Hand Crimp Tool ForMini-Fit™Jr. Male and Female Crimp Terminals

Doc No: ATS-638190900 Release Date:01-24-08 UNCONTROLLED COPY Page 3 of9

Revision: A Revision Date:01-24-08

CONDITIONS:

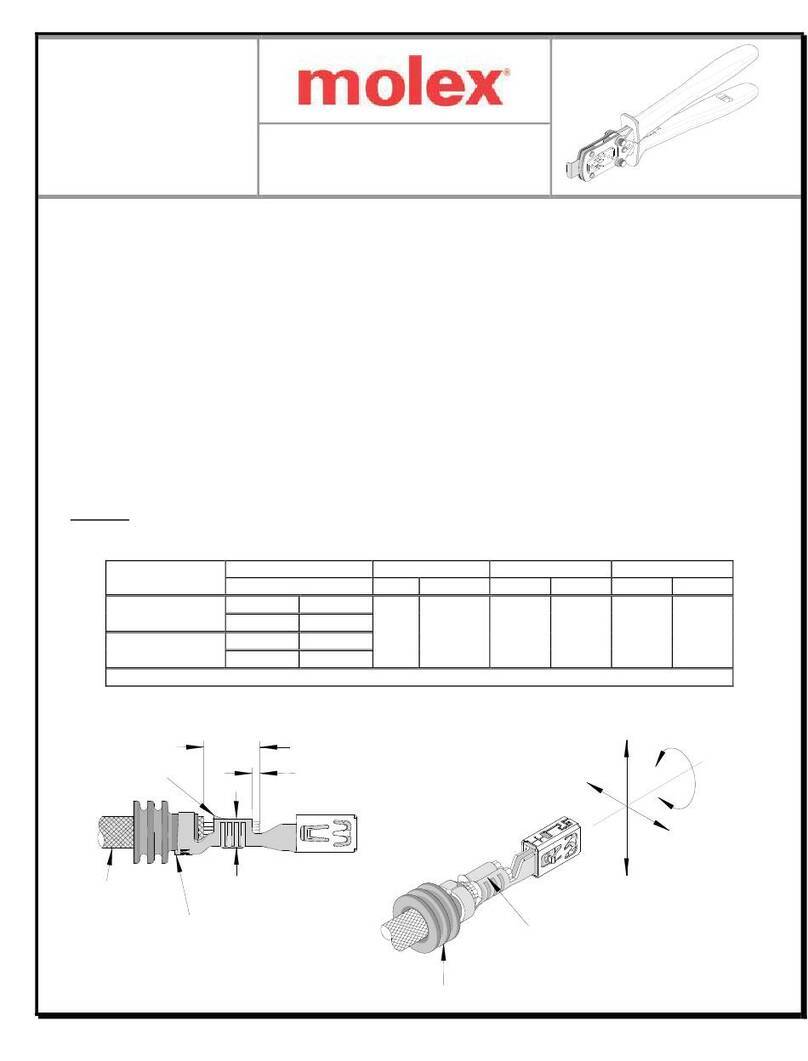

After crimping, the conductor profiles should measure the following.

Conductor Crimp Insulation Crimp

Wire Size Height (Ref.) Width (Ref.) Height (Ref.) Width (Ref.) Pull Force

Minimum +Profile

Terminal

SeriesNo. AWG mm2mm In. mm In. mm In. mm In. N Lb. 16 18 20-24

16 1.30 1.06-1.16 .042-.046 1.92 .076 2.82 .111 2.89 .114 68.5 15.40 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 88.0 19.80 X

20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

22 0.35 0.80-0.90 .031-.035 1.63 .064 2.24 .088 2.61 .103 39.1 8.00 X

5556

24 0.20 0.78-0.88 .030-.034 1.63 .064 2.21 .087 2.60 .102 29.3 6.60 X

16 1.30 1.06-1.16 .042-.046 1.92 .076 2.82 .111 2.89 .114 68.5 15.40 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 88.0 19.80 X

20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

22 0.35 0.80-0.90 .031-.035 1.63 .064 2.24 .088 2.61 .103 39.1 8.00 X

5558

24 0.20 0.78-0.88 .030-.034 1.63 .064 2.21 .087 2.60 .102 29.3 6.60 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 88.0 19.80 X

20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

22 0.35 0.80-0.90 .031-.035 1.63 .064 2.24 .088 2.61 .103 39.1 8.00 X

30490

24 0.20 0.78-0.88 .030-.034 1.63 .064 2.21 .087 2.60 .102 29.3 6.60 X

16 1.30 1.06-1.16 .042-.046 1.92 .076 2.82 .111 2.89 .114 68.5 15.40 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 68.5 15.40 X

44476 20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

16 1.30 1.06-1.16 .042-.046 1.92 .076 2.82 .111 2.89 .114 68.5 15.40 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 68.5 15.40 X

44478 20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

16 1.30 1.06-1.16 .042-.046 1.92 .076 2.82 .111 2.89 .114 68.5 15.40 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 68.5 15.40 X

20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

22 0.35 0.80-0.90 .031-.035 1.63 .064 2.24 .088 2.61 .103 39.1 8.00 X

44485

24 0.20 0.78-0.88 .030-.034 1.63 .064 2.21 .087 2.60 .102 29.3 6.60 X

16 1.30 1.06-1.16 .042-.046 1.92 .076 2.82 .111 2.89 .114 68.5 15.40 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 68.5 15.40 X

45750 20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

16 1.30 1.06-1.16 .042-.046 1.92 .076 2.82 .111 2.89 .114 68.5 15.40 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 68.5 15.40 X

46012 20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

16 1.30 1.06-1.16 .042-.046 1.92 .076 2.82 .111 2.89 .114 68.5 15.40 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 68.5 15.40 X

46018 20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

16 1.30 1.06-1.16 .042-.046 1.92 .076 2.82 .111 2.89 .114 68.5 15.40 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 68.5 15.40 X

46083 20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

16 1.30 1.06-1.16 .042-.046 1.92 .076 2.82 .111 2.89 .114 68.5 15.40 X

18 0.80 1.00-1.10 .039-.043 1.69 .067 2.38 .094 2.68 .106 68.5 15.40 X

46098 20 0.50 0.83-0.93 .033-.037 1.64 .065 2.24 .088 2.65 .104 58.7 13.20 X

+ To Achieve IPC-A-620 Class 2 Crimps, the following over-all wire insulation diameter ranges are recommended:

16 AWG Profile: 1.90-3.10mm (.075-.122 inch)

18 AWG Profile: 1.68-2.85mm (.066-.112 inch)

20-24 AWG Profile: 1.40-2.54mm (.055-.100 inch)