5 6

4. RISK OF PERSONAL INJURY. Never spray compressed air or material at self or others.

5. RISK OF BURSTING. Check the maximum pressure rating in the manual or identification label. The

compressor outlet pressure must be regulated so that it does not exceed the maximum pressure

rating. Relieve all pressure in the hose before removing or attaching accessories.

6. RISK OF BURSTING. Do not adjust the pressure switch or safety valve for any reason. They have

been preset at the factory for this compressor’s maximum pressure. Tampering with the pressure

switch or the safety valve may cause personal injury or property damage.

7. RISK OF BURNS. The pump and the manifold generate high temperatures. In order to avoid burns

or other injuries, do not touch the pump, the manifold or the transfer tube while the compressor is

running. Allow the parts to cool down before handling or servicing. Keep children away from the

compressor at all times.

8.

RISK TO BREATHING. Be certain to read all labels when you are spraying paints or toxic materials,

and follow all safety instructions. Use a respirator mask if there is a chance of inhaling anything you

are spraying. Also, NEVER directly inhale the air produced by a compressor.

9. RISK OF EYE INJURY. Wear ANSI Z87.1 approved safety goggles when using an air compressor. Do

not point any nozzle or sprayer toward a person or any part of the body. Serious injury may occur if

the spray penetrates the skin.

WARNING!

1. Pull the pressure safety valve ring every day in order to ensure that the valve is

functioning properly.

2. The compressor must be located in a well-ventilated area for cooling, and

must be a minimum of 12” (31 cm) away from the nearest wall.

3. Protect the air hose and the power cord from damage and puncture. Inspect them for weak or worn spots every

week, and replace them if necessary.

4. Always wear hearing protection when using an air compressor. Failure to do so may result in hearing loss.

5. Do not carry the compressor while it is running.

6. Do not operate the compressor if it is not in a stable position.

7. Do not operate the compressor on a rooftop or an elevated position that could allow the unit to fall or be tipped

over.

8. Always replace a damaged gauge before operating the unit again.

Extension cords

As the distance from the supply outlet increases, you must use a heavier gauge extension cord. Using extension

cords with inadequately sized wire causes a serious drip in voltage, resulting in loss of power and possible product

damage. Refer to the table here to determine the required minimum wire size.

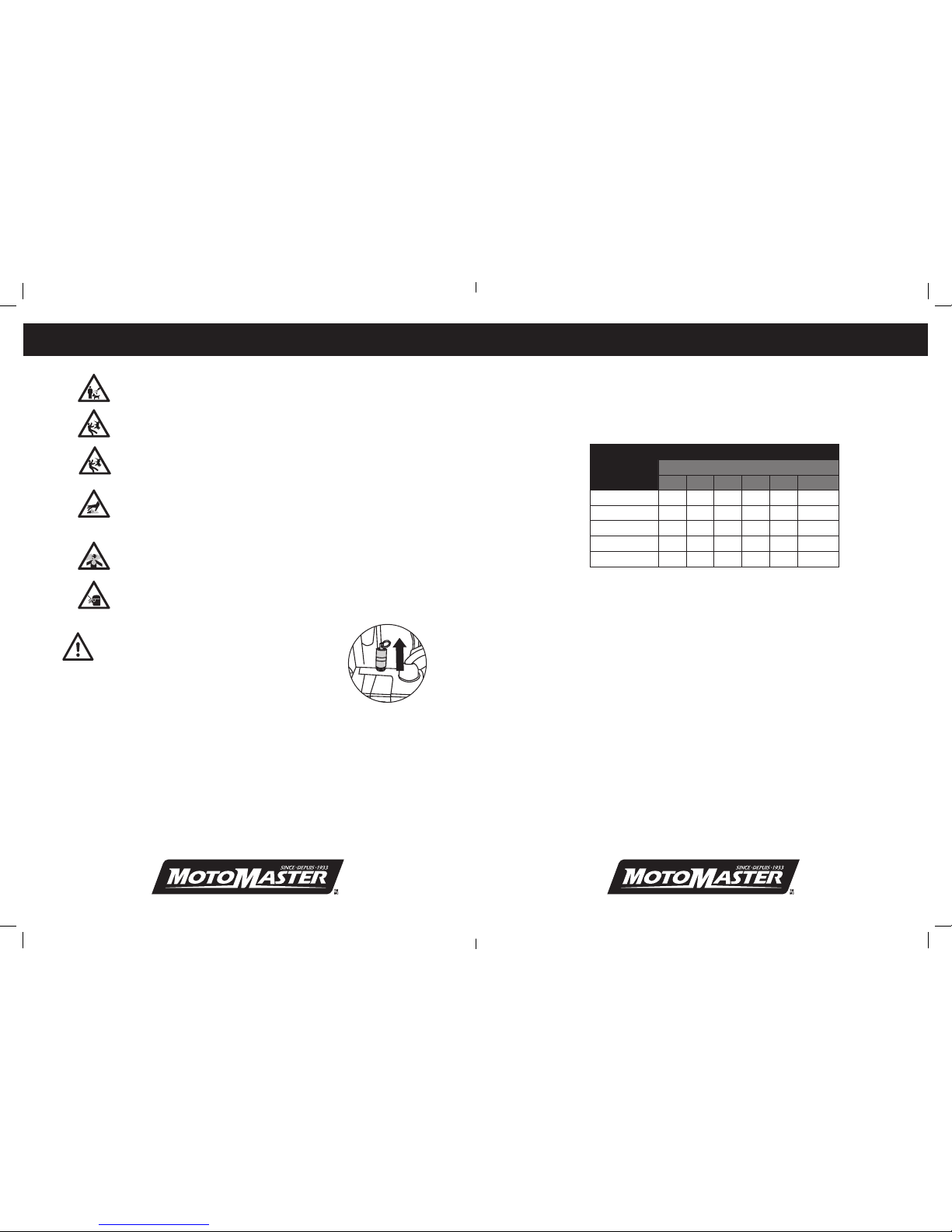

Recommended Minimum Wire Gauge for Extension Cords* (120 V)

AMPERE

RATING

CORD SIZE IN AWG (AMERICAN WIRE GAUGE)

Extension cord length in feet

25' 50' 75' 100' 150' 200'

0 - 5 16 16 16 14 12 12

5.1- 8 16 16 14 12 10 --

8.1 - 12 14 14 12 10 -- --

12.1 - 15 12 12 10 10 -- --

15.1 - 20 10 10 10 -- -- --

* Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

The smaller the gauge number of the wire, the greater the capacity of the cord. For example, a 14-gauge cord can

carry a higher current than a 16-gauge cord. When using more than one extension cord to make up the total length,

be sure each cord contains at least the minimum wire size required.

Guidelines for using extension cords

• Ifyouareusinganextensioncordoutdoors,besureitismarkedwiththesufx"W-A"("W"inCanada)to

indicate it is acceptable for outdoor use.

• Ensureyourextensioncordisproperlywiredandingoodelectricalcondition.Alwaysreplaceadamaged

extension cord or have it repaired by a qualified technician before using it.

• Protectyourextensioncordsfromsharpobjects,excessheatanddamporwetareas.

SAFETY GUIDELINES (cont.)SAFETY GUIDELINES (cont.)

058-7949-6-Air-Compressor-5G-EN-05.indd 5-6 5/14/12 11:14 AM