molex Avikrimp 64005-3000 User manual

Other molex Crimping Tools manuals

molex

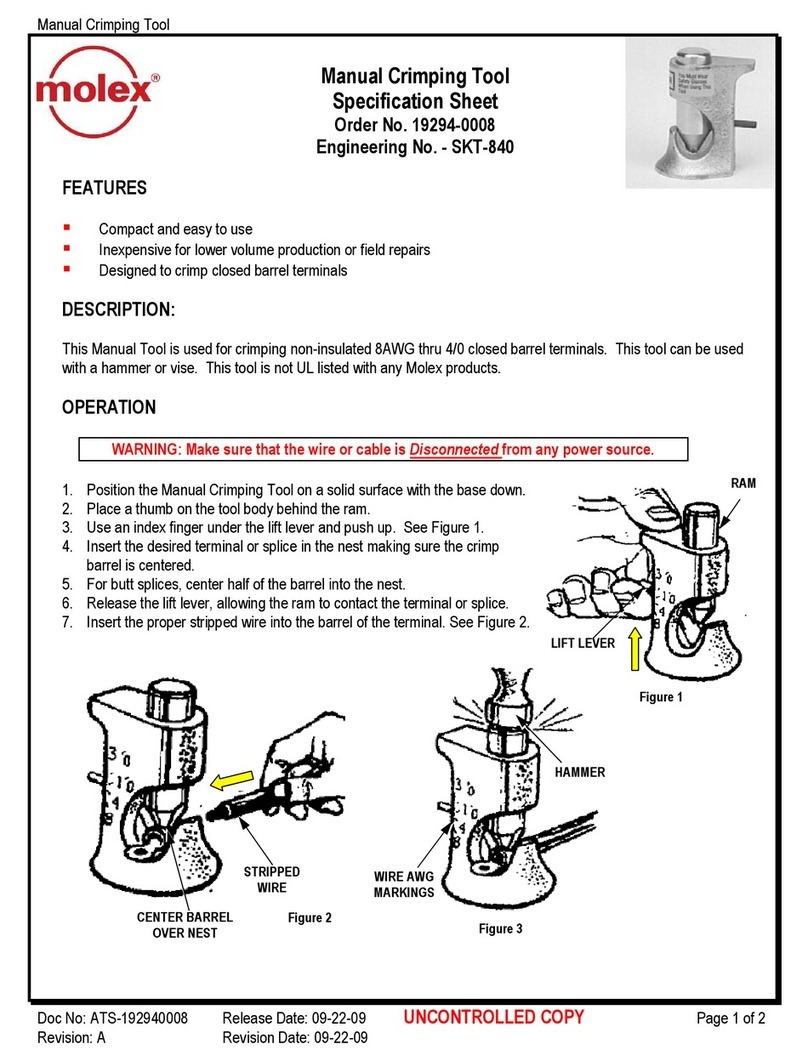

molex 19294-0008 User manual

molex

molex 43178 Series User manual

molex

molex 207129 Series User guide

