension

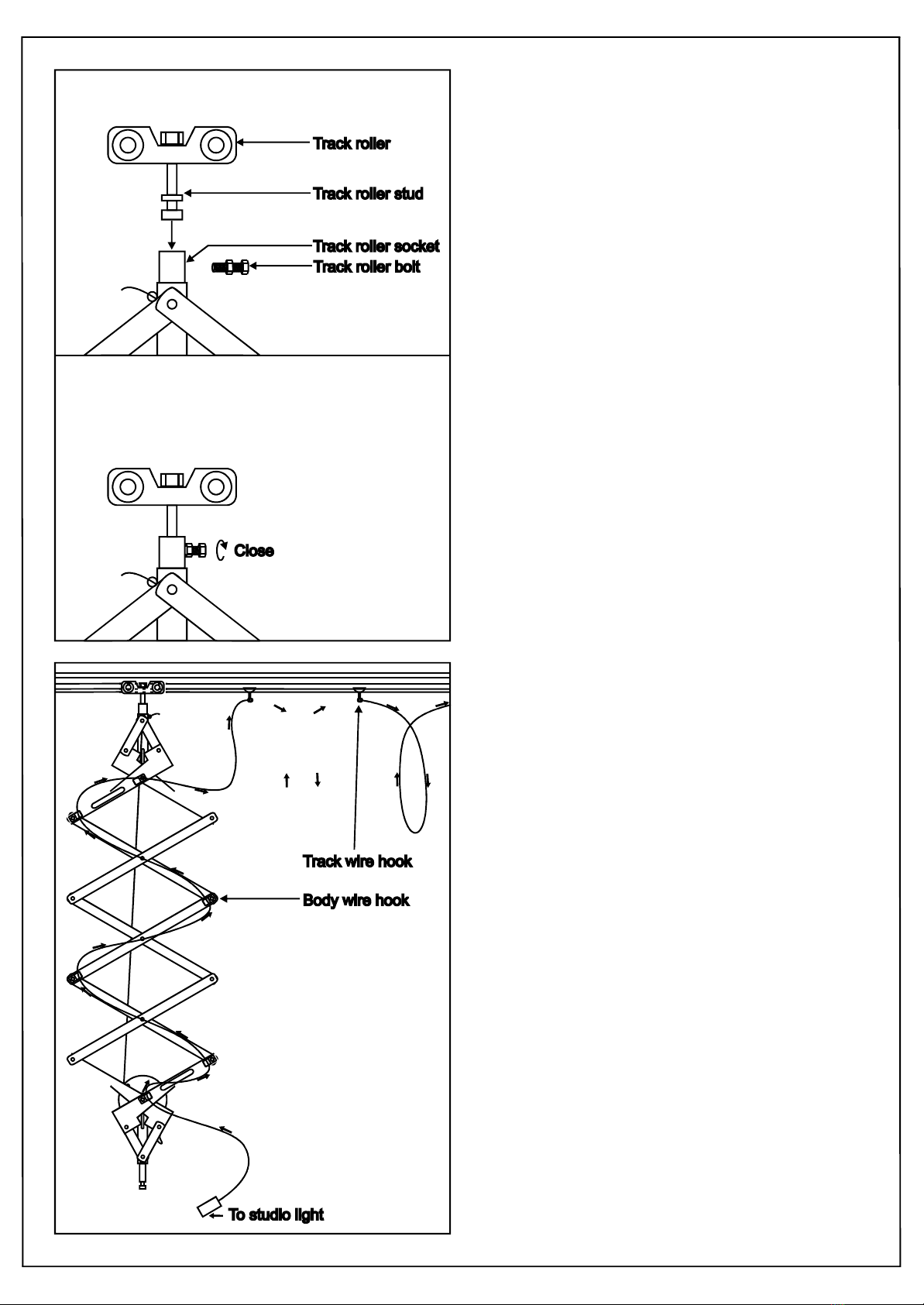

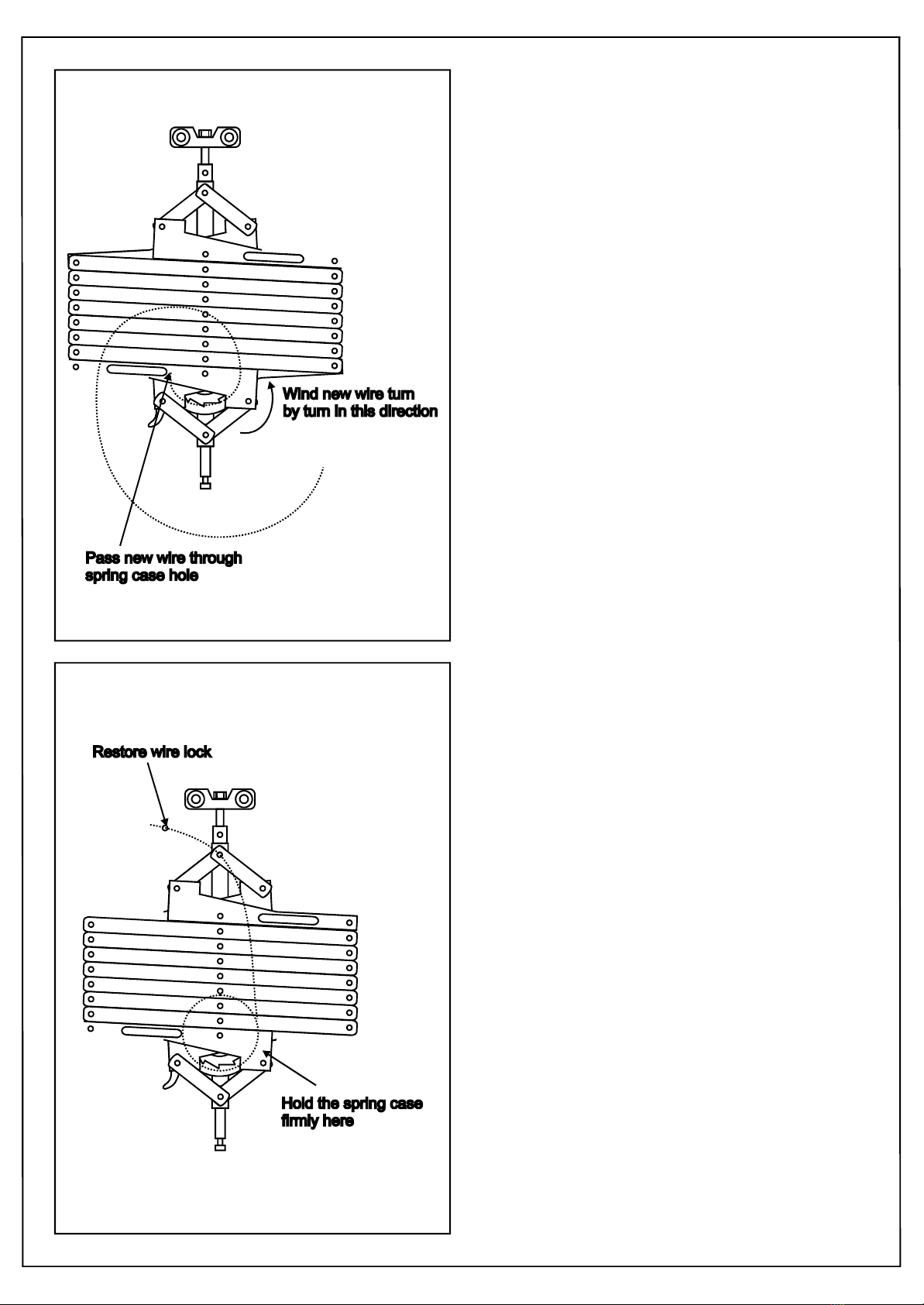

Step1:Openingtensionwirelock

NOTE:

-Unmountthestudiolightattachedtolightstudof

pantographforsafety.

-Openthelowertrackendstopoftheslidingtrack

andunmountthepantographinshortenedform

asshownintheadjoiningdiagram

-Placethepantographfirmlyongroundinaway

thatthelightstudtouchedthegroundand

pantographstaysinuprightpositionasshown

here.

-Holdthespringcasefirmlysothatwhenthe

tensionwireisloosenthealreadyappliedtension

doesnotgetremoved.

