RHT-64001-3800 Hand Crimp Tool

Doc No: ATS-640013800 Release Date: 10-24-03 UNCONTROLLED COPY Pa e 4 of 5

Revision: B Revision Date: 07-28-09

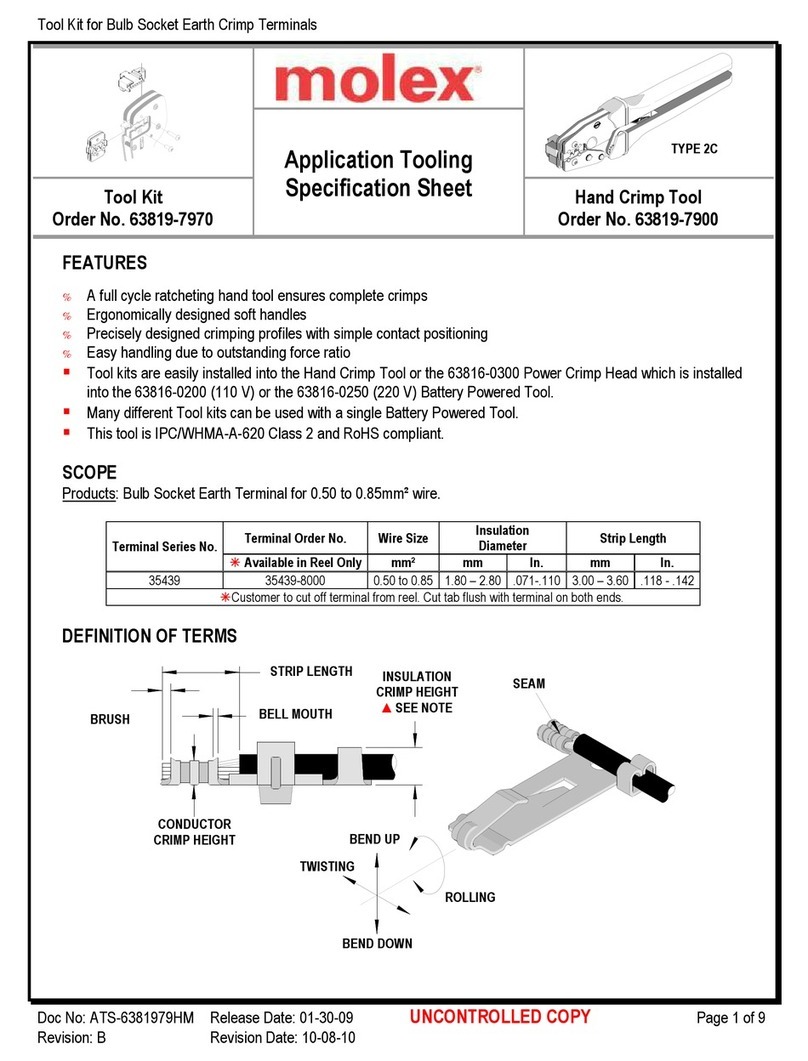

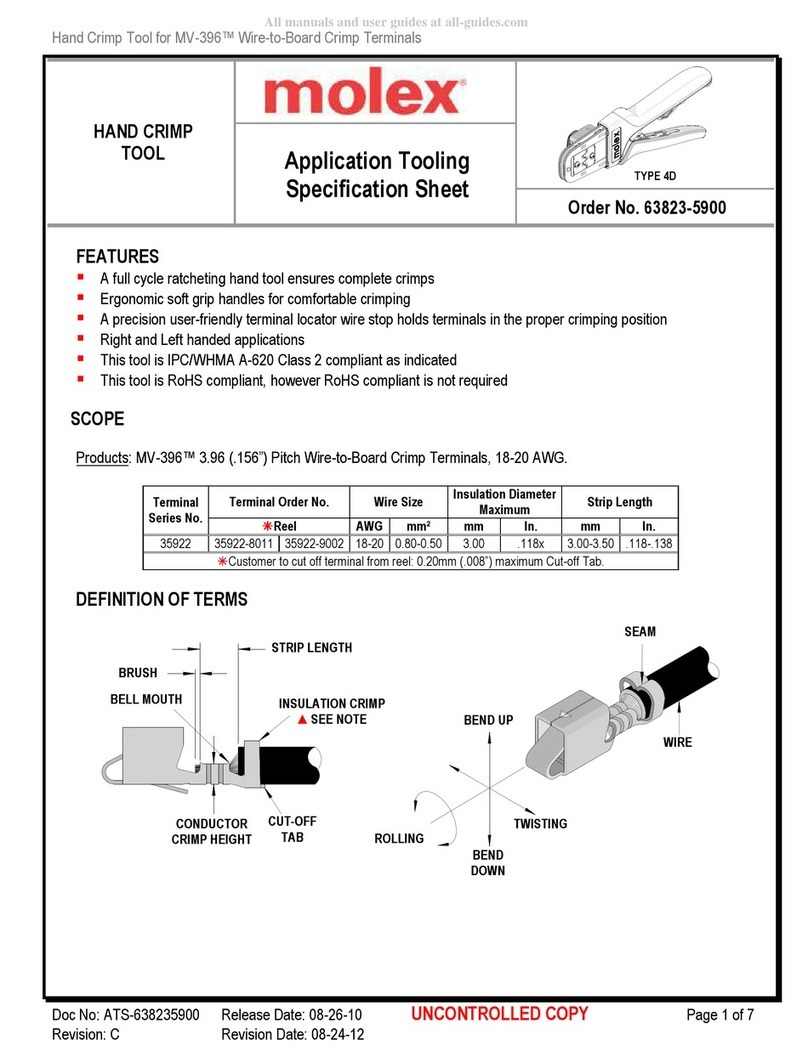

This tool is factory preloaded at 48-65 LBS.

1. Loosen the stud nut on the front of the handle with

a screwdriver.

2. Insert a screwdriver in the slot of the stud (on the

back of the tool) and adjust the force. Clockwise

(CW) will increase the force, counter clockwise

(CCW) will decrease the handle force. See Fi ure

7.

3. Reti hten the nut while holdin the stud on the

front of the tool.

4. Check the crimp specifications after tool force is adjusted.

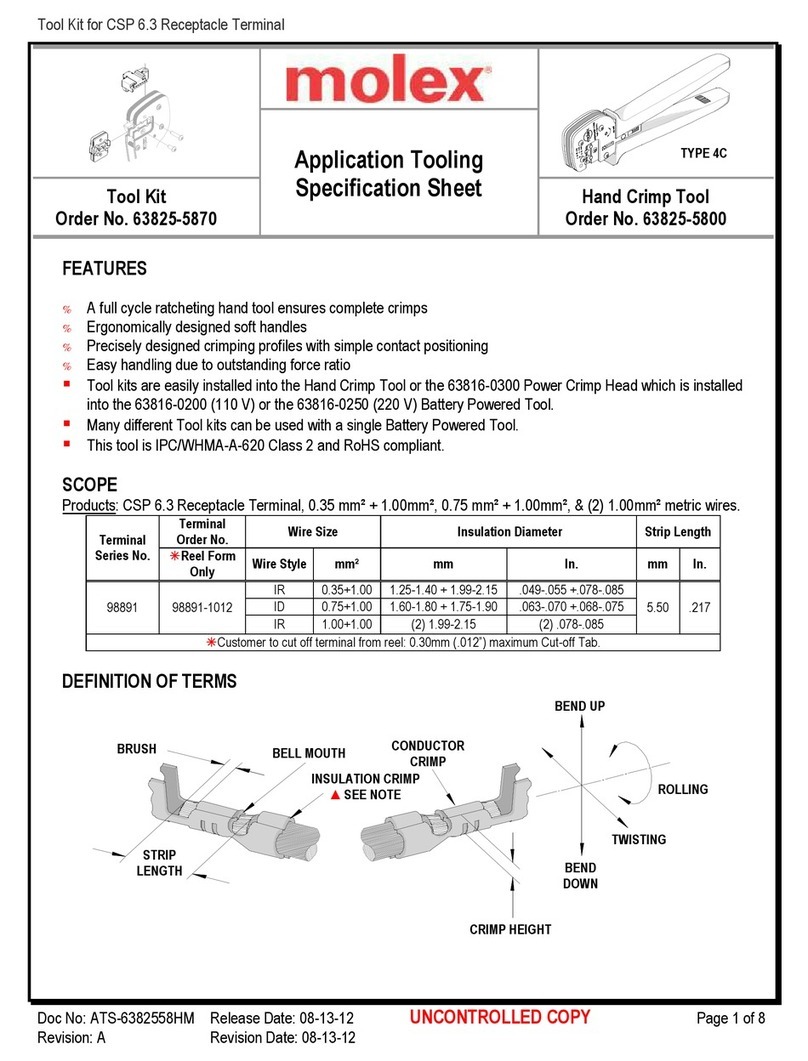

Quality Assurance Test

To check the quality of this tool, pin au e measurements should be taken

in each conductor nest and compared to this chart. The tool should be

lubricated before the quality assurance test to ensure consistent

measurements. Handle preload is factory set to 48-65 LBS See How to

Adjust Crimp Force. See Fi ure 7. If the tool does not meet the

specifications below, durin the quality assurance test, then the tool should

be disqualified and a new tool purchased.

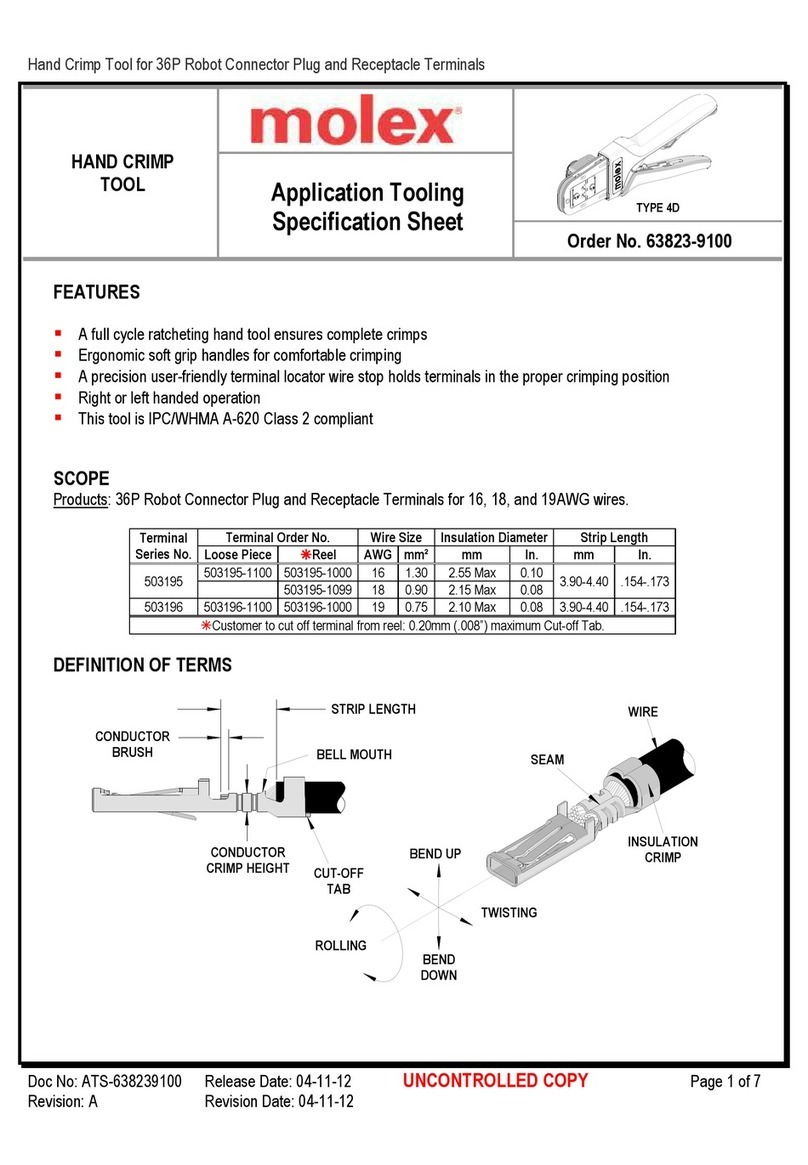

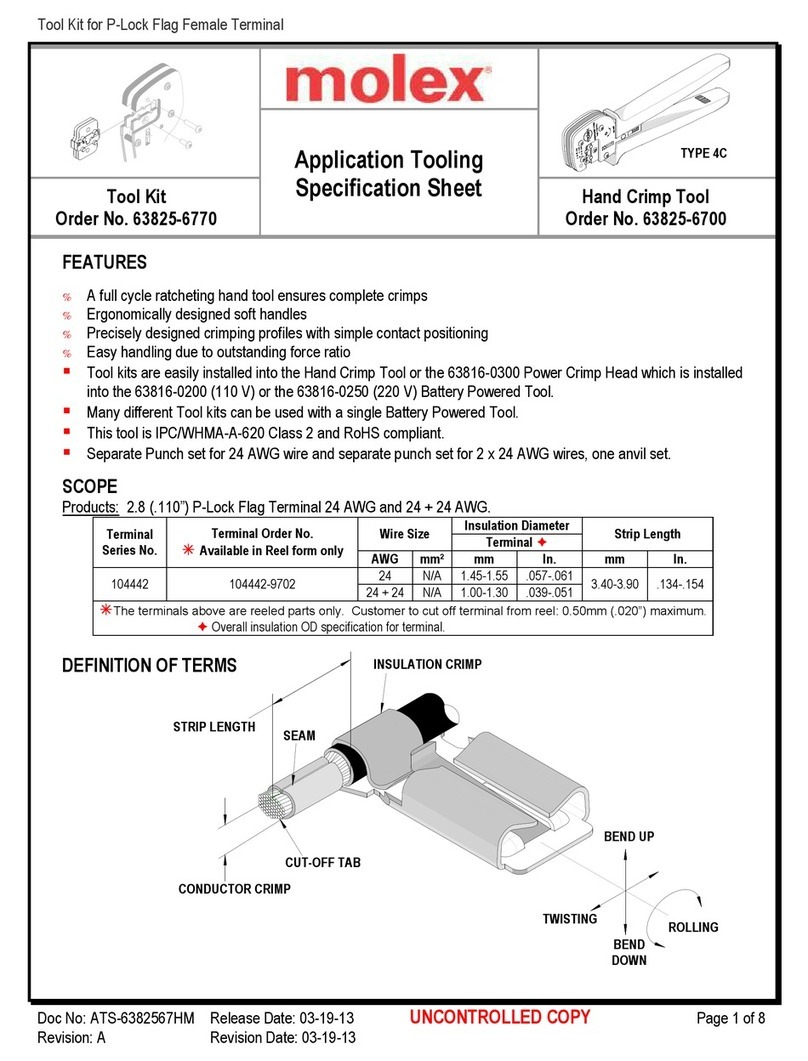

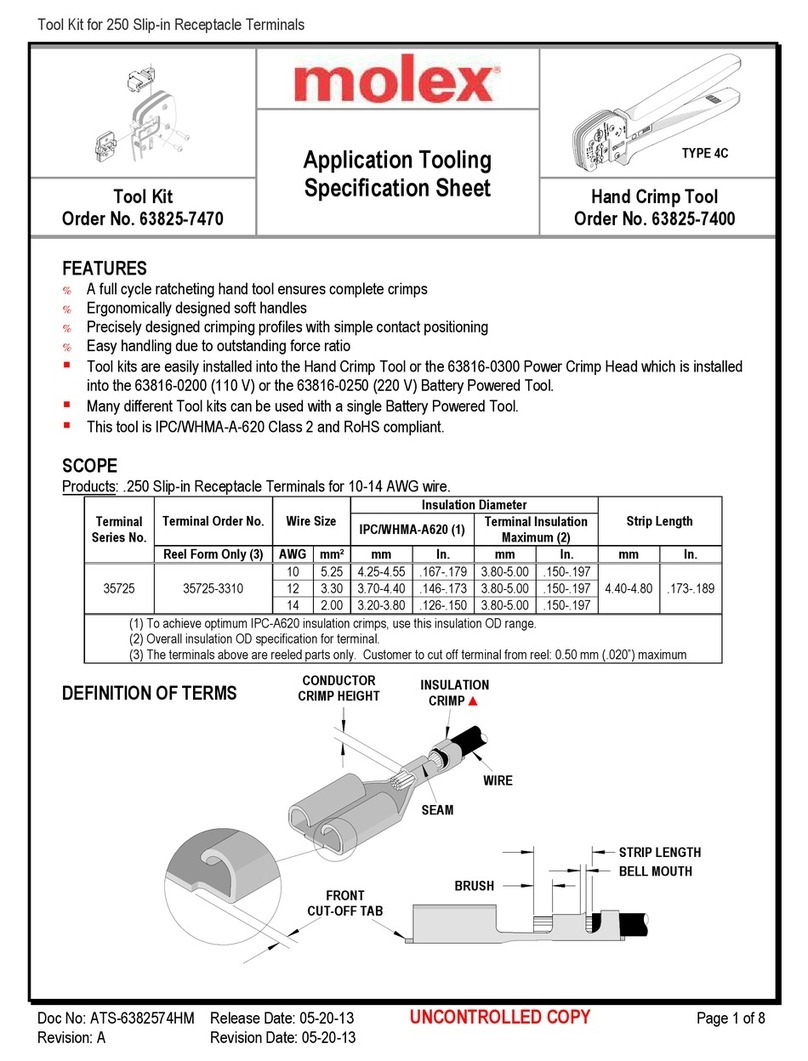

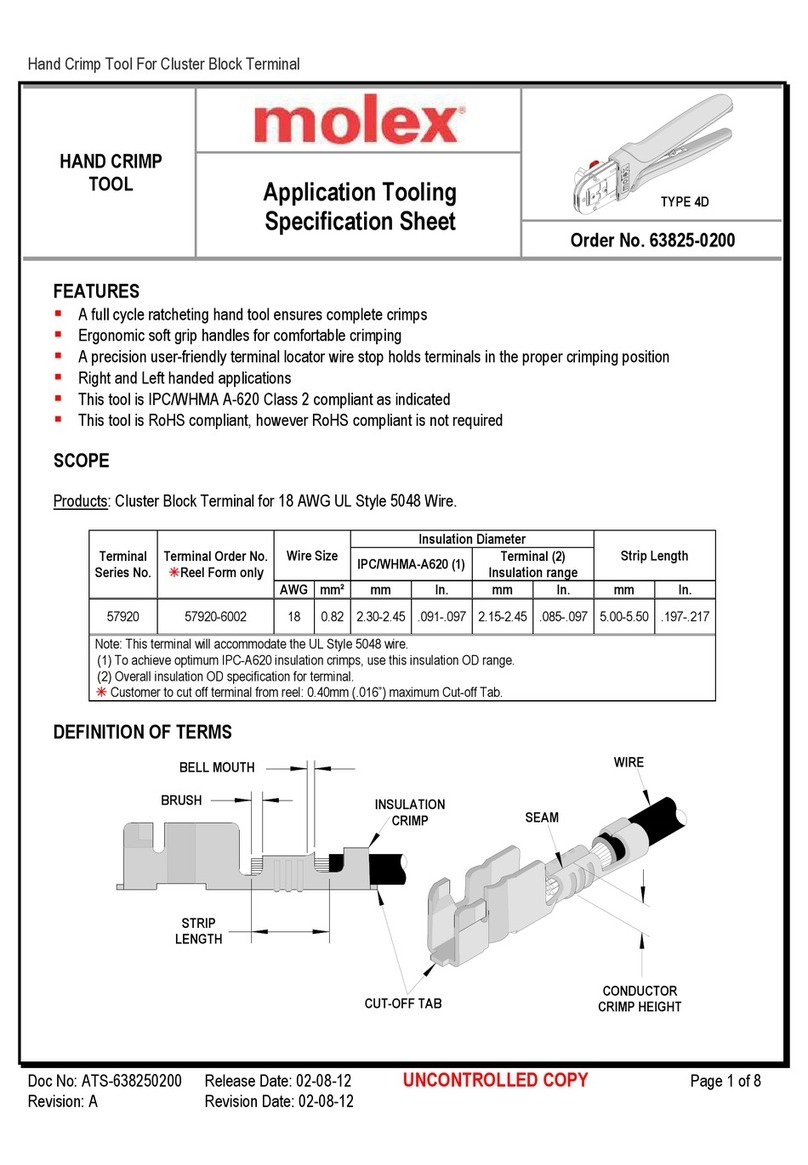

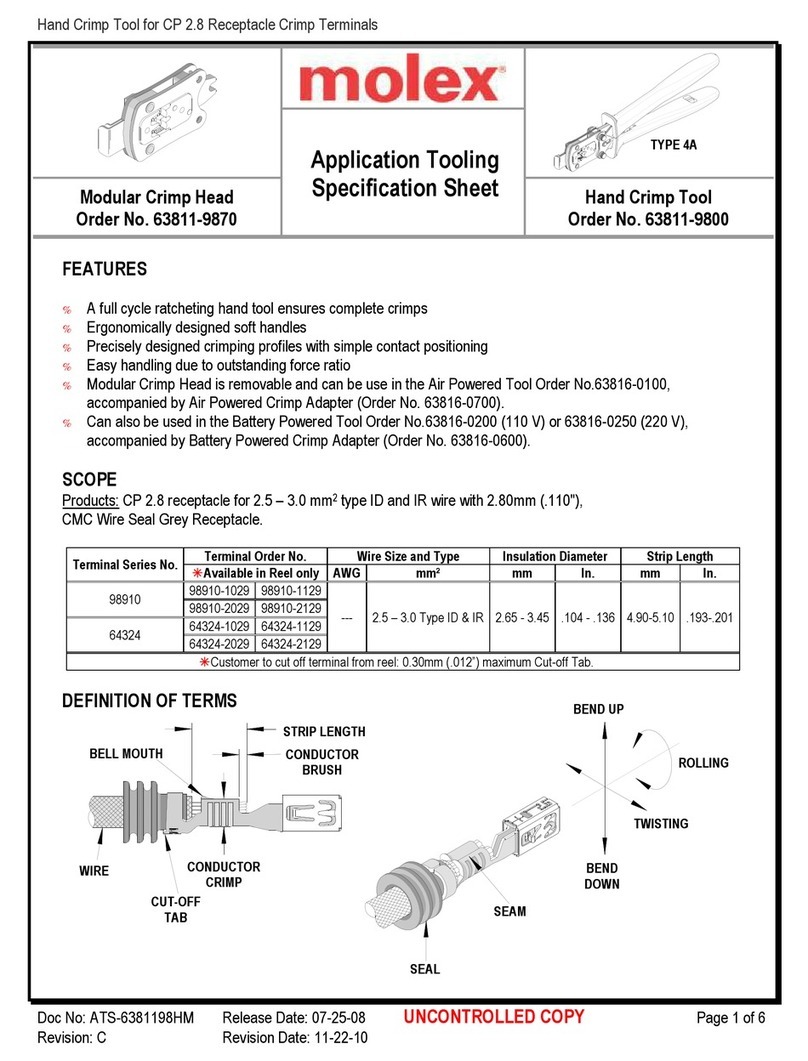

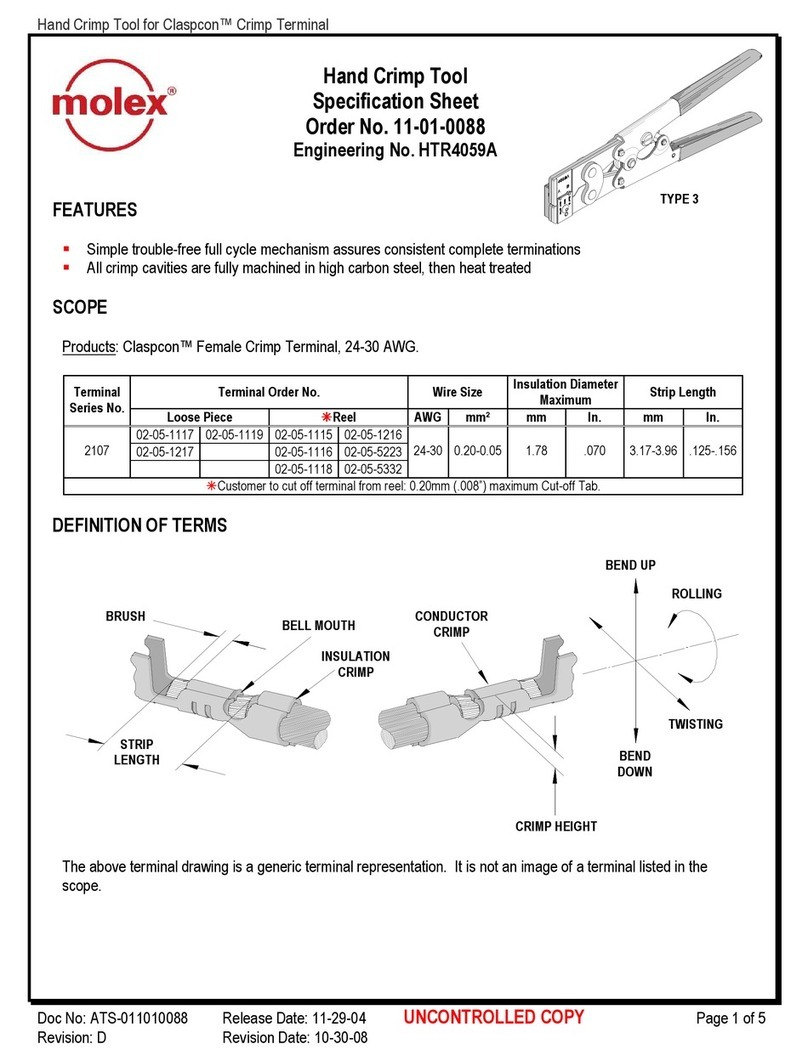

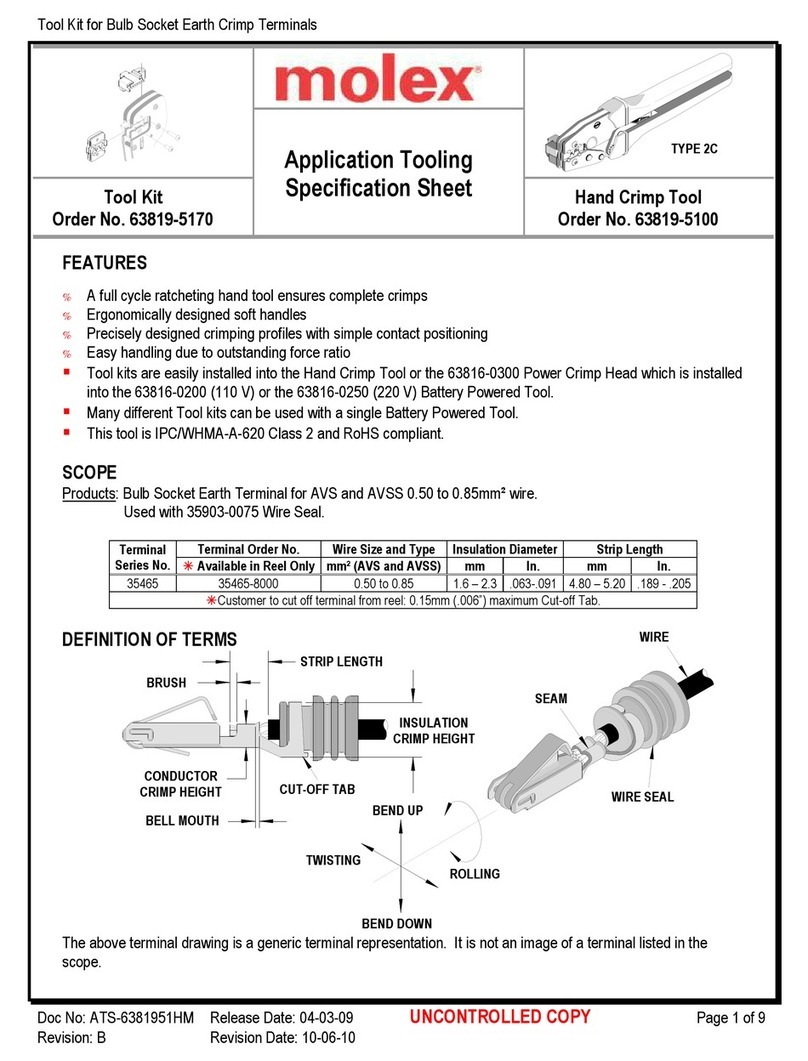

