MOLEAER KINGFISHER

NANOBUBBLE GENERATOR

Owner’s Manual

www.moleaer.com CONFIDENTIAL 8

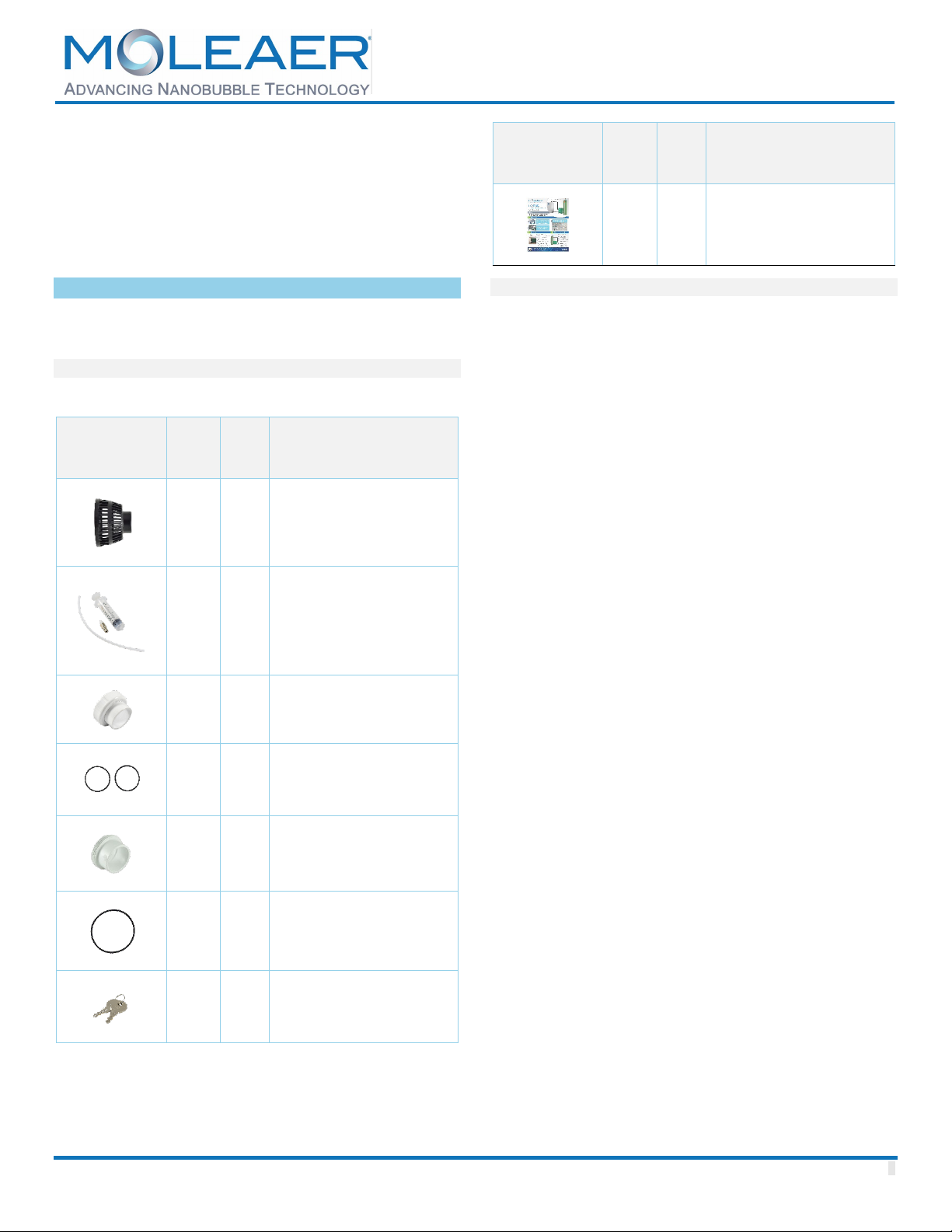

Parts, Tools, and Materials

The following is a list of various parts, materials and tools

required for the installation and startup of the equipment.

As each installation is unique, this is not an exhaustive but

a recommended list.

•PVC Glue

•PVC saw

•PVC pipe primer and PVC pipe cement

•PVC Pipe or hose and fittings to connect to the

tank.

•Wrench

•Pliers

•Level

•Smoke pen for checking leaks on the suction line

•Spray bottle of soapy water for detecting air tube

leaks

•Miscellaneous items including tape measure,

marking pencil, shop towels for cleaning, etc.

Pipe Assembly

Completely bury or submerge all PVC pipes and fittings to

avoid ultraviolet (UV) degradation. All PVC pipe

connections must be solvent welded using PVC cement.

Use only Schedule 40 polyvinyl chloride (PVC) pipe and

fittings. Use only PVC cement formulated for wet conditions

and fast installation to connect PVC pipe to PVC fittings. Do

not use black, acrylonitrile butadiene styrene (ABS) piping

or mix ABS pipe or fittings with PVC pipe or fittings.

All PVC pipe connections must be airtight and leakproof.

Failure to provide airtight suction pipe connections may

negatively impact nanobubble generator performance.

