FEATURES AND FUNCTIONS

• TDS (Torque Data System) software included for complete data management and archiving to a PC.

Includes seamless data synchronisation. See TDS Manual part number 34397 for more information.

• All NorTronic® tools are Torque Handles with a 16mm spigot to interface to additional end fittings and

offsets. A push through ratchet head end fitting is supplied as standard.

• Ability to enter offset compensation for non-standard end fitting.

• NorTronic® can be locked from adjustment “P type” for production environments (via TDS).

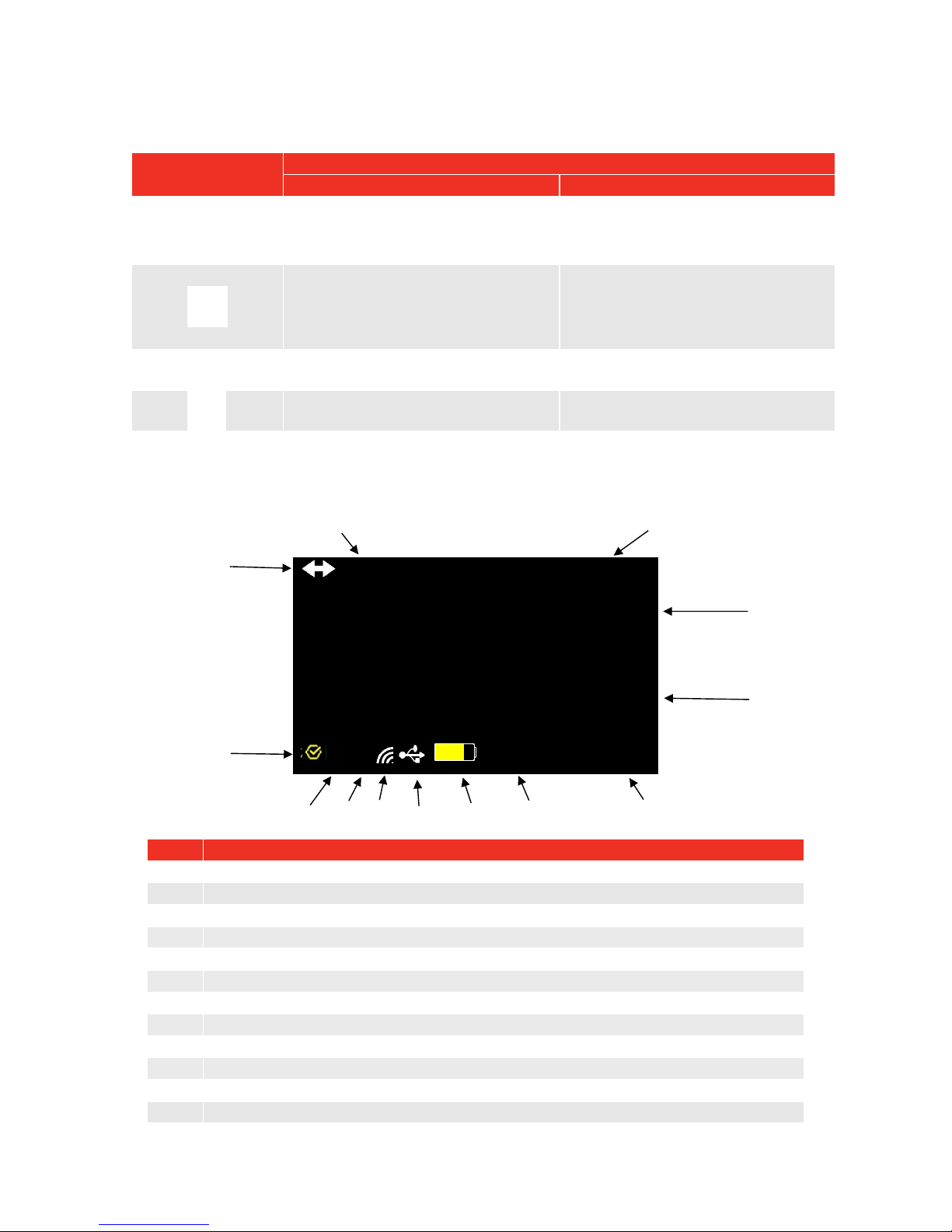

• 2 colour 0.95” OLED displays for visual indication of measurement against Target status.

• Audible indication of Target status.

• Vibration feedback when Target reached.

• 4 digit resolution for all NorTronic® electronic torque wrenches.

• Maximum of 2400 (date & time stamped) reading memory store.

• 5 user buttons.

• Operational from three AA internal rechargeable / non rechargeable batteries.

• Up to 15 linked (or non-linked) Targets can be on the tool at any one time.

• USB port for interface to TDS.

• Built in Wireless transceiver for Wireless interface to TDS.

• 12 Torque units.

• Time & date stamped Test Results.

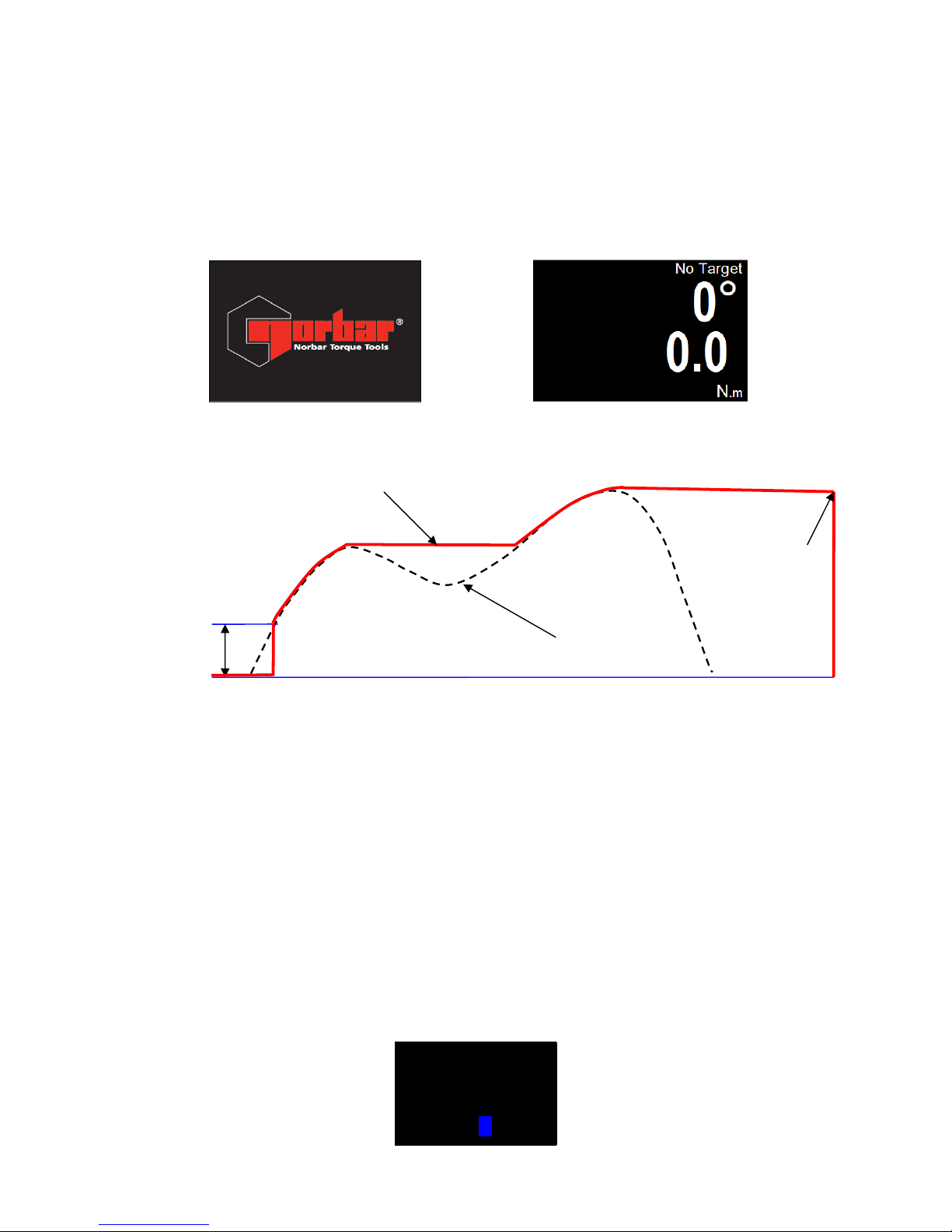

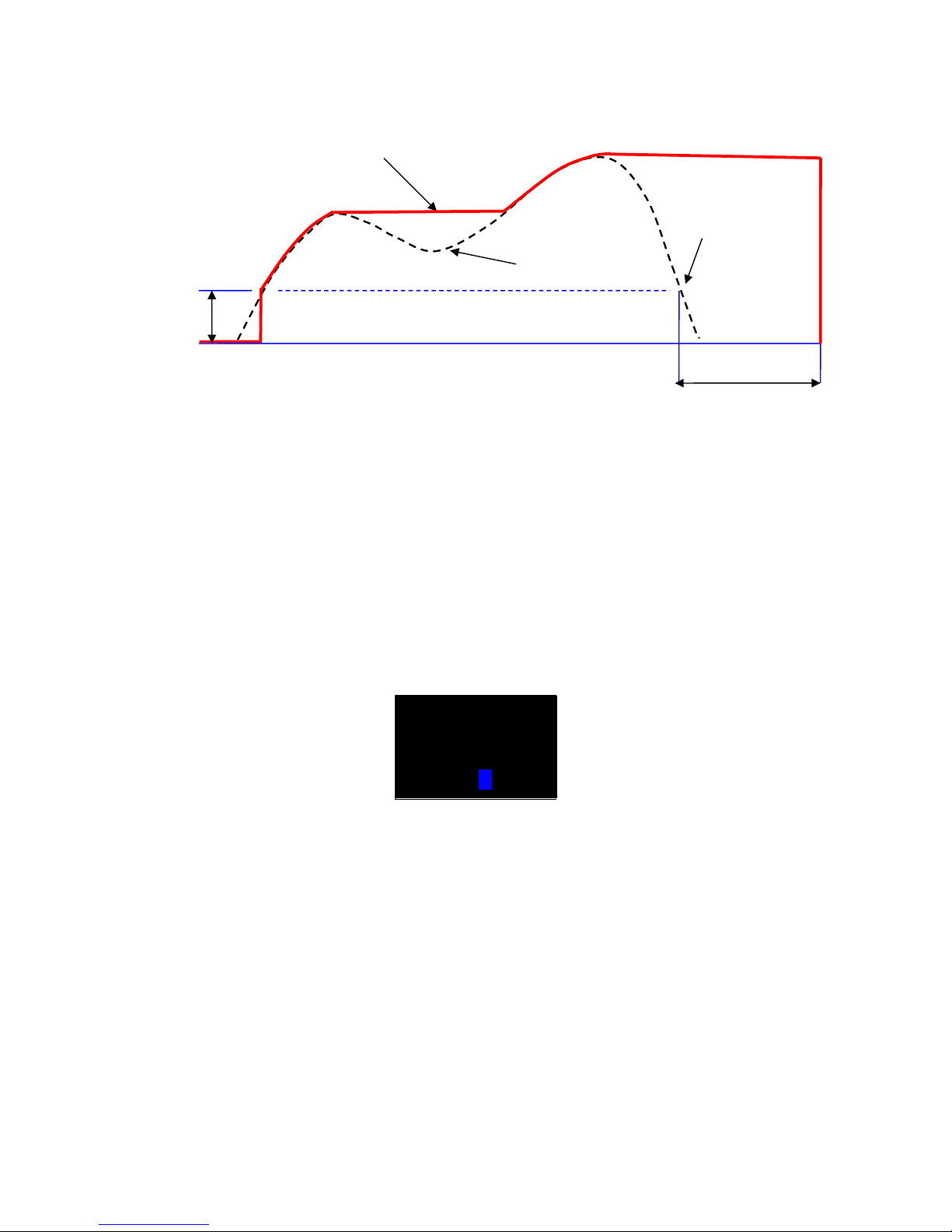

• Displays torque only or torque & angle.

• IP44 protection against dust and water ingress.

• Ability to Ratchet when measuring Angle.

• Directly display and save the output Torque of a HT (Hand Torque) gearbox when used in conjunction

with a NorTronic®.

• Produce, save, view and print Real Time Torque & Angle Graphs in conjunction with TDS.

• View and print Reports for Results in conjunction with TDS.

• 4 Target modes - Torque Target only, Snug Torque followed by Angle Target, Snug Torque followed by

Angle Target + final Torque Target or Audit Torque Target.

• Improved battery life when sleeping (batteries do not need to be removed for storage).

• ASCII mode for interfacing to third party control systems.