molex 64005-4100 User manual

Other molex Crimping Tools manuals

molex

molex RHT-5771 User manual

molex

molex 207129 Series User manual

molex

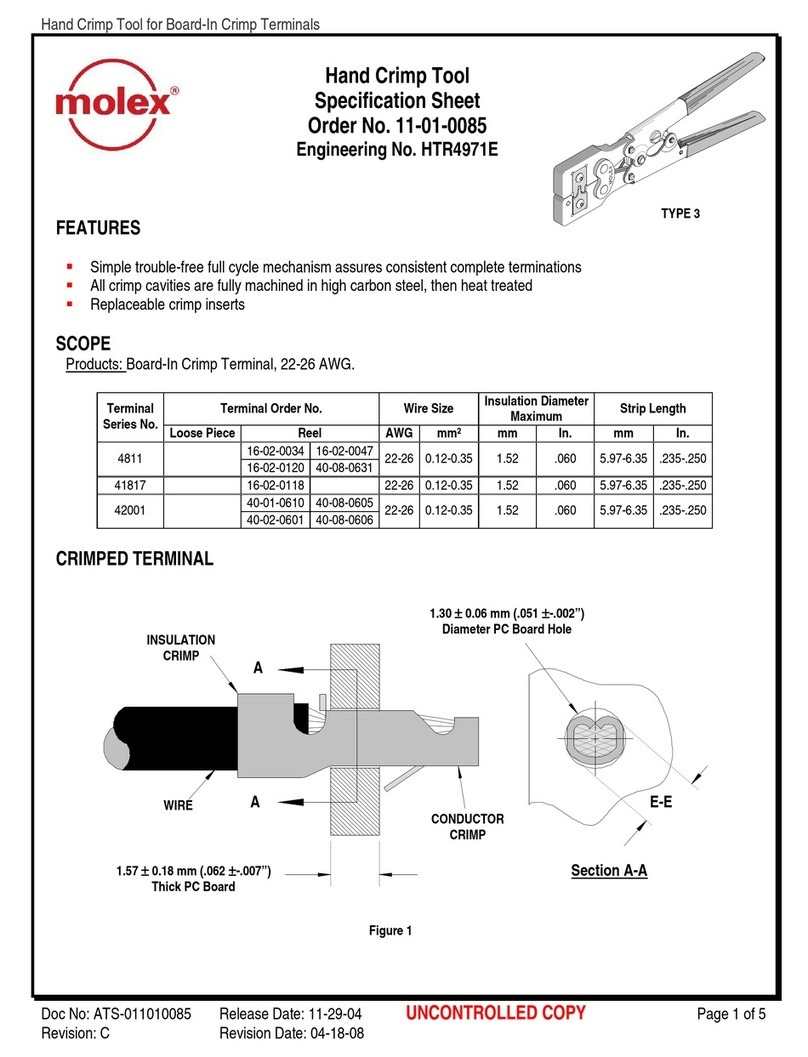

molex HTR4971E User manual

molex

molex 63816-1000 User manual

molex

molex 64001-5900 User manual

molex

molex 63827-6070 User manual

molex

molex PremiumGrade 63827-1700 User manual

