molex 63828-1900 User manual

Other molex Crimping Tools manuals

molex

molex 207129 Series User manual

molex

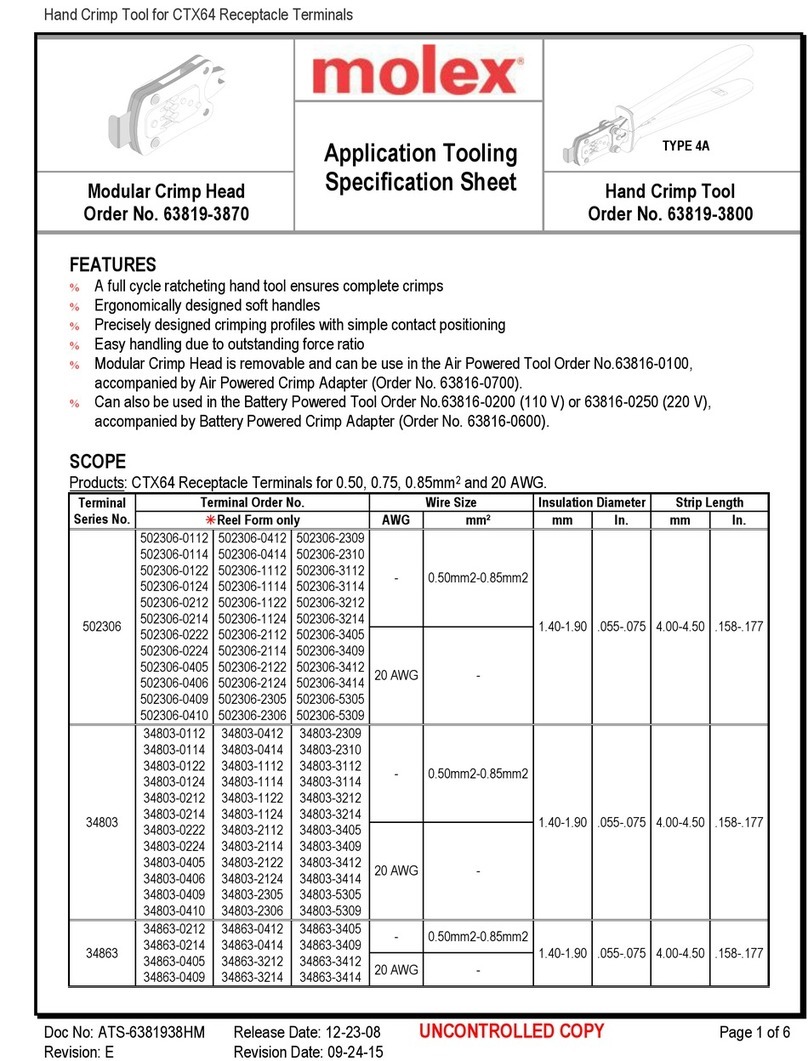

molex 63819-3800 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 63827-3070 User manual