Large bubbles visible at the pump strainer basket are an

indication of suction pipe leaks. Difficulty with pump priming

may also be an indication of suction pipe leaks. Check and

correct for all suction and discharge pipe leaks prior to

burying or submerging the pipe.

Proper technique must be used when gluing PVC pipe and

fittings to ensure an airtight, leakproof connection. For

proper technique, refer to the Appendix. Allow for proper

cure time before wet testing suction and discharge pipes.

Piping

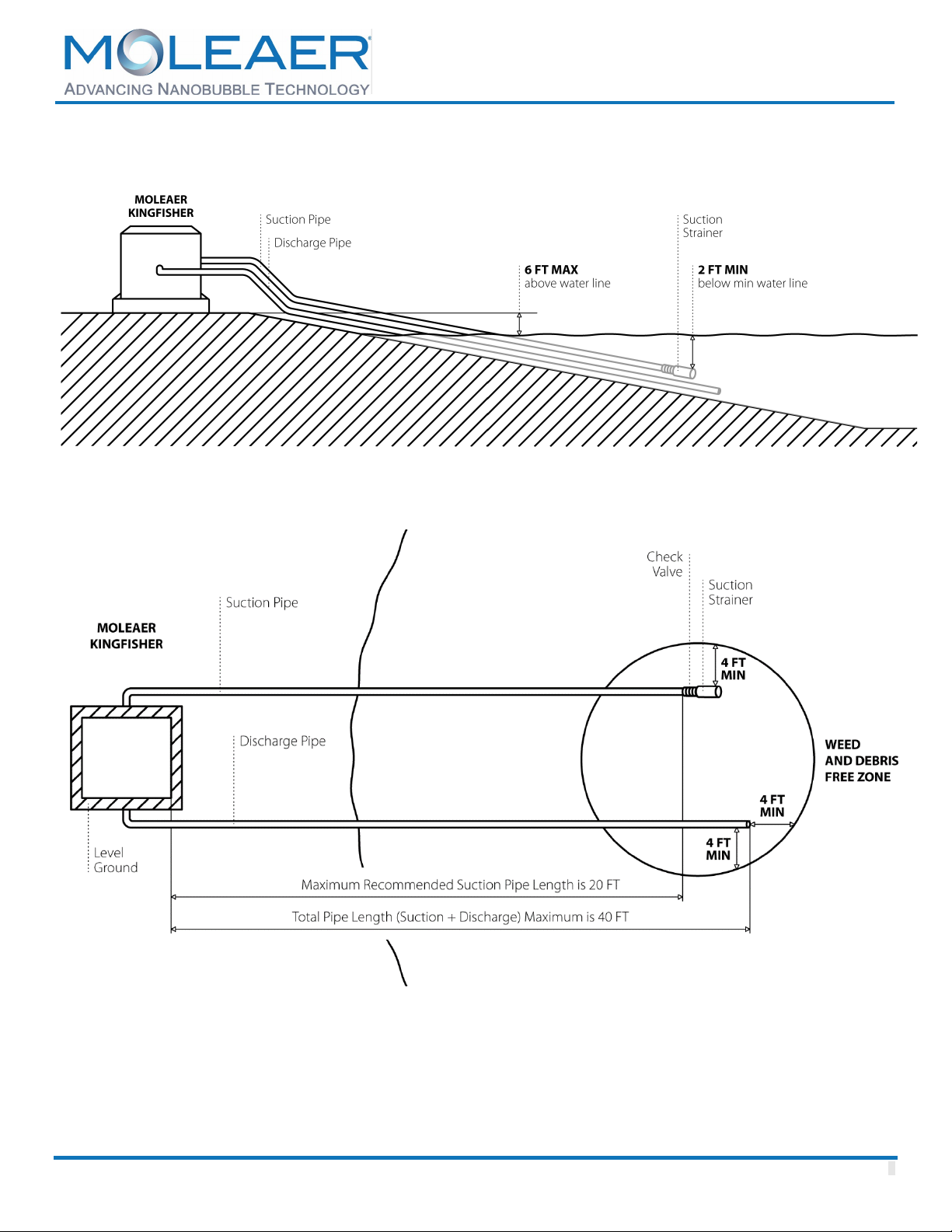

Pipe lengths and unit elevation can play an important role

in the performance of the unit. Standard Installation should

be no higher than 6’ above the water surface, and the total

length of pipe above the water surface should be less than

10’, but in no case longer than 30’. In this Standard

Installation, priming of the pump is expected to require no

more than 5 minutes if there are 10’ of pipe above the water

surface, and will be considerably longer if the length of pipe

above the water surface is between 10' and 30’ in length.

Locate and install the discharge pipe following the

recommendations detailed in Figures 4 and 5.

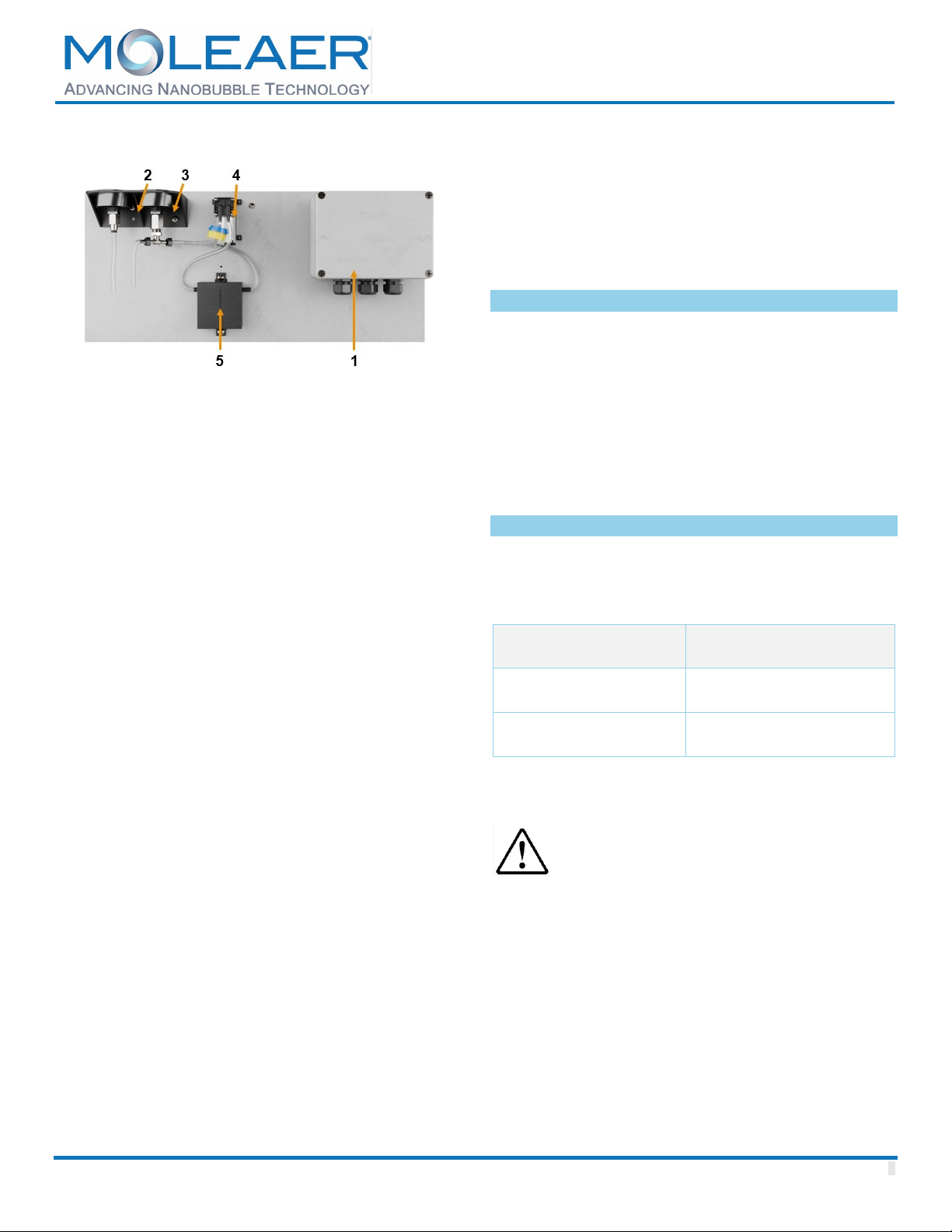

The intake and discharge ports on the Kingfisher are both

1.5” (63 mm) union fittings.

Locate and install the intake structure and suction pipe

following the recommendations detailed in Figures 4 and 5.

Use available fittings as necessary to route the suction

piping from the unit to the waterbody. Do not remove the

bell end of the PVC pipe. The bell end can be used as a

coupling for connecting straight pipe segments.

Install the included intake screen at the suction end of the

pipe to stop large debris from entering the system. Ensure

that the intake screen is fully submerged but elevated from

the lake bottom to avoid sediment buildup. Ensure that the

suction line is continuously rising from the water body to the

inlet of the unit. High spots in the suction line may trap air

and prevent the pump from self-priming properly.

It is recommended to install a swing-style check valve to

facilitate faster priming of the pump during start-up. If a

check valve (not included) is installed on the suction line,

ensure that it is installed with the flow arrow in the direction

of suction flow so as not to restrict the flow of water to the

pump.

Locate and install the discharge pipe following the

recommendations detailed in Figures 1 and 2. Use

available fittings as necessary to route the discharge piping

from the unit to the waterbody. Discharge should be firmly

fixed and pointed towards the center of the water body to

avoid causing erosion. Do not remove the bell end of the

PVC pipe. The bell end can be used as a coupling for

connecting straight pipe segments.

Do not bury either suction or discharge pipe until the system

has been wet tested and is free of leaks.

Power Input

Extension cord use is hazardous and should be

avoided. In certain jurisdictions, permanent

installation using an extension cord is not

permitted. Check with your local electrical code.

Step 1. The Kingfisher requires a dedicated, weather-

resistant power receptacle. After starting the Kingfisher,

perform a voltage drop test to verify voltage is within normal

limits.