IMPORTANT PRODUCT AND SAFETY

INSTRUCTIONS

Safety

The INS Advanced Stabilization upgrade is not a toy and can cause serious injury,

death or damage if not used properly. You must exercise caution during use of the INS

to ensure a safe filming environment for everyone. This Operation Manual describes

safe operation and should be read in conjunction with the applicable online training

videos or additional in-person training.

IMPORTANT: Restricted Use Statement

The INS Advanced Stabilization upgrade must only be used by trained operators 18

years of age or older when properly mounted on an appropriate motor vehicle driven

on a closed course with paved or finished surfaces (for example, asphalt, concrete, or

tarmac) or moderate off-road (for example, gravel or dirt roads) conditions. In addition,

the speed and acceleration of the motor vehicle must not exceed system ratings for

INS as set forth in this Operation Manual.

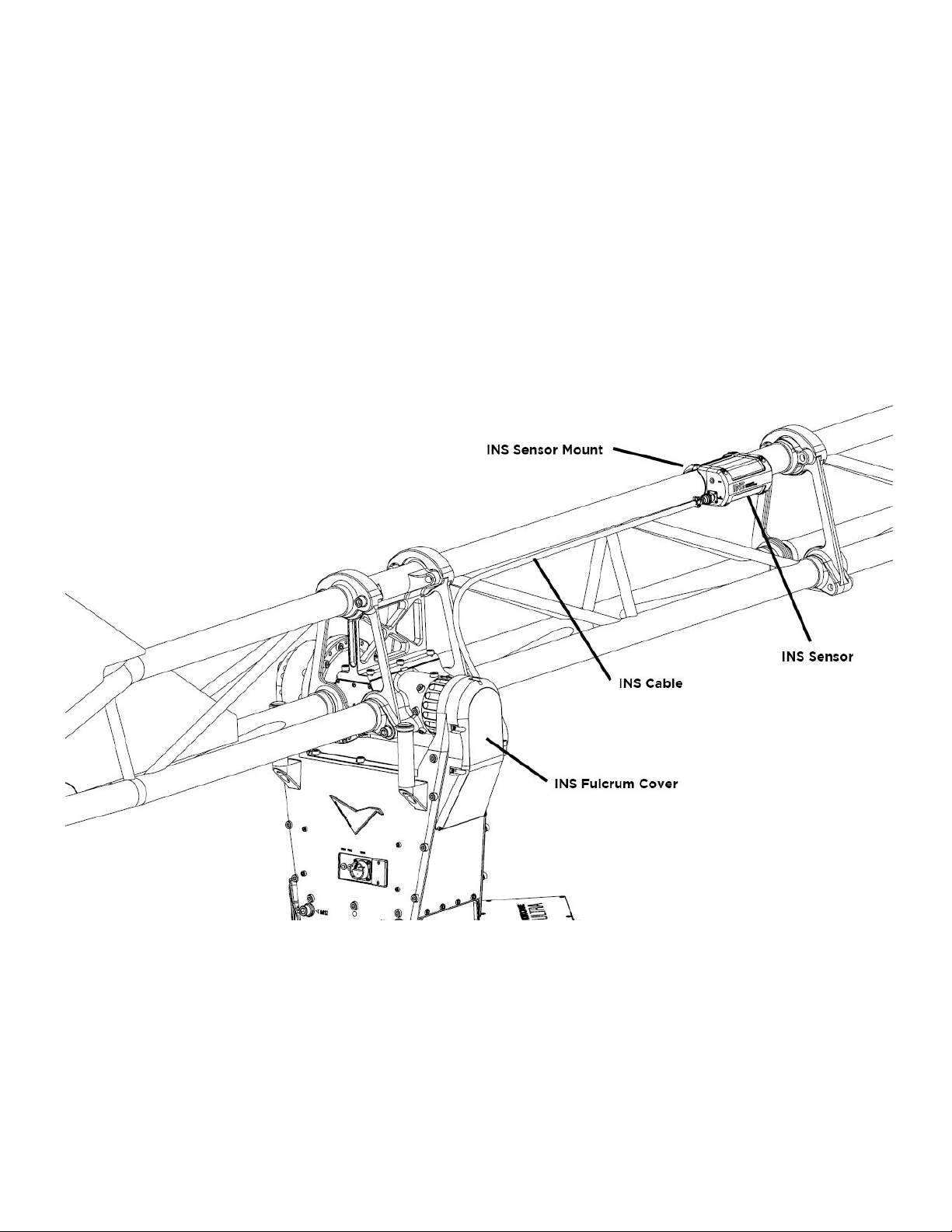

Do not modify or adjust the INS assembly. The INS has been calibrated before it is

shipped to you. No modification or adjustment to the INS is allowed without the

express written approval of MotoCrane, LLC.

Disclaimer and Limitations of Liability

You agree that you are responsible for your own conduct and any content created

while using the INS, and for any consequences thereof. You agree to use this product

only for purposes that are proper and in accordance with local laws, regulations or

other legal requirements.

You also agree:

1. Any part of this disclaimer is subject to change without prior notice. Refer to

www.motocrane.com/support for the latest version.

2. MotoCrane, LLC reserves the right of final interpretation of this disclaimer.

3. MotoCrane, LLC has no control over the use, setup, assembly, modification or

misuse of the INS, and therefore no liability shall be assumed or accepted by

MotoCrane, LLC for any resulting damage, death, or injury incurred directly or

indirectly from the use of the INS. By the act of use, setup or assembly, the operator

accepts all resulting liability.

6