molex

molex 207129 Series User manual

molex

molex RHT 2251-CC User manual

molex

molex 63827-6900 User manual

molex

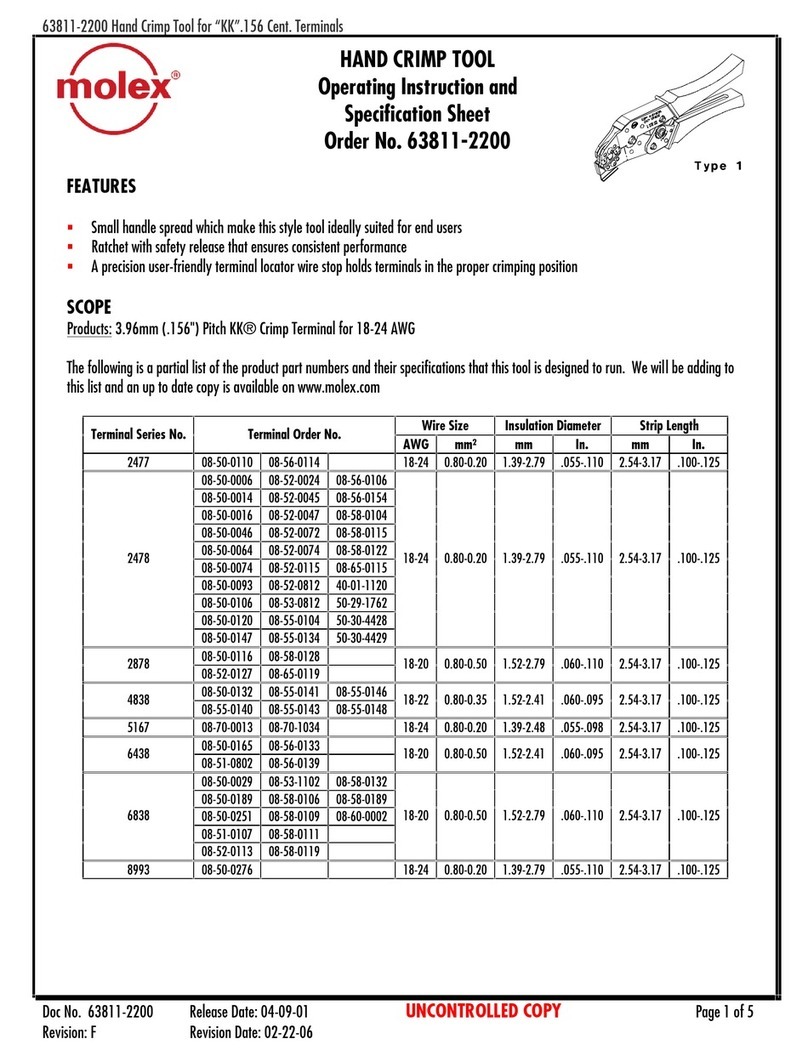

molex 63811-4400 User manual

molex

molex 63827-6270 User manual

molex

molex 78172 Series User manual

molex

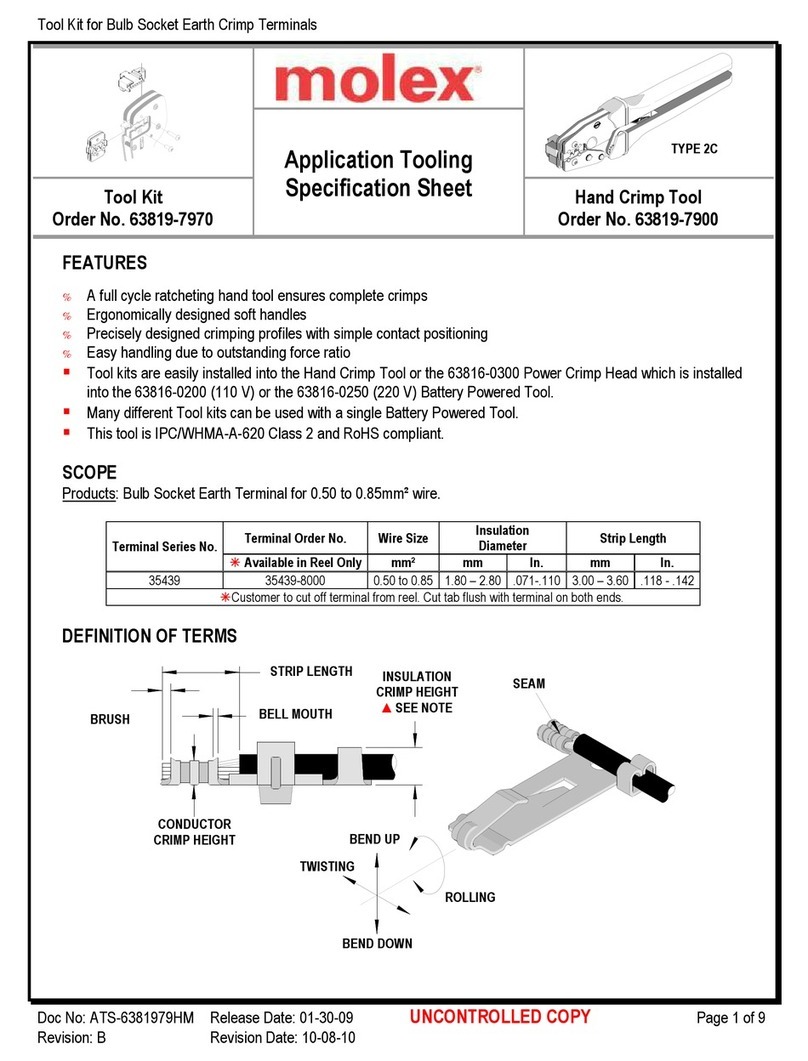

molex 63819-2900 User manual

molex

molex 63819-1300 User manual

molex

molex MTA-100 Manual

molex

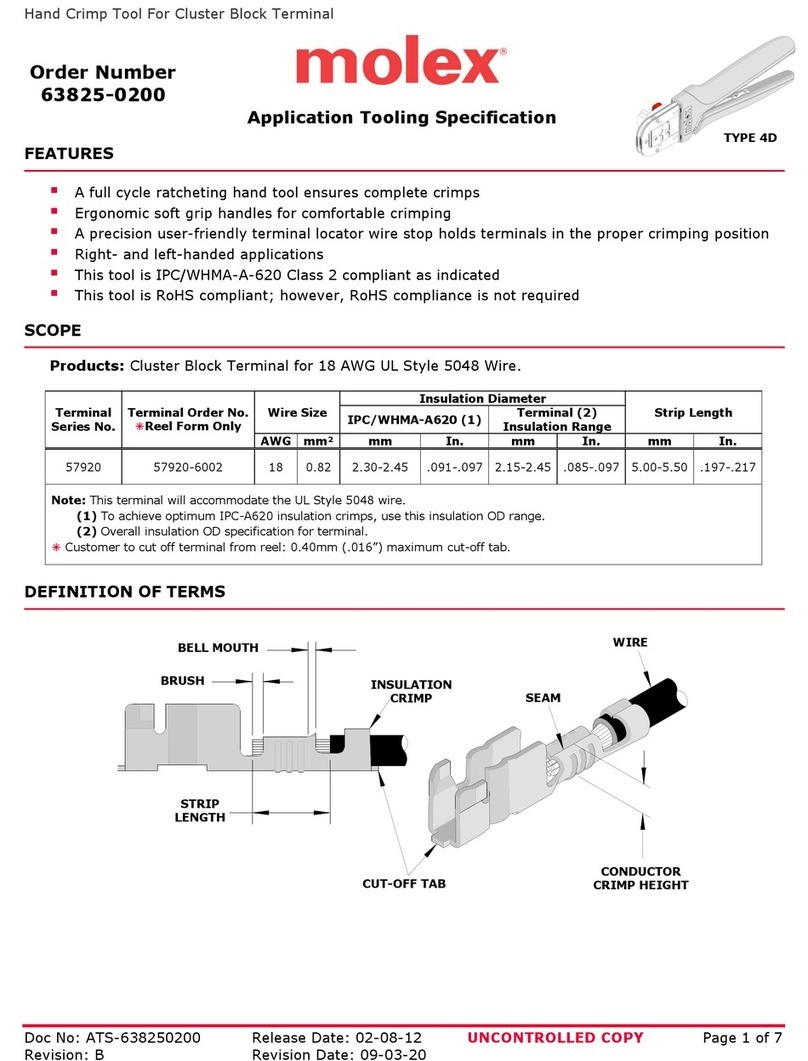

molex 63825-7470 User guide

molex

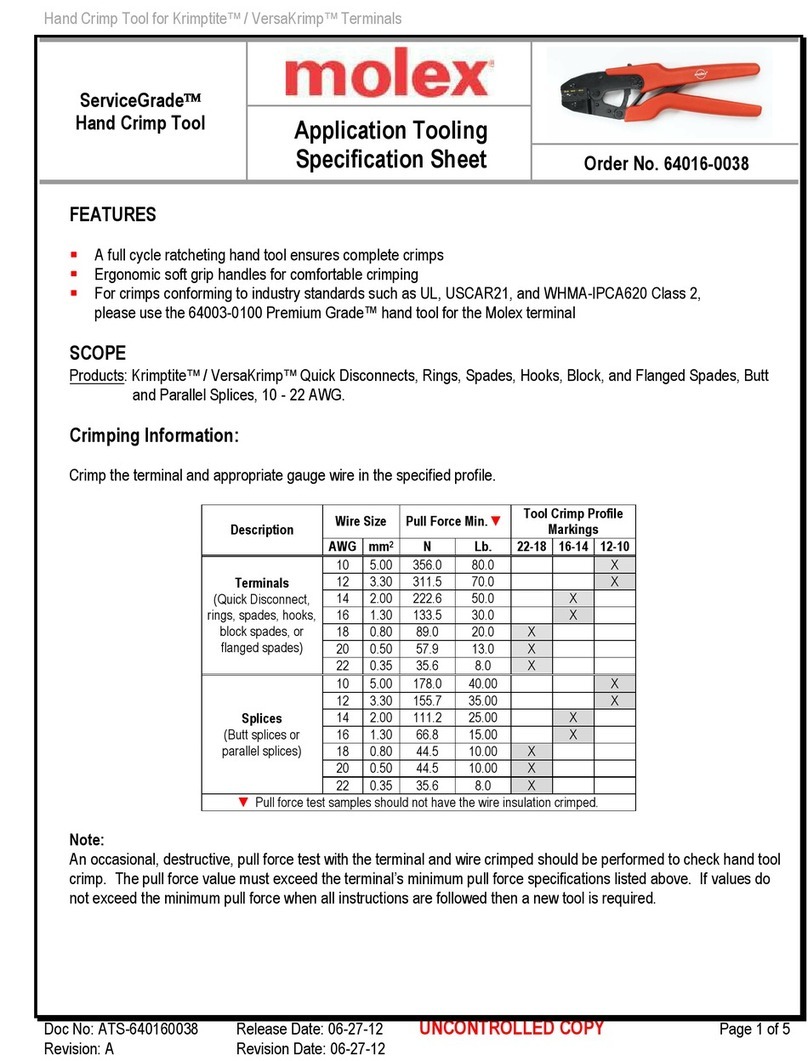

molex ServiceGrade 64016-0038 User manual

molex

molex 207129 Series User manual

molex

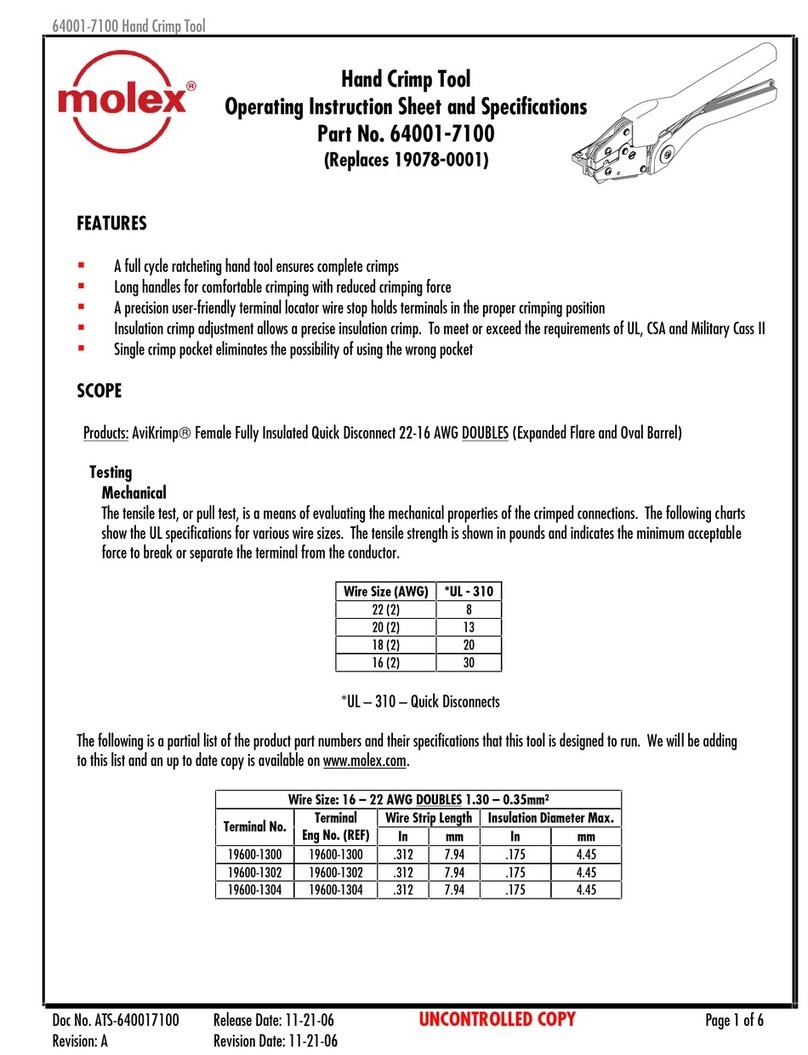

molex 64001-7400 User manual

molex

molex 63827-9300 User manual

molex

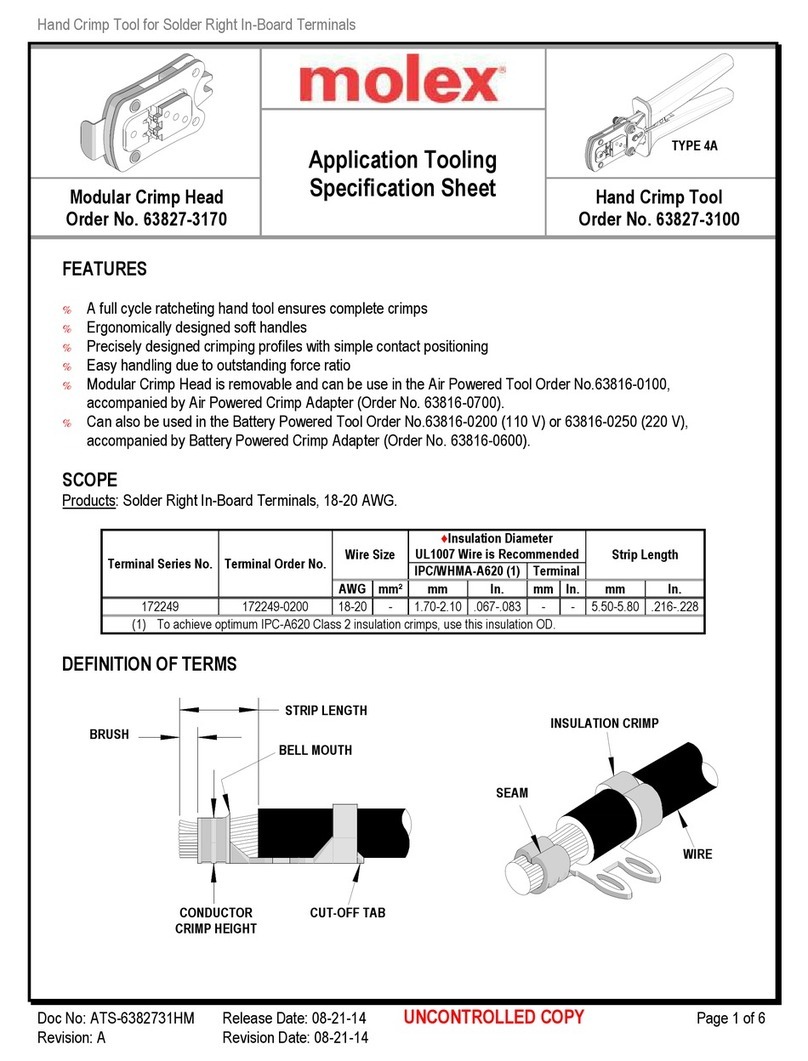

molex 63827-3170 User manual

molex

molex AT-200 Manual

molex

molex 63827-8200 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet