QualityCrimpHandbook

OrderNo63800-0029 ReleaseDate:09-04-03 UNCONTROLLED COPY Page7of24

Revision:B RevisionDate:10-07-05

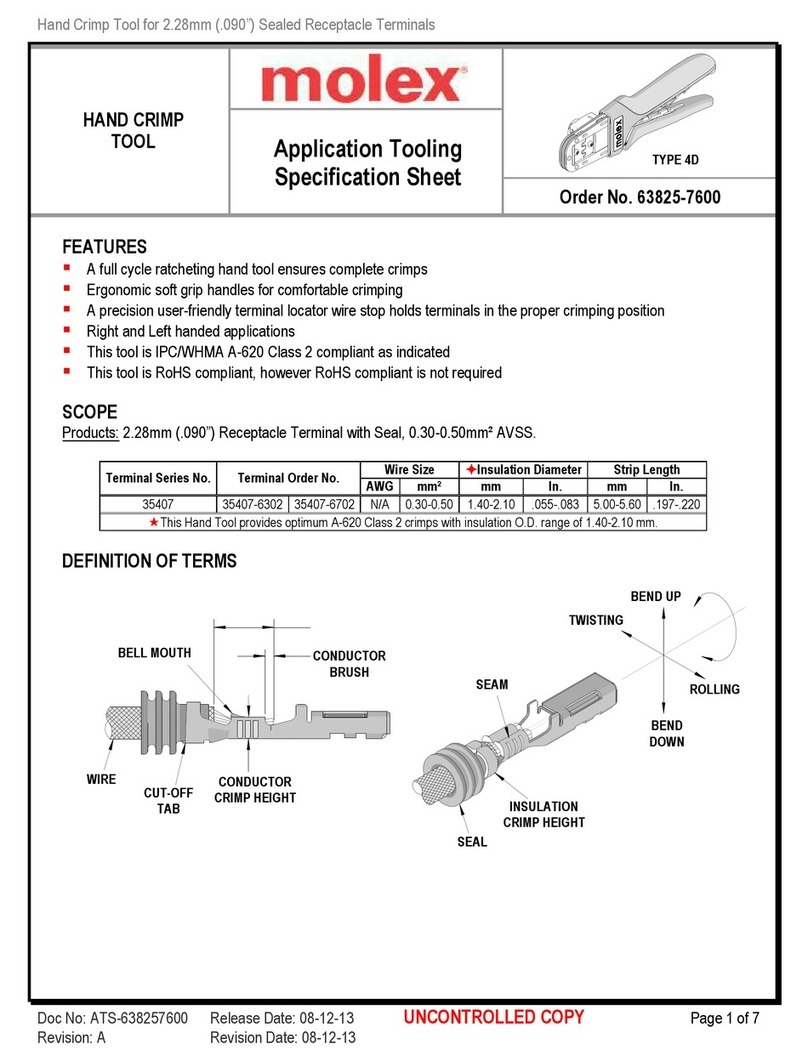

Figure 4-2

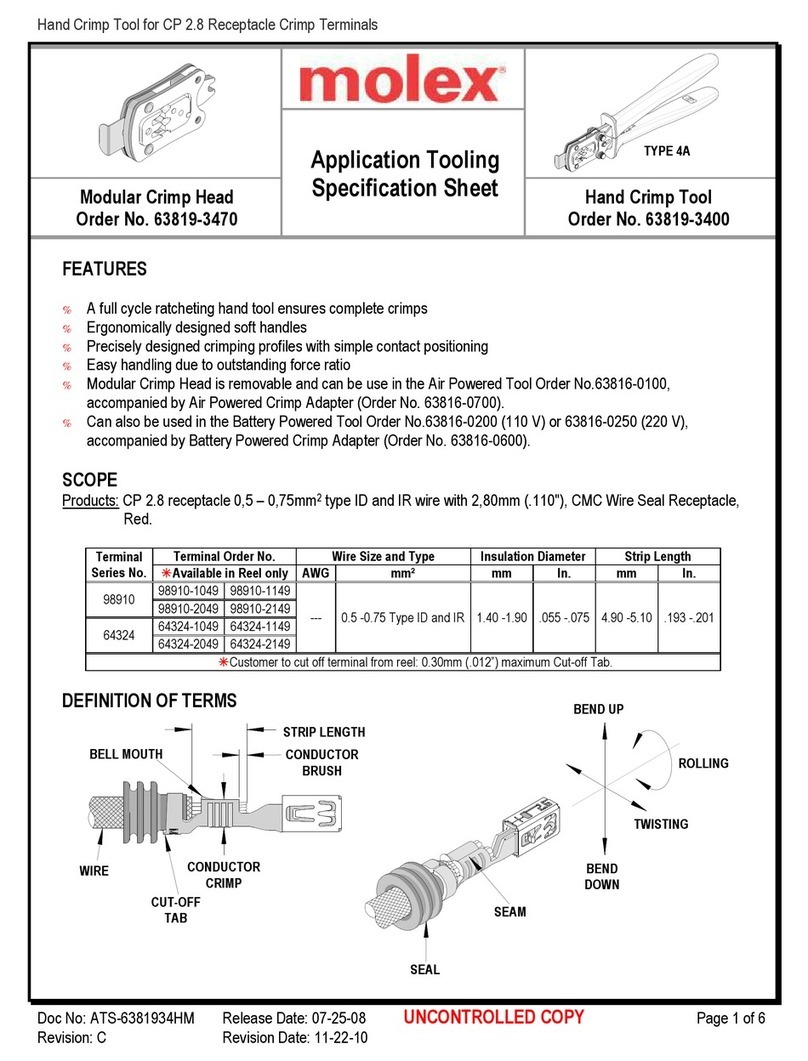

§Cut-off Tab Length

Thismaterialprotrudesoutsidetheinsulationcrimpafter

theterminal is separated fromthecarrier strip. As a rule,

