molex RHT 2761-CC User manual

Other molex Crimping Tools manuals

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

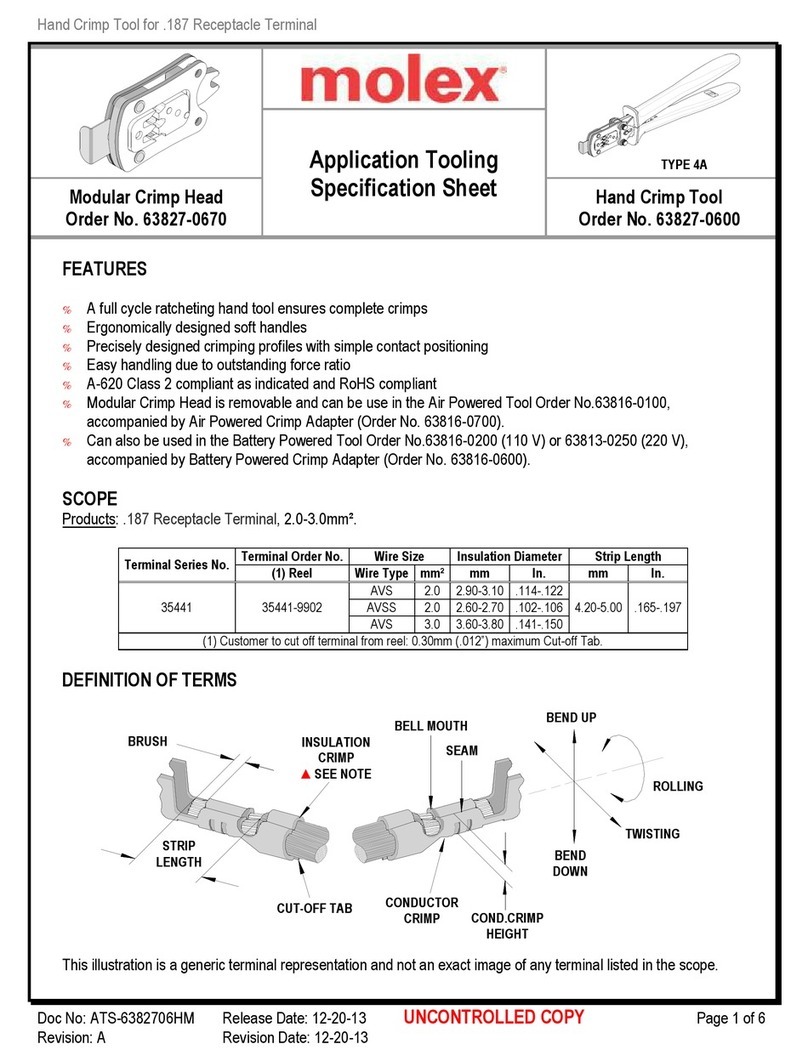

molex 63827-0600 User manual

molex

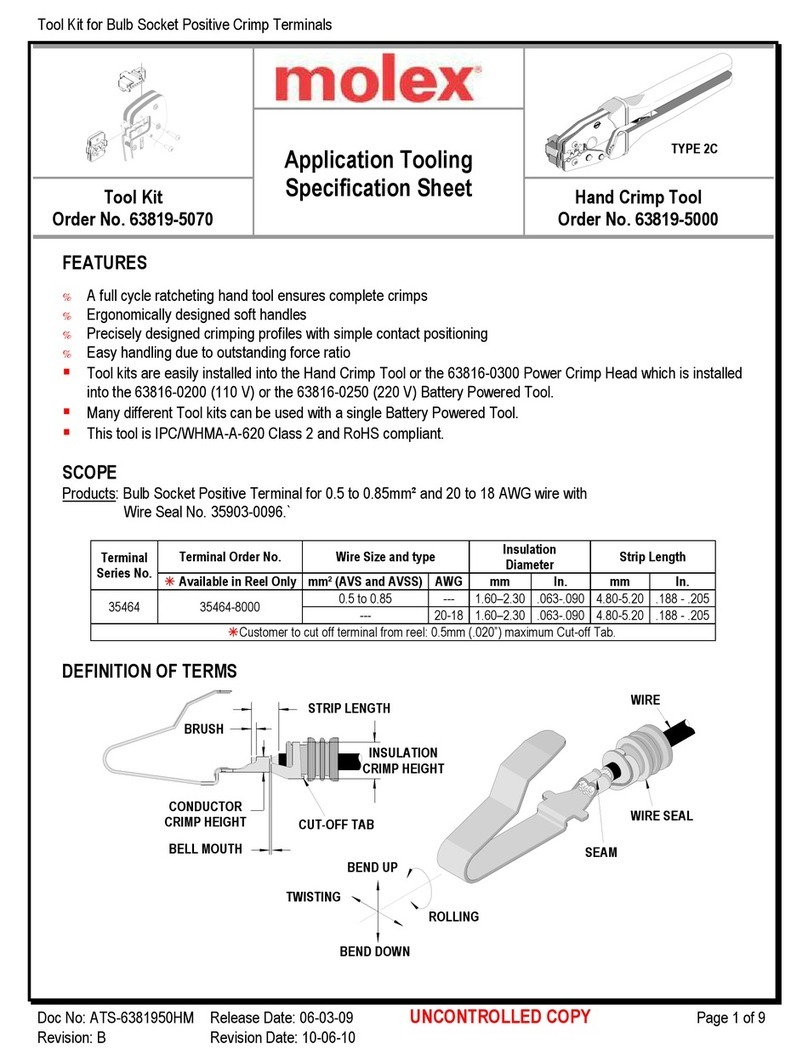

molex 63819-4900 User manual

molex

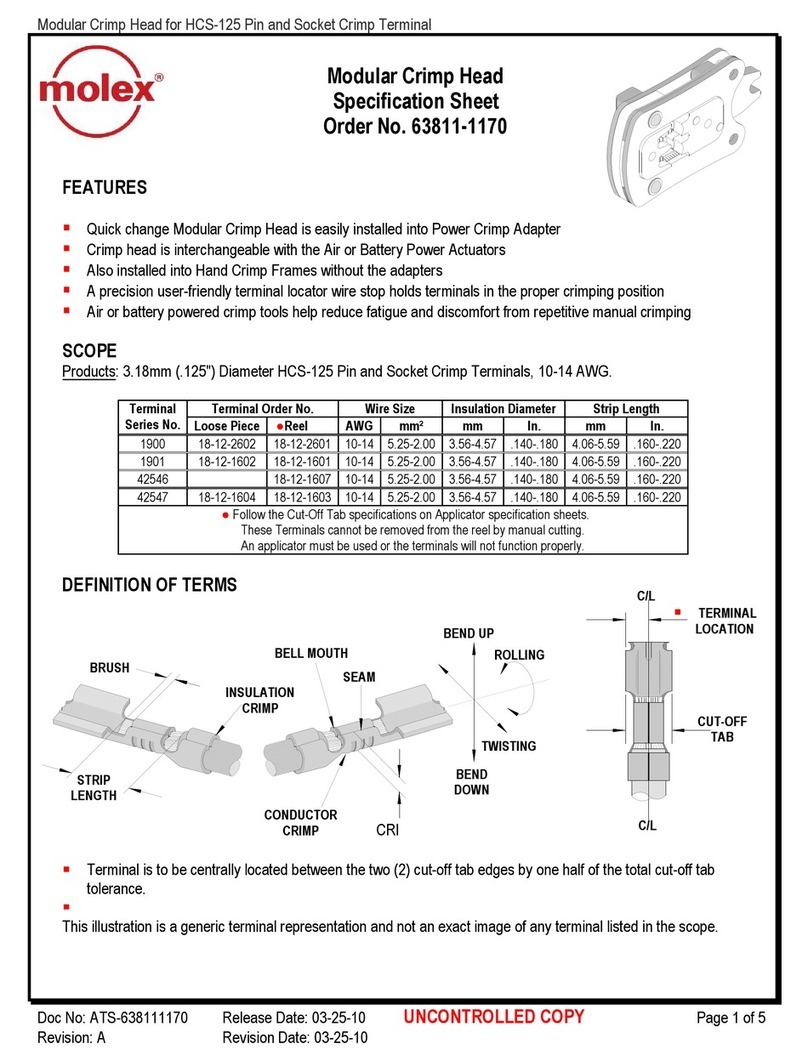

molex HCS-125 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

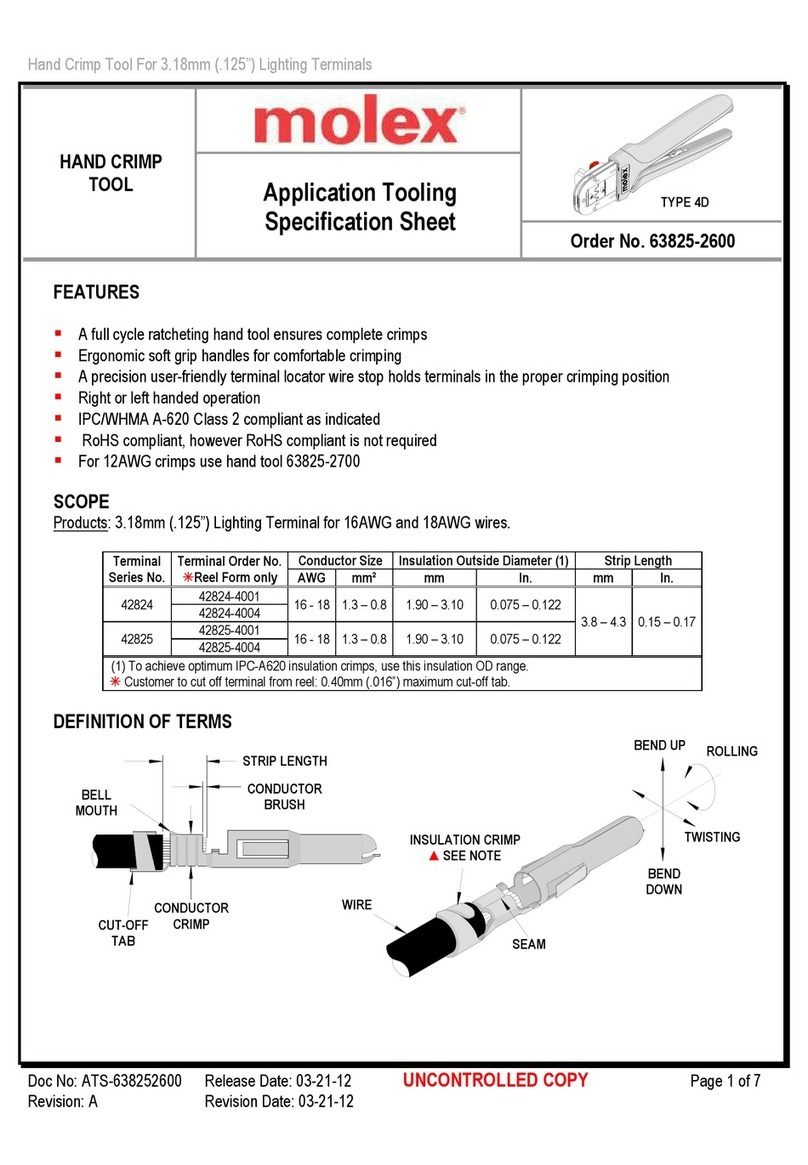

molex 63825-2600 User manual

molex

molex 207129 Series User manual

molex

molex 64005-4100 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 63827-8770 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex RHT 2251-CC User manual

