Moog Tritech Super SeaKing 700 V7 Series User manual

Outstanding Performance in Underwater Technology A Moog Inc. Company

Super SeaKing 700 V7

Bathymetric Sensor

Product Manual

Document No-0688-SOM-00001

Rev2

This page has deliberately been left blank.

Help & Support

First please read this manual thoroughly (particularly the Troubleshooting section, if present). If a warranty is

applicable, further details can be found in the Warranty Statement, 0080-STF-00139, available upon request.

Tritech International Ltd can be contacted as follows:

Address Tritech International Ltd

Peregrine Road

Westhill Business Park

Westhill, Aberdeenshire

AB32 6JL, UK

Telephone +44(0)1224 744 111

Fax +44(0)1224 741 771

Email [email protected]

Website www.moog.com/tritech

Prior to contacting Tritech International Ltd please ensure that the following information is available:

1. The Serial Number of the product and any Tritech International Ltd equipment

connected directly or indirectly to it

2. Software or firmware revision numbers

3. A clear fault description

4. Details of any remedial action implemented

Contamination

If the product has been used in a contaminated or hazardous environment you

must de-contaminate the product and report any hazards prior to returning

the unit for repair. Under no circumstances should a product be returned that is

contaminated with radioactive material.

The name of the organisation which purchased the system is held on record at Tritech International Ltd and

information of new software or hardware packages will be announced at regular intervals. This manual may not

detail every aspect of operation and for the latest revision of the manual please refer to www.moog.com/tritech

Tritech International Ltd can only undertake to provide software support of systems loaded with the software in

accordance with the instructions given in this manual. It is the customer’s responsibility to ensure the compatibility

of any other package they choose to use.

Warning Symbols

Throughout this manual the following symbols may be used where applicable to denote any particular hazards

or areas which should be given special attention:

Note

This symbol highlights anything which would be of particular interest to the

reader or provides extra information outside of the current topic.

Important

When this is shown there is potential to cause harm to the device due to

static discharge. The components should not be handled without appropriate

protection to prevent such a discharge occurring.

Caution

This highlights areas where extra care is needed to ensure that certain delicate

components are not damaged.

Warning

DANGER OF INJURY TO SELF OR OTHERS. Where this symbol is present there is a

serious risk of injury or loss of life. Care should be taken to follow the instructions

correctly.

Copyright Notice.

The copyright in this document is the property of Tritech International Ltd. The document is supplied on the

understanding that it may not be copied, used, or disclosed to others except as authorised in writing by Tritech

International Ltd. We reserve the right to change, modify and update designs and specifications as part of our

ongoing product development programme.

Table of Contents

Introduction 1

Overview .................................................................................... 1

Technical Specifications.................................................... 2

Installations 4

Hardware Installation.......................................................... 4

Powering the Bathy............................................................. 5

Electrical Connections ....................................................... 5

Connecting an Altimeter.................................................. 5

Communications Configurations................................ 6

Ground fault Monitoring.................................................. 6

Wiring Diagrams.................................................................... 7

Wiring Pin-outs....................................................................... 8

Tritech V7 Connector.......................................................... 8

SeaNet Pro 9

Software Overview............................................................... 9

System Requirements ........................................................ 9

SeaNet Pro Software Installation................................. 9

Windows Setup....................................................................10

SeaNet Pro Setup ................................................................11

Magnetic Reset.....................................................................11

Device Conguration Window 12

Seanet Pro Operation.......................................................13

Main Screen............................................................................13

SeaNet Pro Tools ..................................................................14

System Configuration.......................................................16

Optimising the SK700 V7 17

System Check........................................................................17

Pre-dive Setup.......................................................................17

Recommended Pre-Dive checklist...........................18

Factors that affect measurement..............................19

Care and Maintenance 21

After using the Super Seaking 700...........................21

Seaking Basic Maintenance .........................................21

Field Service............................................................................21

Storage.......................................................................................21

Calibration ...............................................................................21

Appendix A 22

ARCNET Termination.........................................................22

Appendix B 23

Depth Derivation ...............................................................23

Default Depth Equation..................................................23

Gravity Formula....................................................................23

Alternative Depth Equation..........................................23

Salinity Equation..................................................................24

Density Equation.................................................................24

Appendix C 25

Chen & Millero Equation.................................................25

DelGrosso Equation...........................................................26

Wood Equation.....................................................................26

Mackenzie Equation.........................................................26

Wilson Equation..................................................................27

Coopers Equation..............................................................27

Medwin Equation..............................................................28

Leroy Equation......................................................................28

This page has deliberately been left blank.

1

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

1. Introduction

1.1 Overview

The Super Seaking V7 series is built on a new platform, introducing an improved front end design, Ethernet

connectivity and software power isolation for AUX port output.

We have incorporated state of the art sensors to gather precision Sound Velocity and Density profiles for accurate

depth and height data. Pairing a V7 Seaking 700 with an altimeter and sonar from Tritech’s Seaking or Gemini

range gives a fully integrated oceanographic system which can be controlled from a single user interface and

easily integrated into any existing survey suit.

The V7 is a direct replacement for a V6 sonar with the exception of customers requiring Ethernet capability. This

will require either a proprietary Tritech ‘V7 connector’ or a compatible connector and cable harness. Arcnet and

Serial comms protocols are still supported.

Depth Accuracy

0.015%

Temperature Accuracy

±0.005˚C

Conductivity Accuracy

±0.3mS/m

of full scale depth

Features

• State-of-the-art sensor integration.

• New generation of algorithms.

• Software switchable Ethernet, ARCNET and

Serial Comms Protocols.

• Free running & interrogate modes.

• Simple integration to survey suites.

• Improved power efficiency.

Benets

• Higher accuracy real-time output for:

• Depth

• Temperature

• Conductivity

• Density

• Sound Velocity and

• Altitude

• Ease-of-use and integration.

• Robust performance for high-speed data

acquisition.

Applications

• ROV

• OCEANOGRAPHIC OPERATIONS

• METROLOGY

Related Products

PA500/6 Altimeter Super Seaking

V7 Sonar

Seaking Side Scan Gemini Multibeam

Sonars

2

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

1.2 Technical Specifications

System Physicals Super Seaking 701 Series SSK704 Series

Weight in air (kg) 3.74 4.19

Weight in Water (kg) 1.44 1.69

Housing Material Anodised Aluminium Alloy

Depth Ratings 700m, 1400m, 2000m, 4000m

ø99

ø110

261

278

392

160

7241

ø47

ø43

303

Super Seaking 701

Super Seaking 704

Dimensions in millimetres.

3

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

Electrical and Communication

Power Requirement Main 20-70VDC @ 8w

Aux Voltage set to 24VDC

Communications

SXXXXX nn ETH Main Ethernet & Serial RS232/RS485

Aux Serial RS232/RS485

SXXXXX nn ARC Main ARCNET & Serial RS232/RS485

Aux

Depth Sensor

Repeatability 0.01% FSD (Full Scale Depth)

Hysteresis 0.015% FSD

Drift 0.015% FSD

Temperature Sensor

Survey Grade Scientific Grade

Range -5˚C to 35˚C -5˚C to 35˚C

Accuracy ±0.01˚C ±0.005˚C

Drift ±0.002˚C per year ±0.005˚C per year

Conductivity Sensor

Survey Grade Scientific Grade

Range 0 to 8.5 S/m 0 to 8.5 S/m

Accuracy ±1.0mS/m ±0.3mS/m

Drift ±0.1mS/m per month ±0.1mS/m per month

Software Requirements Version Build

SeaNet Pro 2.24 548

Genesis (*Limited Functionality) 1.4.1

Altimeter Specifications

Type PA500

Weight in air 1150g

Weight in Water 800g

Frequency 500kHz

Beam width 6˚ conical

Range 0.3m to 50m

Resolution 1mm

Material Stainless Steel (Titanium 6AI4V optional)

4

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

2. Installations

2.1 Hardware Installation

Mount the Seaking 700 using 3mm insulating rubber, and jubilee clamps to firmly secure

to the vehicle.

For accurate pressure measurement, the Seaking 700 Bathymetric sensor can be orientated

in a port up or port down configuration with calibrated offsets provided by the factory.

It’s recommended, during installation, that the bathy and altimeter be positioned so they

receive good water flow while avoiding prop-wash from thrusters.

It’s advisable that the conductivity sensor head should have a free radius of at least 10cm.

Objects within this must be electrically stable (either a fixed dielectric or conductor) and

have a fixed position relative to the sensor. Locate the sensor head away from items such

as motors, sense coils and cameras to ensure accurate readings.

Ensure the Seaking 700 is protected from the possibility of impact damage.

During Installation, be sure to safeguard against damage to the protective anodised

coating on the main housing. Any chips or scratches may lead to corrosion of the housing

which may impact the performance of the system.

Mate connectors/blanks ensuring the washers are in places and have been greased and

the securing screws have been tightened.

DO NOT OVER-TIGHTEN RETENTION SCREWS.

If using a Seacon connector, you are reminded that

the retention ring should be finger tight. Applying too

much pressure risks damaging the connector.

Check that the cables and connectors are not subjected to excessive strain and are not

kinked or bent excessively. The safe bend radius of the V7 cables is 100mm.

Caution

Non-metallic clamps are preferred when securing the

Bathy, however, if metallic clamps are to be used they

must be electrically insulated to protect the housing.

Avoid any clamping material that may

contain brass or bronze.

5

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

2.2 Powering the Bathy

The SeaKing 700 Series units are designed to work from a smoothed DC power supply.

If using a rectified transformer PSU, the output of the PSU must have a filter capacitor of not less than 470μF, for

each unit being powered.

If an unregulated PSU is used, the voltage value measured during power on/off and running conditions at the

unit should be within the voltage range specified for the system.

If powering the unit(s) down a long lead or umbilical, the maximum recommended resistance of the power line

must not exceed 10Ω for one unit, 5Ω for two units and 3Ω for three units.

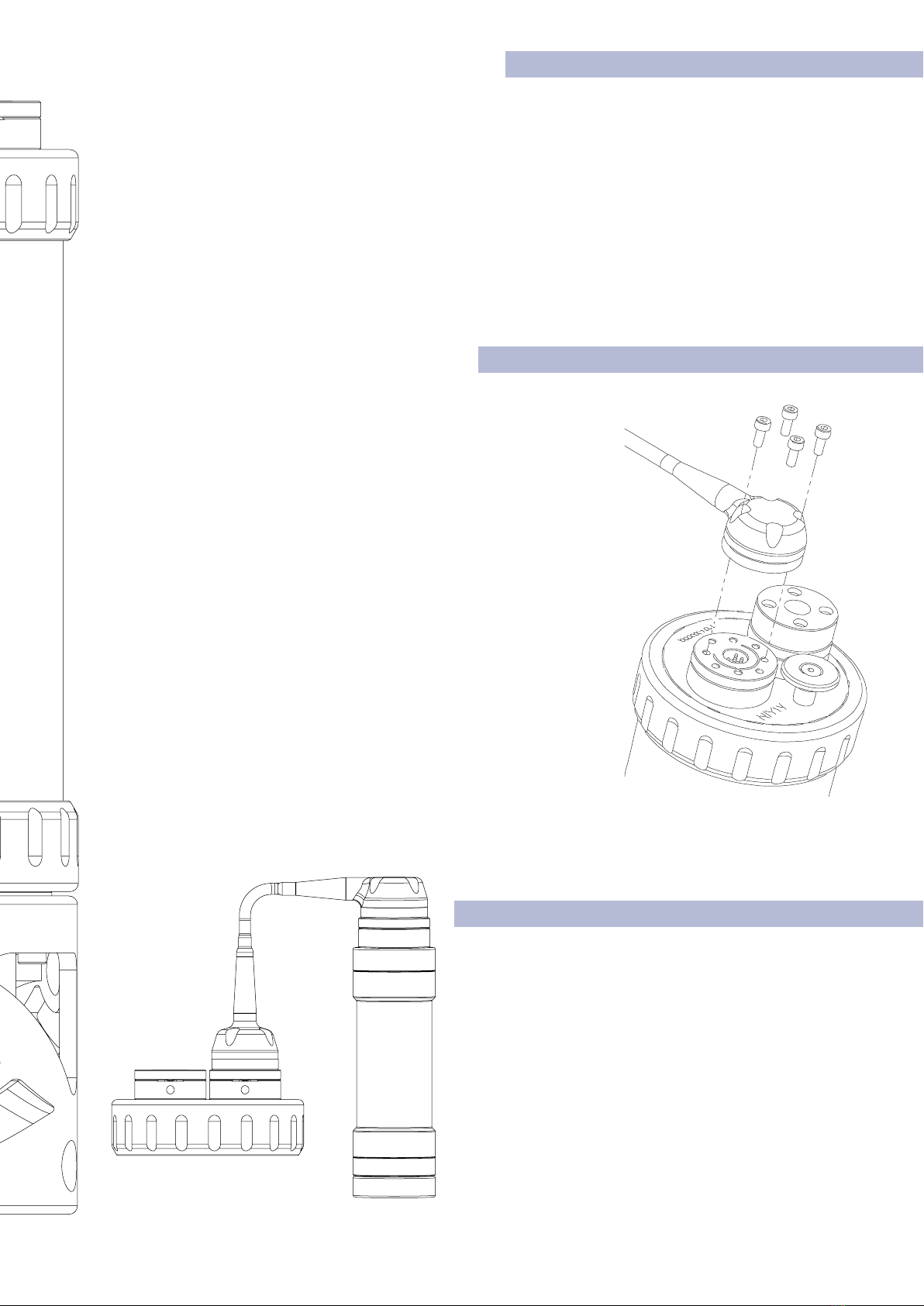

2.3 Electrical Connections

The SeaKing 700 is typically supplied with a 1meter polyurethane

jacketed cable whip, fitted with aTritech connector. Depending on the

specification of the system, the cable will either need to be terminated

to a suitable connector or may be supplied already terminated.

