Page 3

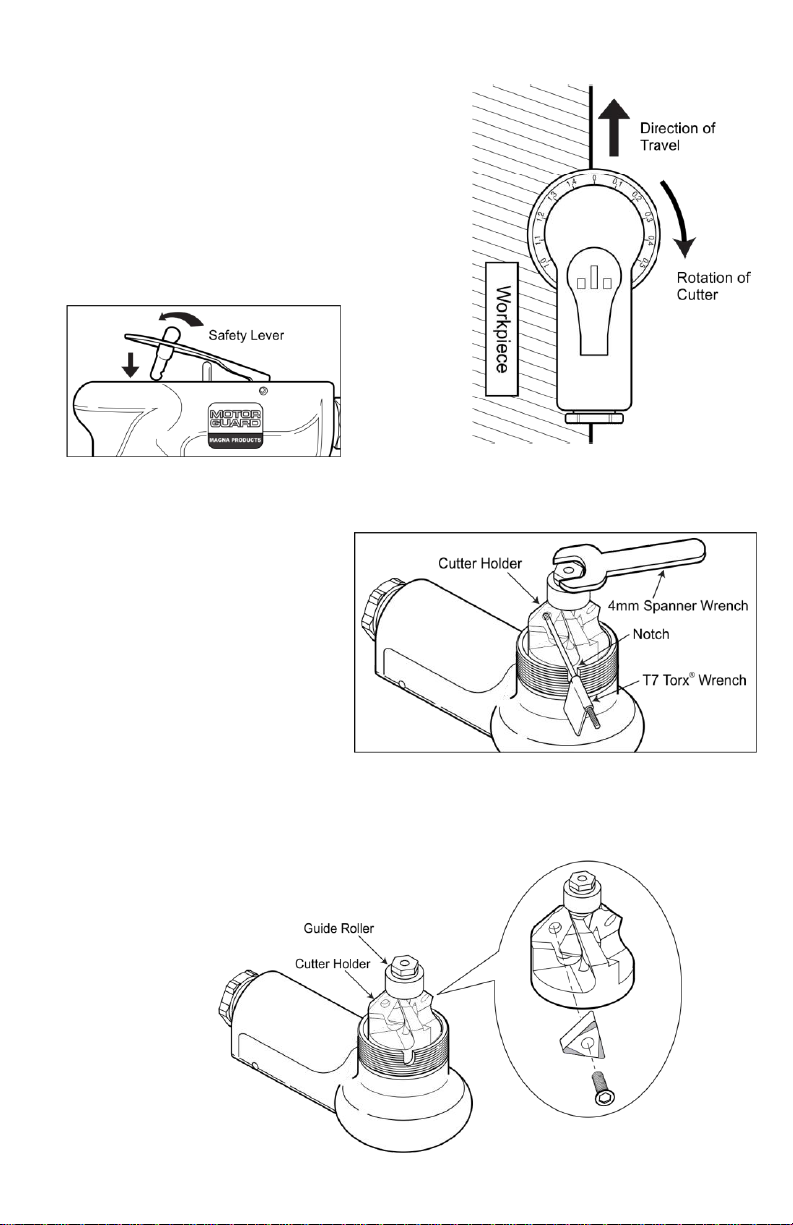

OPERATING THE TOOL

Place Flange flush with flat work surface and operate tool

by rotating safety lever forward to free paddle (Fig. 4)

Press and hold paddle down to operate tool. Cutting

blades must be clear of work surface before beginning

tool rotation. Bring rotating tool into contact with work

surface and move tool smoothly in direction shown (Fig. 5).

Best results are obtained by operating the tool in the

direction shown and travelling at a smooth, steady pace.

Operating in the reverse direction may cause tool to

“climb” the work while excessive travel speed may cause

chatter and a poor surface finish.

CUTTER INDEXING AND REPLACEMENT

IMPORTANT: Disconnect tool

from air supply and relieve internal

pressure before performing any

disassembly or adjustment. Failure to

follow these directions can result in

serious personal injury.

Three-sided cutters can be indexed to

provide a newly sharp edge. Loosen

Flange Screw and remove Flange by

turning counter-clockwise. Rotate Cutter

Holder so that Cutter Bolt can be

accessed through Notch in Housing (Fig.

6). Using Torx®Wrench, loosen Cutter

Bolt by turning counter-clockwise (Fig. 7). Rotate cutter holder to access remaining cutters.

Follow same procedure in reverse to install new cutters. To loosen Guide Roller Nut, insert Torx®

Wrench in Notch to prevent rotation (Fig. 6).