thecut-offtabisapproximately1.0to1.5timesterminal

materialthickness. * Acut-off tabthatistoolong may

exposeaterminaloutsidethehousingorit mayfail

electricalspacingrequirements.In mostsituations,a toolis

setuptoprovideacut-offtabthatisflushto onematerial

thickness.

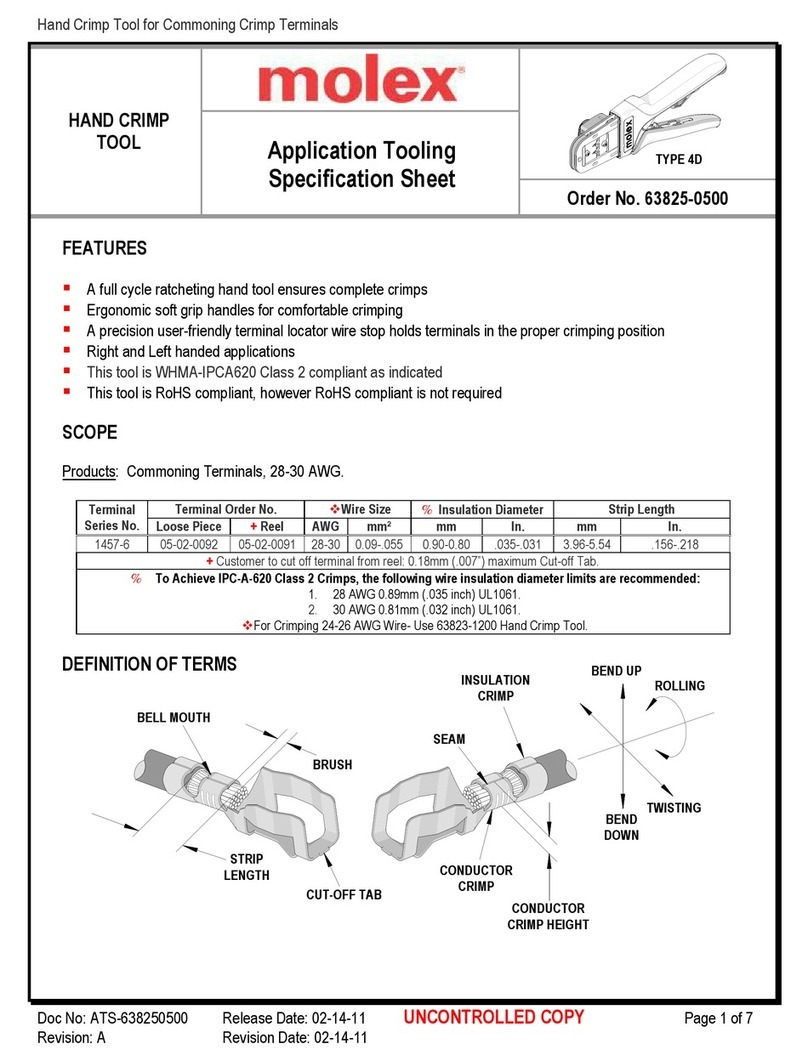

§Extrusions (Flash)

Thesearethesmallflaresthatformonthebottomofthe

conductorcrimpresultingfromtheclearance betweenthe

punchandanviltooling.Iftheanviliswornortheterminal

isover-crimped,excessiveextrusionresults. Anuneven

extrusionmay alsoresult ifthe punch andanvil alignment

isnotcorrect,ifthefeedadjustmentisofforifthereis

insufficient/excessiveterminaldrag.

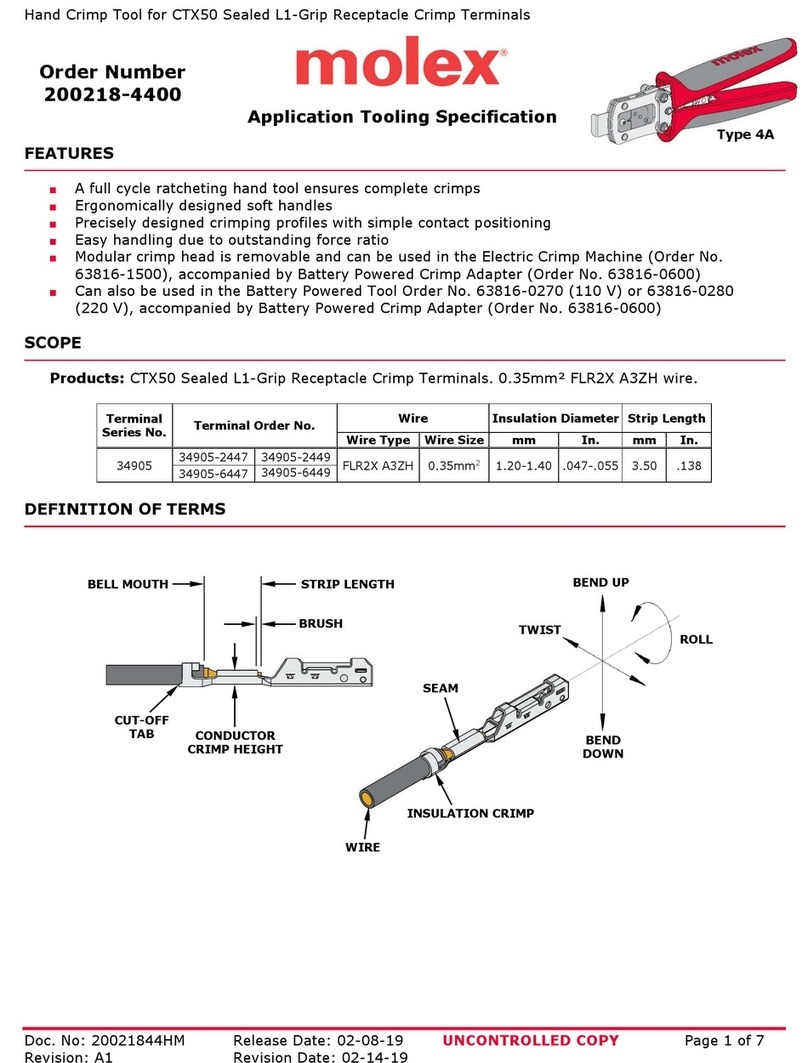

§Insulation Crimp (Strain Relief)

Thisisthepartoftheterminalthat providesbothwire

supportforinsertioninto thehousingand allowsthe

terminaltowithstandshockandvibration. Theterminal

needstoholdthewireasfirmlyaspossiblewithoutcutting

throughtotheconductorstrands. Theacceptabilityofan

insulationcrimpissubjectiveanddepends onthe

application. Abend testisrecommended todetermine

whetherornotthestrainreliefisacceptableforeach

particularapplication.

§Insulation Crimp Height

Molexdoes notspecify insulation crimpheights because of

thewidevarietyofinsulationthickness, material,and

hardness. Mostterminalsaredesignedtoaccommodate

multiplewire ranges. Withintheterminal’s range,the

strainreliefmaynot completelysurroundthewireorfully

surroundthediameterofthewire. Thisconditionwill still

provideanacceptable insulationcrimpformost

applications.

