molex 64001-2800 User manual

Other molex Crimping Tools manuals

molex

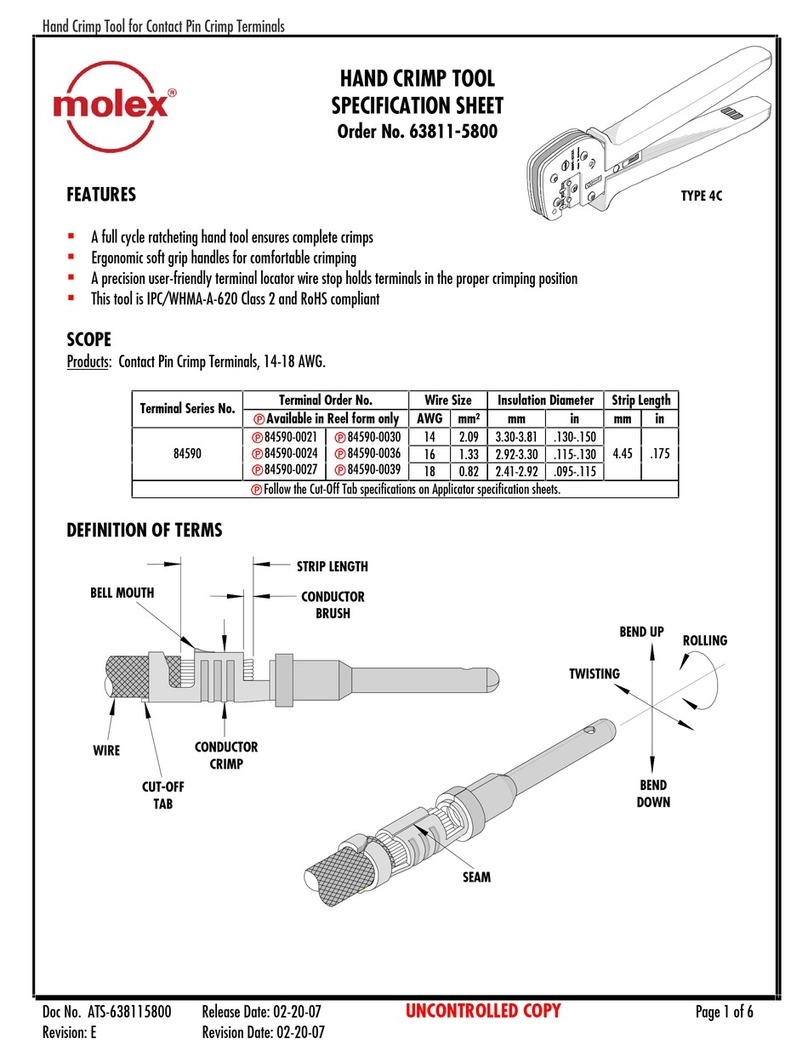

molex 63811-5800 User manual

molex

molex 64001-7300 User manual

molex

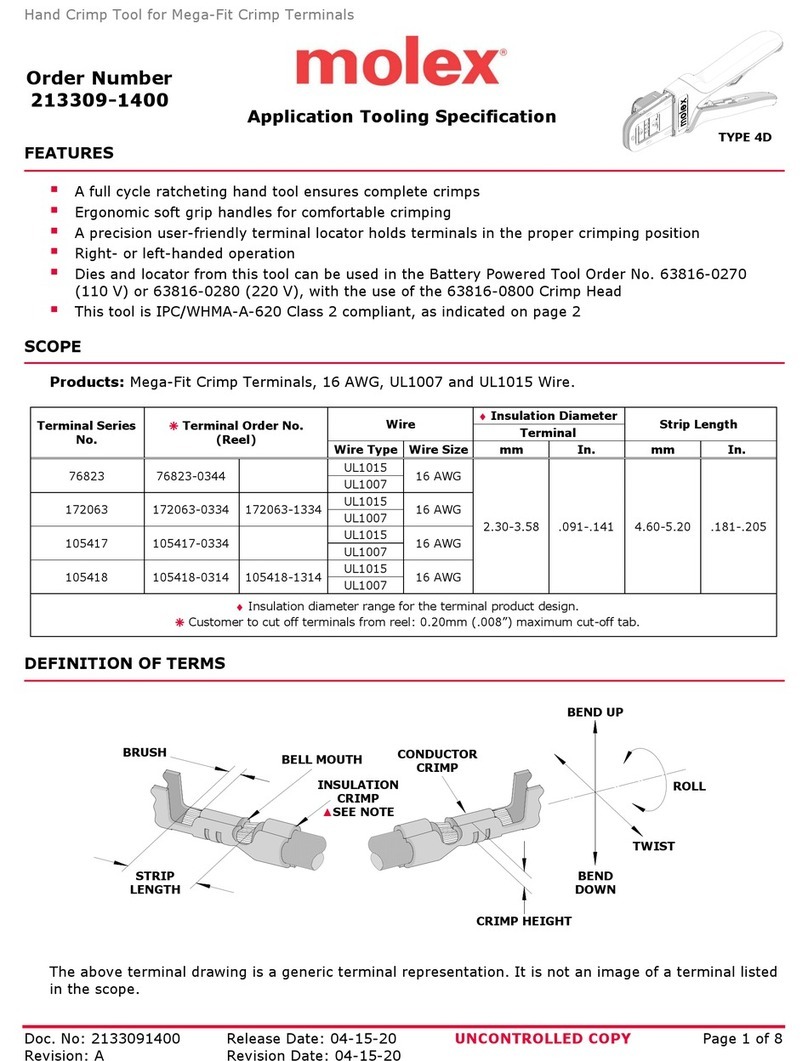

molex 213309-1400 User manual

molex

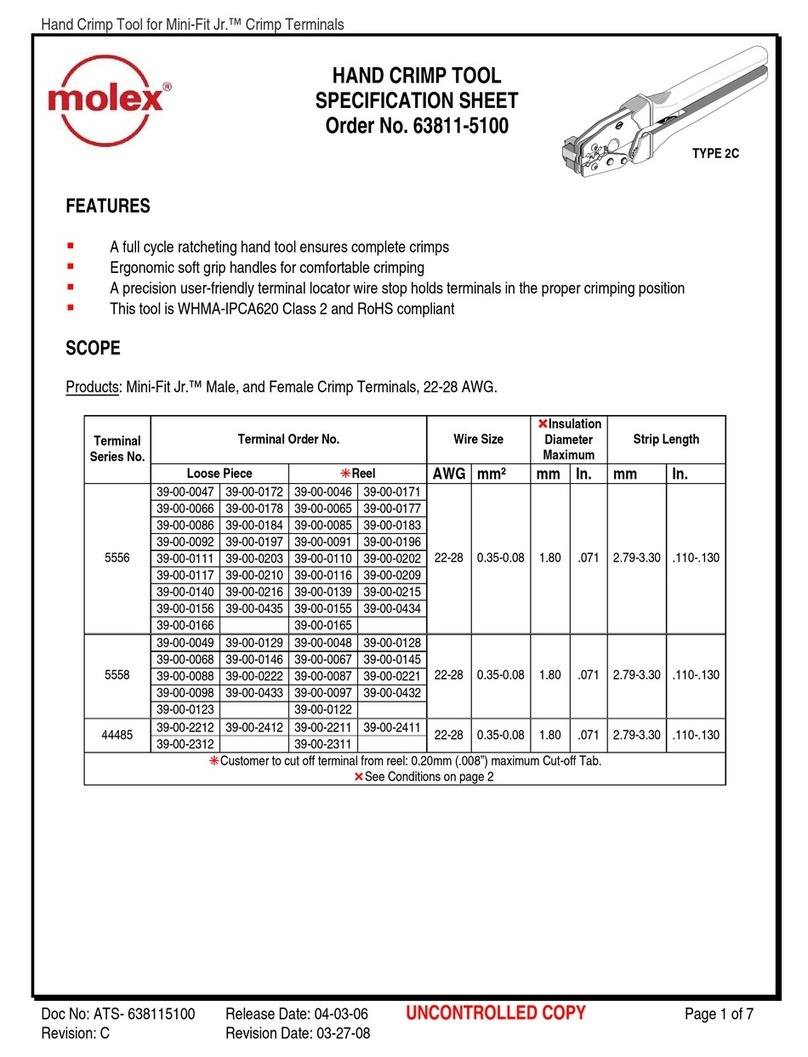

molex 63811-5100 User manual

molex

molex 63811-8100 User manual

