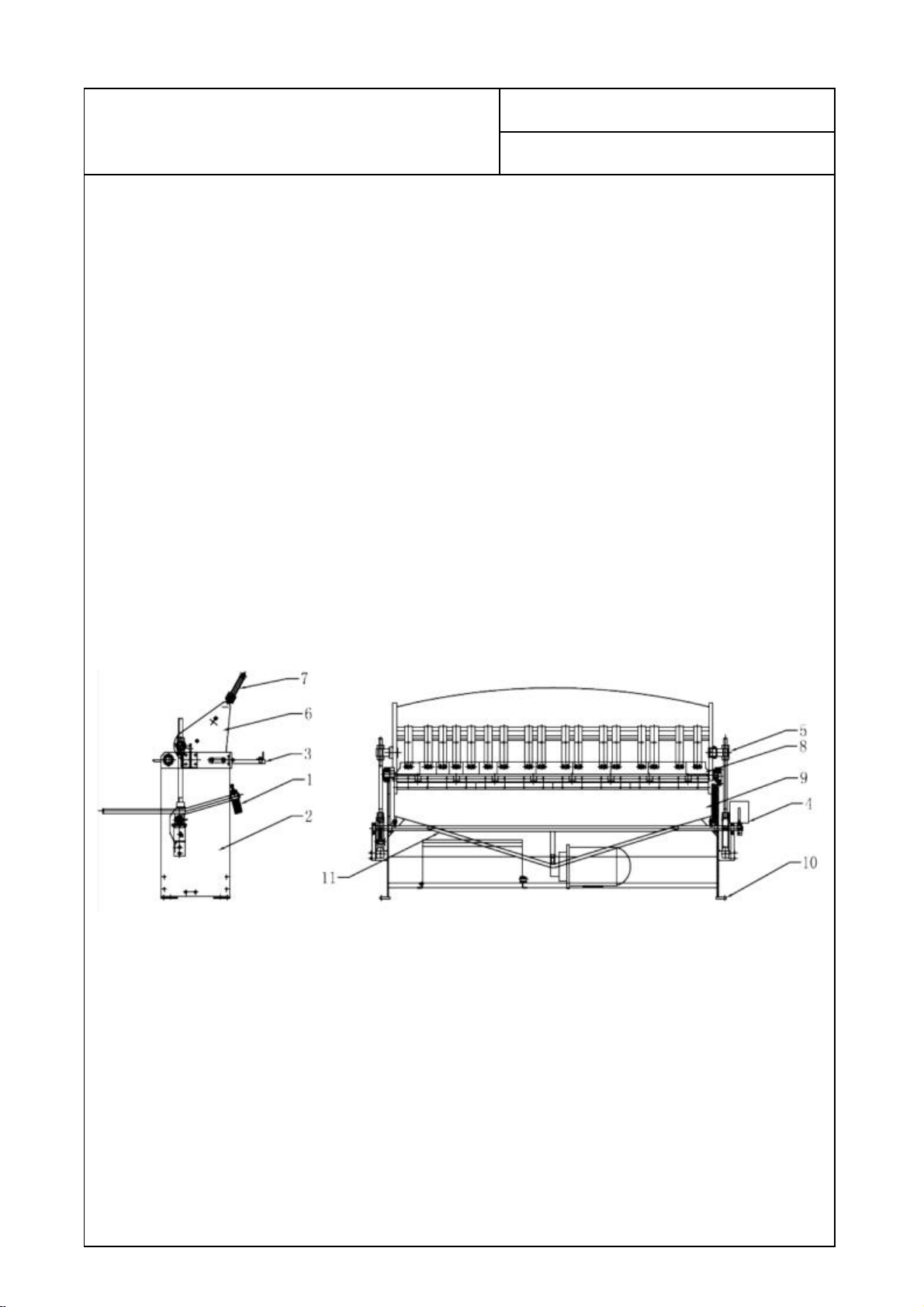

Panbrake

Setup & Operation - Hydraulic Clamp Models

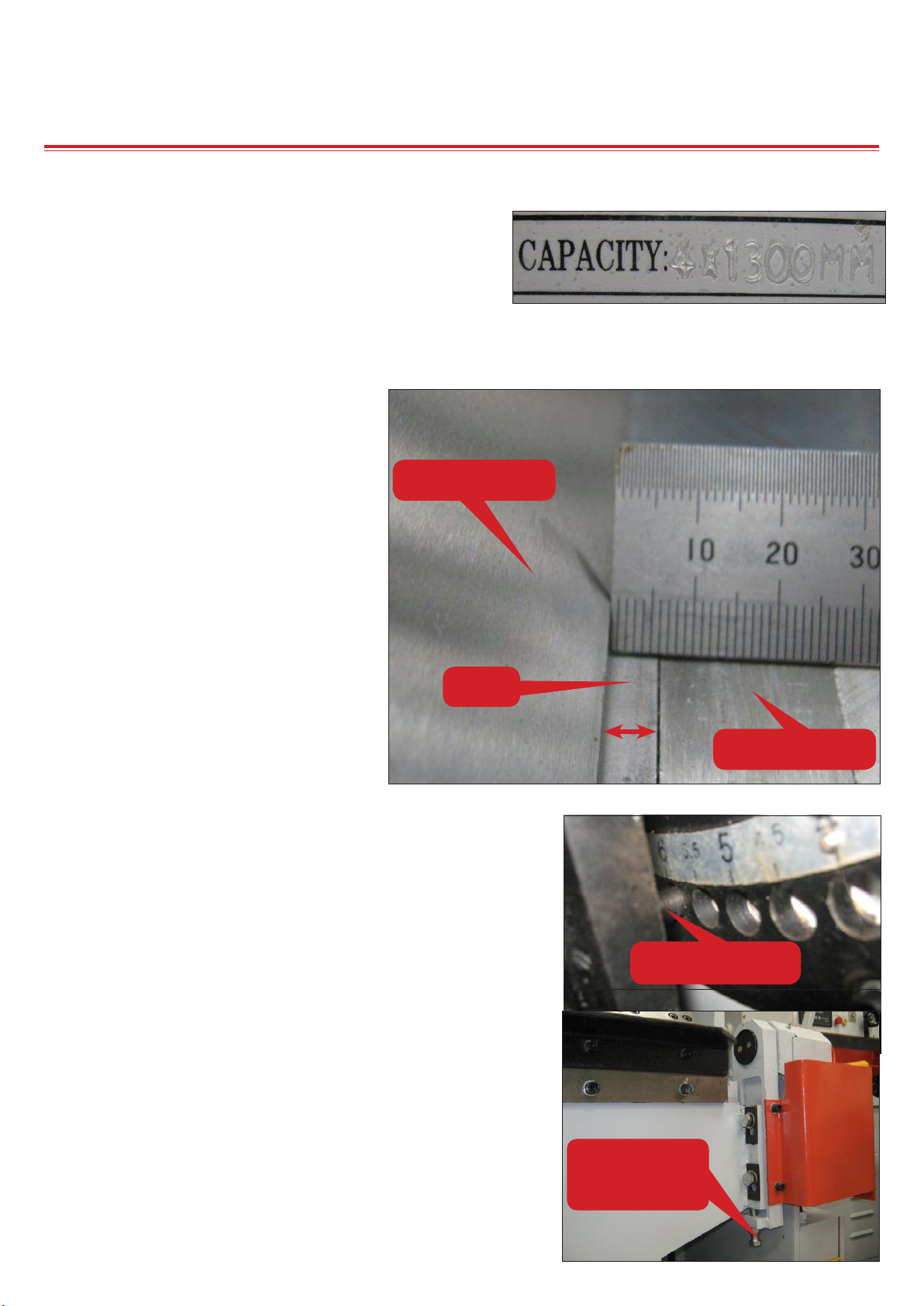

CAPACITY

The capacity of your machine is stated on the

specications plate on the frame. This capacity is a

mild steel rating. The capacity for other materials will

vary. For example Stainless Steel is approximately

0.5x the mild steel rating & aluminium is 1.5x the mild

steel rating.

Some machines have a quick adjusting arm with pin positions

marked 0-8. This should represent your clamp gap.

Example: If you are bending 4mm put the pin in position 6.

