[3]

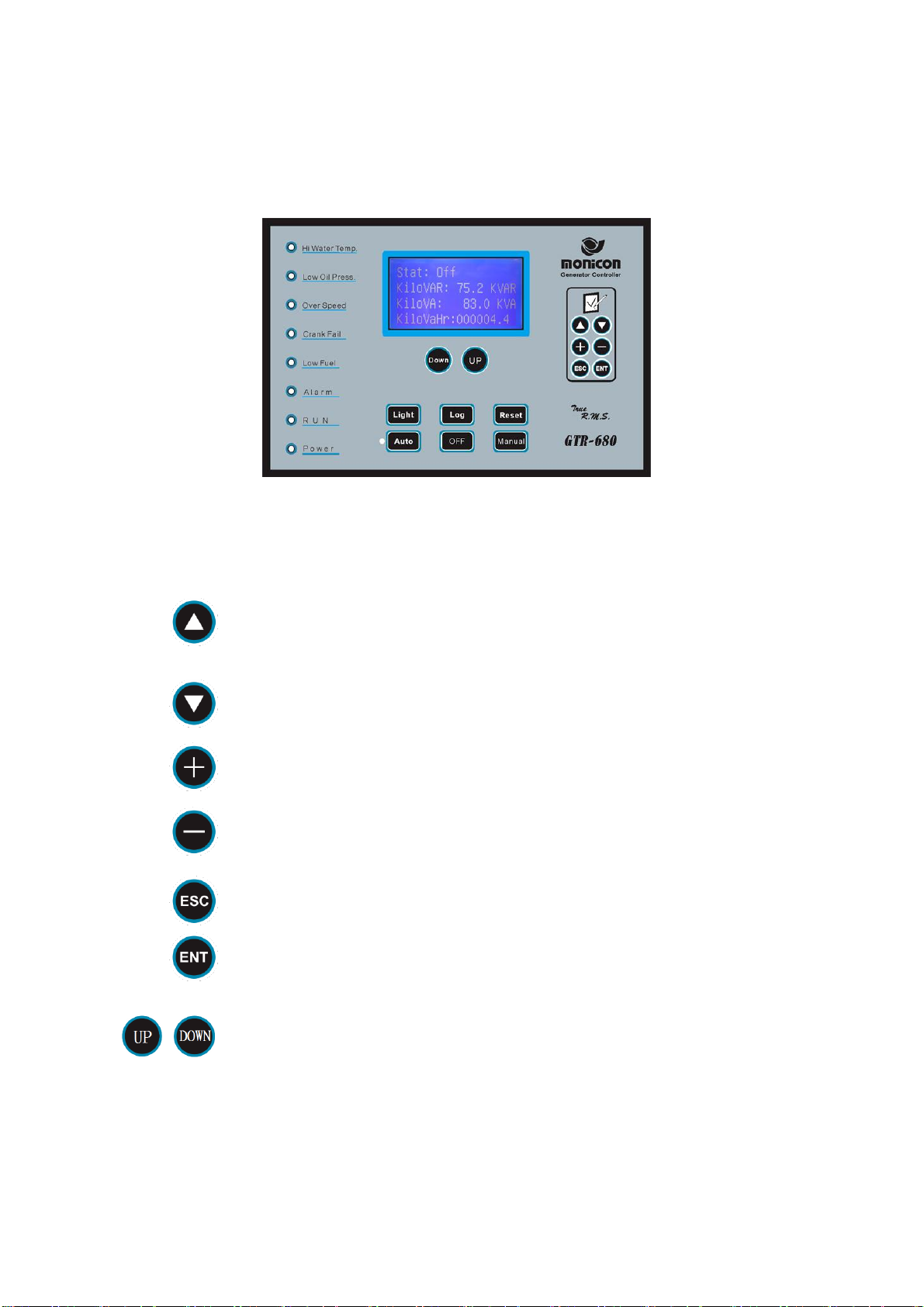

Operational Keypad

【Manual】【Auto】【Off】【Reset】【Light】【Log】

1. Manual:In manual mode, the LCD shows pre-heat function; after pre-heat, engine starts

immediately. If engine fails to start, the GTR-680 returns to the OFF mode. The

pre-heat state may not perform, if parameter setting is disabled. If Pre-fuel is

activated, the fuel outputs before crank procedure.

2. AUTO:In theAuto mode, the GTR-680 starts the engine byATS signal and then the LCD

shows preheat, if pre-heat function is enabled. After pre-heat, the engine starts to

crank. If engine fails to start, the system returns to the pre-heat state and then start

to crank the engine again. For example, if the conditions and parameter settings

are given as follows: 1.stop duration is 10 seconds, crank attempt is 3 times. The

engine cranks for 10 seconds and then rest for 10 seconds, after 3 attempts, the

LCD shows the over crank and triggers the alarm.

3. OFF :Press OFF button stops the engine and then “stop”appears on the LCD. The idle

also appears on the LCD, if the idle function is enabled. After 10 seconds of delay

(depends on the setting), the engine stops completely and idle icon disappears.

RESET:When controller detects malfunction, system goes into protection mode and display

error message on the LCD or LED indicator. Press and hold reset button to clear

faults and reset alarm. The technician can start troubleshooting the faults.

4. Light :Press light button to test LED indicators.

5. LOG : Press LOG button to enter even logs.