v1.1 REV. 12/2020

OPERATION / PROGRAMMING MANUAL EN

MR14

The MR14 receiver is a wireless receiver for managing multiple MX14 emitters.

When receiving information from the emitter, it communicates with the automation

control board via cable, so that the automation can be stopped or reversed.

TECHNICAL CHARACTERISTICS

• Power Supply -Vdc / -Vac

• ECO Inputs

/V

• Relay Vdc A/Vac .A

• Working frequency MHz

• Memory for emitters

• Reach in the open m

• Dimension

x x (mm)

• IP

IP

AES encryption

1

3

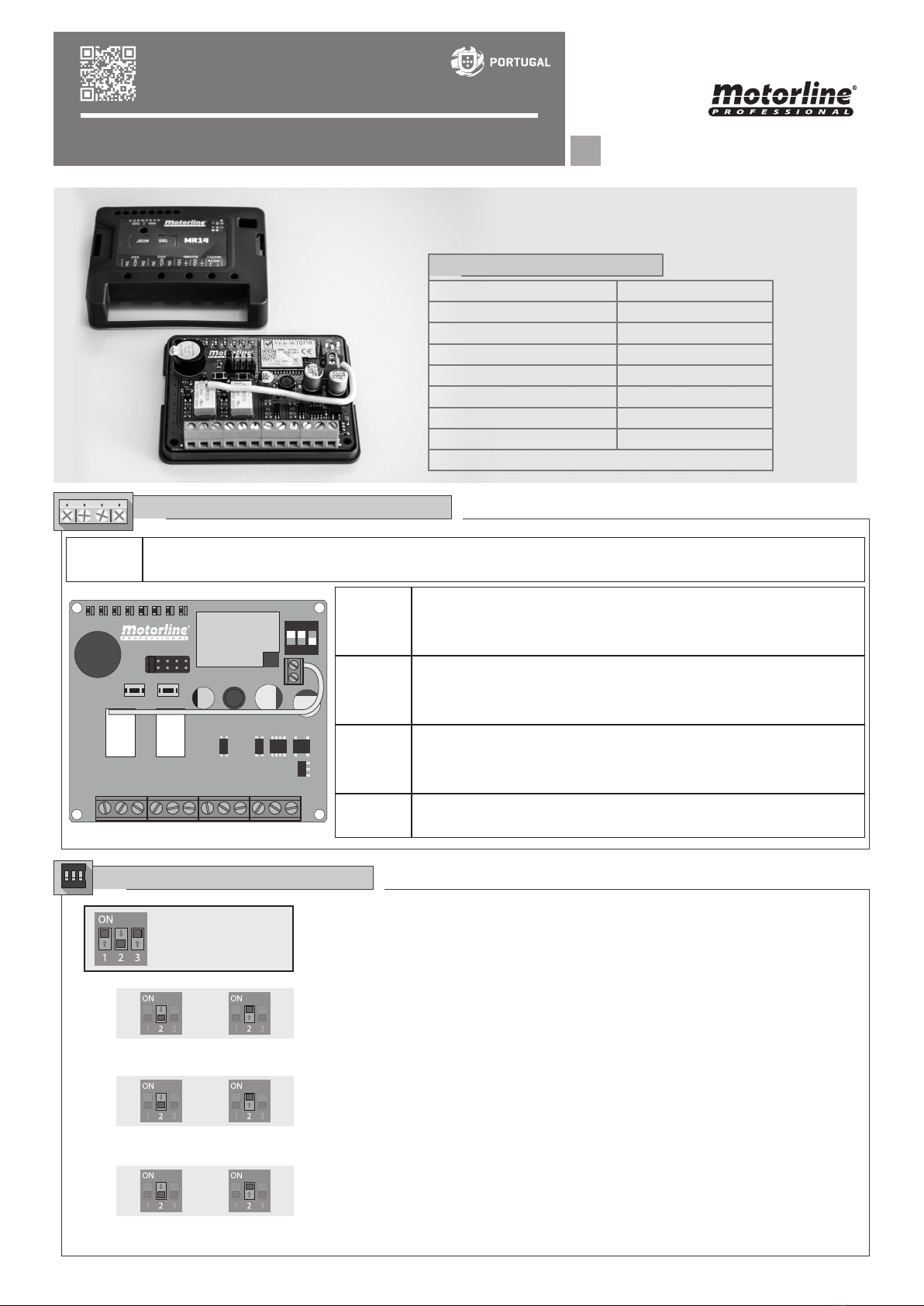

Basic operation:

Dipper 1 → ON;

Dipper 2 → OFF;

Dipper 3 → ON.

ECO NORMAL

ACTIVED

BUZZER DEACTIVATED

BUZZER

1

•

2

•

3

•

NC

COM

NO

Relay output NO channel

>the output is active when any channel 1 emitter is in error

(ex: Door hit an obstacle, communication failed or the battery ran out).

The NC or NO output must be connected to the control board.

4

•

5

•

6

•

NC

COM

NO

Relay output NO channel

>the output is active when any channel 2 emitter is in error

(ex: Door hit an obstacle, communication failed or the battery ran out). The NO

or NC output must be connected to the control board.

7

•

8

•

9

•

10 •

CH1

COM

CH2

COM

/V mode input

>used to activate channel 1 or 2 in ECO mode (Dipper 1 OFF). The control

board must activate this input when the door starts to move.

11

•

12

•

+

-

/ Vdc/ac power supply

LEDs

LED, LED, LED e LED - memory position indicators to be programmed for channel

LED, LED, LED e LED - memory position indicators to be programmed for channel

1 2 3

ON

NC COM NO NC COM NO CH1 COM CH2 COM + -

LED1 LED2 LED3 LED4 LED5 LED6 LED7 LED8

JOIN SEL

1 2 3 4 5 6 7 8 9 10 11 12

INPUTS / OUTPUTS AND LEDS

DIPPER

1 • Transmission mode

• OFF – ECO mode

> With ECO mode, devices will only communicate with each other when the automation is in

operation (opening or closing), in order to save energy.

To use this mode, it is necessary to connect the control board to the MR14 CH1 and / or CH2

inputs. When the door is stopped, communication takes place approximately every 30 seconds.

With the door moving, it will be done in intervals of 300 to 600 milliseconds.

•ON – NORMAL mode

> In this mode, communication is always done at intervals of 300 to 600 milliseconds, ignoring

energy savings.

As such, it is not necessary to connect the control board to the MR14 CH1 and / or CH2 inputs.

2 • Operation of CH1 and CH2 inputs (ECO mode)

> Select the desired status for the CH1 and CH2 inputs information, paying attention to the

settings of the operator control board.

• OFF – NO (MR14 and MX14 only communicate when the circuit is closed);

•ON – NC (MR14 and MX14 only communicate when the circuit is opened).

3 • Activate buzzer (audible alarm)

• OFF – Buzzer Actived;

•ON – Buzzer deactivated.

2

NO NC