-Oncethespringcaseisfirmlyheld,openthe

tensionwirestopwhichisattachedtoitsupper

endneartensionwirestudasshowninadjoining

diagram.

Keepthetensionwirefirmlystretched

aroundthespringcaseintheentireprocess.Ifthe

tensionwireisleftloose,itmightgetcoiled.Inthat

case,entiretensionwirewouldhavetobe

openedandrewoundaroundthespringcase.

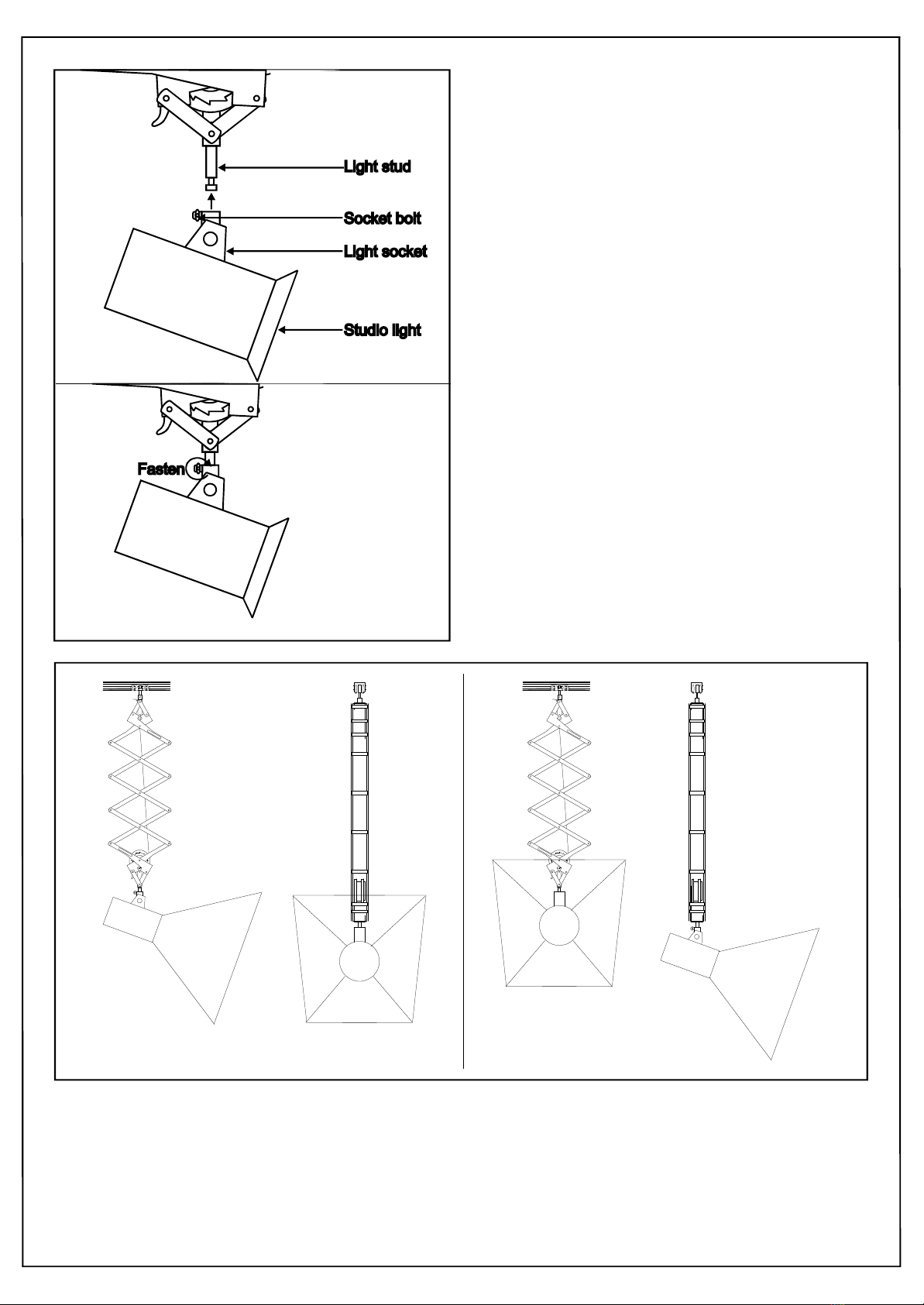

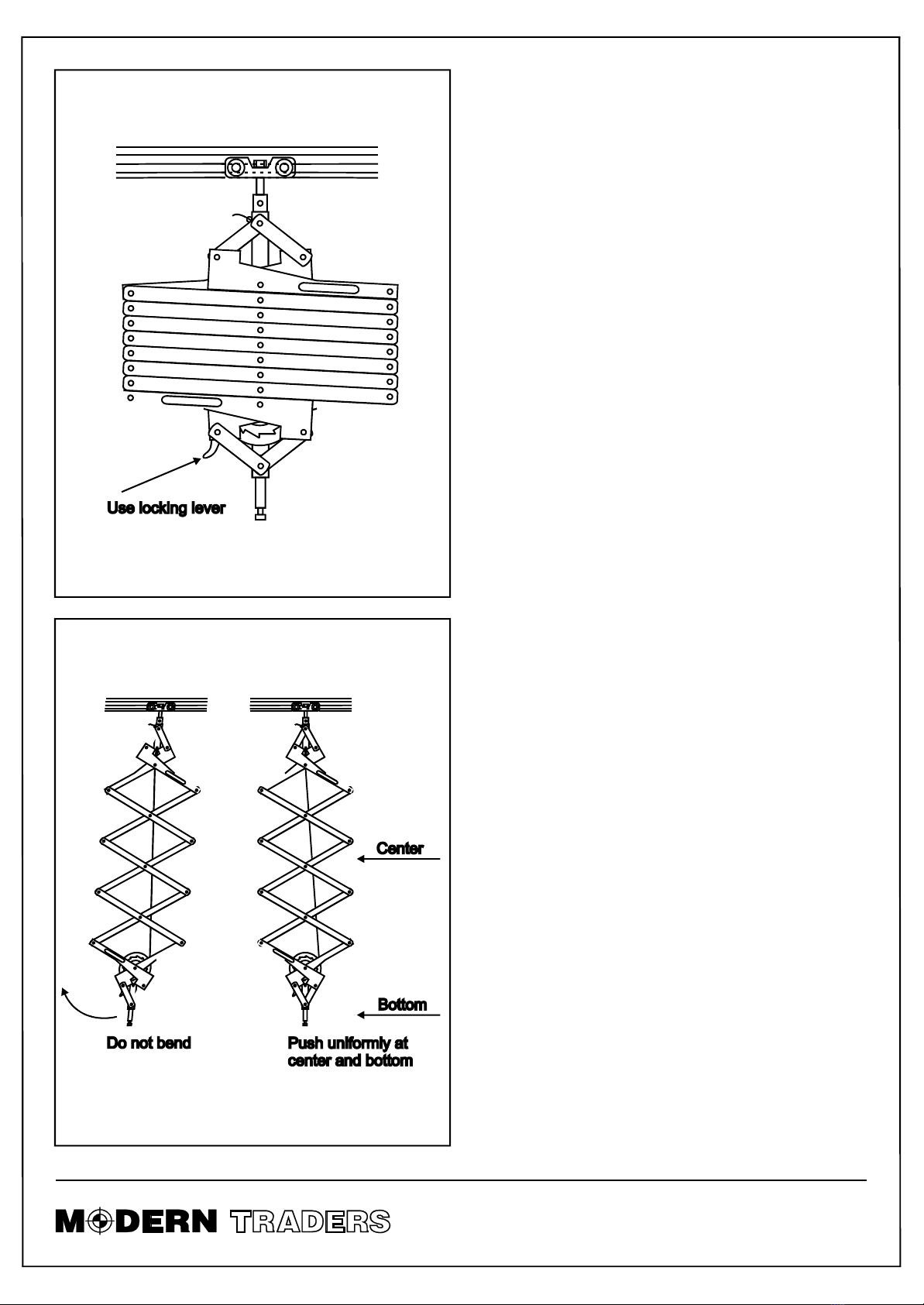

Step2:Increasing/Decreasingtensionin

tensionwire

-Oncethetensionwirelockisremoved,loosen

thespringcaselightly(butstillkeeponholdingit)

andpulloutapproximately1feetoftensionwire.