molex

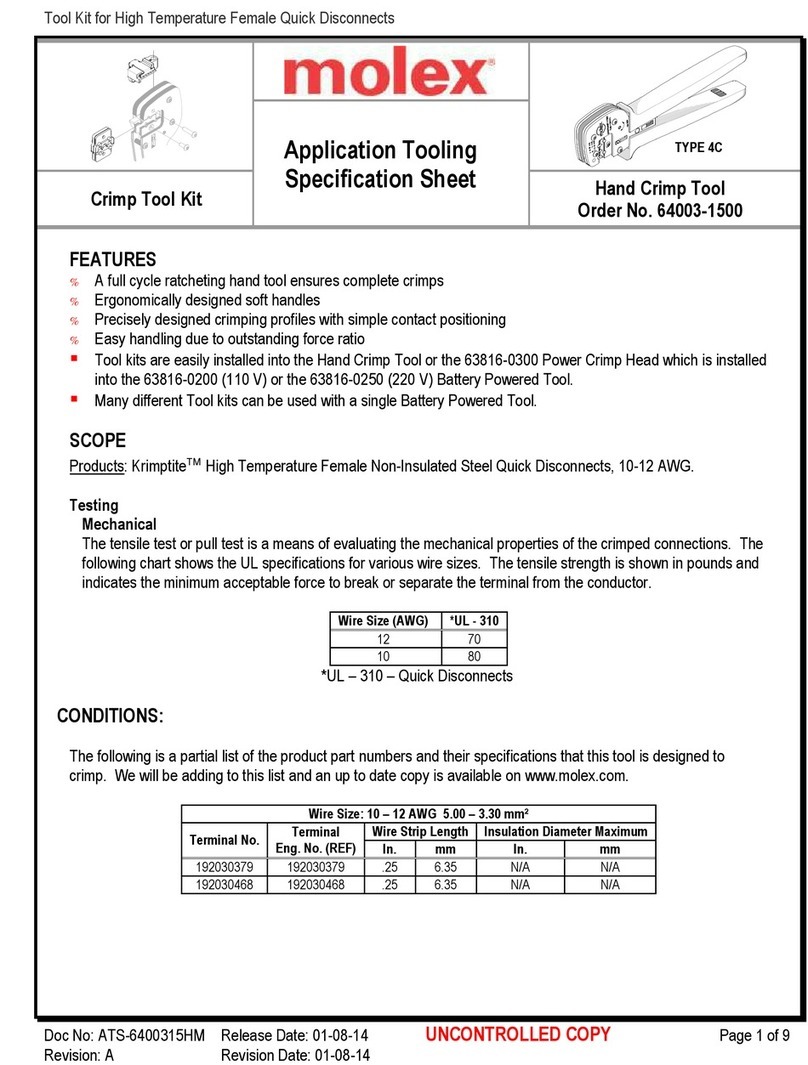

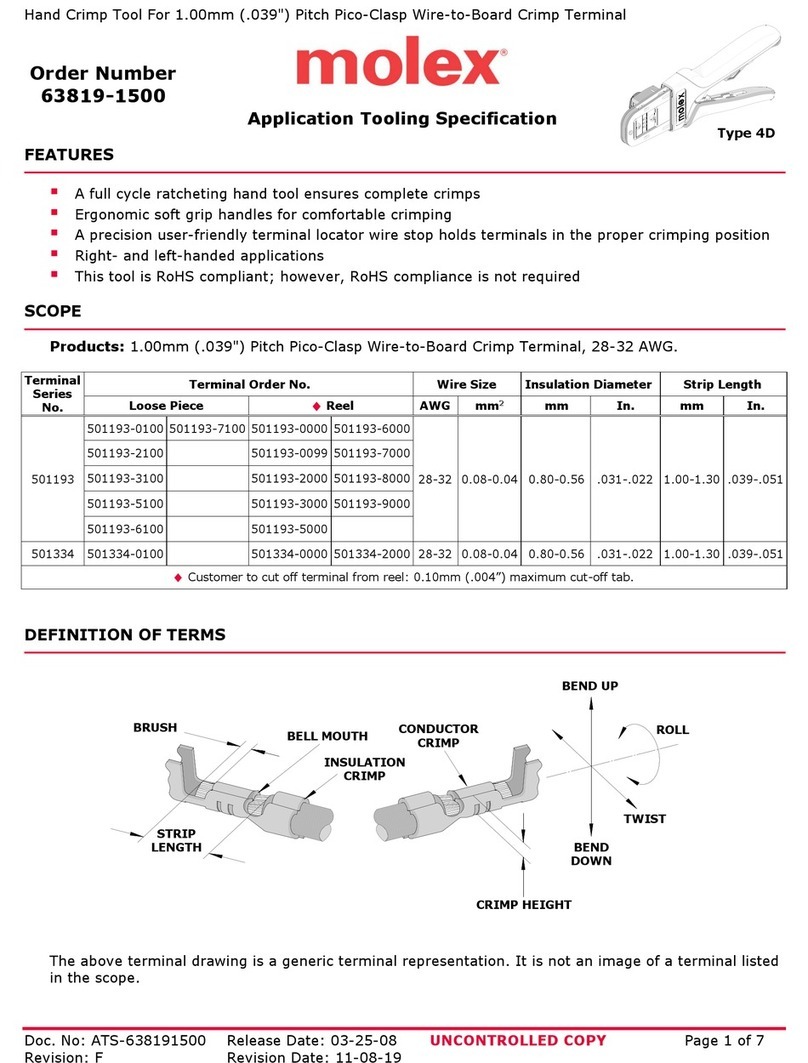

