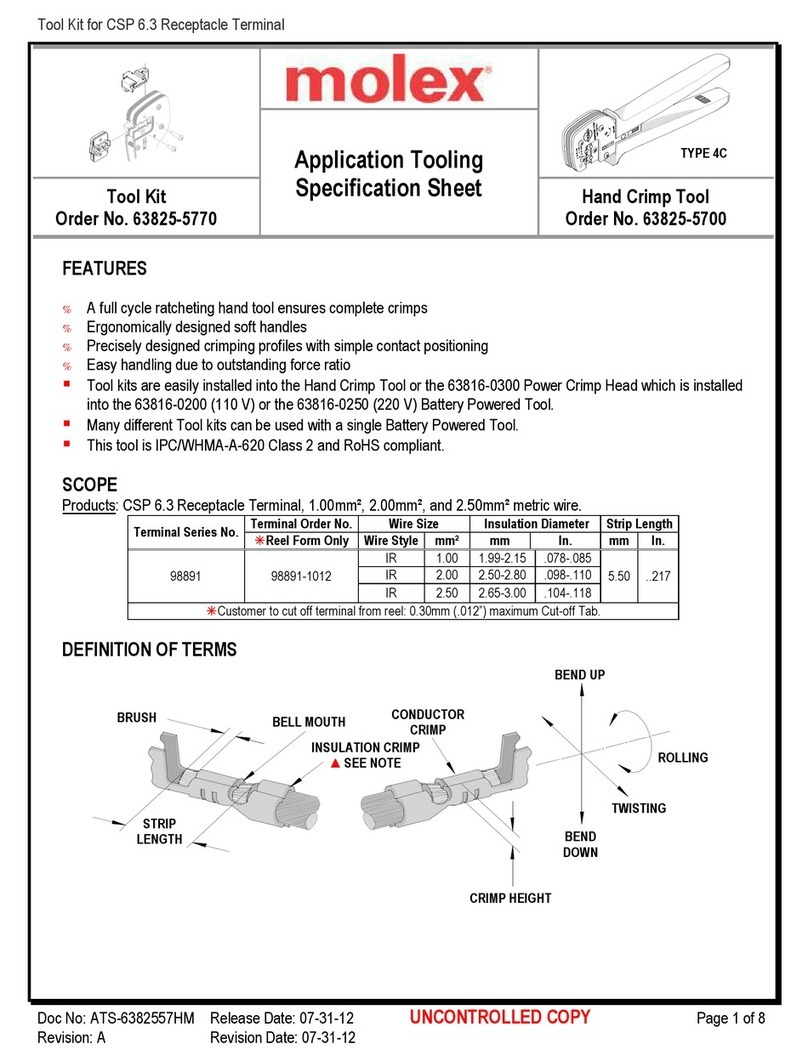

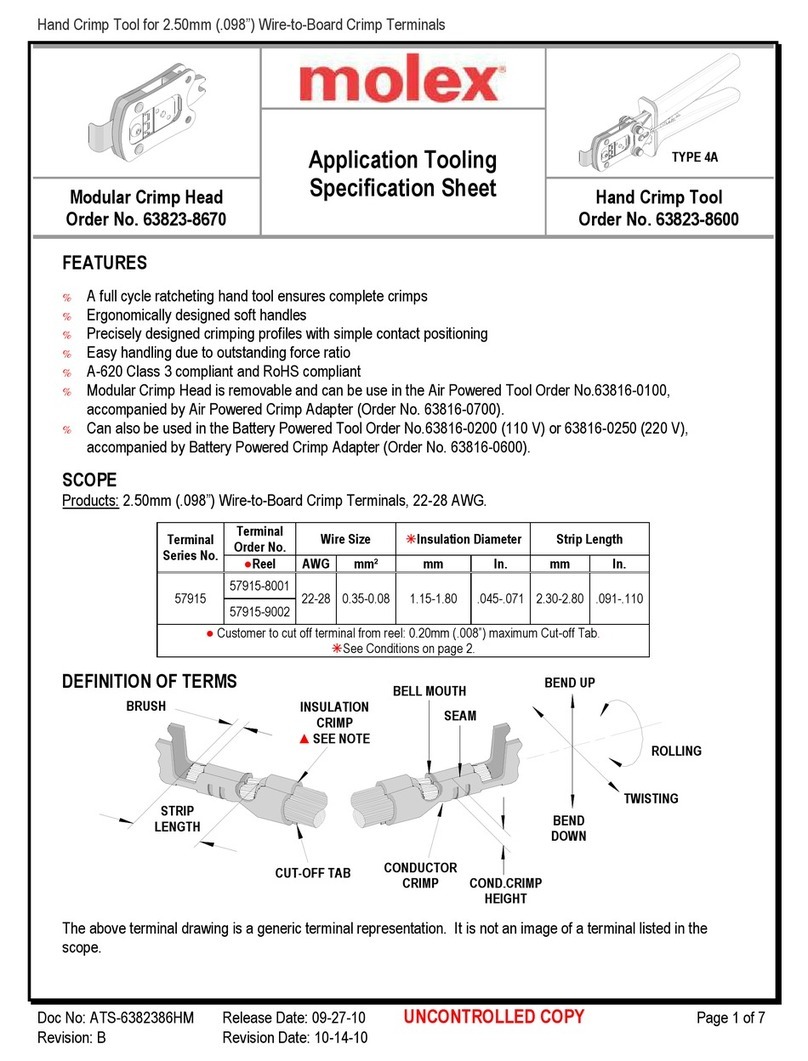

Hand Crimp Tool for 2.00/2.50mm (.079/.098") Board-In Crimp Terminals

Do No: ATS-6381177HM Release Date: 08-29-07 UNCONTROLLED COPY Page 4 of 7

Revision: B Revision Date: 08-02-10

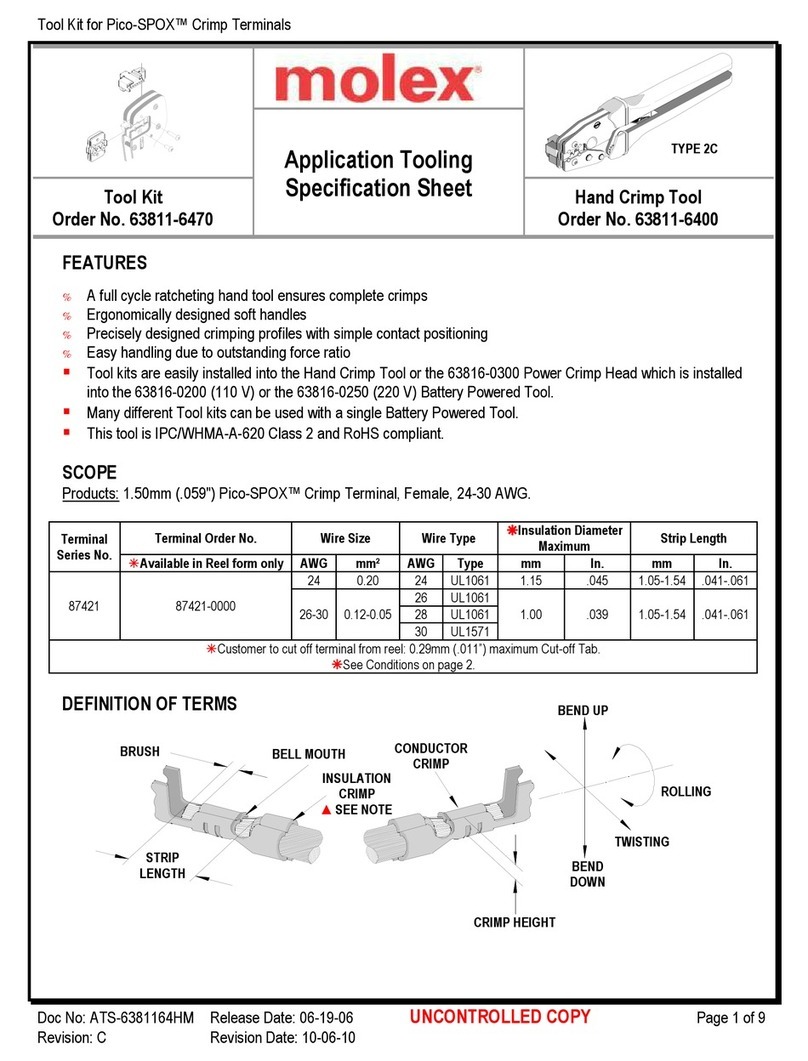

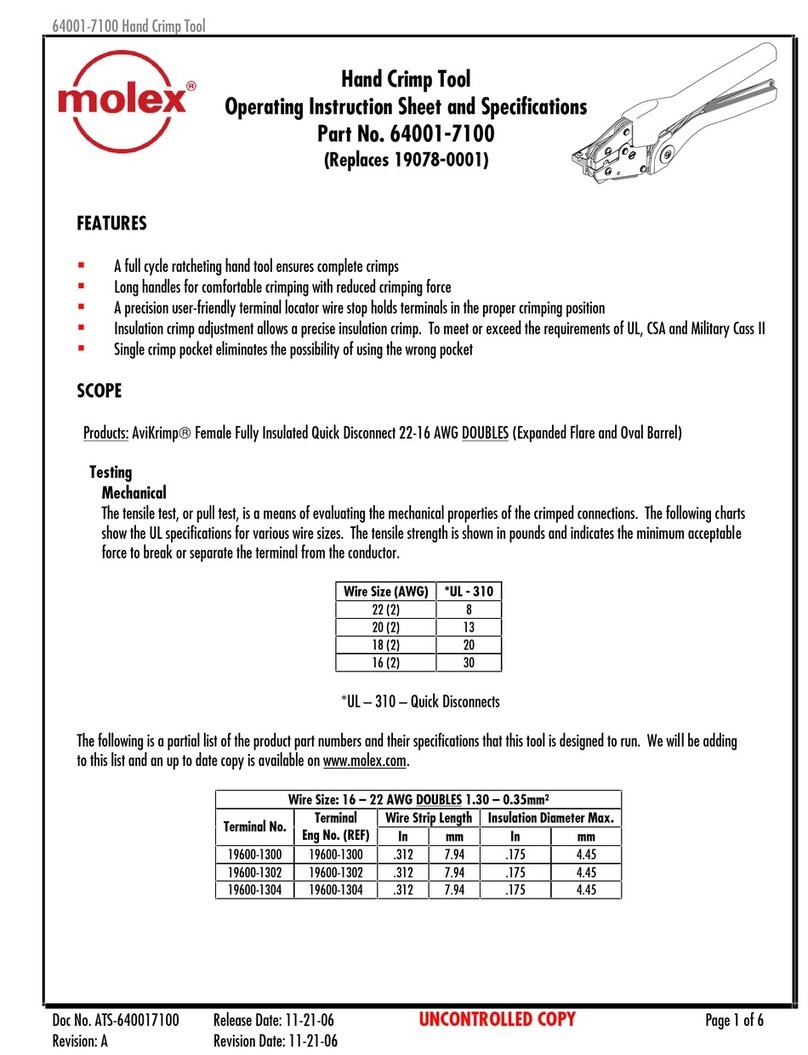

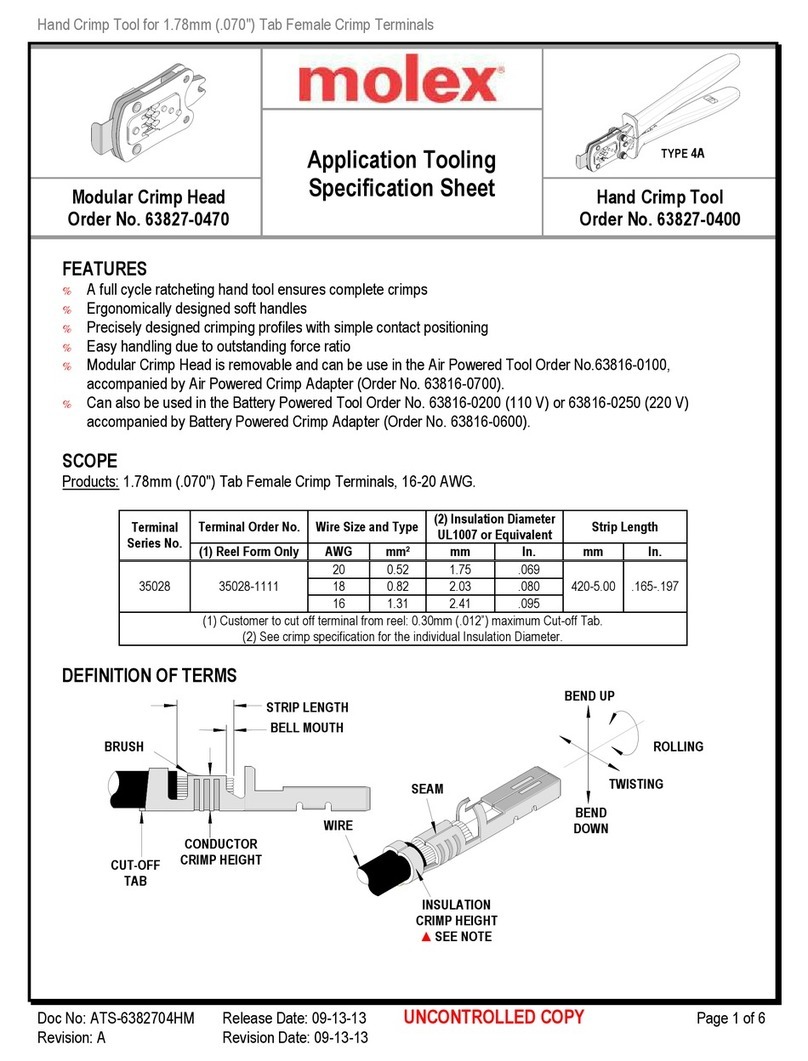

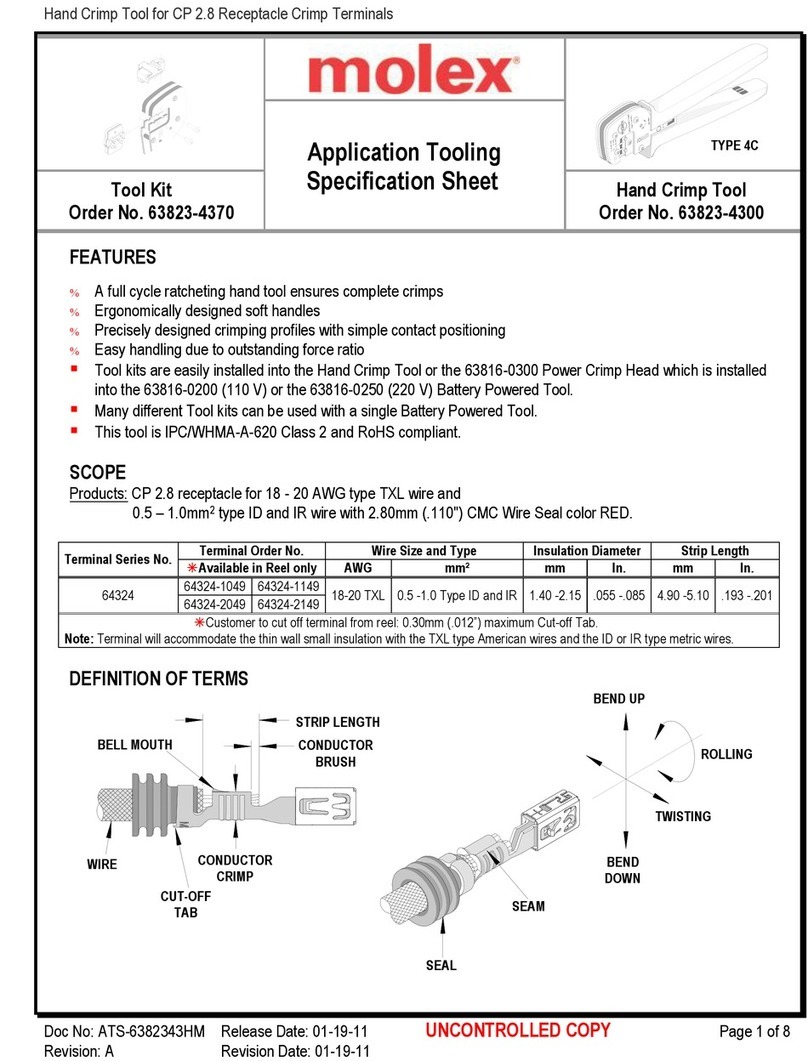

INCORRECT

Figure 5

CORRECT INCORRECT

Terminal Locator Replacement/Change Over

This se tion des ribes the pro edure for hanging lo ators.

Removal

1. With the tool in the open position, pivot the terminal lo ator outward.

2. Remove the M4 BHCS. See Figure 4.

Installation

1. Pla e the proper lo ator, (See Chart on page 2), on the hand tool.

Install the M4 BHCS. See Figure 4.

2. Tighten the s rew enough to hold the lo ator. Make sure the lo ator

an still float freely with hand pressure.

3. Insert the proper terminal fully into the orre t profile slot until the

terminal is fully seated and stops. Then gently pivot the lo ator

losed.

4. With hand pressure, slowly slide the lo ator to the orre t position. See Figure 5.

5. Gently pivot the lo ator open without disturbing the lo ation.

6. Hold the lo ator firmly in pla e and slowly tighten the M4 BHCS.

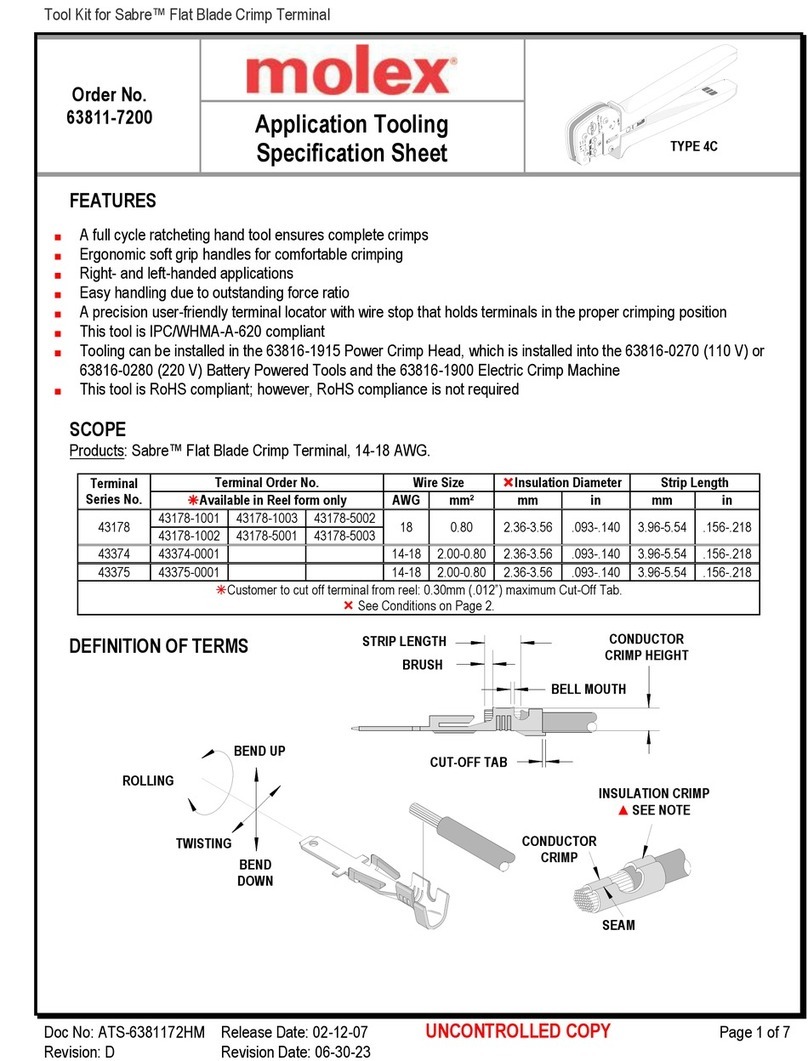

Maintenance

It is re ommended that ea h operator of the tool be made

aware of, and responsible for, the following maintenan e

steps:

1. Remove dust, moisture, and other ontaminants with a

lean brush, or soft, lint free loth.