molex

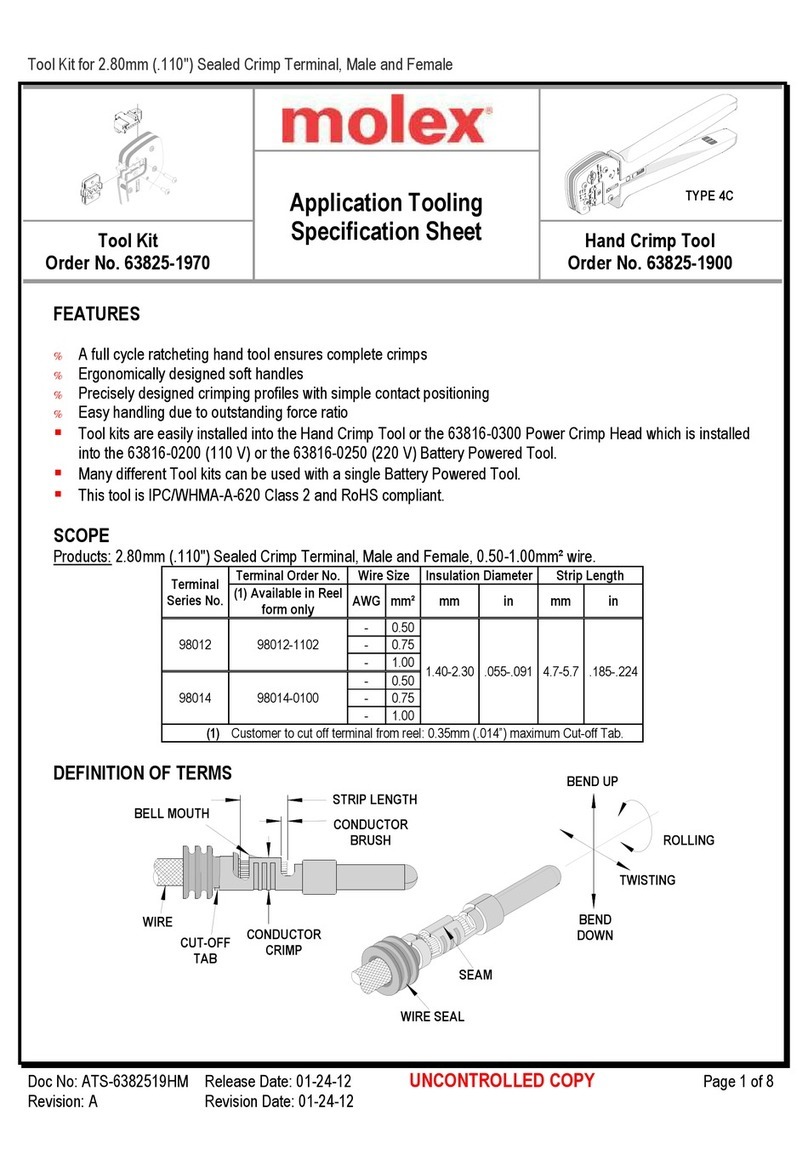

molex 63825-1900 User manual

molex

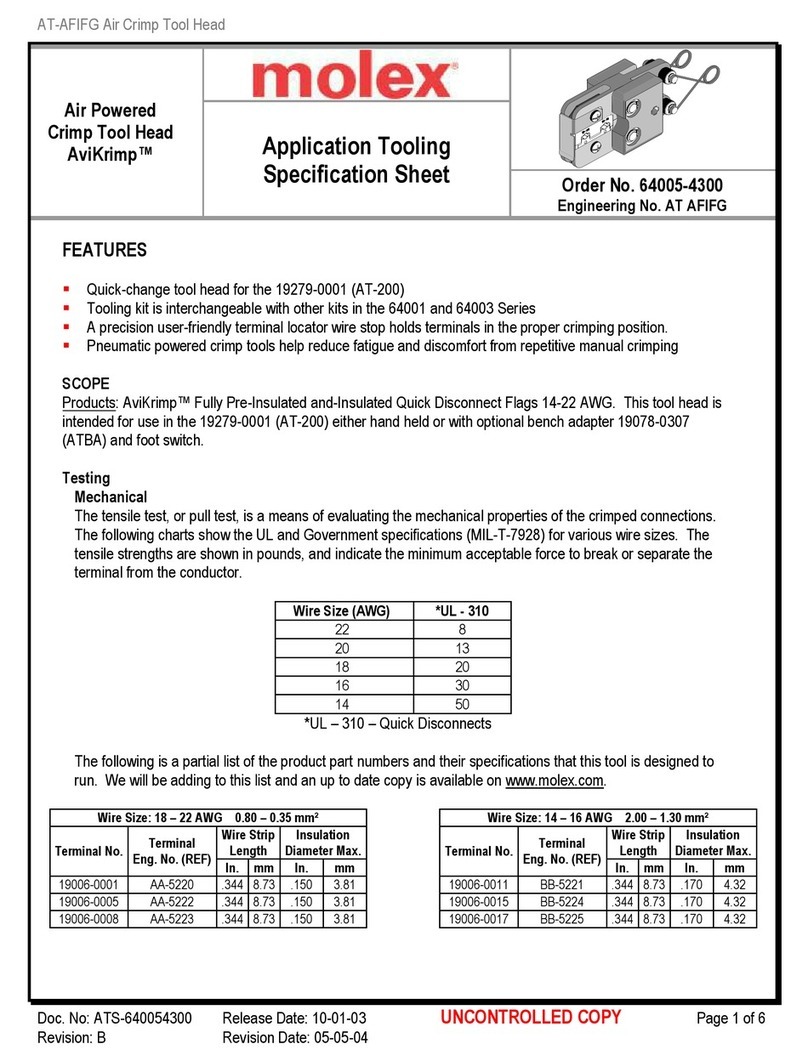

molex AT AFIFG User manual

molex

