Mooney Ranger M20C Reference manual

Other Mooney Aircraft manuals

Mooney

Mooney M20M Installation and user guide

Mooney

Mooney M20M Owner's manual

Mooney

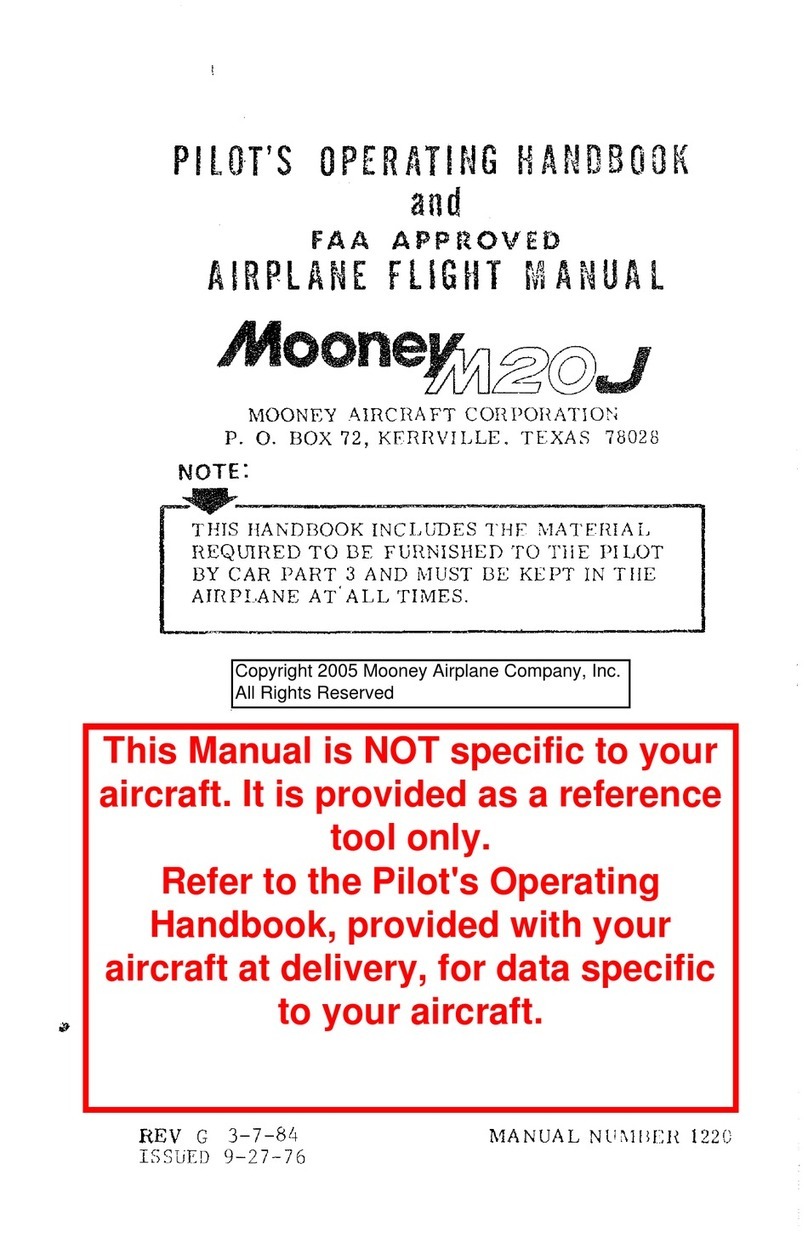

Mooney M20J Technical specifications

Mooney

Mooney M20R - Ovation Reference manual

Mooney

Mooney M20J Owner's manual

Mooney

Mooney M20R - Ovation Technical specifications

Mooney

Mooney M20TN Installation and user guide

Mooney

Mooney M20J 1978 Owner's manual

Mooney

Mooney M20TN S type Owner's manual

Mooney

Mooney M20R - Ovation Owner's manual

Mooney

Mooney M20K Installation and user guide

Mooney

Mooney M20F Executive User manual

Mooney

Mooney M20F Executive User manual

Mooney

Mooney EXECUTIVE 21 1969 User manual

Mooney

Mooney M20V Acclaim Ultra Installation and user guide

Mooney

Mooney M20K Installation and user guide

Mooney

Mooney M20R - Ovation Installation and user guide

Mooney

Mooney 201 User manual

Mooney

Mooney M20L Installation and user guide

Mooney

Mooney M20J User manual