molex MV-396 User guide

Other molex Crimping Tools manuals

molex

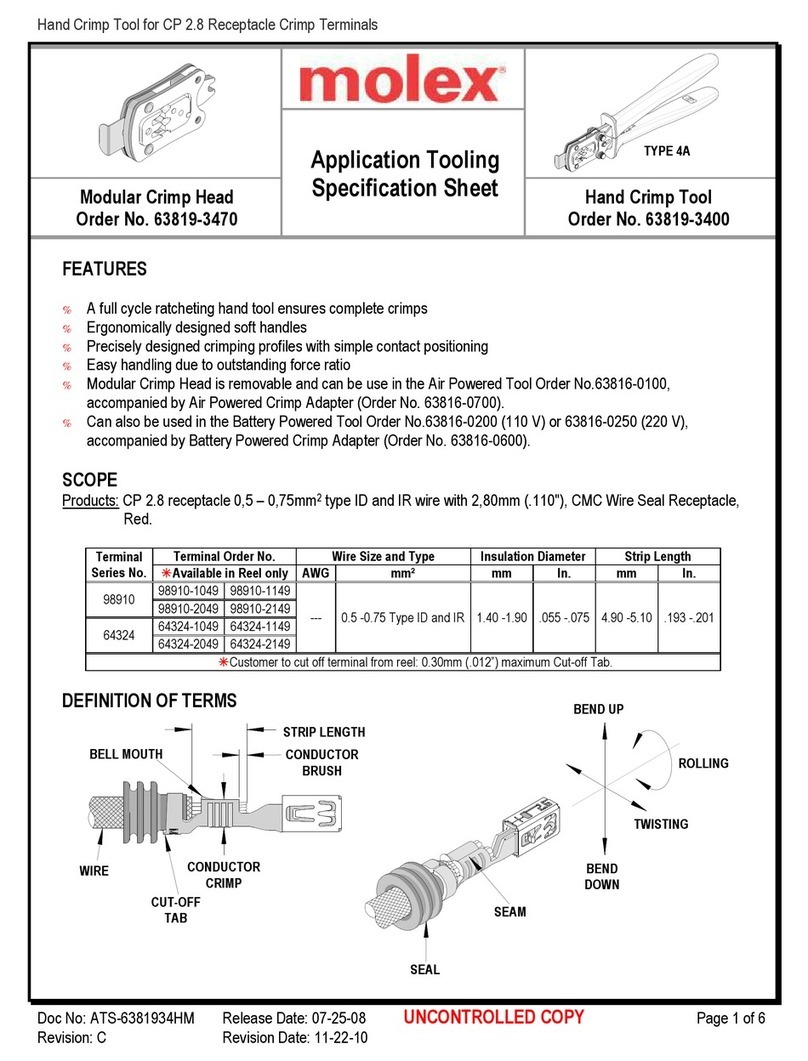

molex 63819-3500 User manual

molex

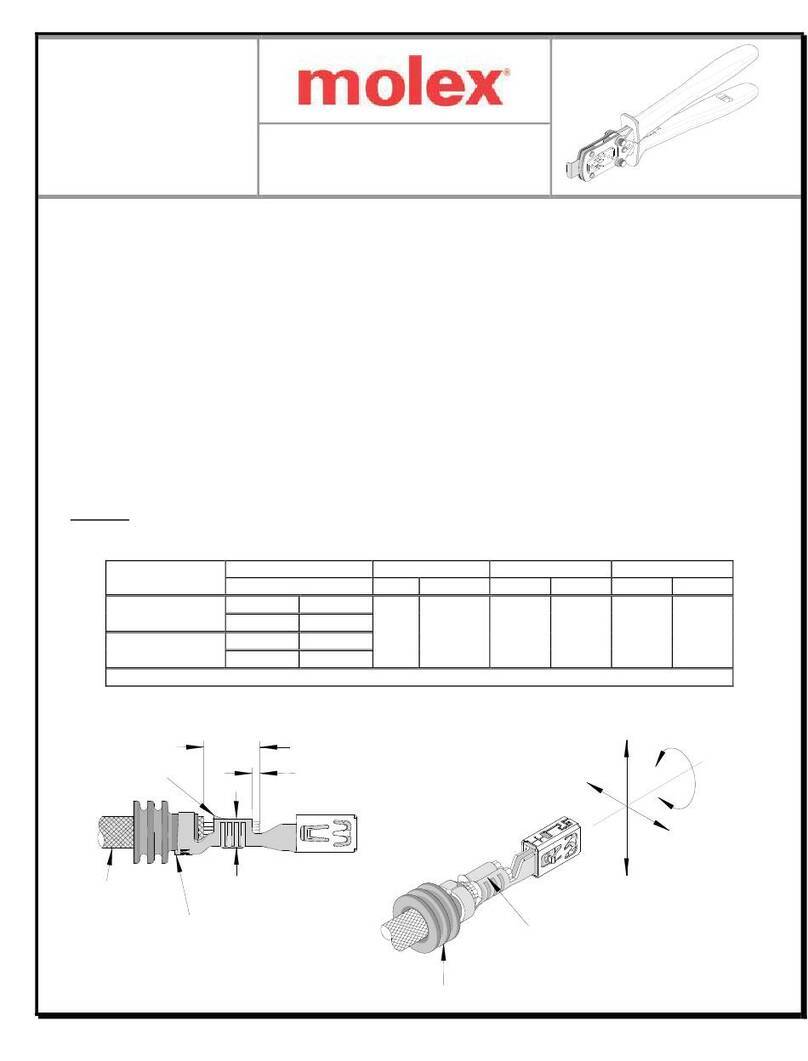

molex 63825-0500 User manual

molex

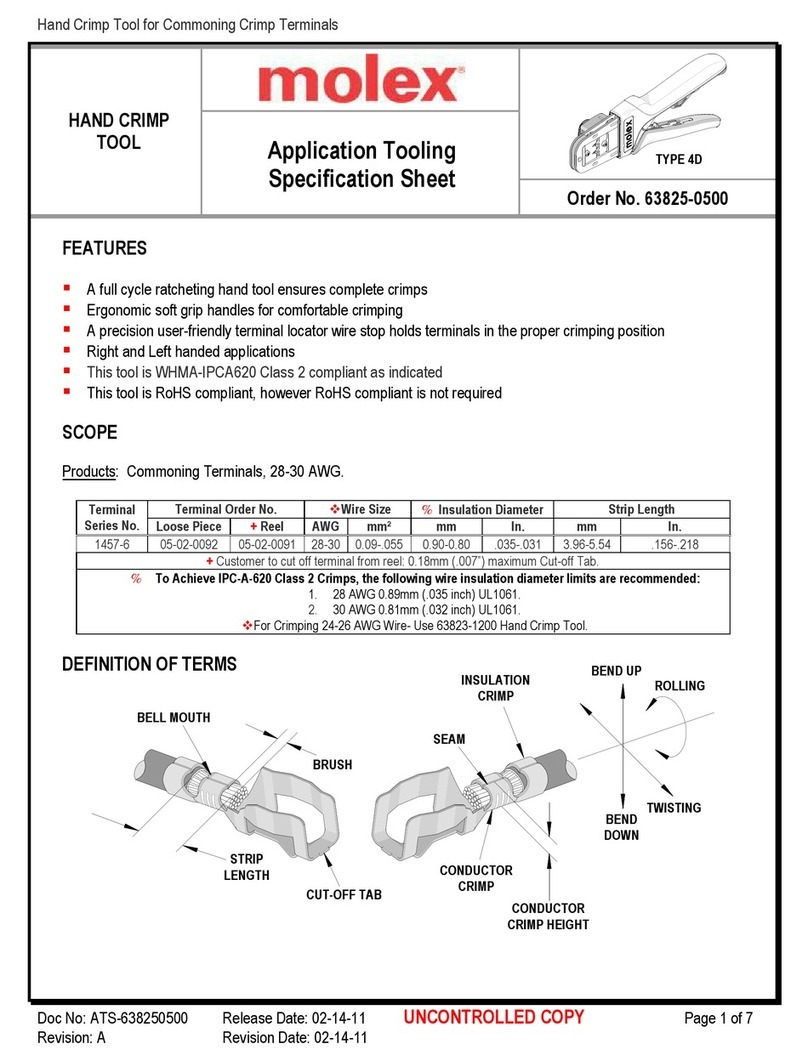

