User Instructions

Should you nd your equipment is no longer of use,

please dispose of in a responsible manner. Please

contact Modulift if you need further guidance

© Copyright 2019 Modulift.

All rights reserved.

WARNING!

Do not under any circumstances hang load(s) from the tube or anges

– the Spreader Frame is designed for compression – not bending.

Ensure that the top Shackle contacts the bow of the corner plate

‘bow-to-bow’.

The CMOD system is designed in accordance with BS EN13155:

Cranes, Safety, Non- xed Load Lifting Attachments.

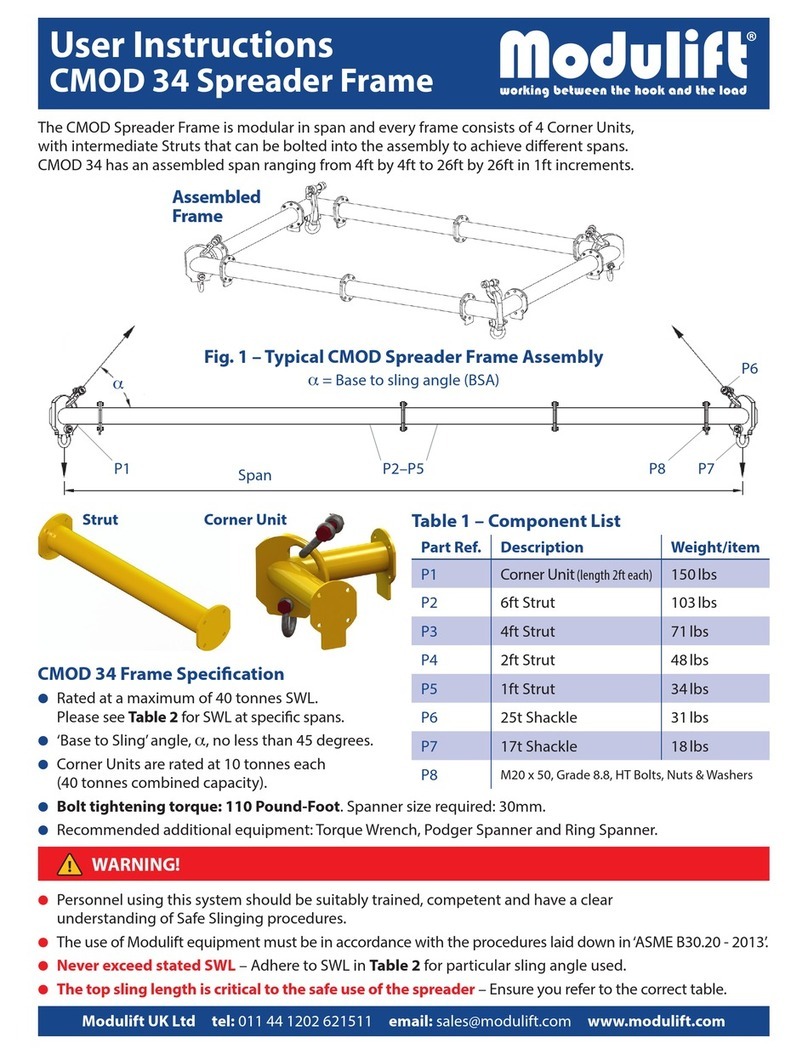

Max number of Struts: 5 per side on the span without T-Piece,

8 per side on span with T-Piece.

All Corner Units and T-Pieces must be connected to crane hook

using top slings and to the load using bottom slings.

All slings must be correctly loaded i.e. no sling (top or bottom)

to be slack at any point during lift.

Sling angle is crucial to the safe use of the frame.

The top sling/turnbuckle must be positioned centrally in the

Shackle pin to ensure even loading. Contact your Modulift

supplier for supply of loose spacers where required.

T-Pieces must be located opposite each other and must connect

to struts.

Do’s & Don’ts

Do ensure enough clearance between frame and the load to

prevent the load hitting the frame. Any collision could cause

failure of the frame.

Do not exceed the individual WLL of any Corner Unit or T-Piece

taking into account CoG osets.

The frame is designed to lift a single solid item using 8 points of

the frame.

To ensure no slings are slack, use turnbuckles on the central top

slings, use matching top slings for the corners, and matching

bottom slings all round. For oset CoGs, or where loads have

dierent spans to the frame, more turnbuckles will be required for

the top and/or bottom slings. Turnbuckles must be adjested until

all slings are in tension. Contact Modulift for advice if in doubt.

Within side with T-Pieces: Max. distance between the two T-Pieces

and between T-Pieces and Corner Units to be no more than 50%

of the total span of that side. Within side without T-Pieces: Min.

distance between the two T-Pieces and between T-Pieces and

Corner Units to be no less than 25% of the total span of that side.

When connecting Corner Units directly to T-Pieces, assembly may

be dicult. Please contact Modulift for assistance.

Do not hang any loads from the Strut tube or anges.

Do not exceed the stated WLL for your span.

Do not rig the lower slings more than 6° from vertical.