This must be done on both sides of the machine.

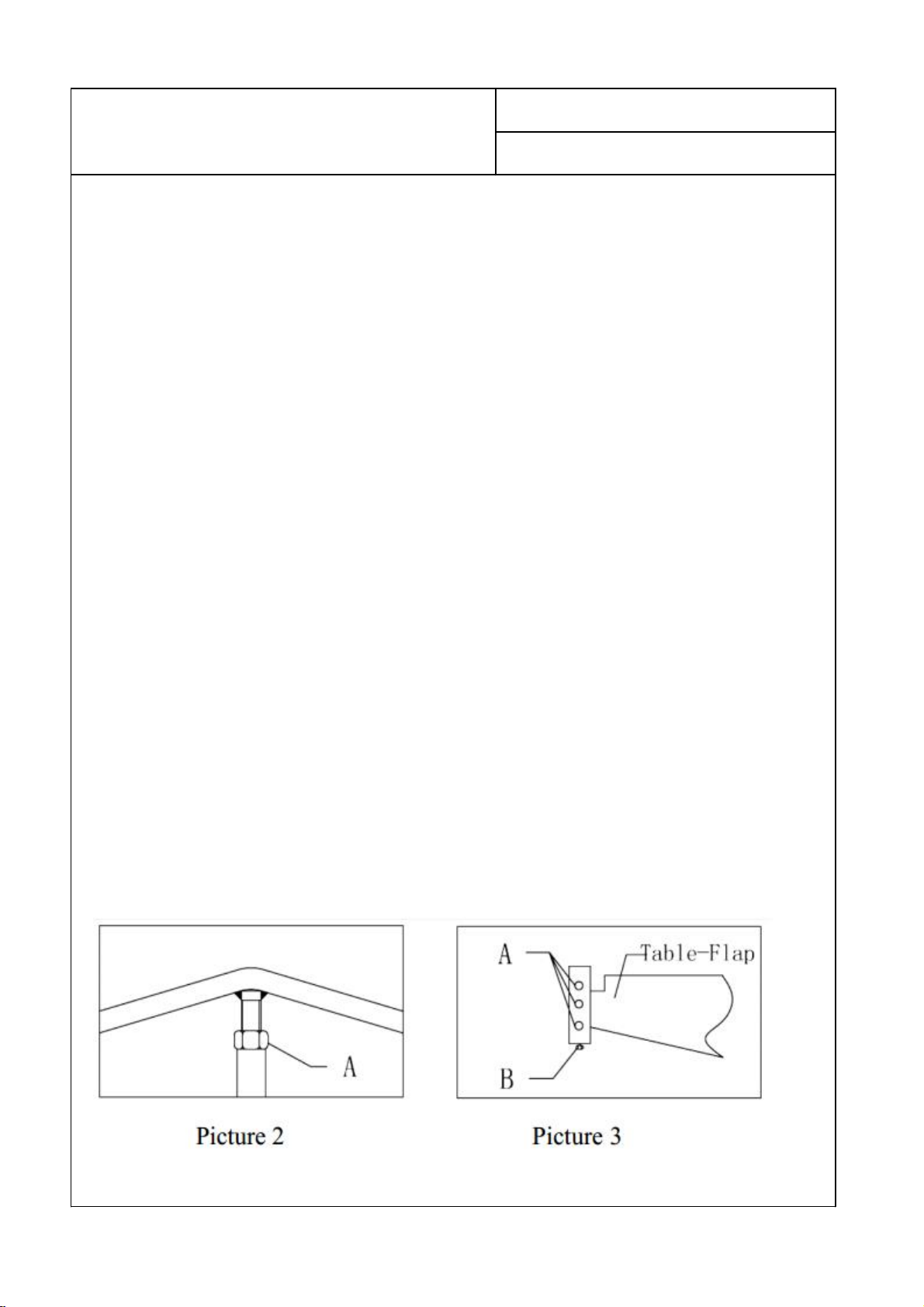

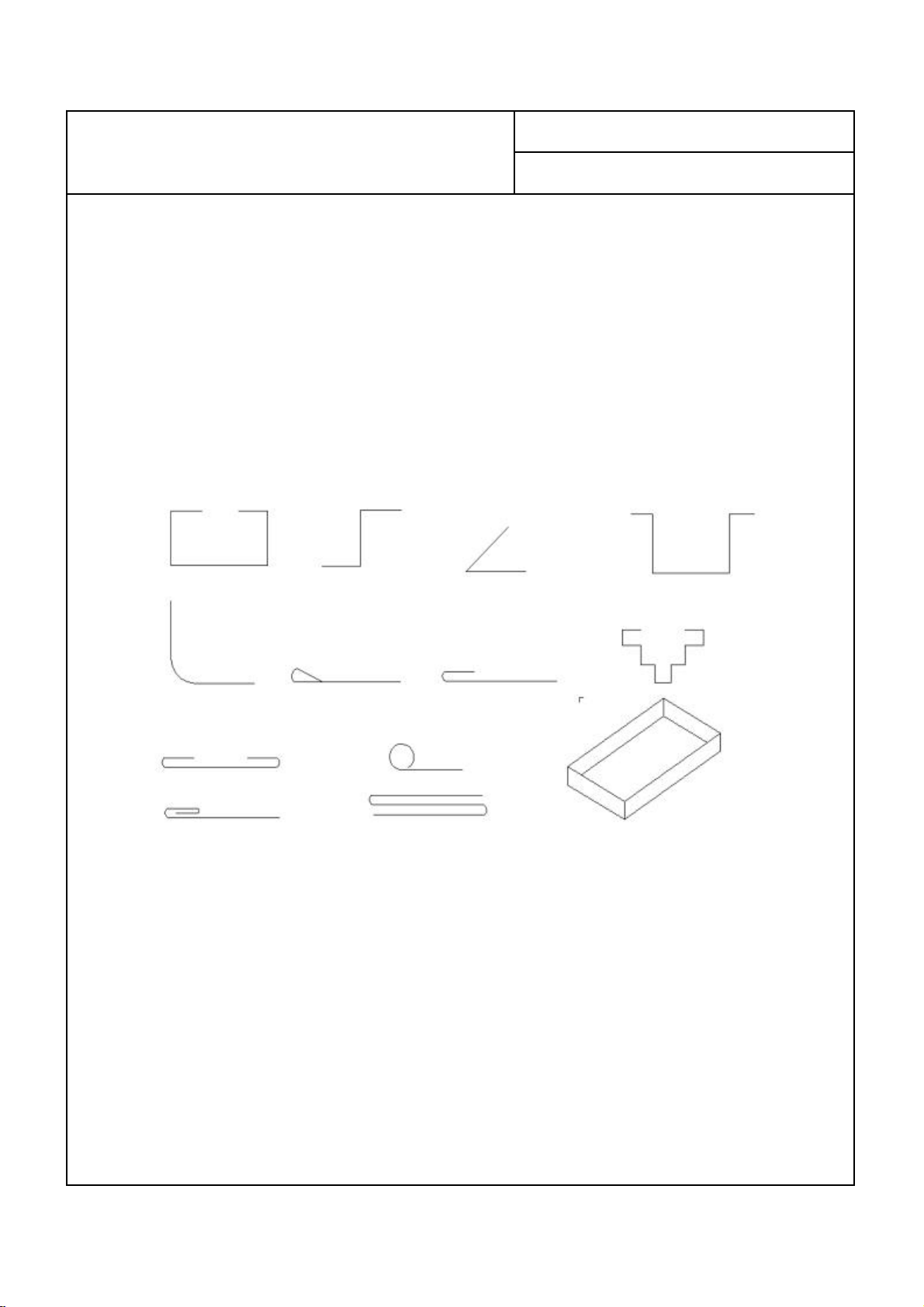

SETTING CLAMP GAP

Set the clamp gap to match your

material thickness.

The clamp gap must be minimum

1.5 x Material Thickness

Example: If 4mm is to be bent, then

the clamp “GAP” must be set to

minimum of 6mm

Each panbrake may have a different

mechanism for adjusting the clamp

gap but you must maintain the 1.5

x Material Thickness to prevent

overload and possible damage.