-Thisstepwillstretchthespringinthespring

caseandasaresultextratensionwillbeaddedto

thetensionwireoutside.

-Fordecreasingthetension,oncethetension

wirelockisremoved,unwind1turnofthetension

wirefromaroundspringcasewhileholdingspring

casefirmly.

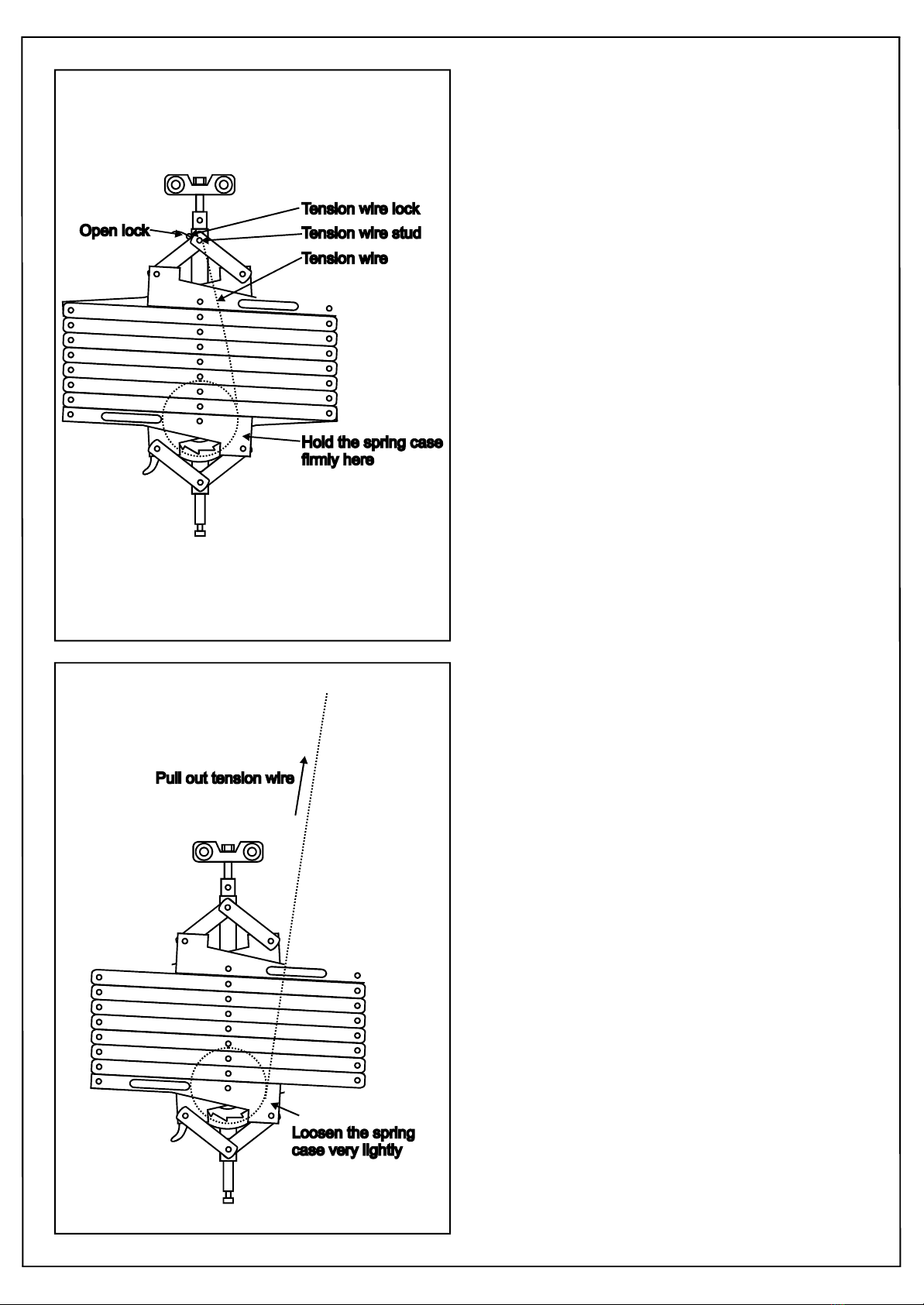

-Nowwhilethetensionwireisfirmlyheld,loosen

thespringcaselightly(butstillkeeponholdingit).