molex

molex 63828-1900 User manual

molex

molex 207129 Series User manual

molex

molex 63827-5470 User manual

molex

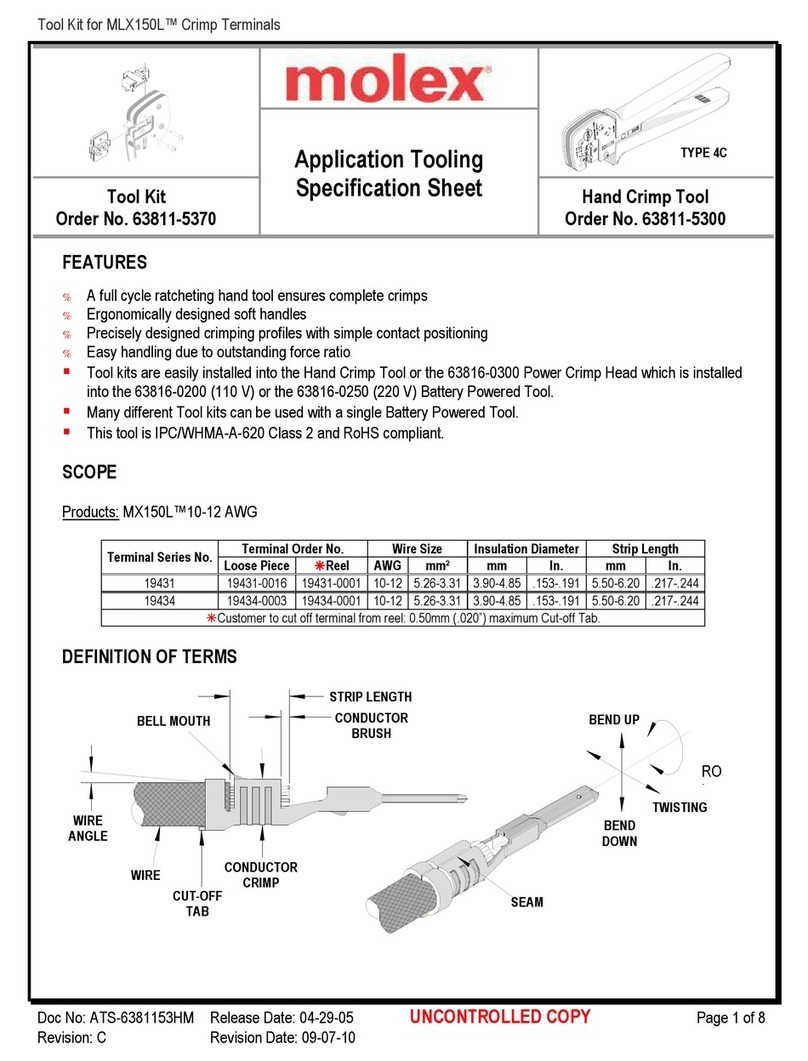

molex 63811-8900 User manual

molex

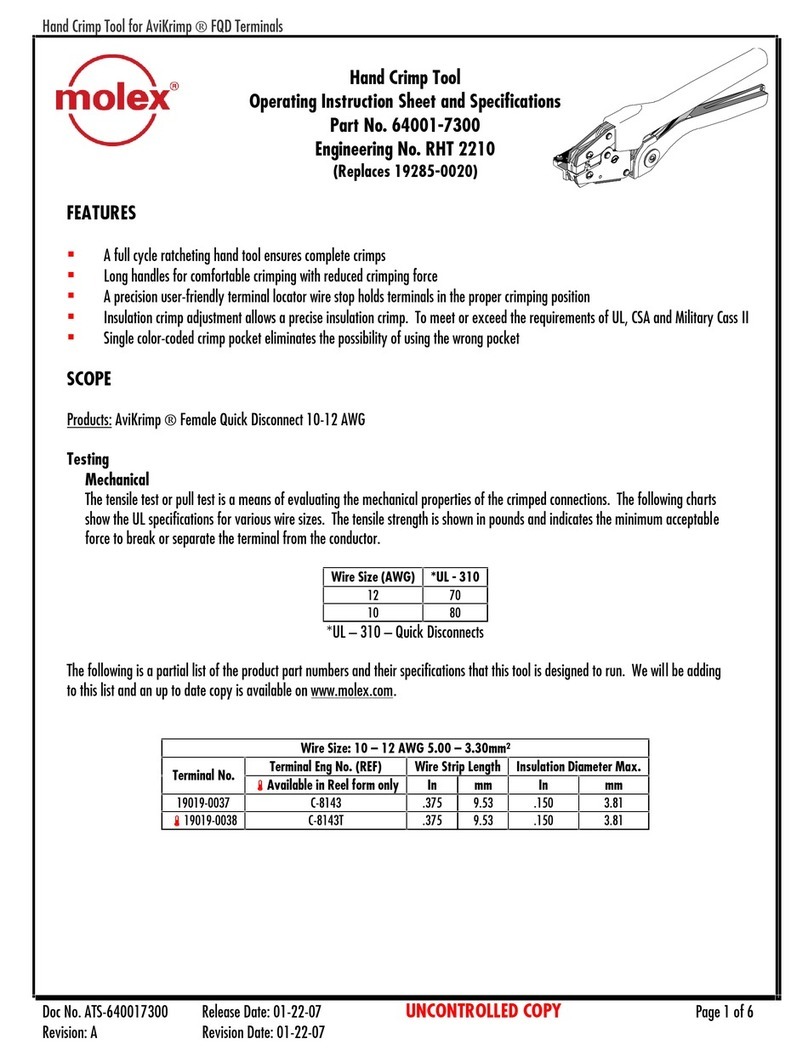

molex 64001-7300 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 63827-1600 User manual

