10

Installation/Owner’s Manual 20201109

For Warranty Service Call 833-474-0367

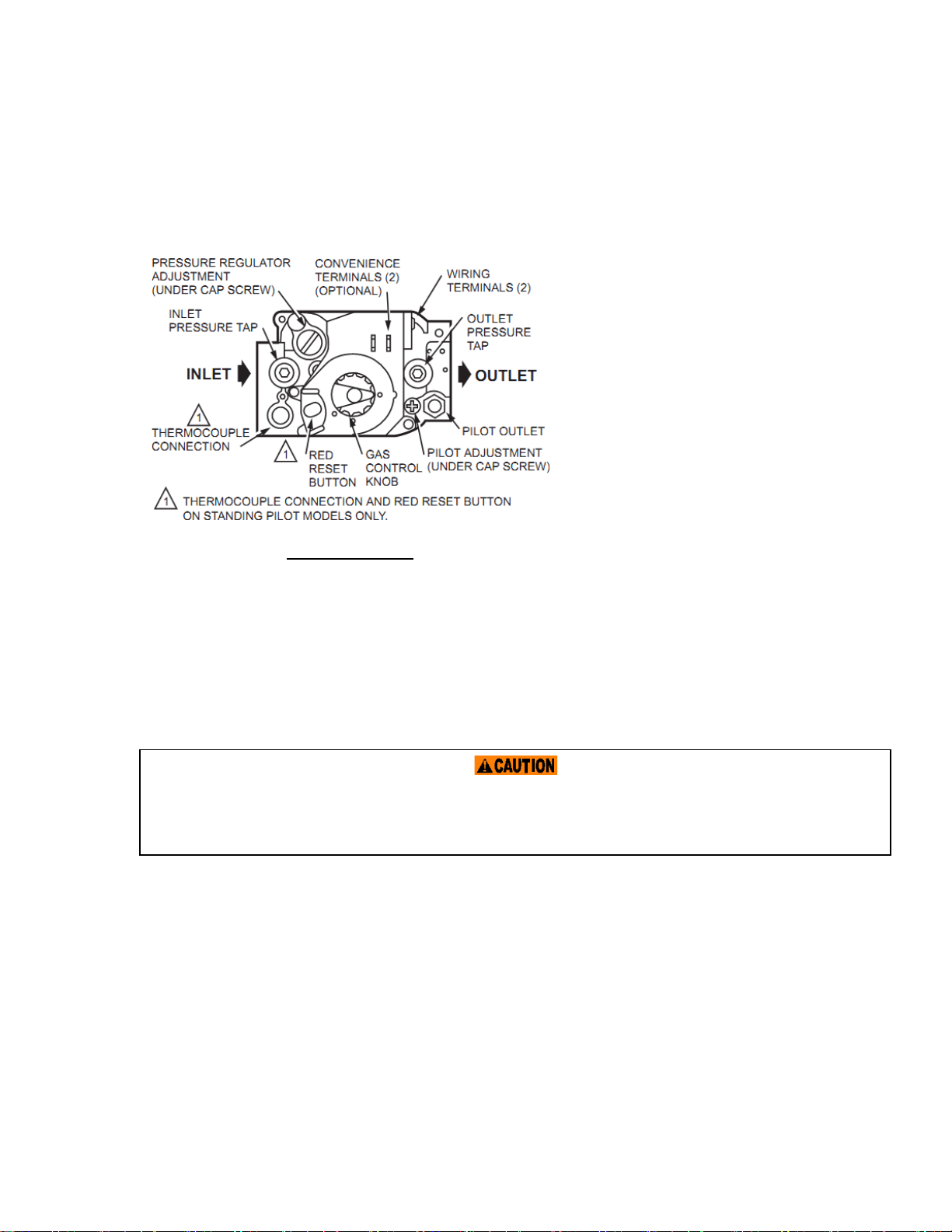

Operating the Controls

A convection oven is a different type of oven that offers many features and advantages to the food service

operation. The additional capabilities and features of the oven require some learning. However, the operation

of the oven is not difficult to understand or control once you have some practice. See the controls in the

following feature:

Operations

Turn the oven ON and select a cooking temperature. Two additional controls are used to control the fan (as

described below). The timer is a reminder to you of when to remove food from the oven. The timer does not

control the temperature of the oven.

To COOK:

1. Turn the oven ON using the Power Switch at the top of the control panel.

2. Select the desired fan speed using the Fan Speed switch. The appropriate fan speed (HI orLOW)

depends on the type of food being cooked.

3. Switch the Fan Mode switch to COOK. The fan will run continuously when the oven doors are closed

(the fan does not cycle on and off with the burners). (If this switch is set to COOL, the only differenceis

that the fan will continue to run when the oven doors are open.)

4. Set the cooking temperature by turning the Cook Temperature Control until the indicator mark on the

knob is pointed to desired cooking temperature. The HEAT ON indicator will light when the burnersare

on and will remain on while the oven preheats.

5. Wait until the HEAT ON indicator has come on and gone out three times. At that time the oven will have

reached the set cooking temperature.

6. Open the oven doors, load the product into the oven, and close thedoors.

7. You can use the Cook Timer as a reminder of when to remove the load from the oven. If so desired,

turn the Cook Timer knob until the indicator mark points to the desired cooking time (up to 55 minutes).

The timer knob will rotate counterclockwise as the timer runs down, indicating how much time remains.

You can turn the knob while cooking to increase or decrease the remaining time. When the timer runs

out, a buzzer will sound for a short time, then turn itself off. (To immediately silence the buzzer, turn the

Cook Timer knob to the OFF position.) The timer is a reminder to you; the timer does not control the

oven. If you open the oven doors, the burners and fan will shut off until the doors are closed. However,

the timer will continue running even if the doors are open.

For ovens that are equipped with an oven interior light, to turn on the light, press and hold the switch

located at the bottom of the control panel.

To COOL DOWN the oven:

When the load has finish cooking, you can rapidly cool down the oven by following the directions below:

1. Turn the thermostat to minimum temperature setting.

2. Open both doors, then set the FAN MODE switch to COOL. The fan will run to cool down the oven.

(For the most rapid cooling, switch the Fan Speed Switch to HI)

3. When the oven has cooled sufficiently, turn the switch to COOK Mode for next Cooking. Or if

finished cooking for the day, allow the oven to cool down for at least 30 minutes beforeshutting

down. (This will prolong the life of the convection oven fan motor.)

4. Once cool then the Cook Temperature Control to the lowest setting (fully counterclockwise) and turn

Power Switch to OFF.

CAUTION: Please follow the COOL DOWN instruction noted above to avoid any burns

as the oven will be hot.