ZX Fire Alarm Control Panels MORLEY-IAS

Installation Manual Document No. 996-174-000-1, Revision: 01 Page i

Table of Contents

1INTRODUCTION..........................................................................................................................1

1.1 NOTICE...................................................................................................................................1

1.2 WARNINGS AND CAUTIONS.......................................................................................................1

1.3 NATIONAL APPROVALS.............................................................................................................2

1.4 EN54 INFORMATION................................................................................................................2

2UNPACKING................................................................................................................................4

3INSTALLATION...........................................................................................................................5

3.1 INSTALLING THE ENCLOSURE ...................................................................................................5

3.1.1 Removing the Chassis...................................................................................................5

3.1.2 Mounting the Enclosure to the Wall...............................................................................5

3.1.3 Remounting the Chassis................................................................................................5

3.2 DIMENSIONS AND FIXING POINTS..............................................................................................6

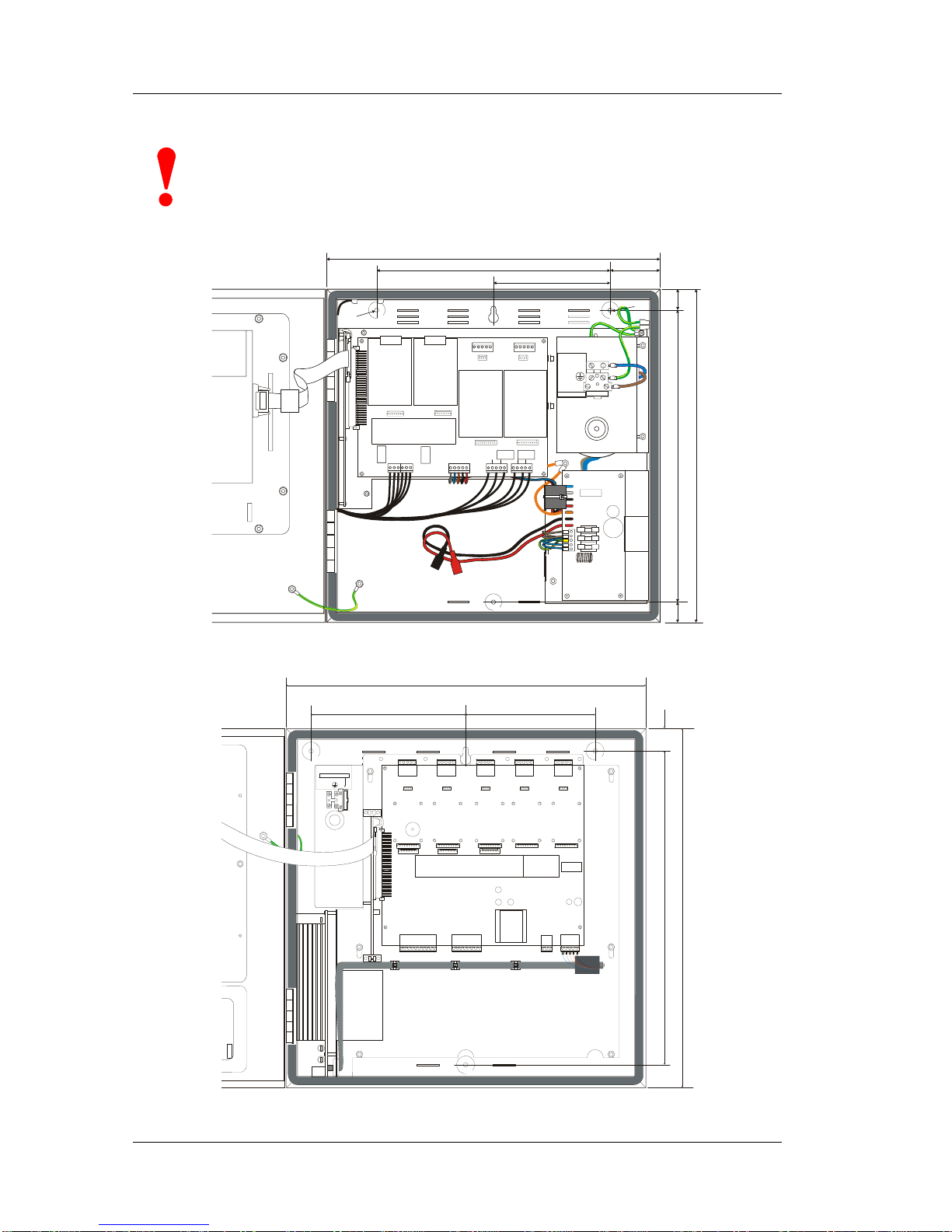

3.3 IDENTIFICATION OF PARTS .......................................................................................................7

3.3.1 CPU Board.....................................................................................................................8

3.3.2 Display / Keyboard.........................................................................................................8

3.3.3 Base Card......................................................................................................................8

3.3.4 Zone Extender Card (ZX5Se Option Only)....................................................................8

3.3.5 Internal Printer (ZX5Se /ZX10Se Option Only)..............................................................8

3.4 EXTERNAL CONNECTIONS........................................................................................................9

3.4.1 Mains Power Input.........................................................................................................9

3.4.1.1 ZX1Se / ZX2Se Arrangement..................................................................................................9

3.4.1.2 ZX5Se Arrangement ...............................................................................................................9

3.4.1.3 ZX10Se Arrangement ...........................................................................................................10

3.4.1.4 Mains Cable Glands..............................................................................................................10

3.4.2 Battery Installation .......................................................................................................11

3.4.2.1 General Introduction..............................................................................................................11

3.4.2.2 ZX1Se / ZX2Se Arrangement................................................................................................11

3.4.2.3 ZX5Se Arrangement .............................................................................................................12

3.4.2.4 General Battery Connection..................................................................................................12

3.4.3 Detection Loops...........................................................................................................13

3.4.3.1 Loop Wiring Installation.........................................................................................................14

3.4.3.2 EMC Compliance..................................................................................................................15

3.4.3.3 Adding Loop Driver Cards.....................................................................................................16

3.4.3.4 Panel Loop Loading ..............................................................................................................16

3.4.4 Sounder Circuits ..........................................................................................................17

3.4.5 Auxiliary Relay Outputs................................................................................................19

3.4.6 Auxiliary Supply Output ...............................................................................................20

3.4.7 Panel Networking / Graphics PC Interface..................................................................21

3.4.7.1 Local Panel Network .............................................................................................................21

3.4.7.2 Master Panel to Superior Master Panel ................................................................................21

3.4.7.3 Panel to Graphics PC............................................................................................................21

3.4.8 Peripheral Loop............................................................................................................22

3.4.9 RS485 Wiring Arrangements.......................................................................................23

3.4.9.1 Daisy Chain Style Installation................................................................................................23

3.4.9.2 Loop Style Installation...........................................................................................................23

3.4.9.3 EMC Compliance..................................................................................................................24

3.4.9.4 Cable Screen – Earth Connections.......................................................................................24

3.4.10 High Integrity Loop.......................................................................................................24

3.4.11 Group Disable Input.....................................................................................................24

3.4.12 Class Change Input .....................................................................................................25

3.4.13 Recommended Cables ................................................................................................25

3.4.14 Cable Routing..............................................................................................................26

3.5 INSTALLING ADDITIONAL EQUIPMENT ......................................................................................27

3.5.1 General Introduction ....................................................................................................27

3.5.1.1 ZX1Se Arrangement .............................................................................................................27

3.5.1.2 ZX2Se Arrangement .............................................................................................................28

3.5.1.3 ZX5Se Arrangement .............................................................................................................28