molex

molex 63811-1200 User manual

molex

molex 50098 Series User manual

molex

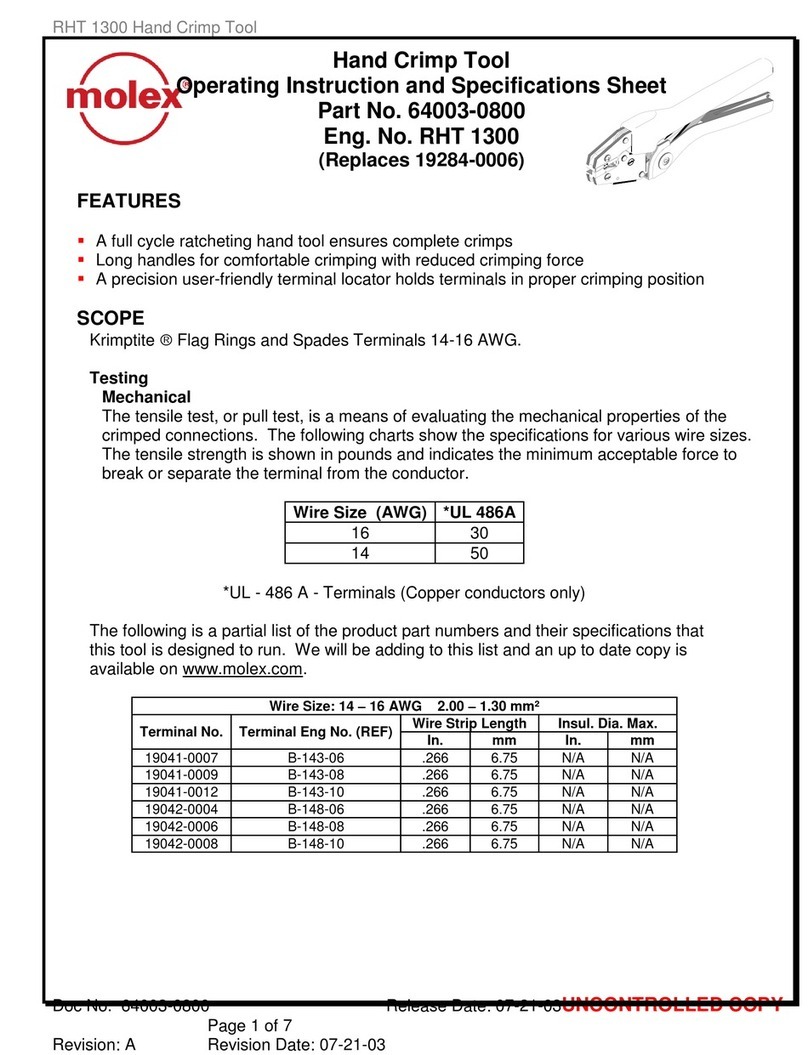

molex 64003-0800 User manual

molex