§Alargestrainrelief shouldfirmlygrip atleast88% of

thewire.

§Asmallerstrainreliefshouldfirmlygripat least50%of

thewireandfirmlyholdthetopofthewire.

Toevaluatetheinsulationcrimpsection,cutthewireflushwith

thebackoftheterminal. Oncethe optimum settingforthe

applicationisdetermined,itisimportanttodocumentthe

insulationcrimpheight. Then,as partof thesetup procedure,

theoperatorcancheckthecrimpheight.

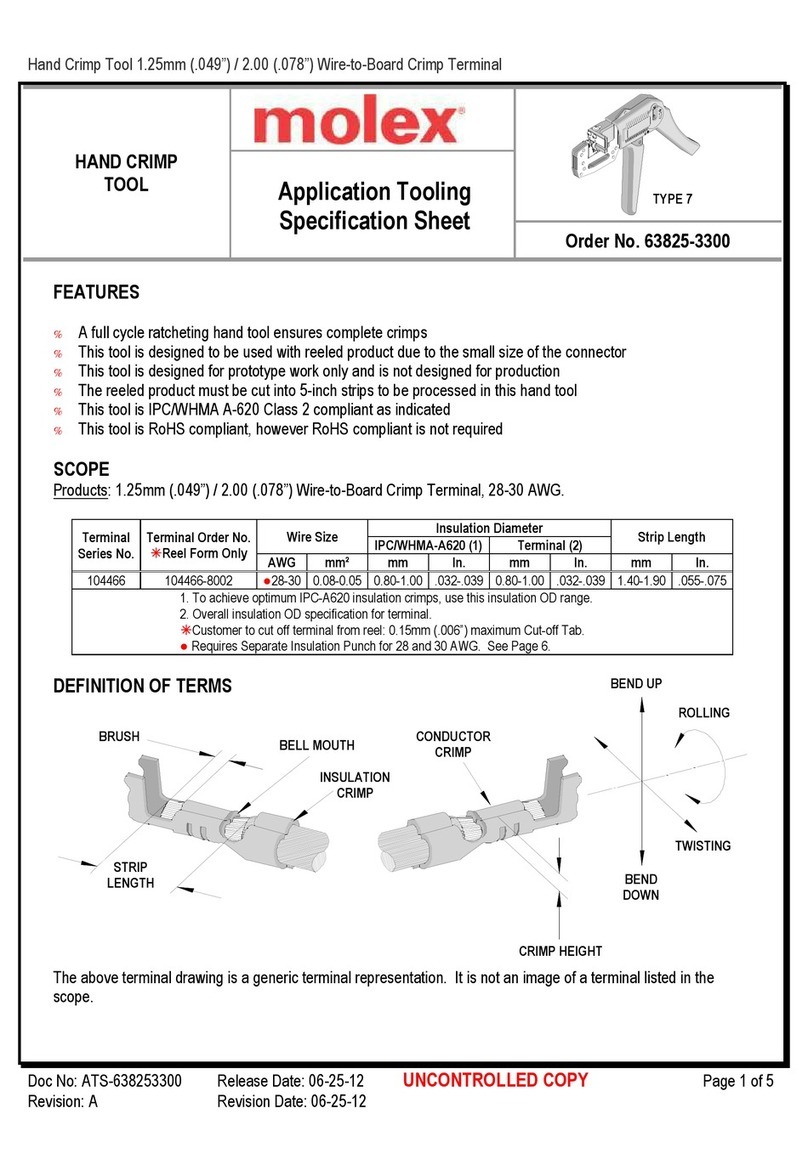

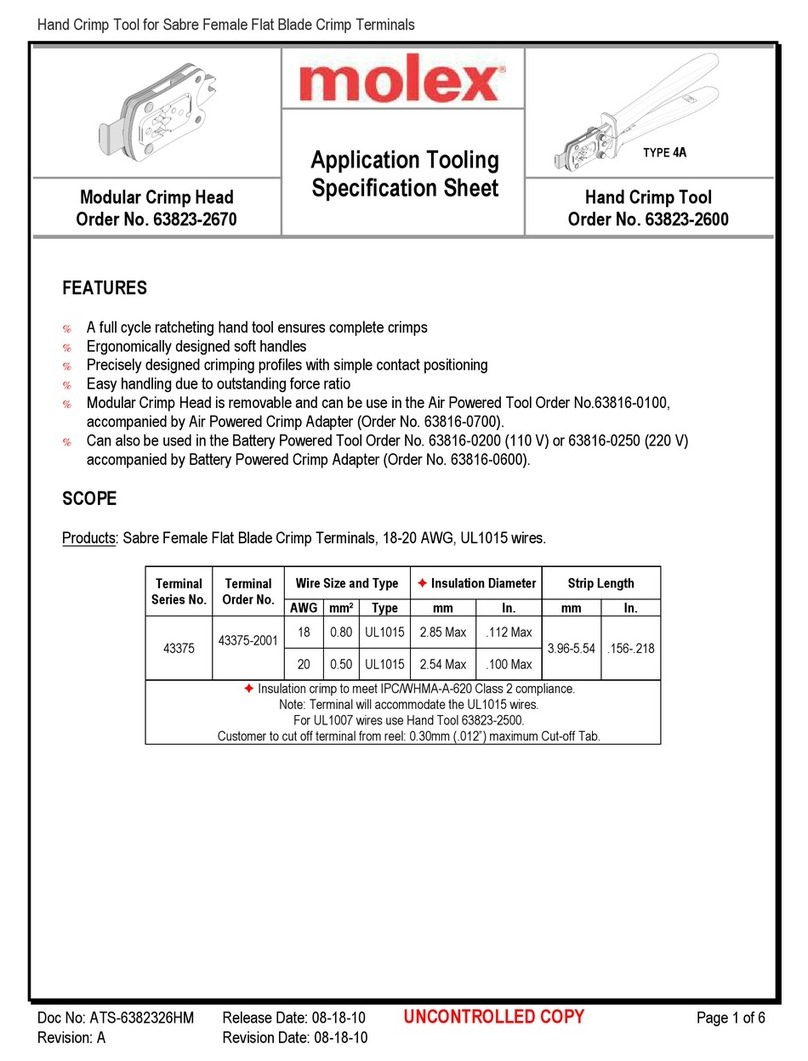

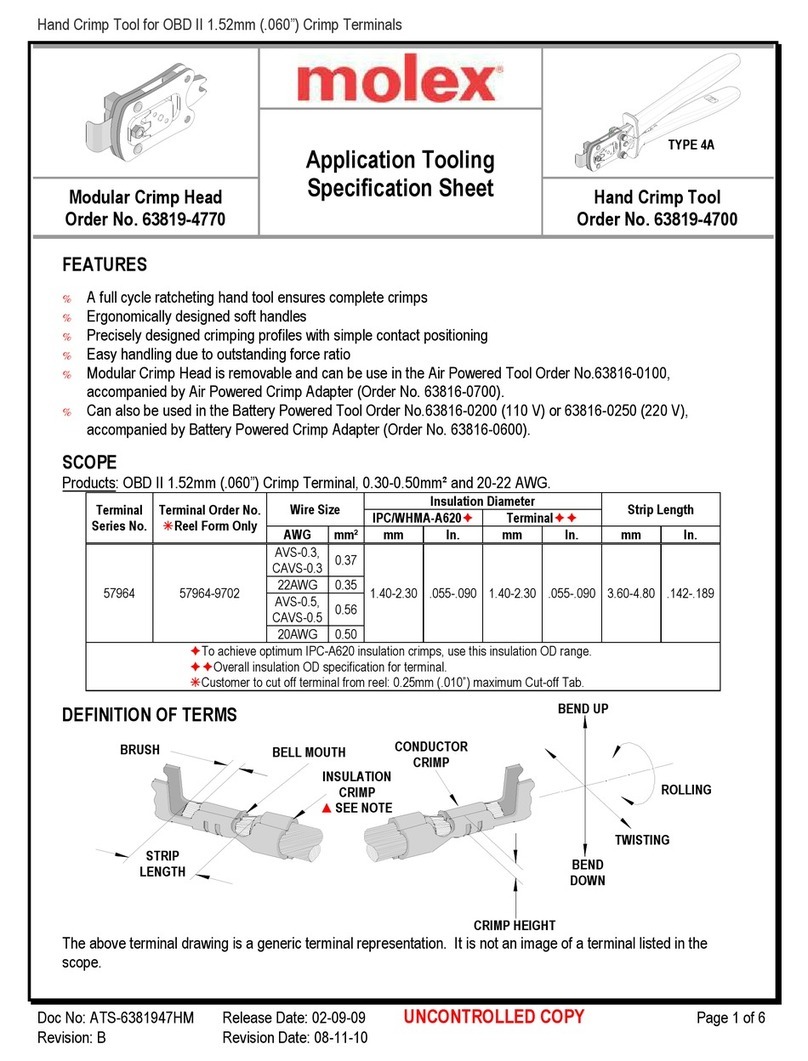

§Insulation Position

Thisisthelocationoftheinsulationin relationto the

transitionareabetweentheconductorandinsulationcrimps.

Equalamountsoftheconductorstrandsandinsulationneeds

tobevisibleinthetransitionarea. Theinsulation position

ensuresthatthe insulationiscrimpedalongthefulllengthof

theinsulation crimp,and thatno insulation iscrimped under

theconductorcrimp. Theinsulationpositionissetbythewire

stopandstriplength forbenchapplications. Forautomatic

wireprocessingapplications,theinsulationpositionis set by

thein/outpressadjustment.

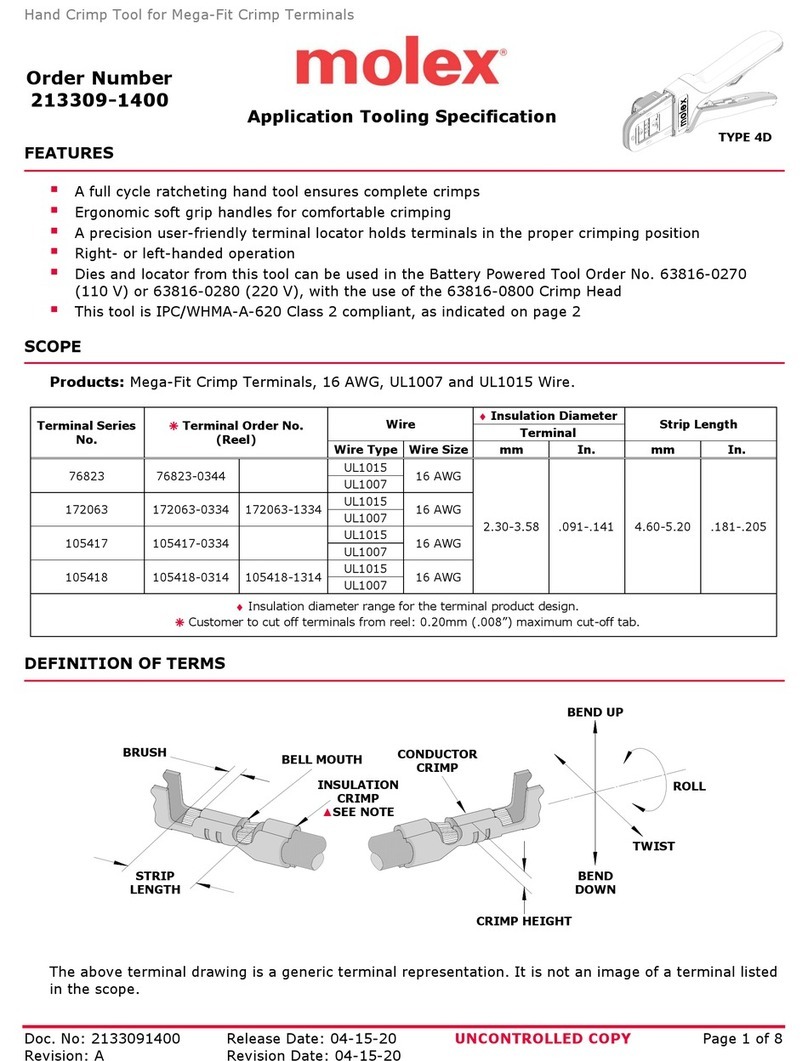

§Strip Length

Thestriplengthisdeterminedbymeasuringtheexposed

conductorstrandsafterthe insulationisremoved. Thestrip

lengthdeterminestheconductorbrushlength whenthe

insulationpositionis centered.

*Consultindividualterminalspecificationrequirements