GAP

CLAMP FINGER

FOLDING ARM

BED

6mm POSITION

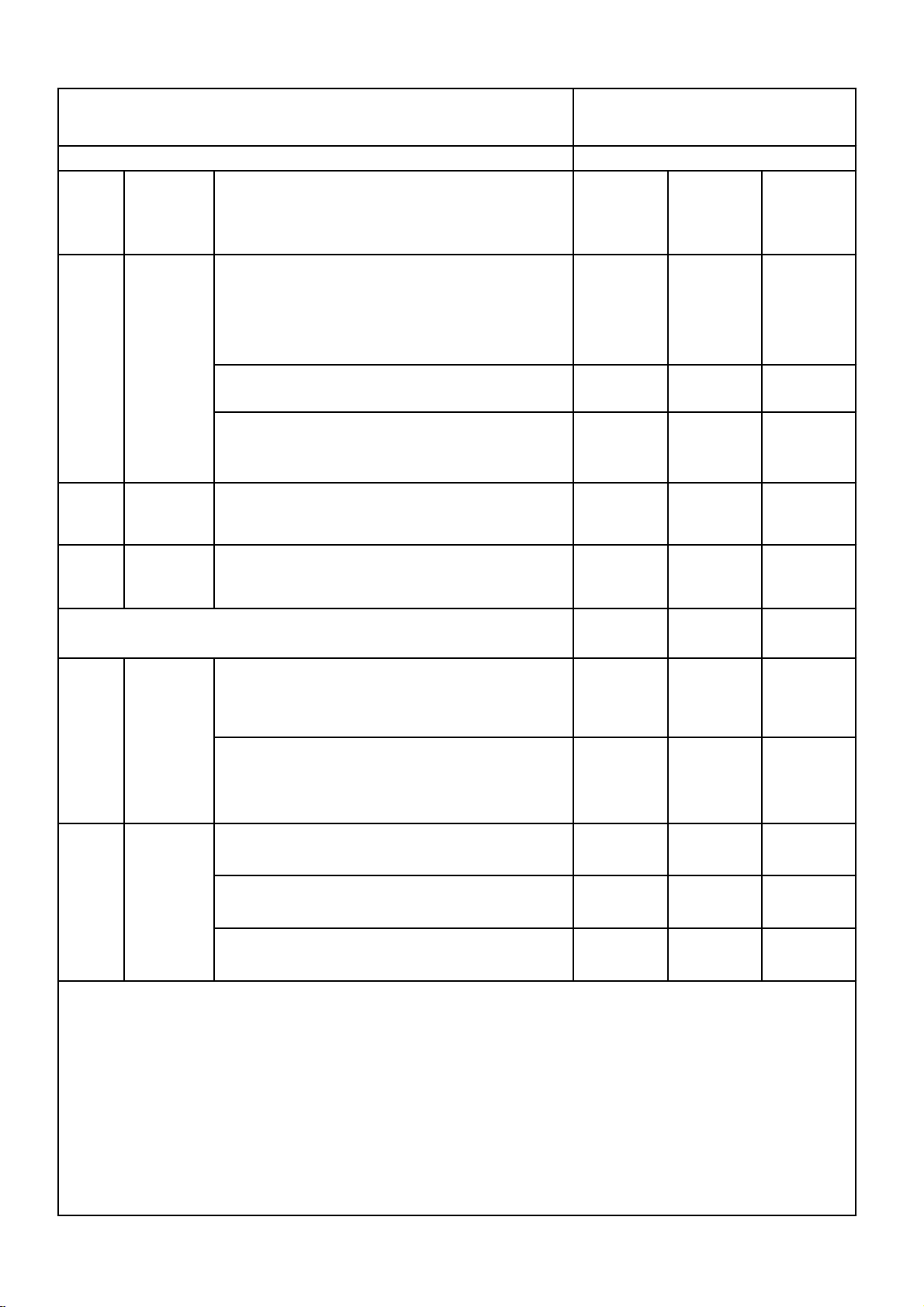

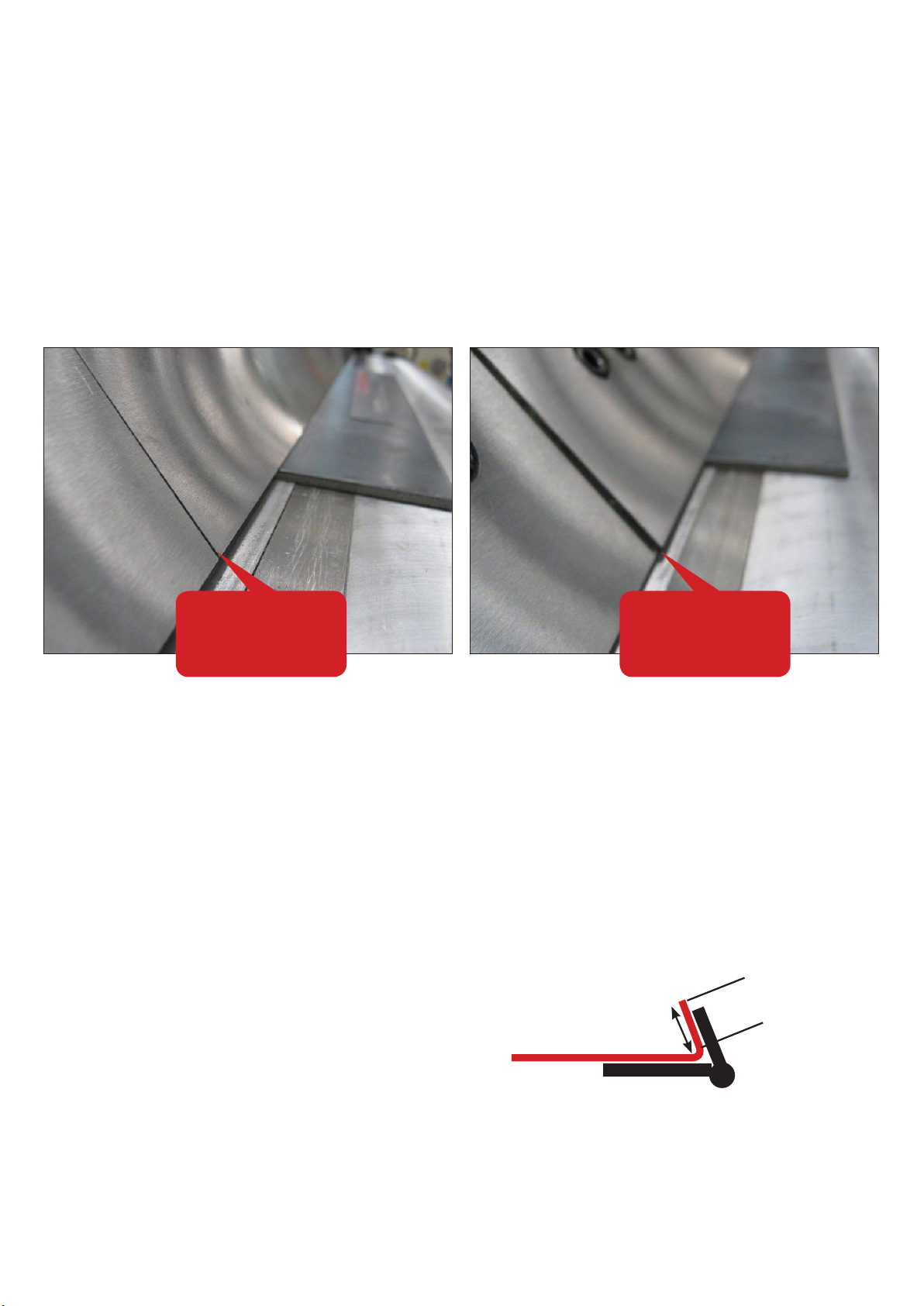

You may have to use a combination of top clamp adjustment

and apron adjustment when doing thicker material like 6mm

aluminium.

(1.5 x 6mm = 9mm, so you need a total gap of 9mm)

Example: If the top clamp gap is 6mm the apron must be

dropped down 3mm to keep a 9mm total gap.

NOTE: Must release locking bolts before adjusting apron

up / down. Tighten when at correct height.

APRON

HEIGHT

ADJUSTMENT