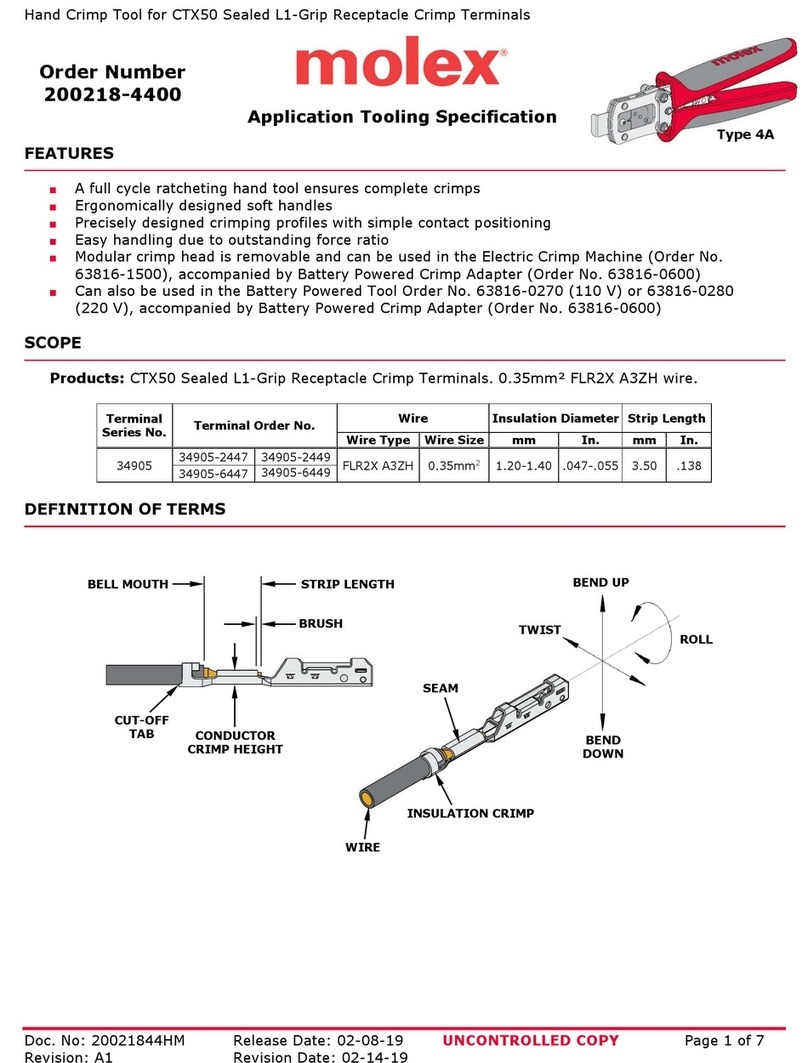

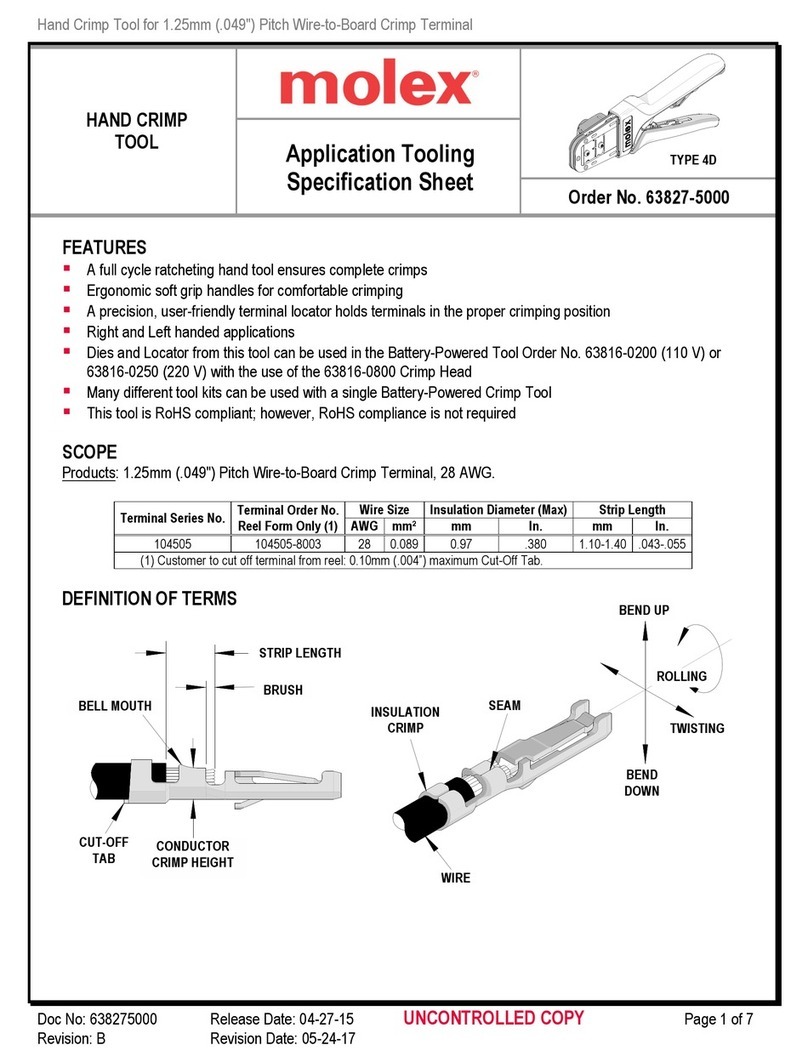

molex 63827-5000 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet