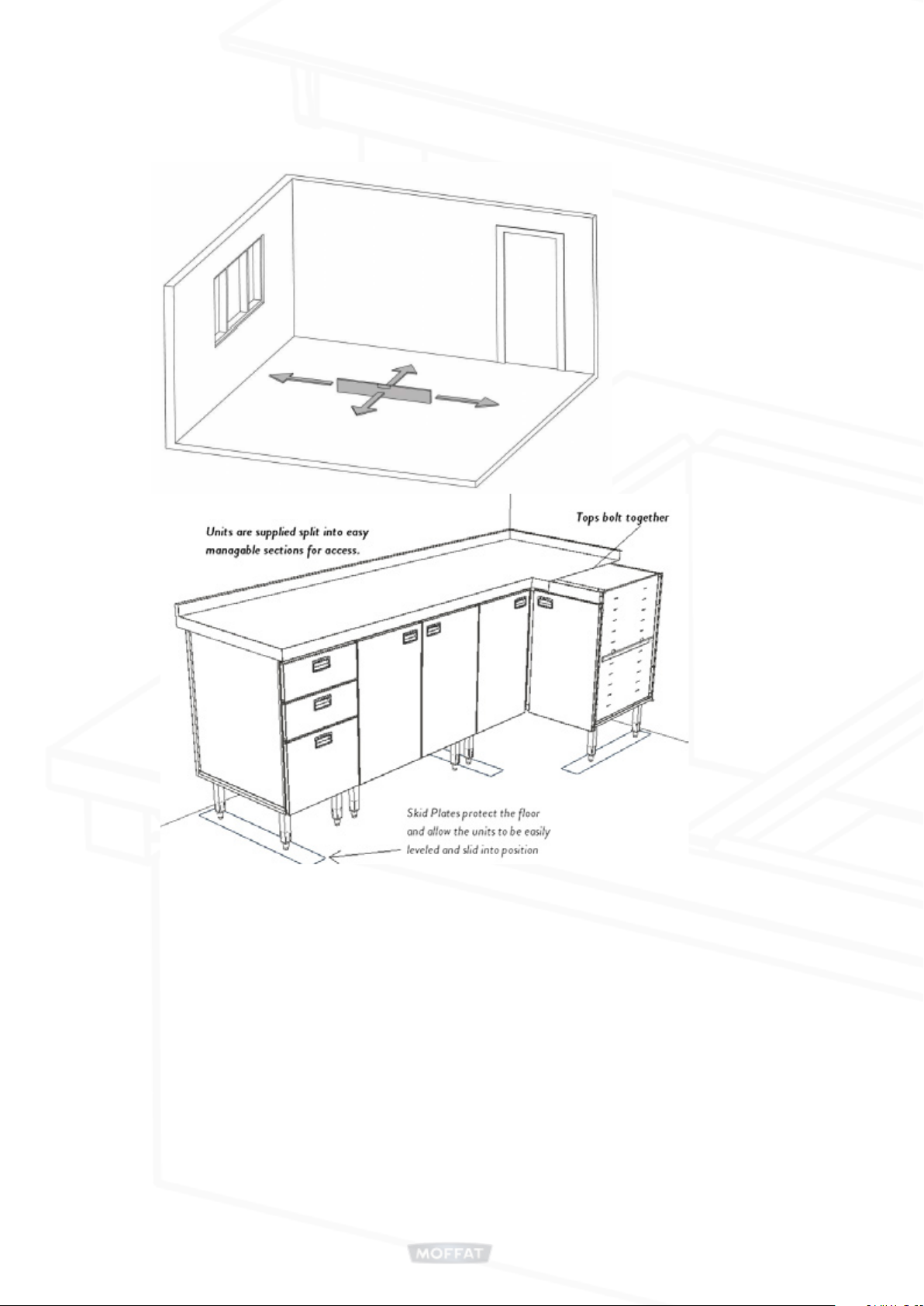

5: Wall-cupboards: Fitting

Commercial grade wall cupboards available in three standard lengths (800mm 1000mm or 1200mm

with a choice of sliding or hinged doors. Wall cupboards are fully enclosed, fabricated in stainless steel.

The internal mid shelf is removable and adjustable for height in 48mm increments.

Designed with a flat roof as standard with the option of a sloping type roof.

Note: The weight capacity for each unit is 150kg

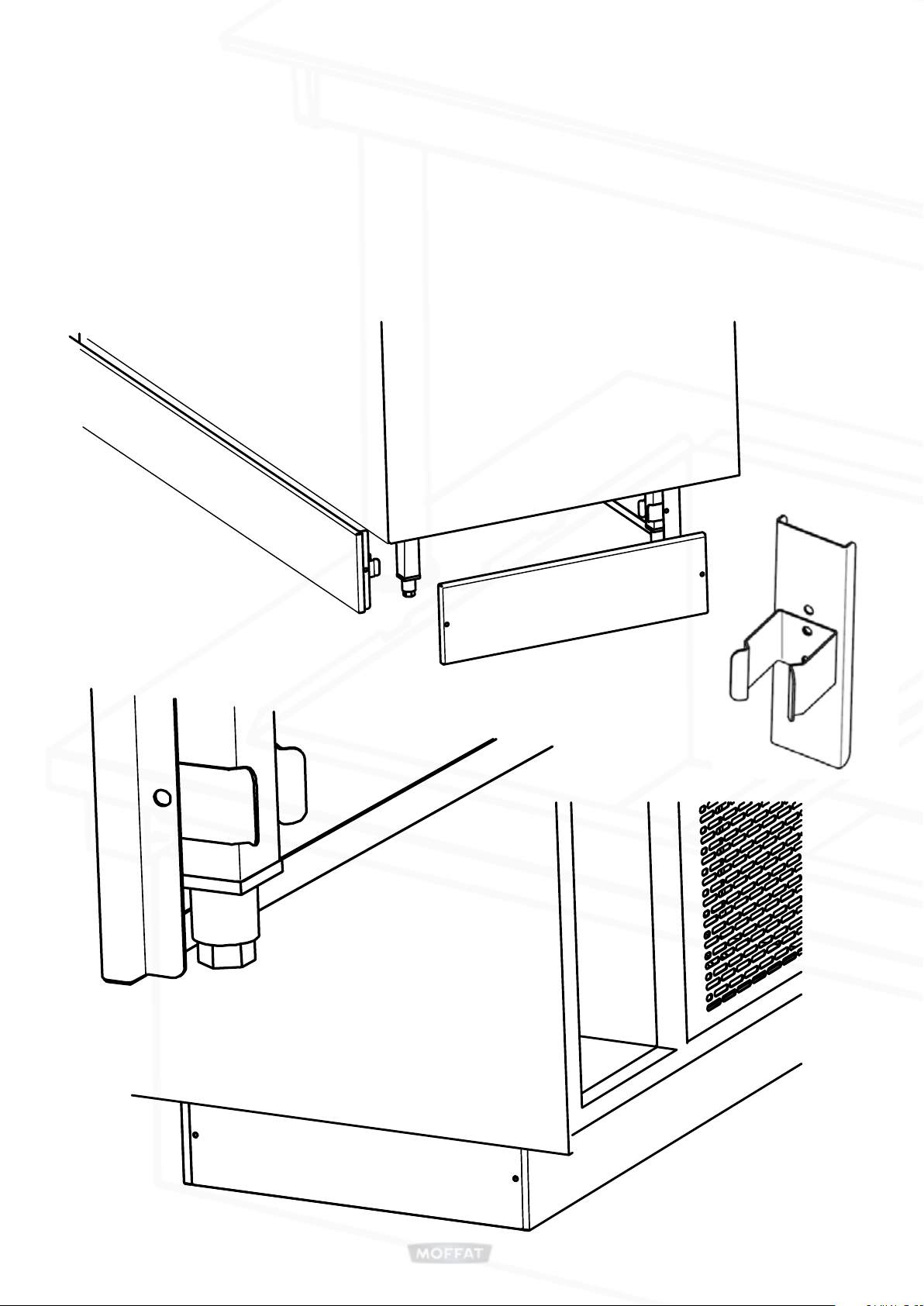

Fitting: (wall fixing)

The wall units are hung onto brackets and double secured through the back on the bottom corners.

Wall units are usually fitted or hung with the bottom of the unit around 500mm above the worktop to

give enough head height for working on the worktop.

The important thing is to work out how close to the ceiling you want the top of the wall unit.

Make sure the units are at the same height and are level all around the room.

Note: Base cabinets and worktops units are usually set at 900mm high.

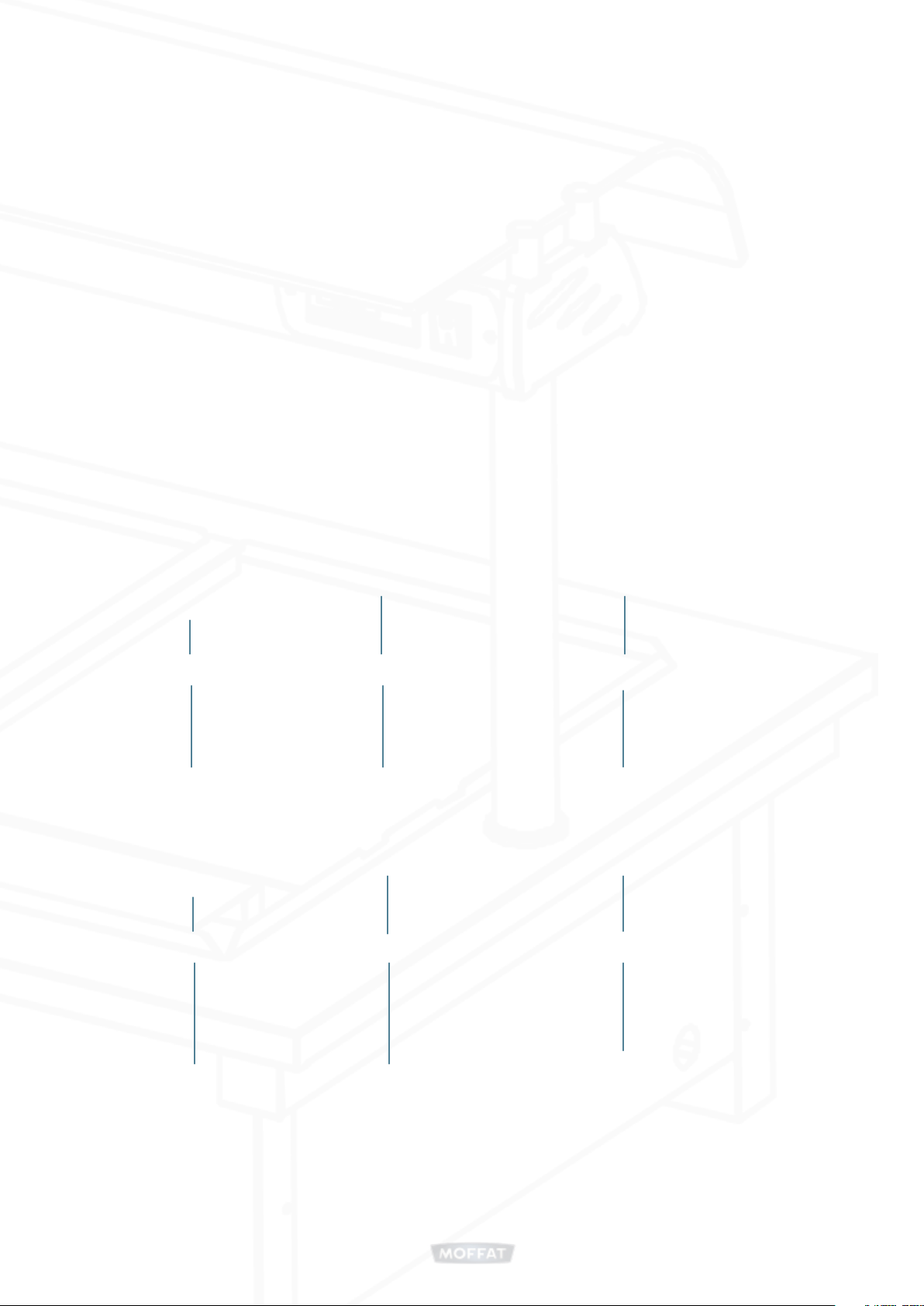

If you have multiple wall units to hang it’s a great idea to mark the height of the wall unit brackets at

both ends of the wall and ping a chalk line between them.

Fix the brackets in place at the correct distance apart for each wall unit and directly onto the line you

marked. (See page 11 for dimensions)

Once the wall brackets are fixed,

• Hang the cupboard and adjust the top corner hanging brackets.

• There are two screws at the back of the internal wall unit bracket.

• One adjusts the height of the bracket for fine tuning on the wall

• The other pulls the unit in towards the wall to keep it tight against it.

Use a spirit level or a laser level to get the units straight and level

There are two additional fixing points located on the bottom corners of the cupboard.

After fixing the top hangers mark and fix the bottom screws. (See page 11 for dimensions)

10