molex

molex 207129 Series User manual

molex

molex 64001-2800 User manual

molex

molex 69008-1100 User manual

molex

molex 63811-9200 User manual

molex

molex 78172 Series User manual

molex

molex 50098 Series User manual

molex

molex 63811-8700 User manual

molex

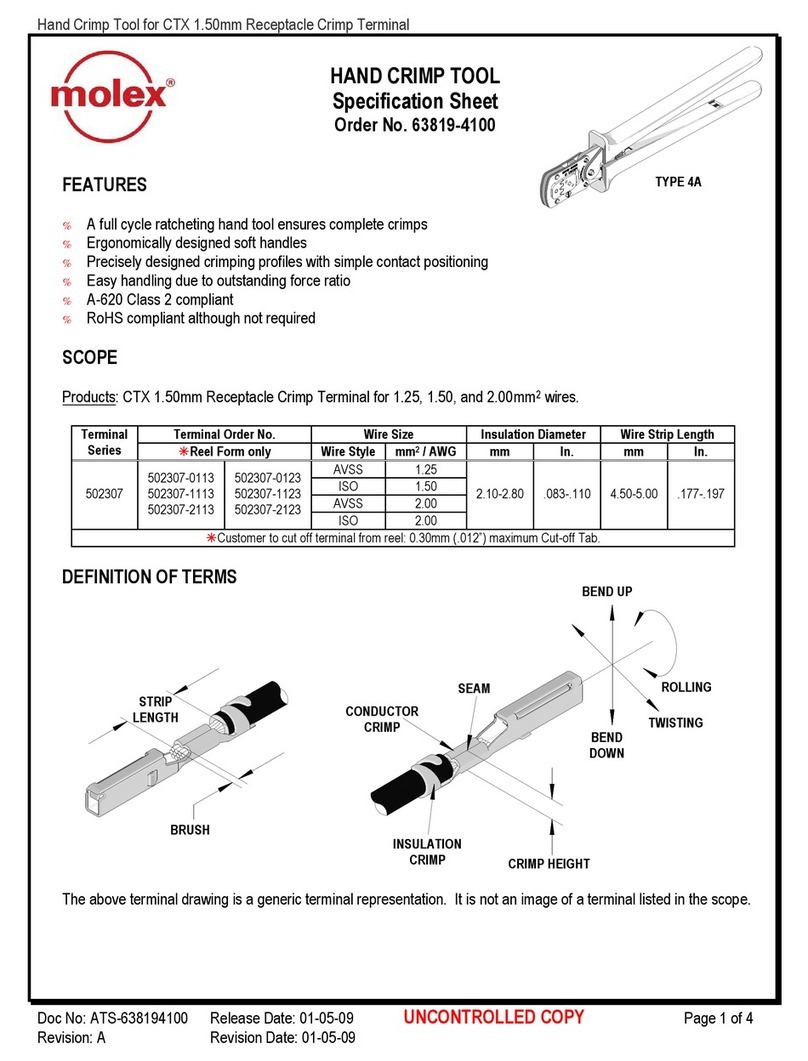

molex 63819-4100 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

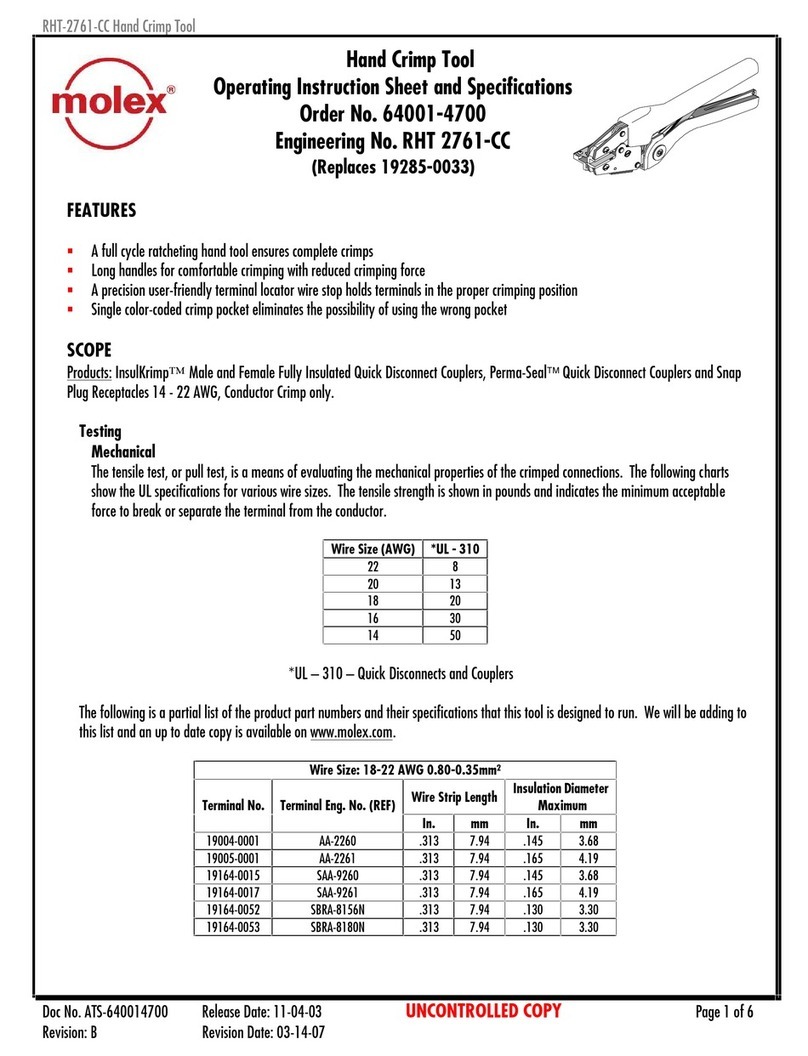

molex RHT 2761-CC User manual

molex

molex 207129 Series User manual

molex

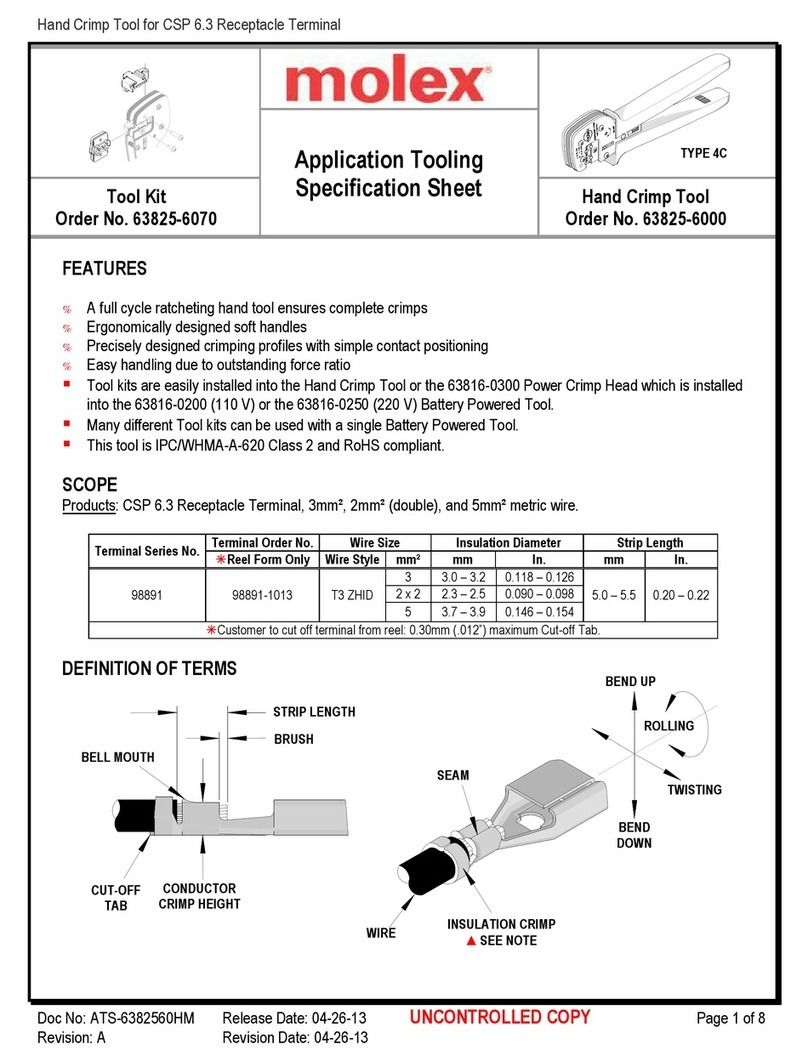

molex 63825-6070 User manual

molex

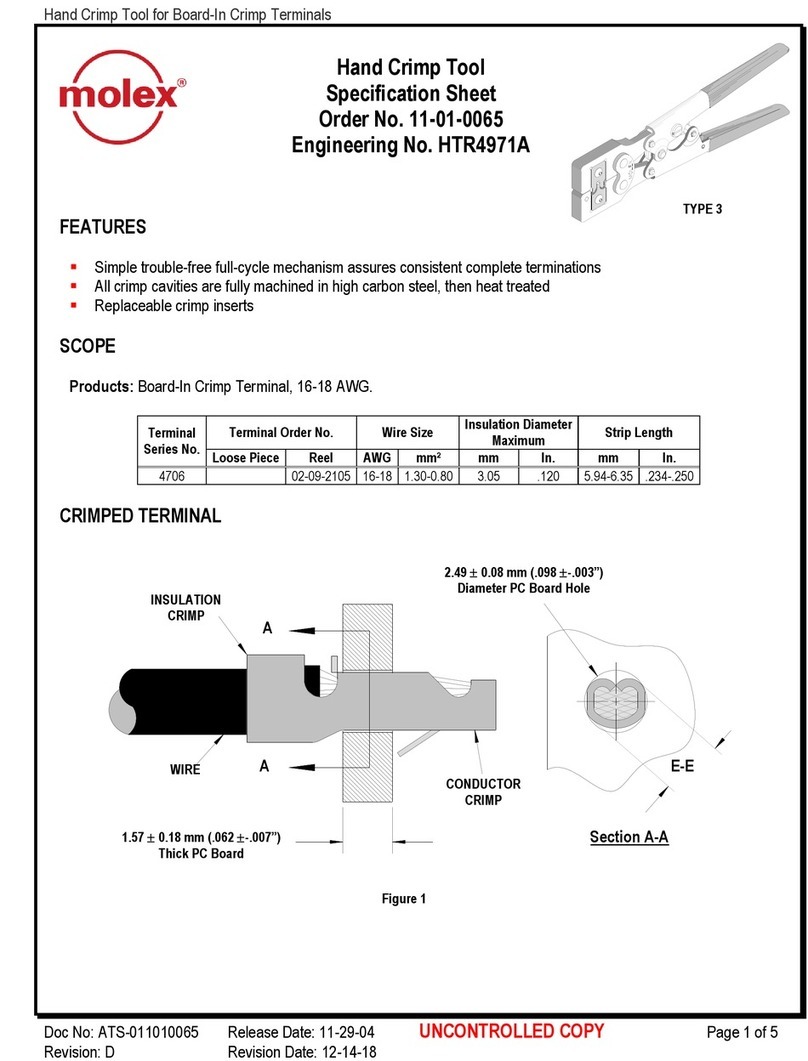

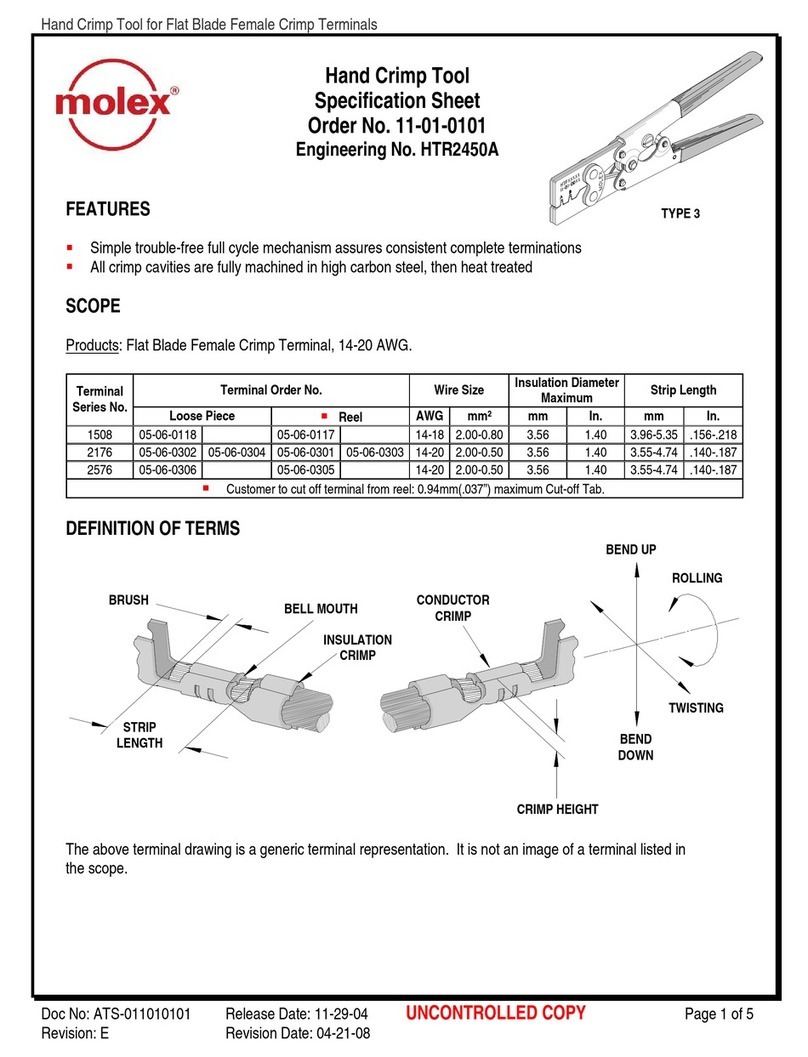

molex 11-01-0101 User manual

molex

molex 207129 Series User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet