IP67 DIGITAL CALIPER WITH ABSOLUTE ENCODING SYSTEM 110DCP SERIES

For more information visit www.moore-and-wright.com Partners in Precision

• To calibrate the absolute origin position: When the external measuring faces are closed and “0.00” is not

displayed due to worn measuring faces, etc, this shows the absolute origin position has changed. Now it’s

necessary to calibrate the absolute origin. 1Switch on the power and make the external measuring faces

touch. 2Press button “mm/in” until “0.00” is displayed then release the button. 3Move the slider back

and forth several times. Make the external measuring faces touch every time and check if “0.00” is displayed.

If “0.00” is not displayed, repeat the operation until “0.00”is displayed.

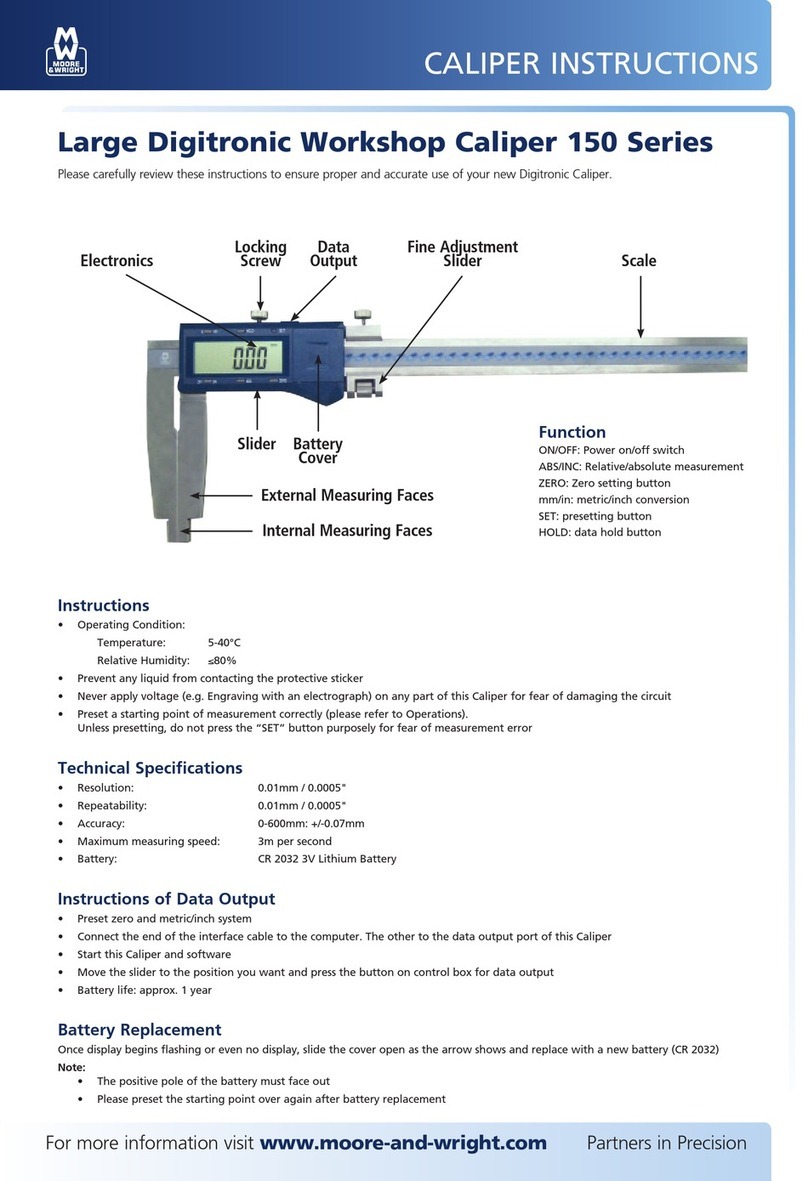

• Workpiece measurement methods: This digital caliper measures internal dimensions (such as slots, holes,

etc.), external dimensions (such as cylindrical, linear outer dimensions, etc.) depth dimensions (such as

groove depth, step height, etc.), etc. Its measurement methods and value reading are the same as ordinary

digital calipers. (See Fig 3 )

Fig 3

Internal Measurement Depth Measurement

External Measurement

Step Measurement

Notes

• Do not charge or burn the battery. If the battery is swallowed, see a doctor immediately.

• The jaws of this caliper have a sharp edge. Handle it with great care to avoid injury.

• Avoid colliding and dropping which may cause deformation and reading errors.

• Keep all the measuring faces and guiding faces clean.

• If it’s not used for a long time, remove the battery and store it in the packing box.

• The electronic components must not be exposed to chemical solvents.

• When replacing the battery, refit the sealing O-ring in case it’s deformed or damaged.

• The digital caliper adopts absolute encoding measuring system, the clearance and position between

the reading head and the steel scale are strict and precise. Do not dismantle any part of it in order to

avoid the reading head’s failure of reading the scale.

Note: Version with thumb roll on request

Fig 2

Fig 3

TROUBLESHOOTING

Serial No. Malfunction Cause Solution

1

Water enters the electronic

components due to

poor gas tightness

1.Battery cover hasn’t been tightened Tighten the screws in the battery cover

2.The sealing O-ring is deformed Adjust the O-ring’s shape

3.The sealing O-ring is damaged Replace the sealing O-ring

4.Other causes Send back for repair

2Incomplete or missing LCD

display

1.Water enters the electronic components Dry it.. Avoid water entering (see no.1)

2. Other causes Send back for repair

3No LCD display

1.Flat battery Replace the battery

2.Poor contact Improve the battery seat

2.Other causes Send back for repair

4LCD displays 1.Low power Replace the battery

5LCD displays “Err-3”

1.The temperature is lower than 0ºC or higher than 40ºC Adjust the ambient temperature between 0°C~40°C

2. Electronic components are damaged Send back for repair

3.Low power / poor contact Replace battery / improve the battery seat

Because of the products’ continuous upgrading, the instructions may be slightly different from the actual product, the actual product shall prevail.