molex 63823-7570 User manual

molex

molex 207129 Series User manual

molex

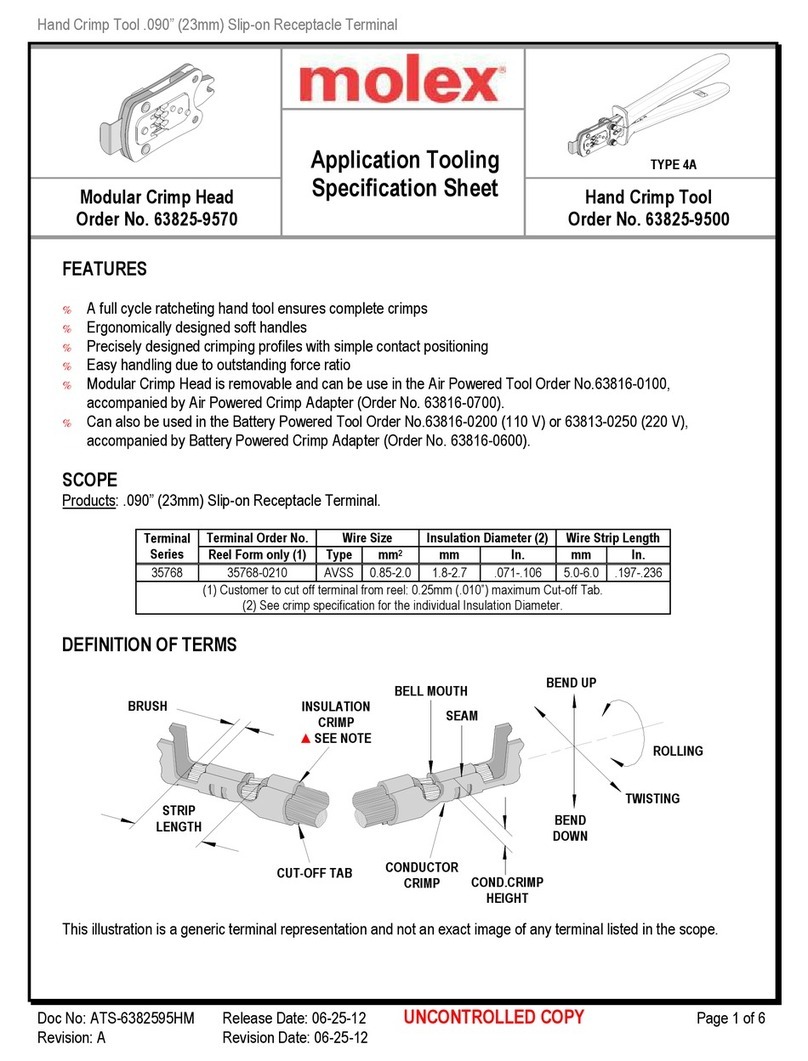

molex 63825-9570 User manual

molex

molex 64001-2800 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 63816-1000 