© 2007 Moog GmbH Operating Instructions D661K, D662K, D663K and D664K (CA49305-001; Version 3.0, 10/07) 3

Table of Contents

1 Safety Instructions page 3

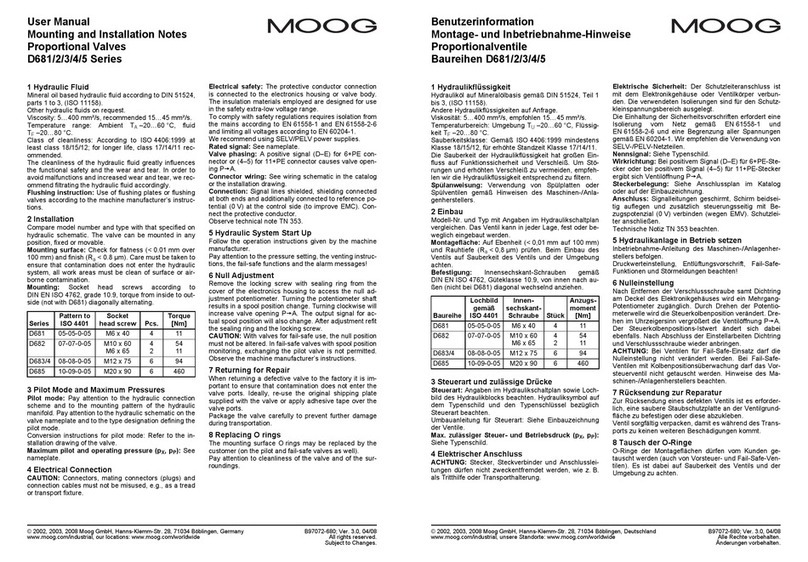

2 Description page 4

3 Technical Data page 7

4 Installation page 10

5 Setting up page 14

6 Maintenance page 14

7 Malfunctions – Causes and Troubleshooting page 15

8 Declaration of Manufacturer page 15

9 Tools page 15

10 Spare Parts and Accessories page 16

11 Ordering Information page 18

1 Safety Instructions

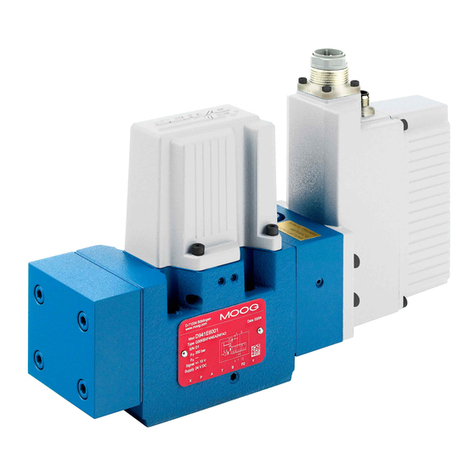

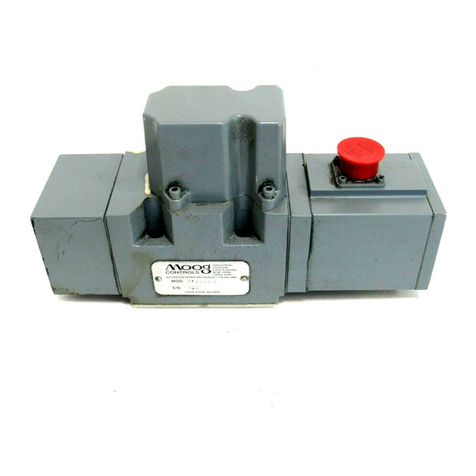

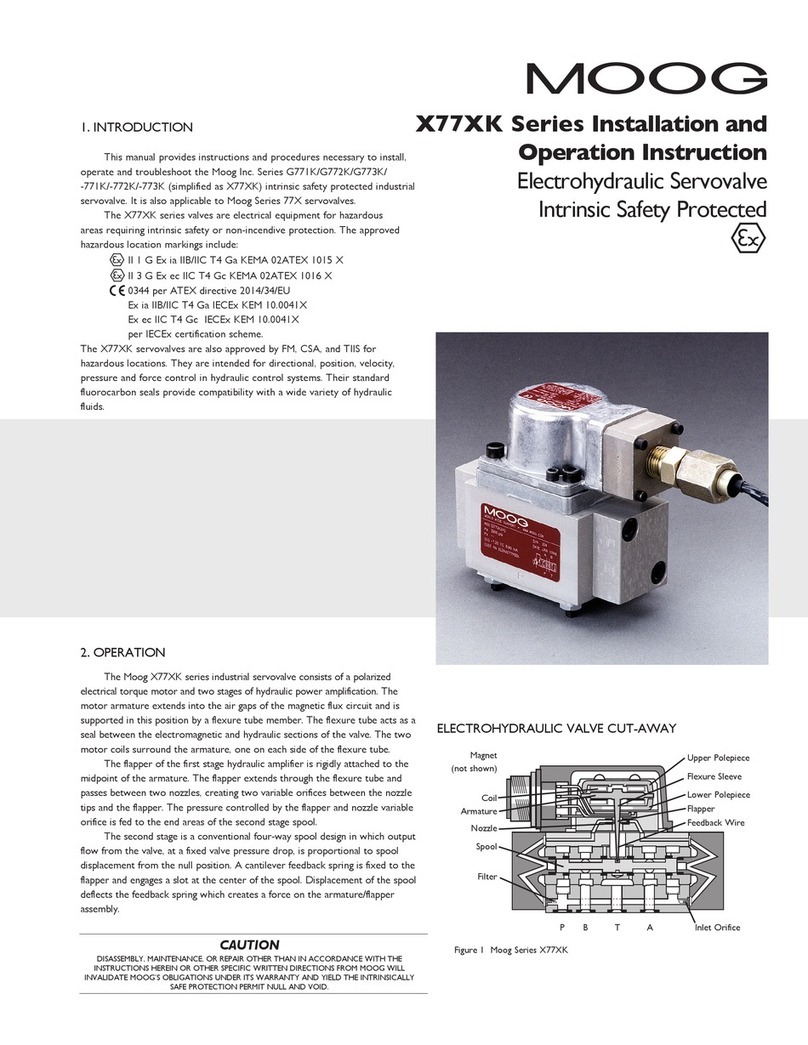

D661K, D662K, D663K and D664K Series

1.4 Selection and qualification of personnel

Service work carried out by the user on explosion protection

valves is prohibited, as intervention by third parties renders

the explosion protection permit null and void.

1.5 Safety instructions for specific operational phases

1.5.1 Take the necessary precautions to ensure that the valve is

used only when in a safe and reliable state.

1.5.2 Check the valve at least once per working shift for obvious

damage and defects (e.g., leakage or damaged cables).

Report any changes to the responsible group/person

immediately. If necessary, stop the machine immediately

and secure it.

1.5.3 In the event of malfunction, stop the machine/plant

immediately and secure it. Have any defects rectified

immediately.

1.5.4 If the machine/plant is completely shut down for

maintenance and repair work at the valve, it must be

secured against inadvertent start up by:

ULocking the principal control elements and

removing the key.

Uattaching a warning sign to the main switch.

1.6 Safety instructions for the operation of hydraulic

plants

1.6.1 Work on electrohydraulic equipment must be carried out

only by personnel having special knowledge and experience

in electrohydraulic controls.

1.6.2 Check all lines, hoses and fittings of the plant regularly for

leaks and obvious damage. Repair damage immediately.

Splashed oil may cause injury and fire.

1.6.3 Before removing the valve depressurize all system sections

to be opened, pressure lines and accumulators of the

hydraulic system in accordance with the specific instructions

for the plant.

1.6.4 When handling oil, grease and other chemical substances,

observe safety regulations valid for each product.

1.1 Warnings and symbols

Refers to special instructions and prohibitions to

prevent damage

Refers to special instructions and prohibitions to

prevent injury or property damage

1.2 Correct application

1.2.1 The permissible gas groups, which are part of the below

identification, have been modified according to IEC 60079.

Operation with other gases is not allowed!

Prior to starting-up the valve, it must be checked if the gas

used is among the permissible gases.

1.2.2 The valves series D661K, D662K, D663K and D664K are

electrical equipment for hazardous areas, type of protection

"d" ("d" Flameproof enclosure to IEC 60079-1).

Identification D661K/D662K/D663K/D664K Series:

II 2G Ex d IIB+H2 T5 Ta: 80°C

Nemko 07ATEX1060, 0123.

1.2.3 The valves are servo and proportional valves intended for

position, velocity, pressure and force control in hydraulic

control systems that operate with mineral oil based fluids.

Using the valves for purposes other than those mentioned

above is considered contrary to the intended use. The user

bears entirely the risk of such misuse.

Correct application involves also observing the operating

instruction and complying with the inspection and

maintenance directives.

1.3 Organizational measures

1.3.1 We recommend to include this operating instruction into

the maintenance plan of the machine/plant.

1.3.2 In addition to the operating instruction, observe also all

other generally applicable legal and other mandatory

regulations relevant to accident prevention and environ-

mental protection. Instruct the operator accordingly.

1.3.3 All safety and danger prevention instructions of the

machine/plant must meet the requirements of EN 982 and

IEC 60079-0.