Asaresultthespringcasewillwinditself

(becauseofthetensioninitsspring)withthe

extralengthoftensionwirethatisjustunwound.

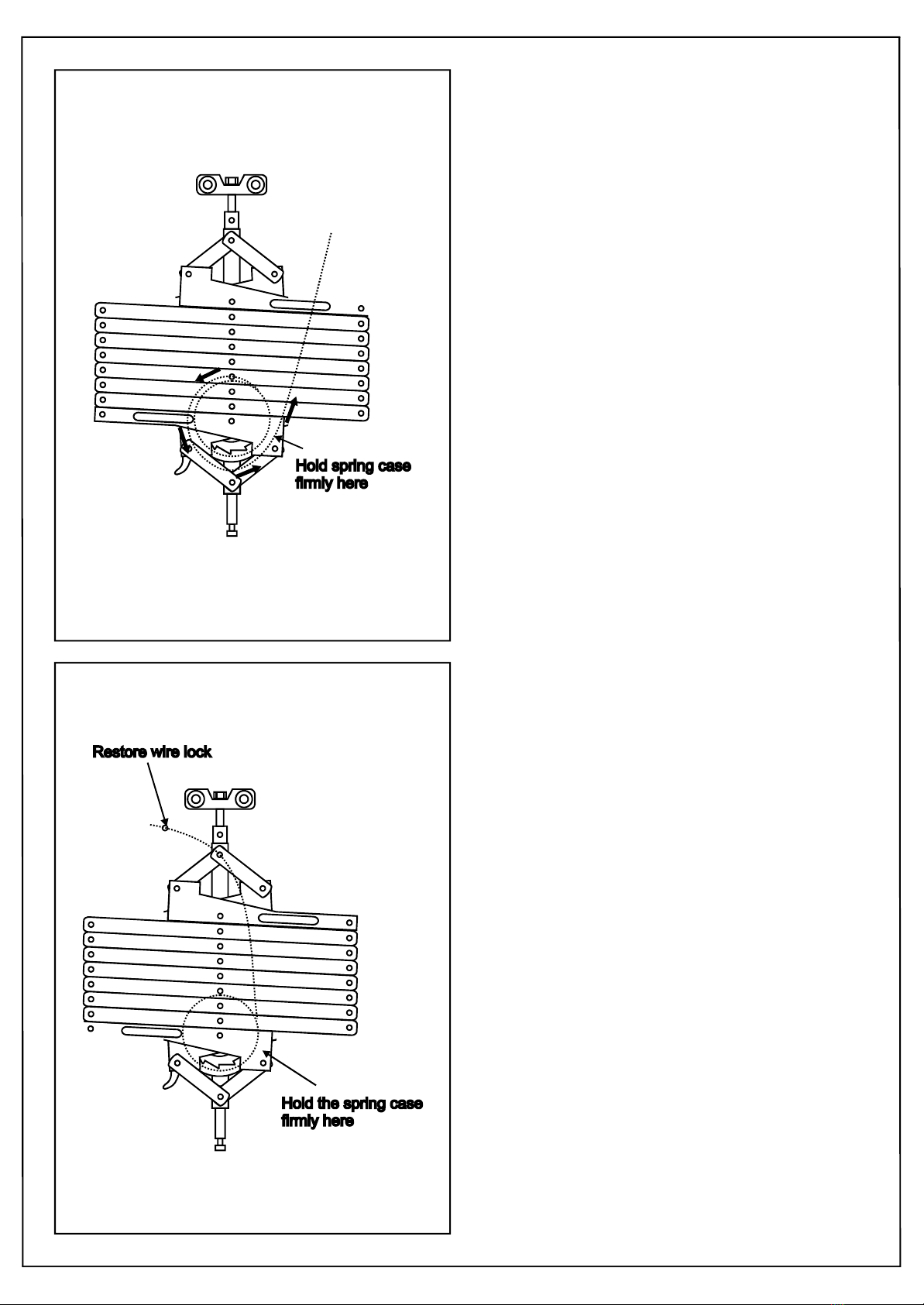

-Thisstepwilldecreasethetensioninspring

insidethespringcaseandconsecutivelyinthe

tensionwireoutside.

4