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 63823-5200 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 64005-4100 User manual

molex

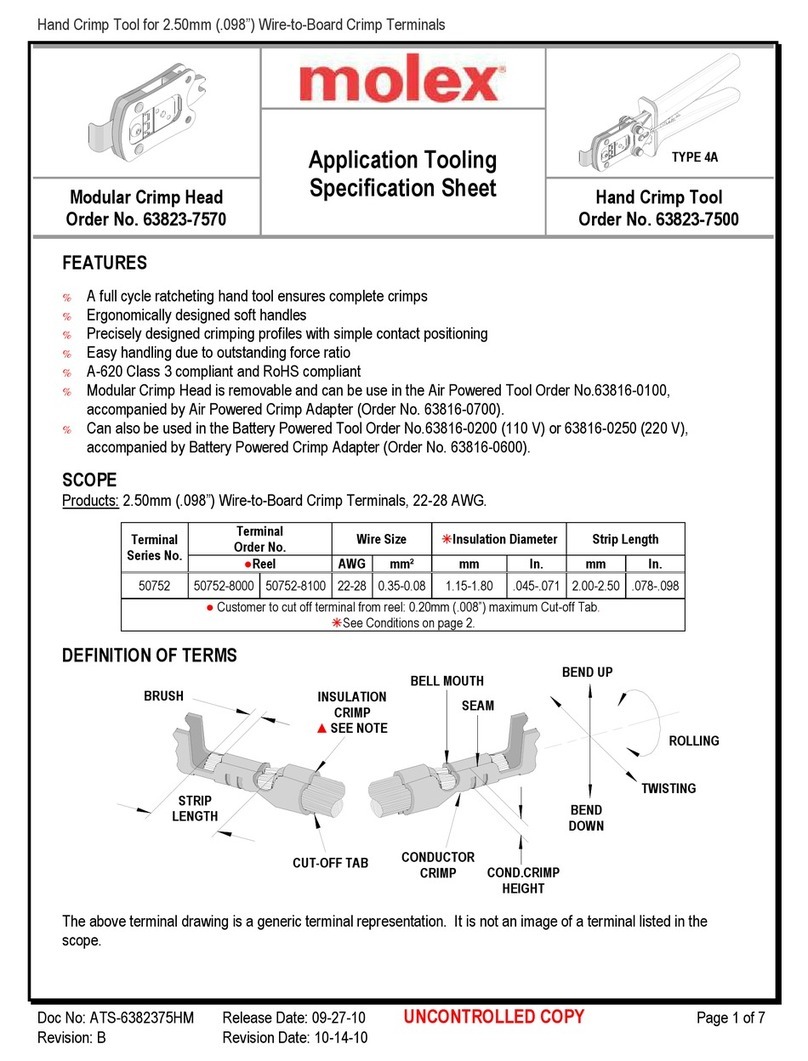

molex 63811-6800 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet