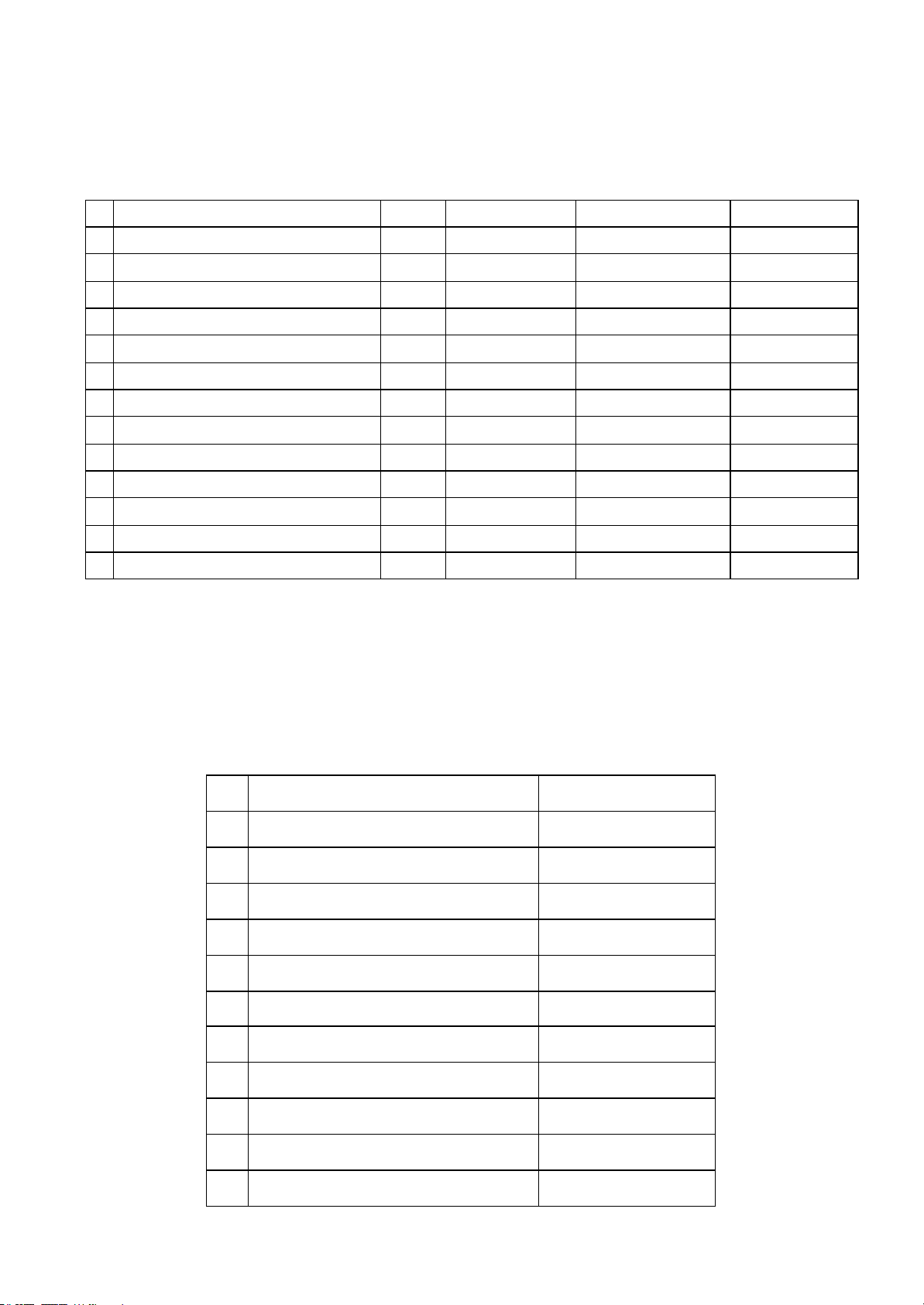

1.3 In order to achieve safe riding, good performance and reduce pollution, please execute the following

recommended maintenance table base upon average driving condition. Driving in unusual dusty

areas, require more frequent servicing. MONTHS/DISTANCE(IN KM)FOR CHECKING

Item

Checking Content 1 or

300 km 3 or

3000k 6 or

5000k 9 or

8000k

12 or

10000k 15 or

13000k 18 or

15000k

Engine oil *Replace (800cc, total 900cc) RReplace it per 1,000km

Oil Filter * Replace RReplace it per 5,000km

Coarse oil filter*(on oil

draining bolt) Clean or replace it if necessary CClean it per 3,000km or replace it if required

Oil cooler Clean or replace it if necessary ICCC

Air filter*Replace it if required Replace it per 1,000km

Gear oil *Replace (90cc, total 110 cc) RRRR

Brake performance Leaking and function check IIIIIII

Brake oil, disk, pad,

hose, master cylinder Leaking and worn-out check or

replace it if necessary IIIIIII

Clutch linings *Check or replace it if necessary IIIIII

Tires Worn-out check or replace it if

necessary IIIIII

Wheel bearing *Fasten tightly if loosen IIIIII

Driving chain *Lubricate & check the slack IIC,A,L IC,A,L IC,A,L

Chassis suspension arm,

spindle *Check looseness. Add greaseif

required IIC,A,L IC,A,L IC,A,L

Steering joint & rod *Check looseness. Adjust it if

required III

Absorber*Leaking and function check IIII

Parking Function check or replace it if

required IIIIIII

Nuts, bolts, fasteners Tighten it if required IIIIIII

Battery Make sure that the voltage

stayed over 12.8V.

battery it required.

Clear the poles.

IIIIIII

Valve gap *Check and adjust when engine

is cool (0.08mm for IN & EX) Adjust it when necessary

Spark plug *Clear or replace if required IIIIII

V belt *Worn out check or replace if

necessary. PPP

Fuel feeding system*Crack and blockage check.

Replace it if necessary. III

Engine idle speed *1700±100 rpm AAAAAAA

Carburetor idle A/F

Adjustment *Check and adjust referring to

CO/HC Percentage. AAAAAAA

A: adjust C: clean I: inspect, clean or replace if necessary L: lubricate R: replace

1. Items with “*” mark indicate our recommendation to have it done by PGO dealer.

2. “P” denotes that function check or replace it when the engine performance reduces significantly.

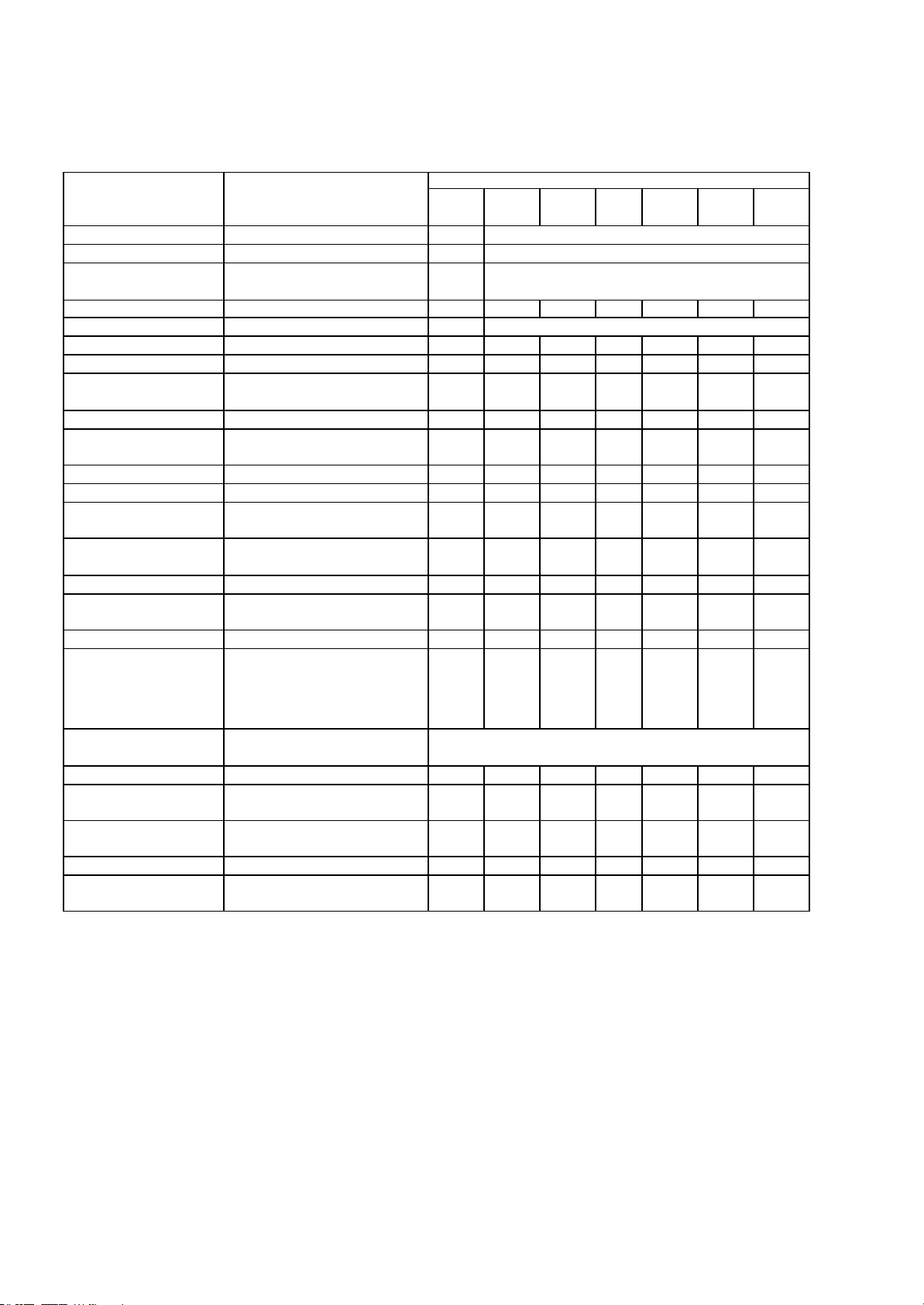

NOTE 1

:

The engine oil shall be changed completely after run-in period 300 km or one month later. This can

make sure the engine runs smoothly.

NOTE 2

:

The exchange of brake fluid

1. After disassembling of brake main cylinder or caliper, do change the new fluid.

2. Check the fluid level often, refill if necessary.

3. Change the oil seal of main cylinder and caliper every two years.

4. Change the brake fluid hose every four years.