Assembly Procedure

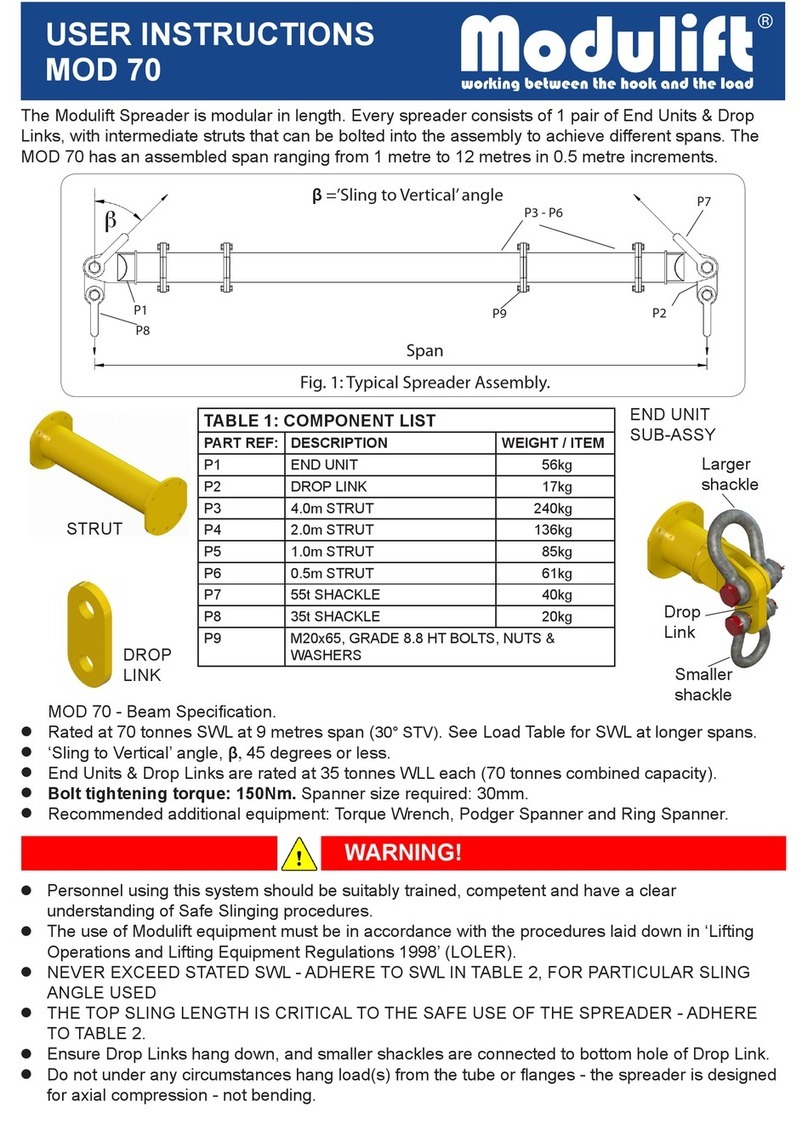

Check the ID plates on each Modulift component to ensure the

correct size is used.

Lay out the Struts, T-Pieces and Corner Units in the correct

conguration.

Check all anges are clear from debris, sand etc. before connection.

Bolt the components together* using bolts, nuts & washers provided.

Tighten the bolts to torque as shown overleaf.

Loop the top Shackles through the bows of the Corner Units so they

contact‘bow-to-bow’. The eye of the top slings can then be passed

through the jaws of the Shackles and the pins replaced.

Loop the top Shackles through the remaining top slings and connect

Shackles to the top of the T-Pieces.

Loop the bottom Shackles through the eyes of the drop slings and

connect to the bottom of the Corner Units and T-Pieces with the

Shackle pins.

Attach the lower slings to the load to be lifted.

The assembled Spreader Frame and lifting rig must be thoroughly

checked by a competent person prior to lifting.

*The use of a Podger Spanner will aid in assembly by helping to align the

bolt holes by forcing it through.

Table 2 – Load v Span

First pick the overall span required for your frame

(e.g. 1m x 2m) and the Sling Angle (we recommend

30° STV where possible), then check the WLL via the

appropriate table. Read the table by locating the

lower span on the y axis of the chart and the larger

on the x. The cell which you are referred to, will

indicate the WLL for your chosen span. If your exact

span is not noted in the table, then please round up

or down to the values that will give you the lowest

WLL (to ensure no overloads are applied). Please

contact Modulift for conrmation on your WLL if

required. WLL given in tonnes.

CMOD 50: 8-Point UK JAN 2019

CMOD 50: 8-Point Frame

CMOD 50: 8-Point Frame WLL / tonnes @ 30° STV

CMOD 50: 8-Point Frame WLL / tonnes @ 45° STV

11 60 50 50 43 32

10 60 60 50 50 41 31

960 60 60 50 50 39 29

860 60 60 60 50 48 37 28

760 60 60 60 60 50 45 35 27

660 60 60 60 60 60 50 43 33 26

560 60 60 60 60 60 60 50 40 32 25

460 60 60 60 60 60 60 50 49 38 31 24

360 60 60 60 60 60 60 60 50 47 37 30 23

260 60 60 60 60 60 60 60 60 50 45 36 29 23

160 60 60 60 60 60 60 60 60 50 44 35 28 22

Span

(m) 2 3 4 5 6 7 8 9 10 11 12 13 14 15

11 34 28 28 24 18

10 40 34 28 28 23 17

940 40 34 28 28 21 16

850 40 40 34 28 27 20 15

750 50 40 40 34 28 25 19 14

650 50 50 40 40 34 28 24 18 14

550 50 50 50 40 40 34 28 23 17 13

450 50 50 50 50 40 40 28 28 21 17 13

350 50 50 50 50 50 40 40 28 26 21 16 12

250 50 50 50 50 50 50 40 34 28 28 20 16 12

150 50 50 50 50 50 50 40 34 28 25 20 15 12

Span

(m) 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Side with T-Piece

Side with T-Piece

Side without T-Piece Side without T-Piece