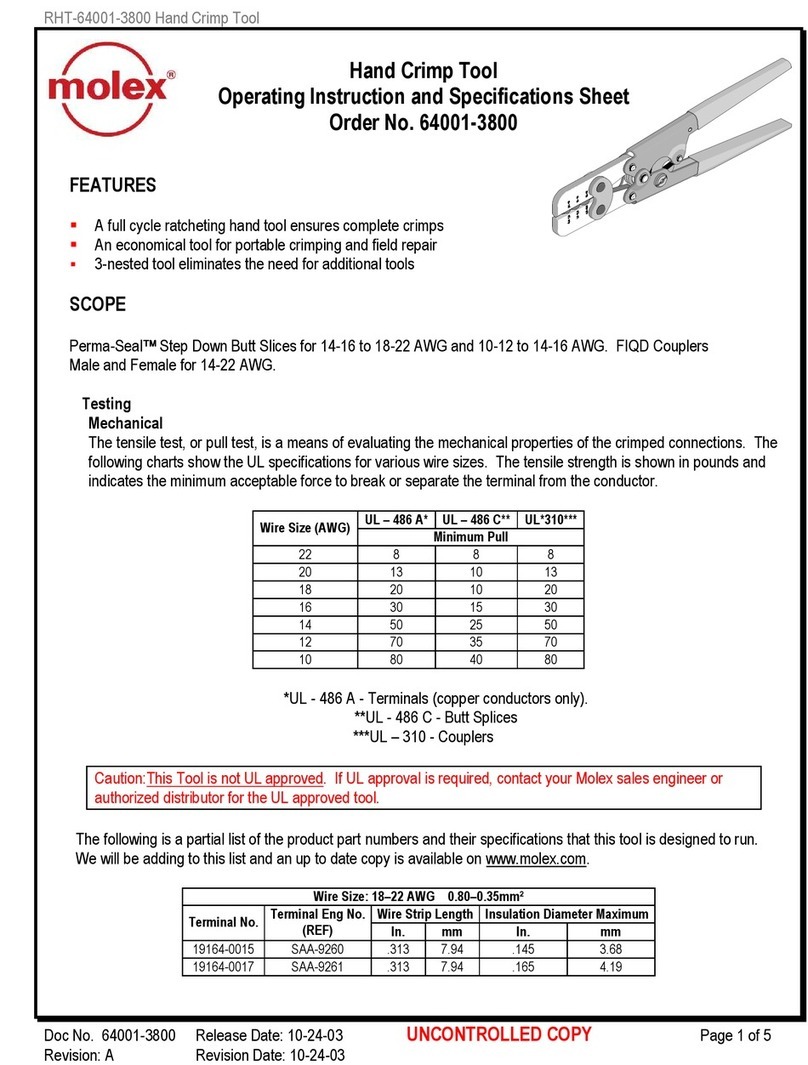

molex 63819-1500 User manual

molex

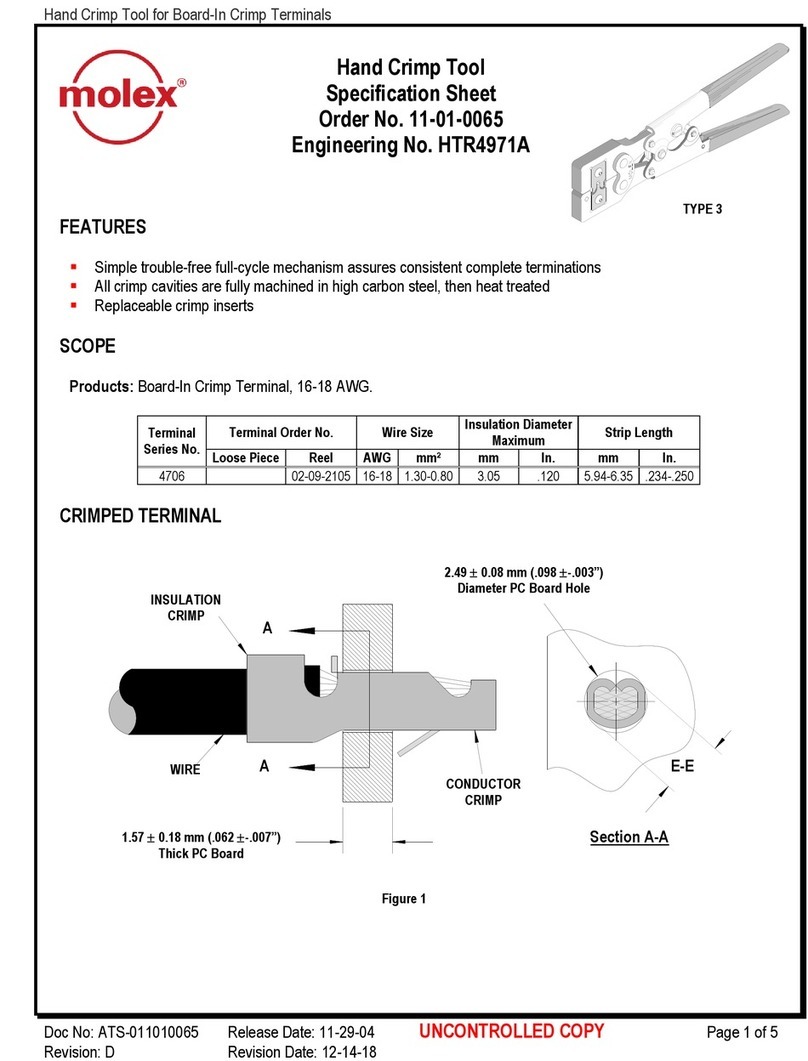