molex CR5904 User manual

molex

molex 207129 Series User manual

molex

molex 63816-0800 User manual

molex

molex 63825-9400 User guide

molex

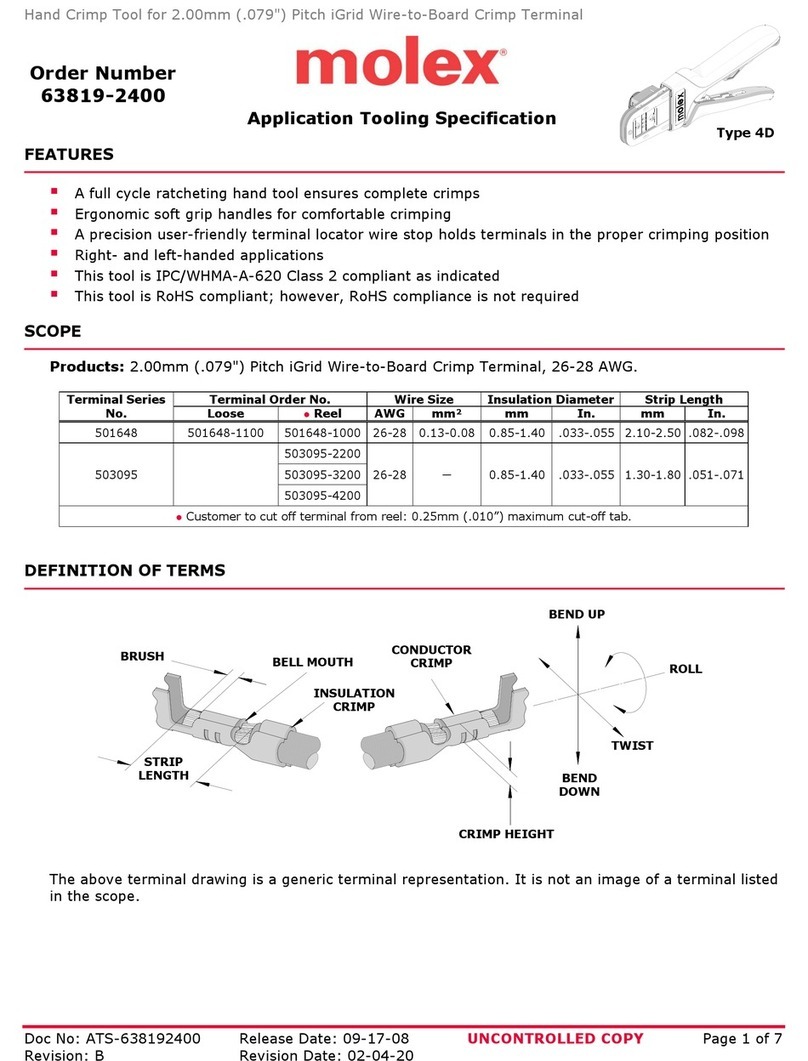

molex 4D User manual

molex

molex 63825-7470 User guide

molex

molex 64005-4100 User manual

molex

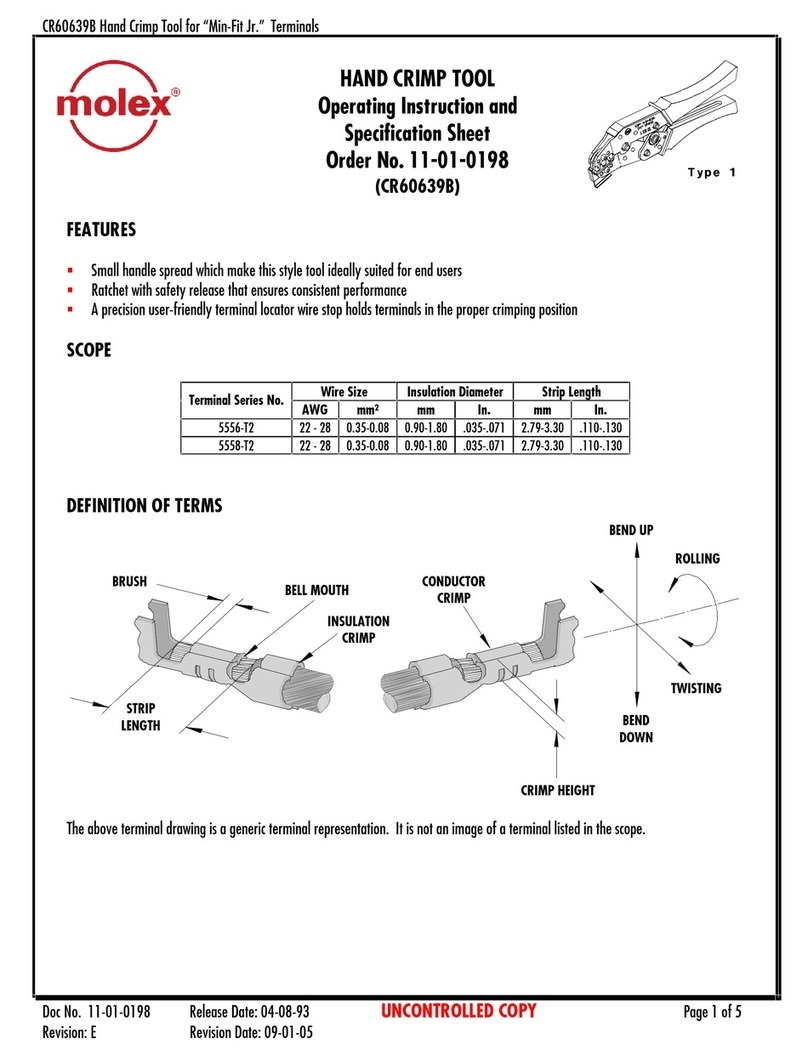

molex CR60639B User manual

molex