2. Do not use any abrasive materials that ould damage the

tool.

3. Make ertain all pins; pivot points and bearing surfa es

are prote ted with a thin oat of high quality ma hine oil.

Do not oil ex essively. The tool was engineered for

durability but like any other equipment it needs leaning and lubri ation for a maximum servi e life of trouble

free rimping. Light oil (su h as 30 weight automotive oil) used at the oil points, every 5,000 rimps or 3

months, will signifi antly enhan e the tool life.

4. Wipe ex ess oil from hand tool, parti ularly from rimping area. Oil transferred from the rimping area onto

ertain terminations may affe t the ele tri al hara teristi s of an appli ation.

5. When tool is not in use, keep the handles losed to prevent obje ts from be oming lodged in the rimping dies,

and store the tool in a lean, dry area.

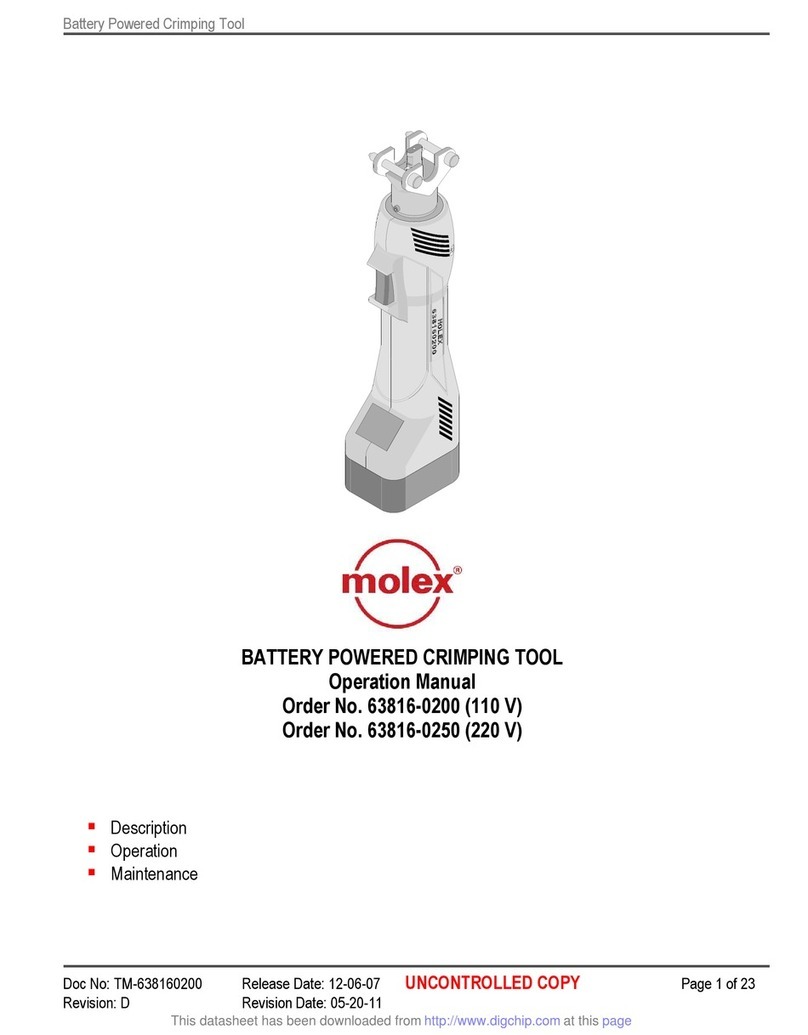

Miscrimps or Jams

Should this tool ever be ome stu k or jammed in a partially losed position, Do Not for e the handles open or

losed. The tool will open easily by lifting the rat het release lever. See Figure 9.

Warranty

This tool is for ele tri al terminal rimping purposes only. This tool is made of the best quality materials. All vital

omponents are long life tested. All tools are warranted to be free of manufa turing defe ts for a period of 30

days. Should su h a defe t o ur, we will repair or ex hange the tool free of harge. This repair or ex hange will

M4 BHCS

Figure 4