The standard Tritech connector may be disconnected from the unit

by unscrewing the four retaining screws and removing the connector

from the water block that is fitted to the end-cap. Do not remove the

water block.

While the cable is removed the exposed connectors should be fitted

with appropriate blanking caps to prevent the ingress of dirt or

moisture.

For devices fitted with non-Tritech connectors this procedure will vary.

For information on Tritech Standard wiring, connectors and pin-outs

please refer to Section 2.6 of this manual.

2.4 Connecting an Altimeter

The Bathy is designed to directly interface with a Tritech

PA500/06 altimeter. Connection is made to the Bathy Aux

Port using a standard Tritech double ended S01226 (R/A

to Str) interconnect cable.

6

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

2.5 Communications Configurations

The V7 is a direct replacement for a V6 sonar with the exception of customers requiring Ethernet capability. This

will require either a proprietary Tritech ‘V7 connector’ or a compatible connector and cable harness. Arcnet and

Serial comms protocols are supported..

Seaking 700 Bathymetric sensors can be configured as Ethernet with Serial RS232/485 or as ARCNET and Serial

RS232/485 communication protocols. There is no ARCNET and Ethernet option.

See section on software setup for guidance on configuring your network.

Ethernet & Serial (RS232/RS485)

When connecting via Ethernet, the Bathy can communicate at 100Mbps while

returning environmental data.

If the Bathy shares it’s Ethernet link with other high bandwidth devices, such as

video cameras, it is recommended that a gigabit (or faster) network interface be

used to the surface to reduce possible network congestion.

Basic Ethernet Cable Setup

ARCNET & Serial (RS232/RS485)

The SeaKing 700 series can be set to form part of an ARCNET multidrop network

of sensors that are normally interfaced to a Surface Control Unit (SCU) through

an internal DA-15 ARCNET interface (AIF) port or through the DA-15 AIF port

on a SeaHub.

Normal communication with the Bathy head is via a customised version of the

ARCNET network system and requires a good quality balanced twisted pair.

There is also the option to run a single head from an RS232/RS485 connection.

Note

The ARCNET system requires termination resistors to be fitted at each end of

the umbilical. Please refer to Appendix A, ARCNET Termination for more details

of the termination requirements.

2.6 Ground fault Monitoring

The power supply within SeaKing subsea devices contain an electrically isolated

DC-DC converter. There is a small capacitive connection to the sonar chassis

which should not noticeably affect any impressed current ground fault indicator

(GFI) equipment.

PSU

S12102 XM SK V7 to 12w

Souriau Pwr / Ethernet Test Cable Xm

S11561 Gemini Power / Ethernet

Break-out Cable

S11346 Gemini Imaging Sonar

Power Supply Unit

7

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

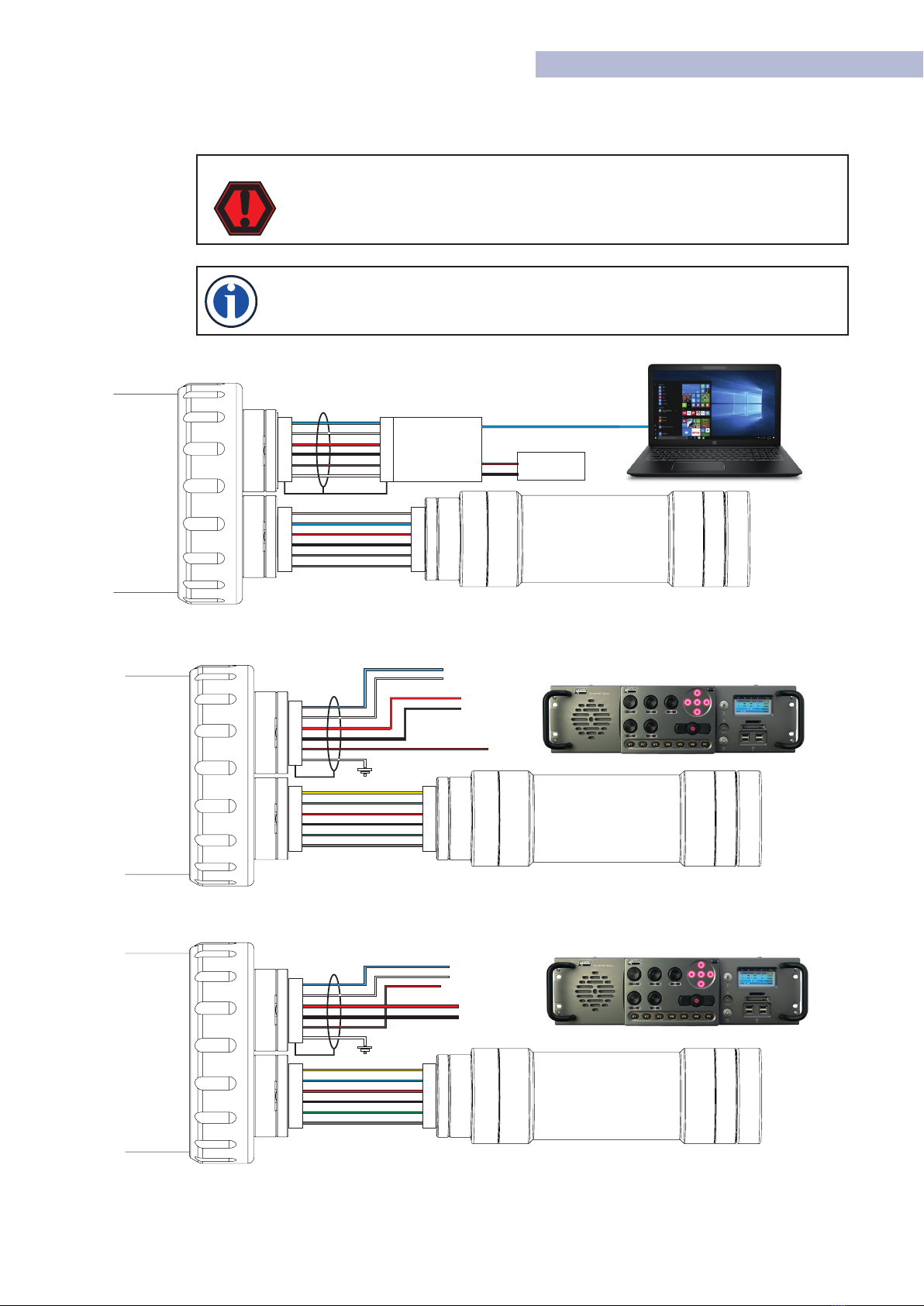

2.7 Wiring Diagrams

The below wiring diagrams refer to the standard Tritech connector, other connector options are available upon

request. Please contact our sales team for full details.

WARNING

Application of reverse supply voltage to the unit or supply voltage across any of

the communication connections may lead to equipment damage not covered

under the warranty conditions.

Note

Ethernet communications require the use of V7 cables. Other communications

modes are compatible with both V7 and Standard Tritech cables.

Ethernet Wiring.

ARCNET Wiring.

Serial RS232/485 wiring.

TX_P

TX_N

+VDC

0VDC

RX_N

RX_P

C

F

D

G

A

B

Breakout

PSU

RJ45

0 VDC

+VDC +VDC

0 VDC

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

Screen Pins

PA500/6

Altimeter

MAINAUX

1

2

3

4

5

6

1

2

3

4

5

6

N/C

PA500/6

Altimeter

SCU 5

MAINAUX

1

2

3

4

5

6

ARCNET A

ARCNET B

PSU

0 VDC

+VDC

SCU 5

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

PA500/6

Altimeter

MAINAUX

Serial RX

Serial TX

RS232 Gnd

PSU

0 VDC

+VDC

8

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

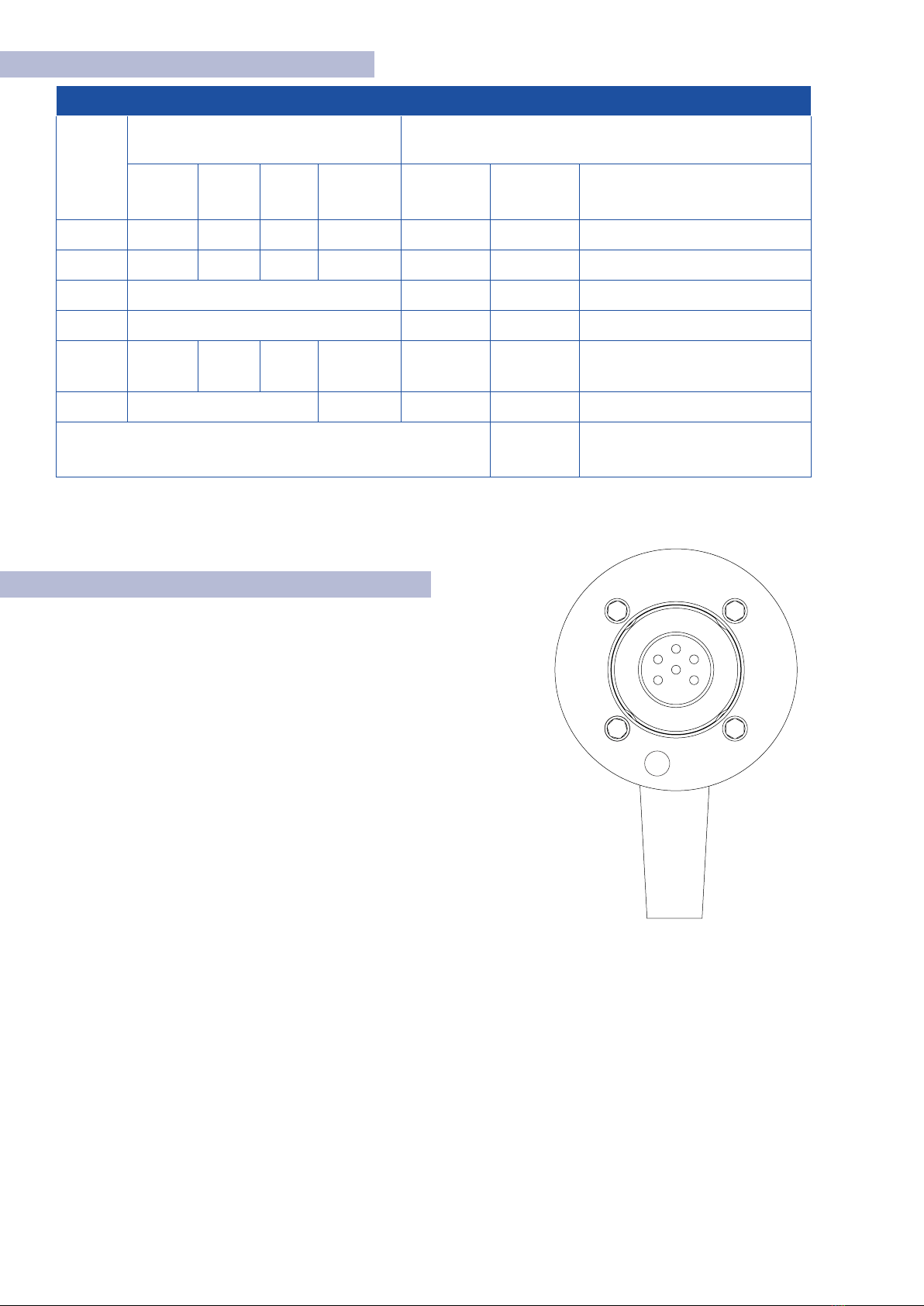

2.8 Wiring Pin-outs

V7 Cable Pin-Out

Contact

Pin-Out Cable

ARCNET RS232 RS485 V7 Conn.

Ethernet

Conductor

Colour V6

Conductor

Colour V7 Conductor ID

1 A TX A TX_P Yellow Blue UTP #1: 0.22mm² / ~24 AWG

2 B RX B TX_N Blue White UTP #1: 0.22mm² / ~24 AWG

3 +VDC Red Red 0.5mm² / ~20 AWG

4 -VDC Black Black 0.5mm² / ~20 AWG

5 N/C RS232

GND N/C RX_P Green Red UTP #1: 0.22mm² / ~24 AWG

6 Earth RX_N Screen White UTP #1: 0.22mm² / ~24 AWG

Chassis Earth Connection Screen /

Drain Wire

Foil Screen with

Drain wire 0.022mm²

Cable Connector

Pin View

1

435

Screen

62

2.9 Tritech V7 Connector

TheV7 cable connector has the addition of the screen pin in the outer

ring of the connector. This makes contact with the chassis ground of

the system which is required when using Ethernet Comms.

When using ARCNET and Serial Communications systems, standard

cables are compatible.

9

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

4. SeaNet Pro

SeaNet Pro is Tritech’s proprietary software which enables control and communication to our full range of

products. SeaNet Pro is capable of displaying and outputting multiple sensors simultaneously. This means Sonar,

Bathy and PA Altimeter data can all be displayed on the same screen.

4.1 Software Overview

SeaNet Pro is Tritech’s survey data acquisition and logging software package. Seanet Pro can simultaneously run

and display several combinations of Imaging Sonar, Profiling Sonar, USBL Positioning, Bathymetric and Sidescan

sensors. Seanet Setup is used to display status of all connected nodes and to download new software and

firmware upgrades into the subsea devices.

4.2 System Requirements

In order to install and run SeaNet Pro to its full potential, the operating system should meet the

following system requirements:

Minimum Recommended

Processor 2GHz 2GHz dual core

RAM 1GB 2GB

Graphics 3D hardware accelerated graphics card

OpenGL Version 2.0 or greater

Display 1280x1024 (32bit colour) 1600x1200 (32bit colour)

Disk space

Serial Hardware based, or USB converters for RS232 or RS485 communications

Networking 100MB/s (fast Ethernet) 1000MB/s (Gigabit Ethernet)

4.3 SeaNet Pro Software Installation.

Tritech Software is provided with each purchase of our equipment

either on CD-ROM or a USB memory stick.

Updates and latest versions of software can also be downloaded from

the Tritech website www.moog.com/tritech

Once installed, you can launch the application from the desktop icon

or from the Start menu in windows.

Updates

Download the latest software versions from www.moog.com/tritech

Tritech International Ltd continually develop our software so it is recommended

to check the website for updates regularly.

10

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

4.4 Windows Setup

Ethernet Protocol Settings

The Ethernet adapter needs to be setup on the host PC to be in the same IP address range as the sensor being

attached. Using network comms allows multiple sensors to be integrated using standard networking equipment.

A minimum 100BASE−TX link is recommended. The Ethernet enabled Tritech Systems Require 100Mbps in order

to function correctly and may not work on lower 10BASE−T lines. It’s not recommended to connect Tritech units

through a network hub, a network switch is recommended to be used instead.

Note

If Ethernet devices don’t appear when connected and powered on, check

the computer’s TCP/IPv4 settings in Windows Network Centre and ensure the

IP address and Subnet masks use the correct range of 192.168.2.XXX with

Subnet Mask 255.255.255.0

Do not set the host computer IP address the any of the sonar devices or reserved

addresses xxx.2.17, xxx.2.200, xxx.2.201

Also, do not use the“Obtain an IP address automatically”option.

Warning

By default our Ethernet enabled systems have their subnet set to ‘2’. and main IP

address set to 192.168.2.17. Make sure that the host computer’s IP address does

not conflict with this IP address.

Windows Firewall Settings

Check your anti-virus settings. Firewalls will see the data

from the network and may stop the broadcast message.

Occasionally a firewall will allow the broadcast message

but will stop the high data rate from the sensor believing it

to be a denial of service attack. If this is the case, navigate

to “Allowed Apps” in windows and add permissions to the

firewall settings for Seanet Software.

Serial Comms Setup

COM port allocations vary depending on the computer

you use. They can be found by opening Windows Device

Manager where there is a list of COM ports called Ports

(COM & LPT).

NOTE

When using ARCNET It is worth noting that a SeaHub or Tritech SCU is required

to interface with the sensor. This is because Tritech use our own proprietary

version of the ARCNET protocol.

Wiring diagrams and pin-outs can be found in section 2.6 of this manual..

11

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

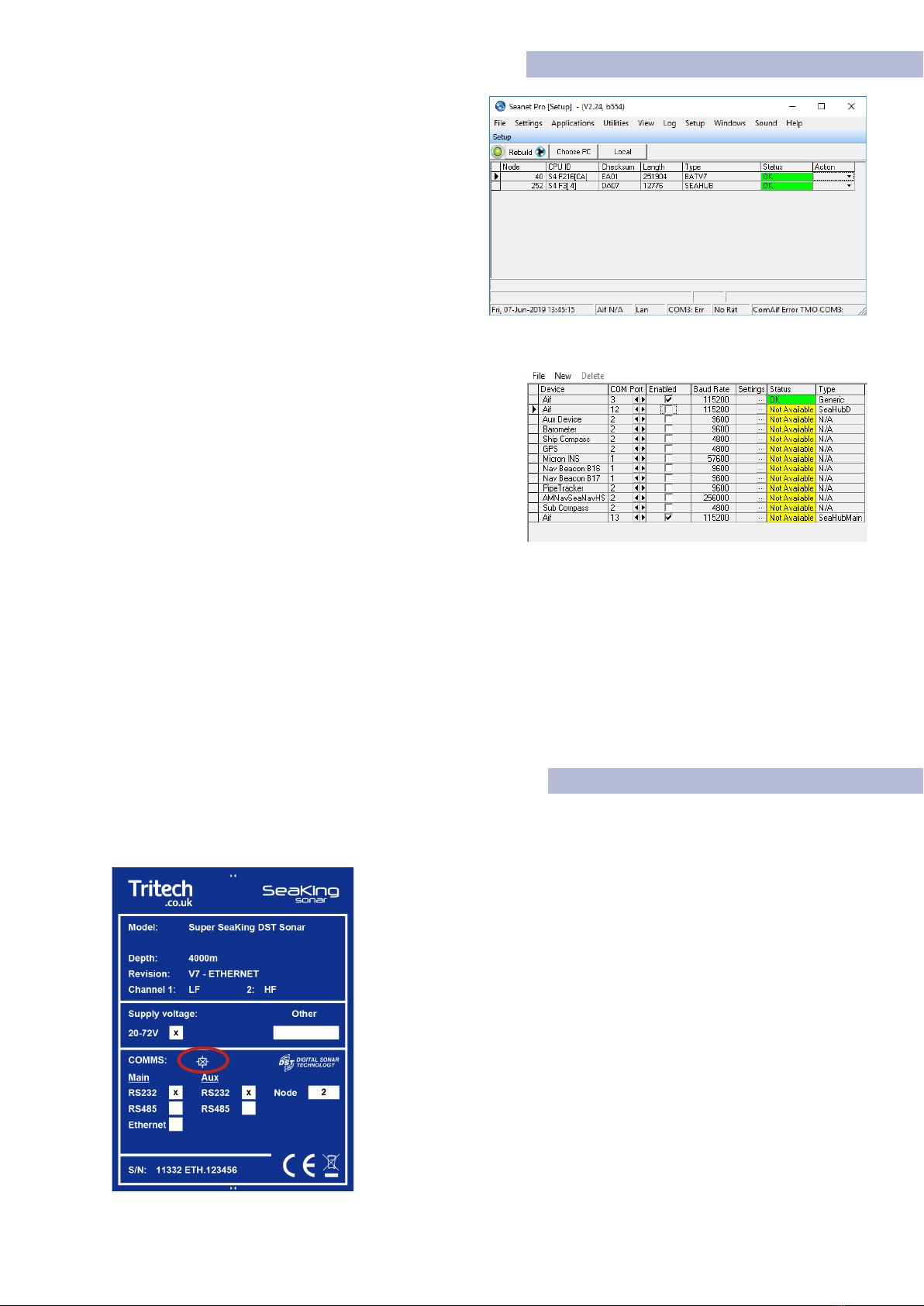

4.5 SeaNet Pro Setup

Setup window

Having installed the hardware it is now time to setup

communications within SeaNet Pro.

To do this go to the Applications in menu at the top of

the screen and select Setup.

This brings up the Node list where the sensors will

appear.

If using Ethernet the sensor will be detected

automatically and will appear in the Node list.

Serial Comms Setup

Make sure the com ports are activated by clicking the

Utilities menu and select Com Setup.

In the Channel Setup dialogue (right) that appears, find the

entry called“Aif”(by default, it is the top entry). if not, it can

be added by selecting New then Aif.

Check the com port number is correct and corresponds to

the port of your device and that the Enabled check box is

ticked.

When SeaNet Pro’s comms Interface has been properly configured, the device/s will appear in the Node List

where they can be fully configured.

Changing the Comms Protocol of the Device

The comms protocol on V7 systems is software selectable. This means changing between Ethernet/Arcnet and

serial comms can be done from the node list in Seanet Pro setup. Click on the drop-down under the Actions

column in the node list to bring up the Device Setup Window. Full details can be found in section 4.

4.6 Magnetic Reset

If the comms mode or baud rate of a system has been changed to an unknown state, there is a quick solution to

reset the communications protocol to a known state.

The following steps will reset the unit to RS232 comms protocol..

◊ Connect the unit under test to an available RS-232 interface.

◊ Do not apply power just yet.

◊ Return to ‘Seanet Setup’.

◊ Ensure the Com Port of the device is setup and enabled

◊ Place a S11247 magnet on the Reset symbol on the label (Circled in red).

◊ Hold the magnet in position and power up the instrument.

◊ When the node appears in Seanet Setup, remove the magnet.

If after 15 seconds, the device does not appear in the Seanet Node list,

ensure magnet is aligned correctly and cycle the power.

12

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

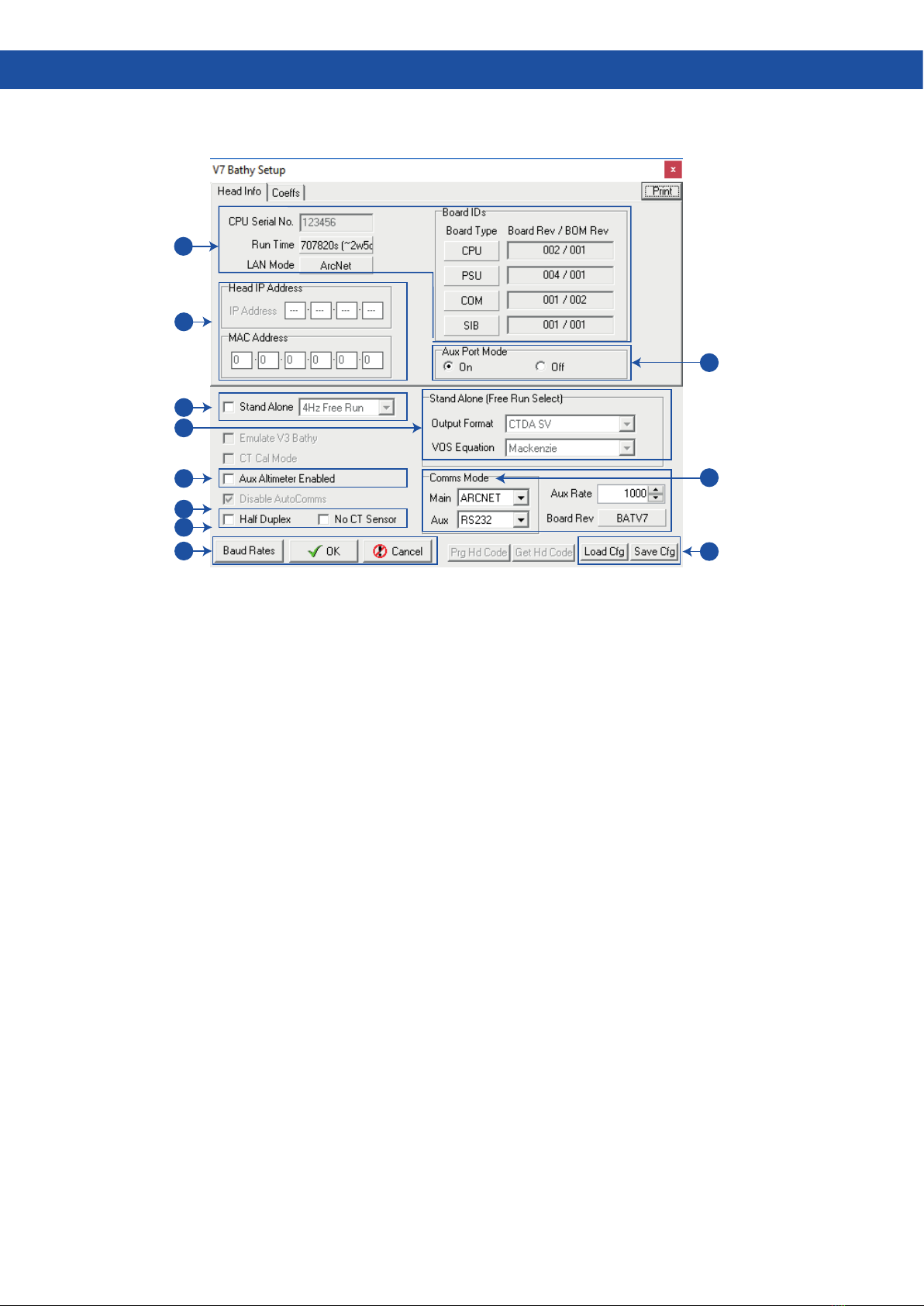

1. Head Info/Coes Tab- Information relating to

the instrument build. The Run Time field will

show the total time the instrument has been logging

for (between calibration dates). LAN Mode will either

be ARCNET or ETHERNET dependant on system

configuration.

2. Head IP Address- This section is only relevant to

‘ETH’ instrument variants. The IP Address field is

modifiable to allow reprogramming of the static IP set

by the factory. The MAC Address is a read only control

that displays the allocated MAC for the instrument,

and will be populated at the factory during build.

3. Standalone Mode- This enables the alternate

‘stand-alone’ communications mode. In this

mode, the instrument will output ASCII text in a

range of CSV formats. Output rates range from 1-4Hz

(free-running), as well as the option to interrogate for

data. For further details about ‘stand-alone’ mode, see

Appendix C.

4. Output Format- These settings are in respect

to ‘stand-alone’ operational mode. The output

format drop-down offers a range of string formats.

For output formats including ‘SV’(Sound Velocity), the

VOS equation drop-down offers a range of industry

standard VOS calculations. Please note these VOS

calculations are only in respect to ‘stand-alone’ mode,

and will not affect the value derived in Seanet (when

running in normal operational mode).

5. Aux Altimeter Enabled- This setting notifies the

instrument to reserve the AUX port for a Tritech

PA (altimeter). By default, this option will be checked.

6. Half Duplex- This option is auto-selected when

operating over RS-485. It may also be required

when operating over RS-232 via a serial MUX.

7. No CT Sensor- This is a factory-only option, and

is specific to the SK701 instruments.

8. Baud Rates- This control will open the Baud Rate

setup dialog.This window allows the operator to

make changes to the Main/Aux port communications

speeds. For further details on changing comms modes,

please see section 3.4.

9. Aux Port Mode- This control allows the

operator to turn off power to the AUX port on

the instrument. Please note that even if the AUX Port

Mode is set to off, a blanking cap must still be fitted

to the AUX port before immersion of the instrument.

10.

COMMS Mode- These controls allow changing

of the communication modes for both

MAIN and AUX. For further details on changing the

communication modes, see section 3.4

11.

Load/Save Cfg- This allows the operator to

save the current settings/coefficients to a

‘UserBBCfg’ file. It also offers the option of loading a

previous ‘UserBBCfg’ file back into the instrument.

These can be provided by the factory if accidental

changes are made to the instrument settings.

4. Device Configuration Window

The device Configuration window is accessed from the node list by clicking on the drop-down (under the action

column) and selecting setup. Below is an overview of the Configuration window.

1

11

9

10

3

4

2

5

6

7

8

13

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

4.1 Seanet Pro Operation

The Following section covers basic operation within SeaNet Pro.The SeaKing 700 series can be operated alongside

other devices in a multi-window application. For this example we will focus on the Single Bathy Application.

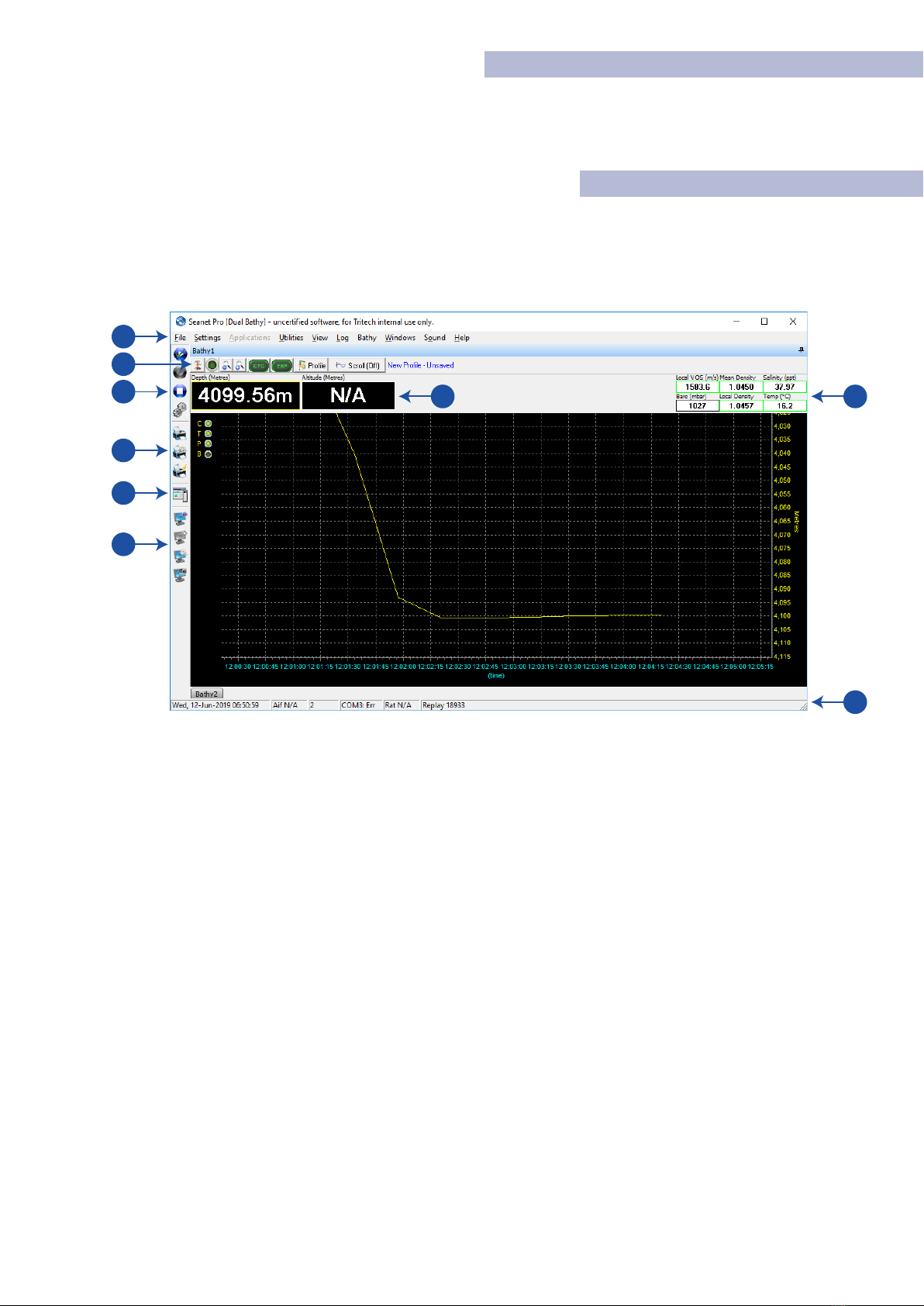

4.2 Main Screen

In the Applications menu at the top of the window, select “Single Bathy” to bring up the main Bathy interface

screen. Below is brief overview of the Bathy Application window.

1

8

9

7

3

2

4

5

6

1. Main Seanet Menu- This accesses the global

functions of Seanet Pro. Here you will also find

environmental offsets and configuration for devices as

well as the ability to load and playback stored log files.

2. Bathymetric Settings Bar- Quick access to some

of the basic functions of the bathy. To the left is

the Application tools button which accesses the bathy

setup and configuration. See section 3.9 for full details

on the Application Tools Menu. Next is the start/stop

sensor button.

3. Logging Short- Cuts- Logging controls to load

existing log files, Start and stop a new log. The

gears icon accesses the log settings panel to select file

destinations

4. Print Bar- Print, Quick Print and Print setup

options for printing the screen data.

5. Side Bar Short-cut- Opens a side bar which can

be used as an events logger or to store project

specific information to the log.

6. Screen Capture- Seanet Pro has it’s own screen

capture built in. Basic start/stop and setup can

be found here.

7. Depth and Altitude - Text boxes that display

live depth and altitude reading . Note that“NA”is

displayed when no Altimeter is connected.

8. Bathymetric Data- The system displays sensor

measurements for VoS, Density, Salinity, pressure

and temperature.

9. System information bar- Seanet system

information including local time and com status

are displayed.

The Bathy Application generates a rolling display showing depth against time. The two main toolbars used

consist of the data display bar (running horizontally across the top of the bathy application), and the Seanet

controls short-cut bar (running vertically down the LHS of the display). There are two main toolbars, one long

the top of the screen and one vertically on the left of the depth profile.

14

0688-SOM-00001, Rev: 02 © Tritech International Ltd.

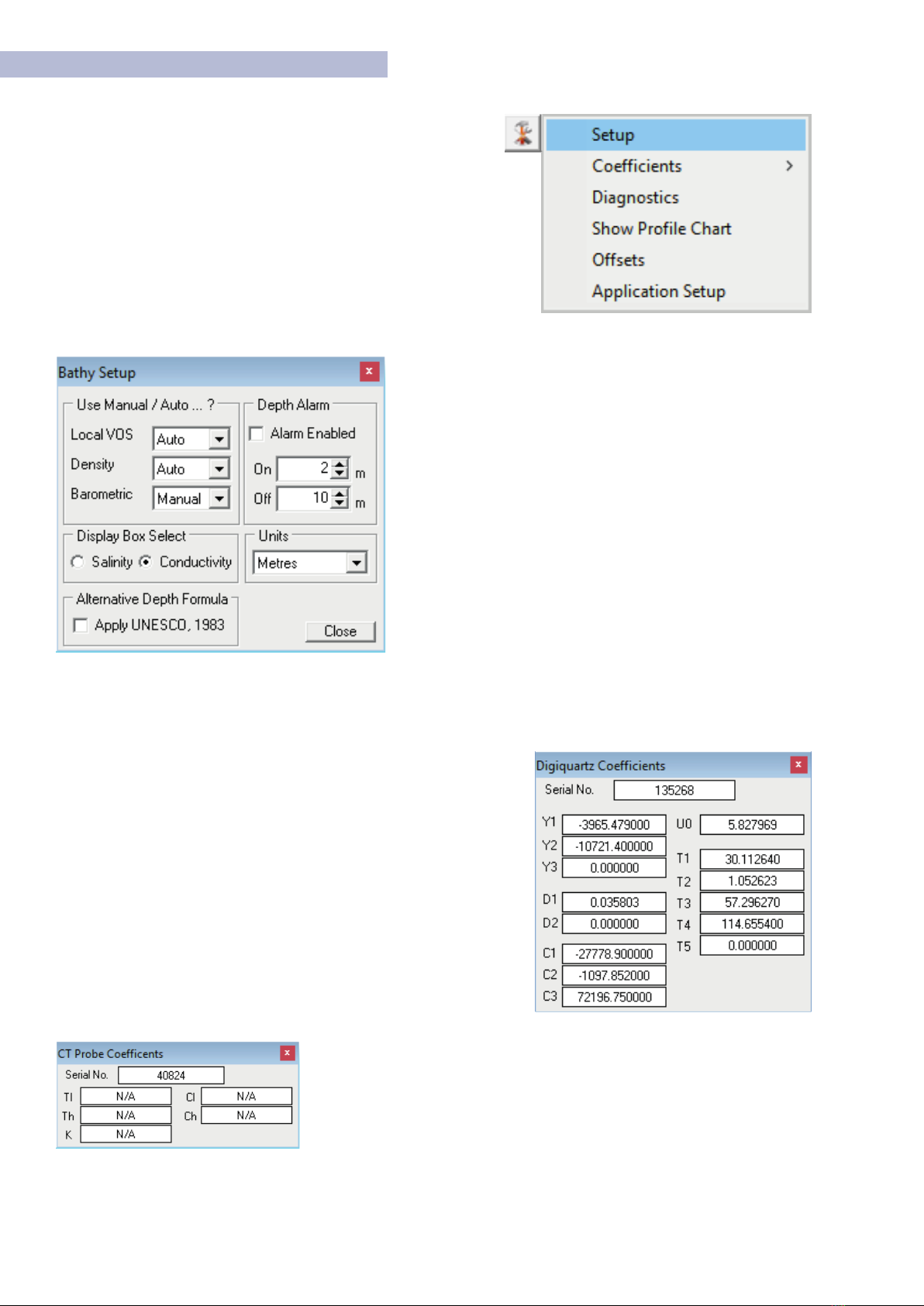

4.3 SeaNet Pro Tools

Bathy Application Menu

The Bathy application menu can be accessed either by clicking the

menu icon in the top left of the top toolbar or by right clicking the

mouse in the Bathy application window.

Here you can access all settings and information screens for the bathy.

Setup

Set Auto or Manual values for Local VOS, Density, and

Barometric. If Auto, the application calculates the correct

based on Bathymetric data available. Otherwise manually

entered values must be applied in the environmental settings.

Display Box Select - Toggles the display between Salinity or

Conductivity in the top right of the main Bathy Screen.

Alternative Depth Formula - Uses the UNESCO standard

depth calculation described in Appendix B .

Depth Alarm - Set the depth range for alert. When activated,

the Bathymetric Display will flash.

Units - Selects units of measurement Meters, Feet, Fathom

or Yards.

Coecients / View DQ Coecients

Opens a pop-up window displaying all coefficient data relating to the

Digiquarts. These values are calculated during the calibration process

of the Bathy.

This data is for information only and cannot be modified. If Coefficient

values need to be updated please refer to the CoeffsTab in the Device

Configuration window as outlined in section 3.6

Coecients / View CT Coecients

This is a legacy option from the V3 Bathy and is not relevant to V7 systems.

Only the CT probe serial number is available to view.

This manual suits for next models

2

Table of contents