5

5-594.11

SPECIAL PRECAUTIONS / SI (METRIC) CONVERSION FACTORS

CAUTION

1. Installation must conform with local building codes or

in the absence of local codes, with Part 7, Venting of

Equipment, of the National Fuel Gas Code, ANSI Z223.1

(NFPA 54)-latest edition. In Canada installation must be in

accordance with CSA B149.1.

2. Purging of air from gas lines should be performed as

described in ANSI Z223.1 - latest edition “National Fuel

Gas Code”, or in Canada in CAN/CGA-B149 codes.

3. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not less than the rated

voltage.

4. Do not reuse any mechanical or electrical component

which has been wet. Such components must be replaced.

ATTENTION

1. L'installation doit se faire conformément aux codes

locaux de la construction ou, à défaut de tels codes,

conformément à la Partie 7 « Venting of Equipment »

du National Fuel Gas Code, ANSI Z223.1 (NFPA 54) –

dernière édition. Au Canada, l'installation doit se faire

conformément à la norme CSA B149.1.

2. La purge de l’air des tuyauteries de gaz doit se faire selon

la procédure ANSI Z223.1 de la dernière édition du «

National Fuel Gas Code » ou des codes CAN/CGA-B149

du Canada.

3. Vériez que la tension d’alimentation de l’appareil n’est pas

inférieure de plus de 5 % à la tension nominale inscrite sur

la plaque de série.

4. Ne tentez pas de réutiliser un composant mécanique ou

électrique qui a été mouillé. Ces composants doivent être

remplacés.

IMPORTANT

1. For installation only in locations not accessible to the

general public.

2. Unit can be operated up to a maximum of 10,000 feet

(3048 m).

3. To prevent premature heat exchanger failure, the input to

the appliance, as indicated on the serial plate, must not

exceed the rated input by more than 5%.

4. To prevent premature heat exchanger failure, observe heat

exchanger tubes by looking at the heat exchanger through

the eld installed access openings in connecting ductwork

in cooling package units or the unit access doors in blower

package units. If the bottom of the tubes become red

while blower and duct furnace are in operation, check to

be sure the blower has been set to the proper rpm for the

application. Refer to page 29 for Blower Adjustments.

5. Start up and adjustment procedures, installation, and

service of these appliances must be performed by a

qualied installation and service agency.

6. To prevent premature heat exchanger failure, with all

control systems, a blower starting mechanism must be

provided so that the blower is running or energized within

45 seconds of the gas control operation.

7. To check most of the Possible Remedies in the trouble-

shooting guide listed in Table 58.1 refer to the applicable

sections of the manual.

IMPORTANT

1. Pour installation uniquement dans des endroits non

accessibles au public.

2. Pour installation uniquement dans des endroits non

accessibles au public.

3. Pour éviter une défaillance prématurée de l’échangeur de

chaleur, le pouvoir calorique du gaz utilisé ne doit pas

excéder de plus de 5 % la valeur nominale inscrite sur la

plaque signalétique de l’appareil.

4. Pour éviter la défaillance prématurée de l’échangeur de

chaleur, examinez les tubes de l’échangeur de chaleur en

le regardant à travers les ouvertures d’accès installées

sur les lieux lors de la connexion des tuyaux ou les portes

d’accès à l’unité où il est possible de voir l’échangeur

de chaleur. Si le bas des tubes devient rouge lorsque

la souante et la chaudière canalisée sont en marche,

vériez que le régime de la souante est approprié pour

l’application. Pour le réglage de la souante, reportez-

vous à la page 29

5. Les procédures de démarrage et de réglage, l’installation

et le service de ces appareils doivent être conés à un

centre d’installation et de service qualié.

6. Pour éviter la panne prématurée de l'échangeur thermique,

avec tous les systèmes de commande, un mécanisme

de démarrage de la souerie doit être fourni pour que

la souerie démarre dans les 45 secondes qui suivent

l'activation de la commande de gaz.

7. Pour essayer la plupart des solutions possibles suggérées

dans le guide de dépannage du Table 58.1, reportez-vous

aux sections correspondantes du manuel.