molex 63811-5600 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

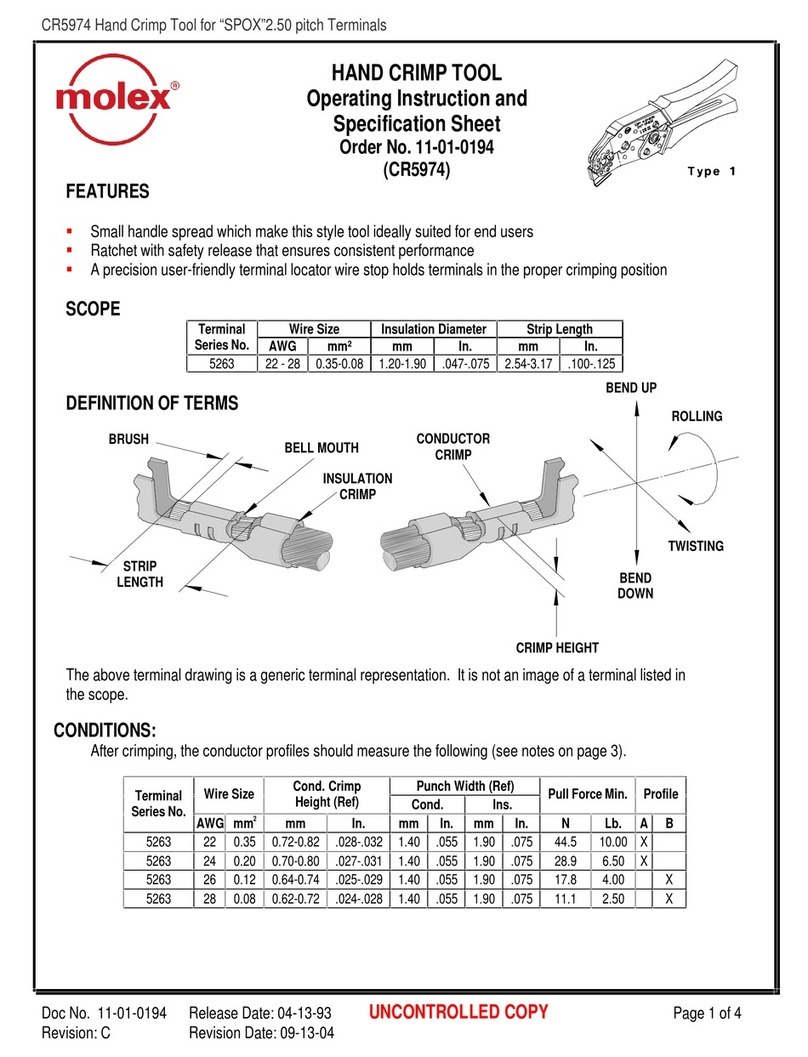

molex CR5974 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet