iWMC Integrated Servo Wheel User Manual

Table of Contents

PREFACE………………….................................................................................................................1

Cauons................................................................................................................................. 1

Chapter1 Model Descripon & Installaon ......................................................................... 1

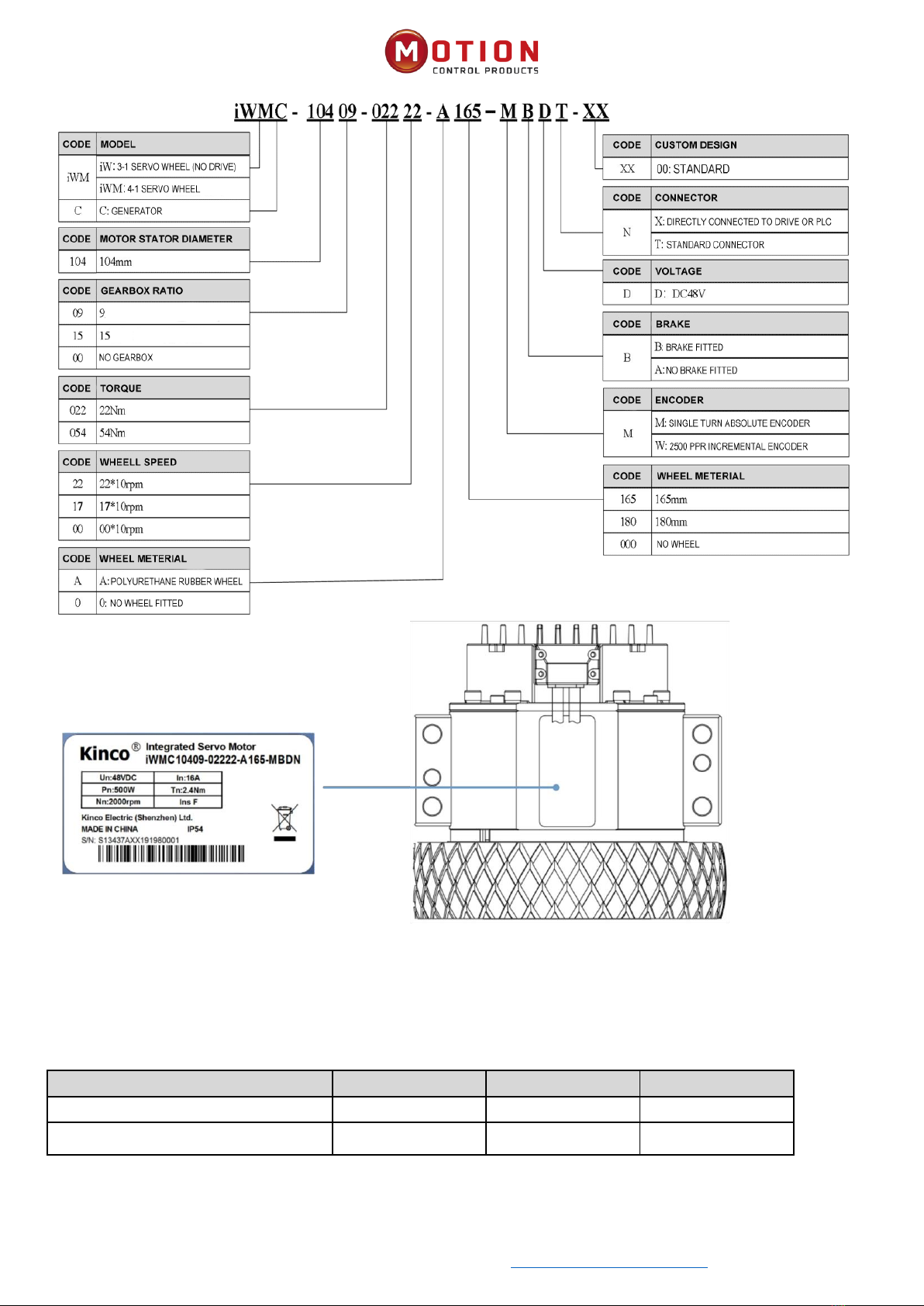

1.1 Product Introducon and Nameplate Descripon ............................................................1

1.1.1 iWMC Integrated Servo Wheel Models ..........................................................................1

1.2 iWMC Integrated Servo Wheel Installaon & Precauons.....................................................2

1.2.1 Installaon Dimension ....................................................................................................3

1.2.2 Operator Requirements...................................................................................................3

1.2.3 Electrical Requirements...................................................................................................4

1.2.4 Environment requirements .............................................................................................4

Chapter2 System Interfaces And Wiring............................................................................... 5

2.1 iWMC Servo Wheel Wiring Diagram.......................................................................................5

2.1.1 iWMC Wiring Diagram....................................................................................................5

2.1.2 Brake Resistor And Fuse Specicaons ..........................................................................5

2.2 Interface denion..................................................................................................................6

2.2.1 iWMC Integrated servo wheel with Integrated Terminals ............................................6

2.2.2 Power Supply Port ...........................................................................................................7

2.2.3 Brake Resistor Port ..........................................................................................................8

2.2.4 Terminal Specicaons ...................................................................................................8

Chapter 3 KincoServo+ Soware Introducon....................................................................... 9

3.1Fast Start ..................................................................................................................................9

3.1.1 Language Conguraon .................................................................................................9

3.1.2 Open And Save Project Files............................................................................................9

3.1.3 Start Communicaon ....................................................................................................10

3.1.4 Node ID And Baud Rate.................................................................................................10

3.1.5 Object (Add, Delete, Help) ............................................................................................11

3.2 Inialise, Save And Reboot....................................................................................................11

3.3 Load Firmware.......................................................................................................................12