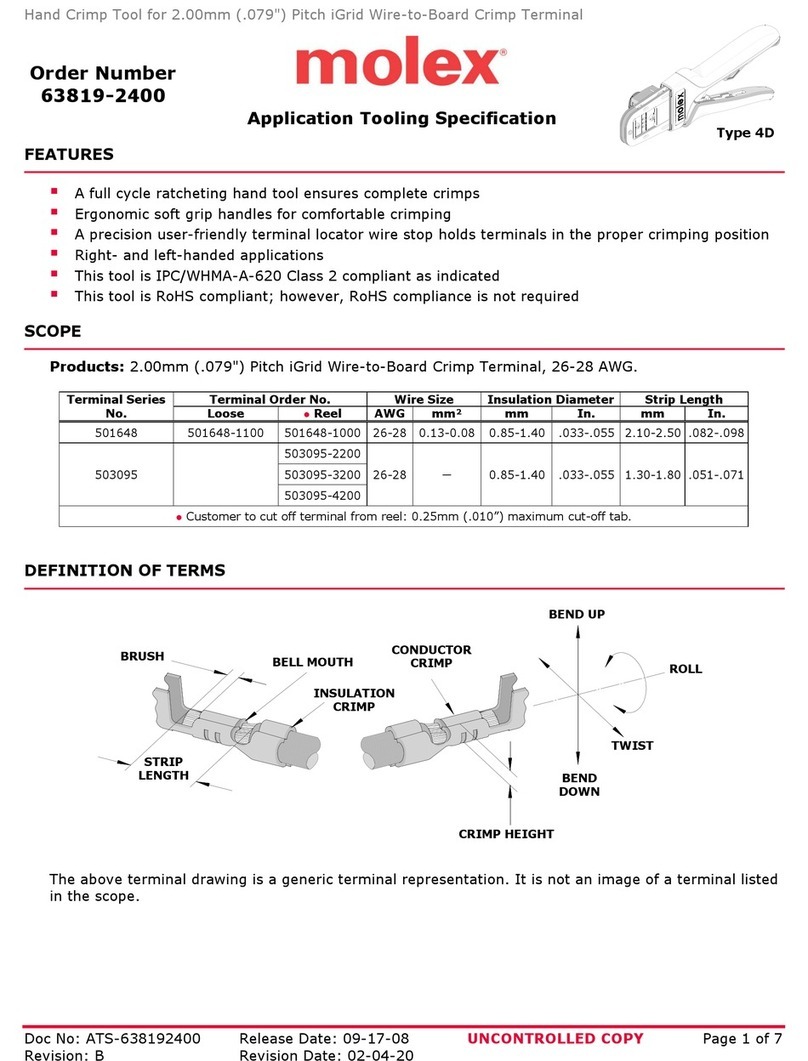

Wire Range “X” Dimension Conductor Crimp

Nest Color Code AWG mm² Mean Go No Go Crimp Inspection Marking

Red 18 - 22 0.35 - 0.80 .094 .090 .098 ---

Blue 14 - 16 1.30 - 2.00 .115 .110 .119 ---

Yellow 10 - 12 3.30 - 5.00 .161 .156 .167 ---

Hand held crimpin tools are intended for low volume, prototypin , or repair requirements only.

Caution: Repetitive use of this tool should be avoided.

Cautions

1. Termination quality is dependent on proper profile choice. Molex customers should independently verify that

the termination they intend to use, meets their quality and performance needs because this tool does not have

a terminal locator. Not all terminal, wire, and profile combinations will achieve minimum pull force

requirements, or provide an acceptable crimp form if the terminal is not positioned as described in these

operation instructions. As such, Molex makes no warranties, express or implied, as to the performance or

reliability of the crimp, or the appropriateness of the customer’s application.

2. Manually powered hand tools are intended for low volume or field repair. This tool is NOT intended for

production use. Repetitive use of this tool should be avoided.

3. Insulated rubber handles are not protection a ainst electrical shock.

4. Wear eye protection at all times.

CONDUCTOR CRIMP