Contents

1. Operating instructions

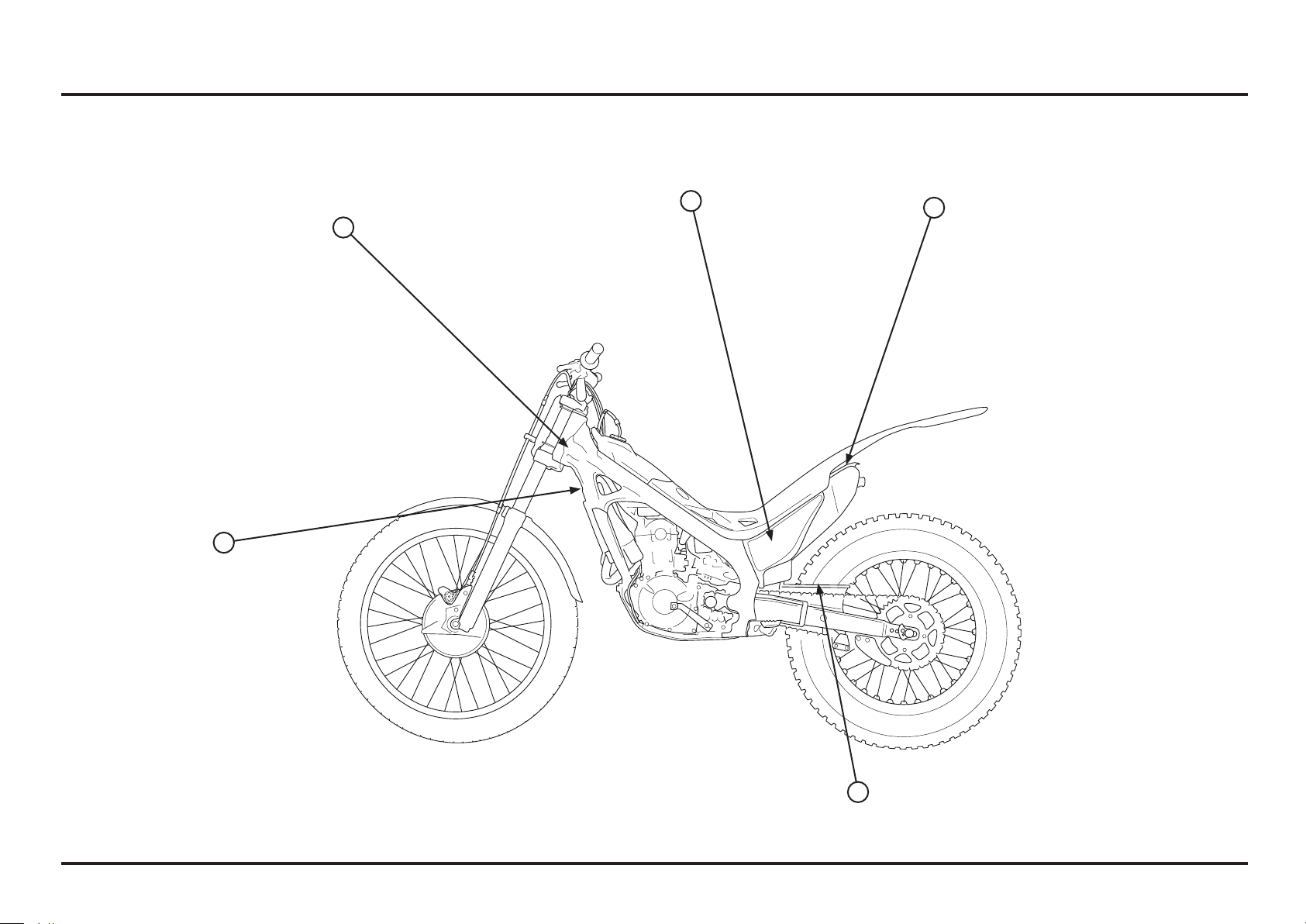

Operation component locations ...................... 1-1

Fuel ............................................................ 1-2

Coolant ....................................................... 1-2

Basic Operation ............................................ 1-2

Shifting gears .............................................. 1-4

Braking ....................................................... 1-4

Parking........................................................ 1-4

Controls ...................................................... 1-5

2. Service data

Specifications .............................................. 2-1

Service data................................................. 2-2

Torque Values.............................................. 2-5

Tools .......................................................... 2-7

Special........................................................ 2-7

Tools .......................................................... 2-7

Common ..................................................... 2-7

Lubrication & Seal Points............................... 2-8

Cable & Harness Routing ............................... 2-11

3. Service and maintenance

Maintenance schedule................................... 3-1

Pre-ride Inspection ........................................ 3-1

Warming-up Inspection.................................. 3-2

Ride Inspection............................................. 3-2

After Ride Inspection .................................... 3-2

Replacement Parts ........................................ 3-2

Fuel Line ..................................................... 3-3

Air Cleaner .................................................. 3-3

Spark Plug ................................................... 3-4

Valve Clearance ........................................... 3-4

Engine Oil/Oil Filter ....................................... 3-6

Engine Idle Speed ......................................... 3-8

Transmission Oil........................................... 3-8

Coolant ....................................................... 3-9

Clutch System ............................................. 3-10

Exhaust Pipe And Muffler .............................. 3-10

Drive Chain.................................................. 3-11

Drive Chain Slider ......................................... 3-11

Drive/Driven Sprockets.................................. 3-12

Brake Fluid .................................................. 3-13

Brake Pad Wear............................................ 3-14

Brake System............................................... 3-14

Handlebar And Steering Head Bearings............ 3-15

Wheels And Tires ......................................... 3-15

Front Suspension.......................................... 3-16

Fork ...........................................................

3-16

Rear Suspension........................................... 3-17

Cleaning...................................................... 3-18

Storage ....................................................... 3-18

4. Engine servicing

Oil Pressure Relief Valve................................ 4-1

Oil Pump ..................................................... 4-1

Fuel Feed Hose ........................................... 4-4

Fuel Line Inspection ...................................... 4-5

Connect the fuel pump 2P connector. ............. 4-6

Fuel Tank/Fuel Pump..................................... 4-7

Removal ...................................................... 4-7

Remove the rear fender. ................................ 4-7

Disconnect the fuel injector 2P connector. ....... 4-7

Remove the fuel injector socket bolts.............. 4-7

Injector ....................................................... 4-13

Throttle Body ............................................... 4-13

Water Seal And Bearing Replacement.............. 4-15

Radiator Removal/Installation ......................... 4-17

Engine Removal/Installation............................ 4-18

Cylinder Compression ................................... 4-20

Cylinder Head Removal ................................. 4-23

Cylinder Head Disassembly ............................ 4-25

Cylinder Head Inspection ............................... 4-26

Valve Guide Replacement .............................. 4-27

Valve Seat Inspection/Refacing ...................... 4-28

Cylinder Head Assembly................................ 4-31

Cylinder/Piston ............................................. 4-32

Cylinder Head Installation .............................. 4-37

Camshaft/Cylinder Head Cover Installation....... 4-38

Right Crankcase Cover .................................. 4-40

Clutch Slave Cylinder .................................... 4-41

Clutch......................................................... 4-43

Kickstarter................................................... 4-46

Gearshift Linkage.......................................... 4-47

Left Crankcase Cover.................................... 4-49

Flywheel ..................................................... 4-52

Crankcase Separation/Disassembly ................. 4-54

Crankshaft/Transmission Inspection ................ 4-56

Crankcase Bearing Replacement ..................... 4-56

Transmission Assembly ................................. 4-58

Crankcase Combination ................................. 4-59

5. Frame servicing

Front Wheel ................................................. 5-1

Fork............................................................ 5-3

Steering stem .............................................. 5-12

Rear Wheel .................................................. 5-15

Shock Absorber............................................

5-16

Shock Linkage.............................................. 5-19

Swingarm.................................................... 5-20

Front Brake Pad Replacement......................... 5-24

Rear Brake Pad Replacement ......................... 5-25

Front brake caliper ........................................ 5-25

Rear brake caliper ......................................... 5-26

Front master cylinder .................................... 5-27

Rear master cylinder ..................................... 5-28

Brake pedal.................................................. 5-28

Clutch master cylinder .................................. 5-29

6. Electrical servicing

Charging system inspection ........................... 6-1

Ignition system inspection ............................. 6-3

PGM-FI System inspection ............................. 6-5

MIL and DTC (ISO) error codes for

the PGM-FI injection system. ......................... 6-8

Bank angle sensor inspection ......................... 6-9

Engine stop switch inspection ........................ 6-10

Cooling fan system inspection........................ 6-10

Wiring diagram............................................. 6-11

7. Manufacturer and authorized representative for

the USA markets

Manufacturer ............................................... 7-1

Authorized Representative USA market..............7-1