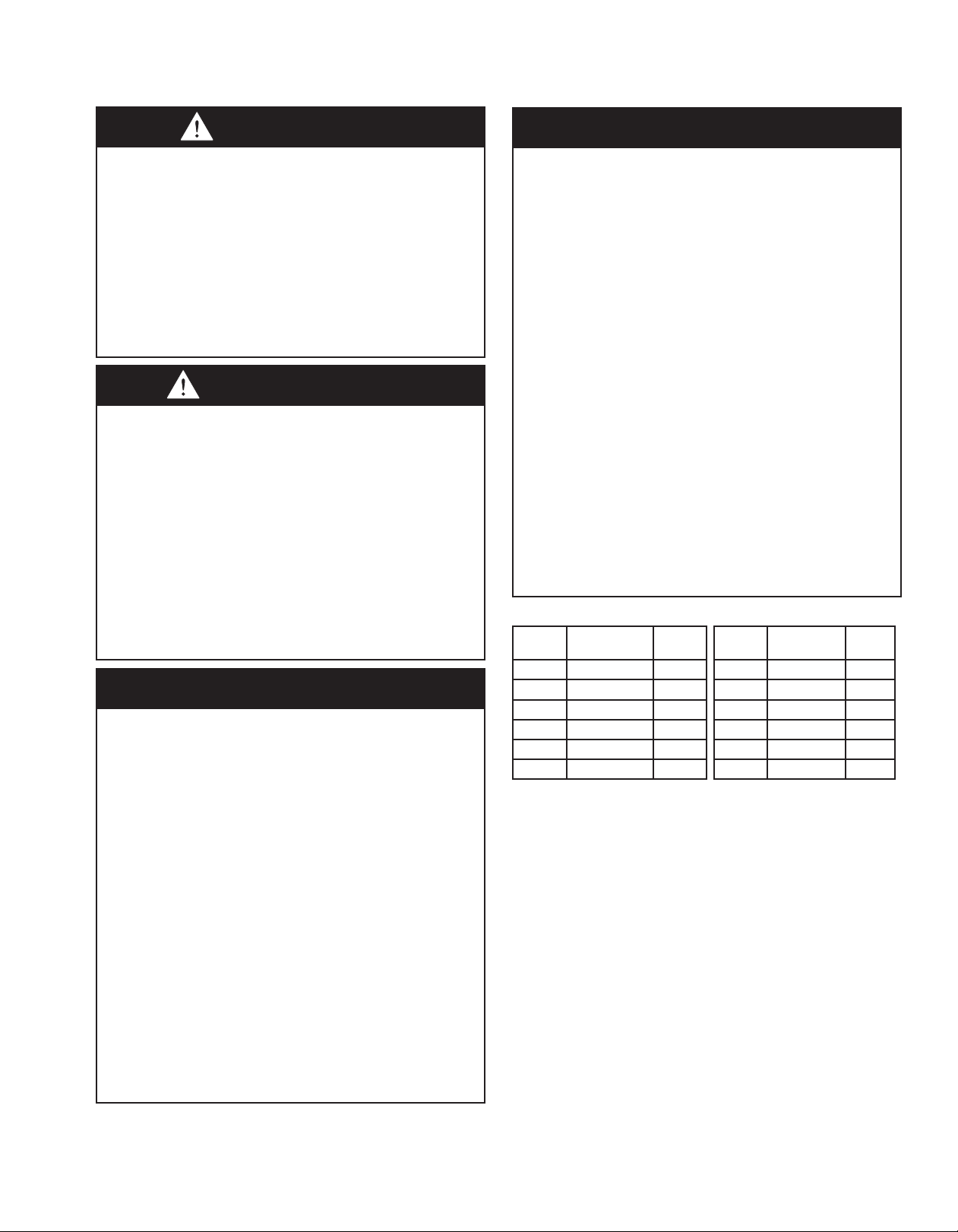

Figure 5.1 - SI (Metric) Conversion Factors

To

Convert Multiply By To

Obtain

To

Convert Multiply By To

Obtain

"W.C. 0.24 kPa CFH 1.699 m3/min

psig 6.893 kPa Btu/ft30.0374 mJ/m3

°F (°F-32) x 0.555 °C pound 0.453 kg

inches 25.4 mm Btu/hr 0.000293 kW

feet 0.305 meters gallons 3.785 liters

CFM 0.028 m3/min psig 27.7 "W.C.

SPECIAL DESIGN REQUESTS

Units are sometimes built with special features as requested by

the customer. This manual only covers standard features and does

not include any changes made for special feature requests by the

customer. Units built with special features are noted with a 5-digit

SPO (Special Product Order) Number on the Serial Plate.

STORAGE PRIOR TO INSTALLATION

If the unit is stored outside prior to installation, the unit should be

covered.