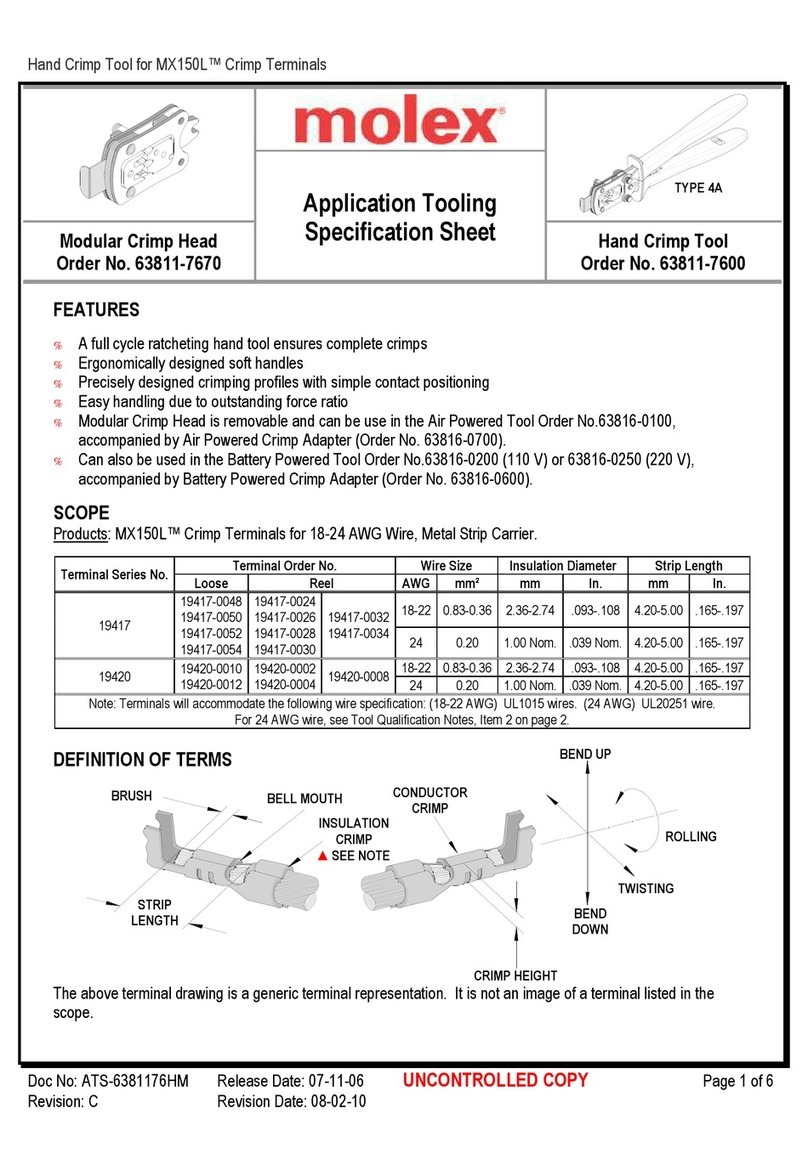

molex 63811-7000 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet