3

(A) (C)(B)

Installation

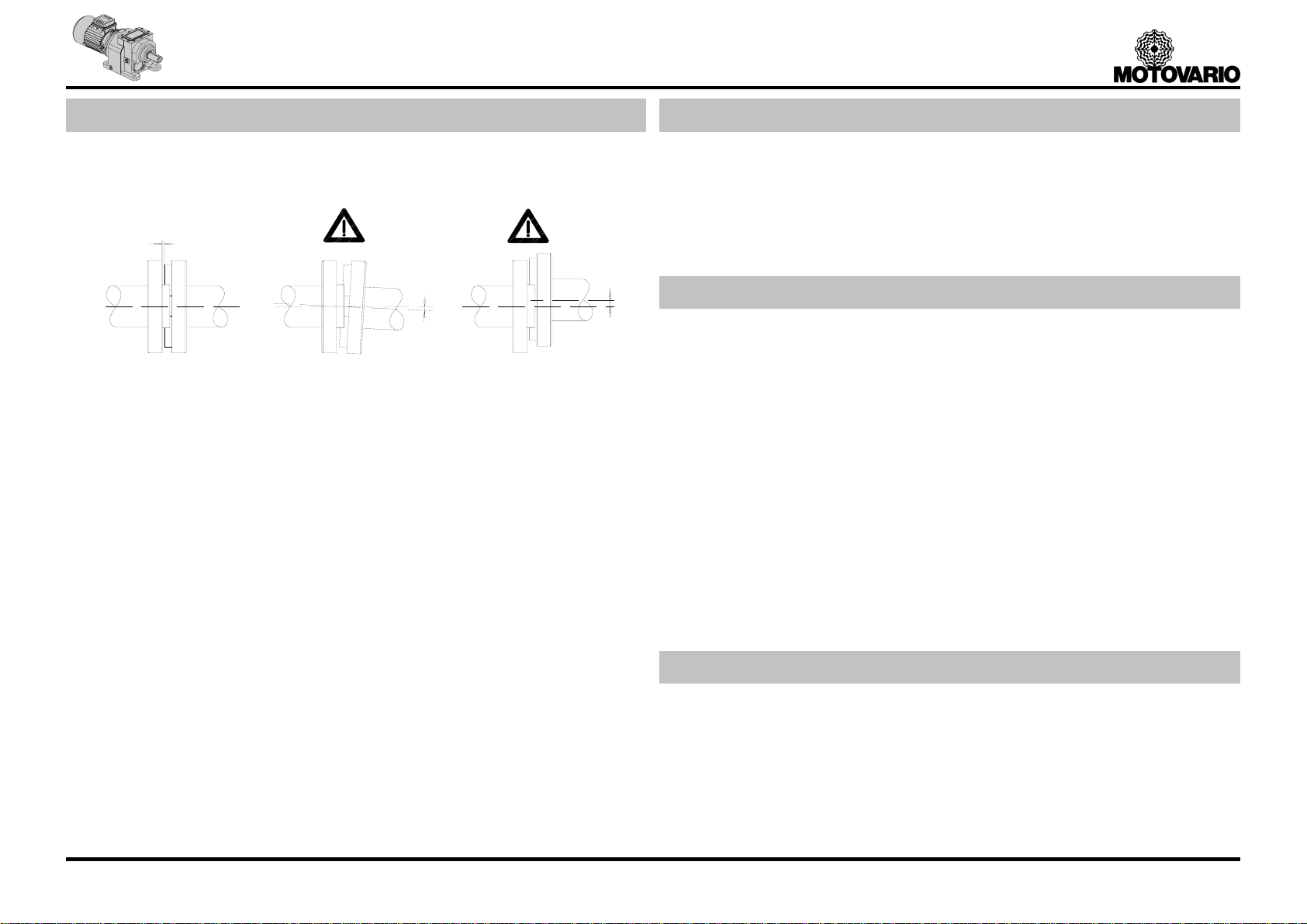

Correct and incorrect examples of coupling connections

Starting up

The unit should be started up gradually: do not immediately apply the maximum load the

machine is able to take ; look for and correct any malfunction that may be caused by incorrect

mounting.

Running-in is not essential for the reduction unit to run properly since modern construction

techniques for the gears and castings, the extreme cleanliness of the internal parts, and the

excellent qualities of the lubricants used, ensure that the internal parts receive a high degree

of protection even during the first moments.

Servicing

The high degree of finish of the internal parts ensures that the unit will work correctly with only

a minimum amount of servicing

Generally speaking, the following rules should be followed: periodically check that the exterior

of the assembly is clean, especially in the cooling areas; periodically check to see if there are

any leaks, especially in the areas around the oil seals.

Assemblies that are lubricated for life and thus do not have any oil plugs do not require any

special maintenance except as stated above.

For other assemblies, low maintenance is required with an oil change at 8/10,000 hours of

use. The change of oil naturally depends on the type of environment and use to which the unit

is put.

Apart from the normal maintenance rules given above, make sure the breather hole in the plug

is clean and, using the oil window, periodically check that there is sufficient lubricant.

Should it be necessary to top up with lubricant, use the same type that is already in the reducer

or one that is compatible with it.

In case of doubtful incompatibility between lubricants, we recommend you empty out the oil

from the gearbox completely and, before refilling with new oil, wash out the unit to remove any

residue.

When changing the oil, follow the previous instructions.

Troubleshooting

If any problems should arise when starting the unit or during its first few hours of operation,

contact the after sales service unit of Motovario.

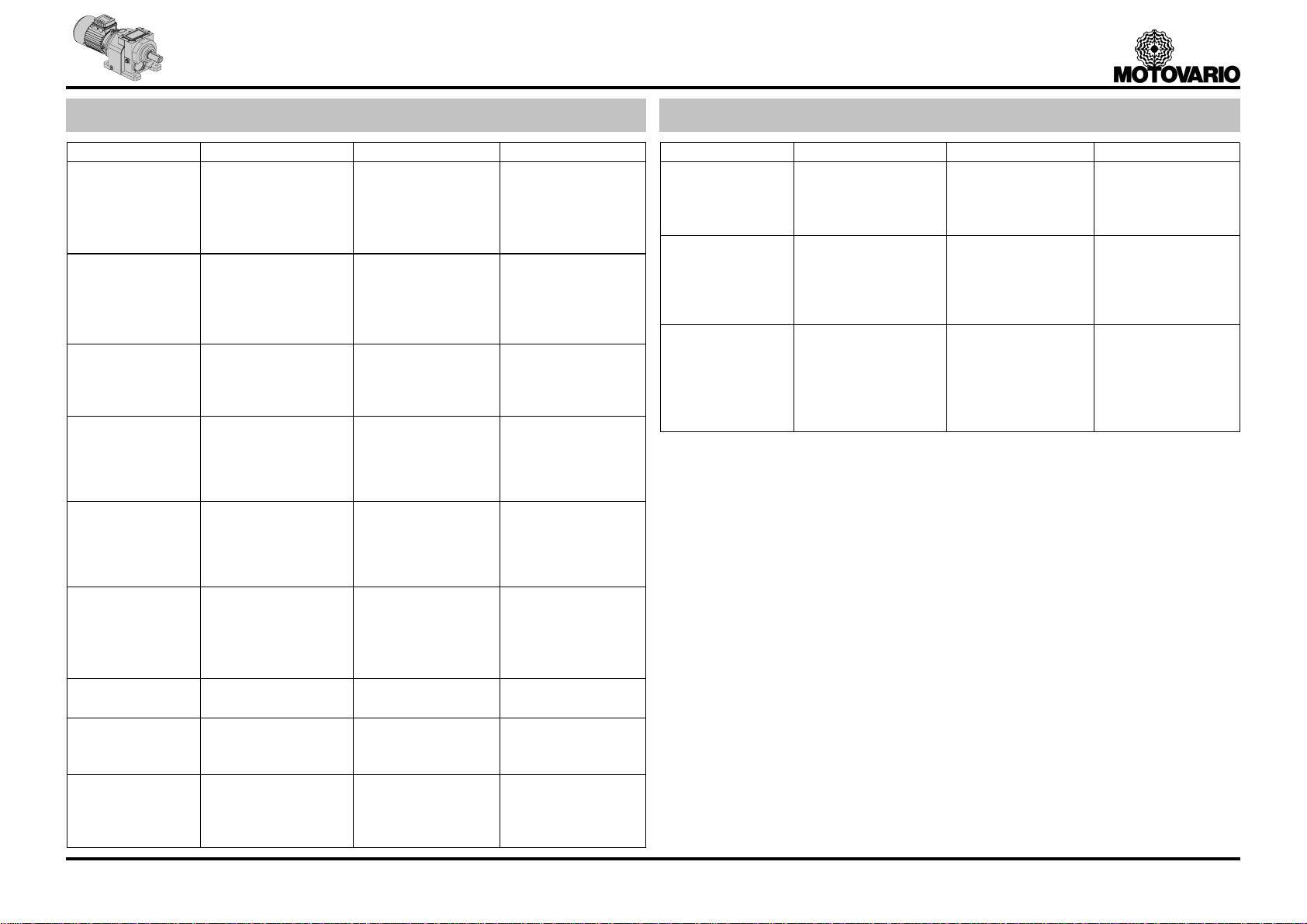

The table shows a series of problems with a description of possible remedies.

It should be kept in mind however that the information given is for reference only, as all the

drives manufactured by Motovario are thoroughly tested and checked before they leave the

factory.

Please note that tampering with the assembly without prior authorization from Motovario

immediately invalidates the warranty and often makes it impossible to ascertain the causes of

a defect or malfunction.

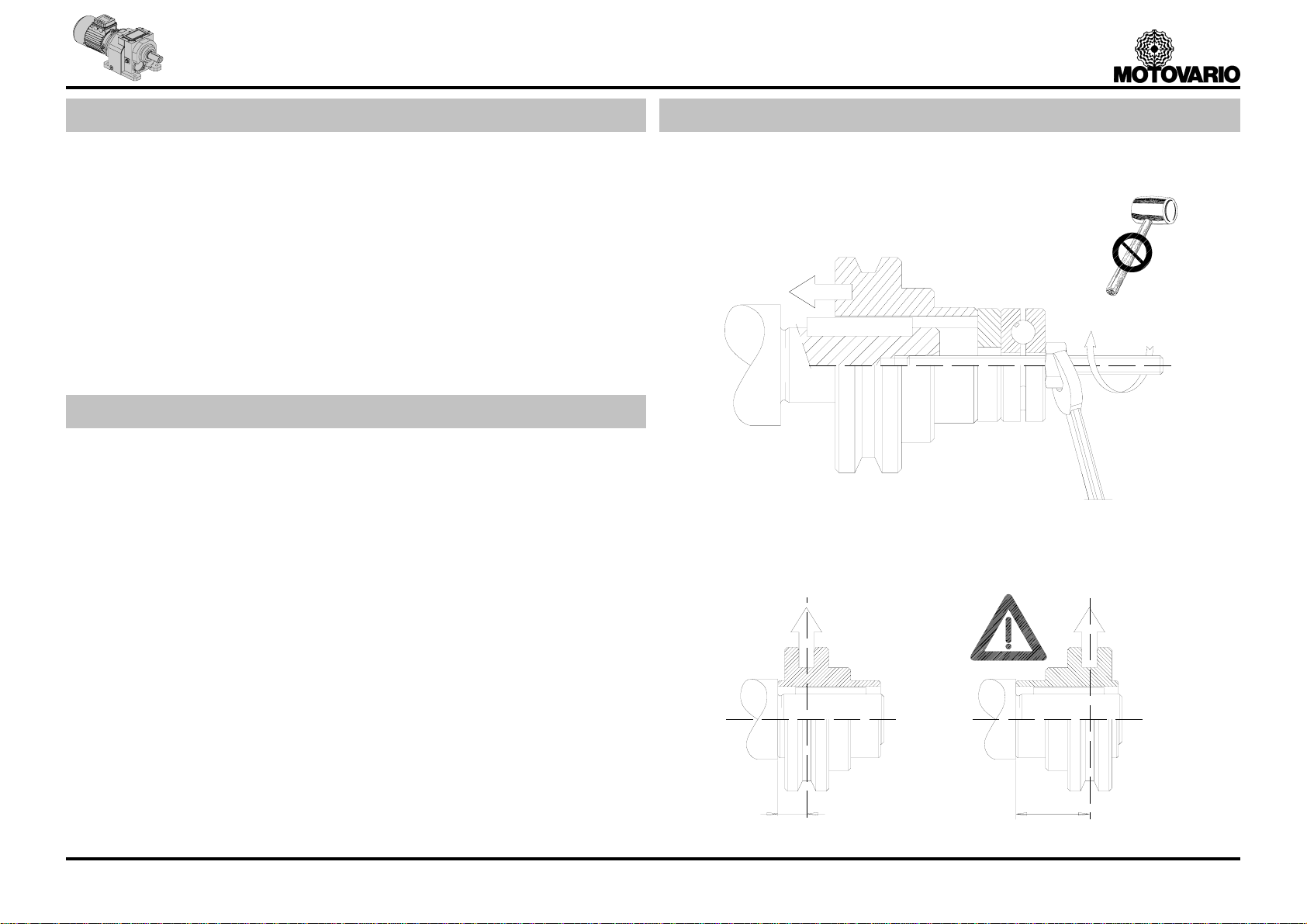

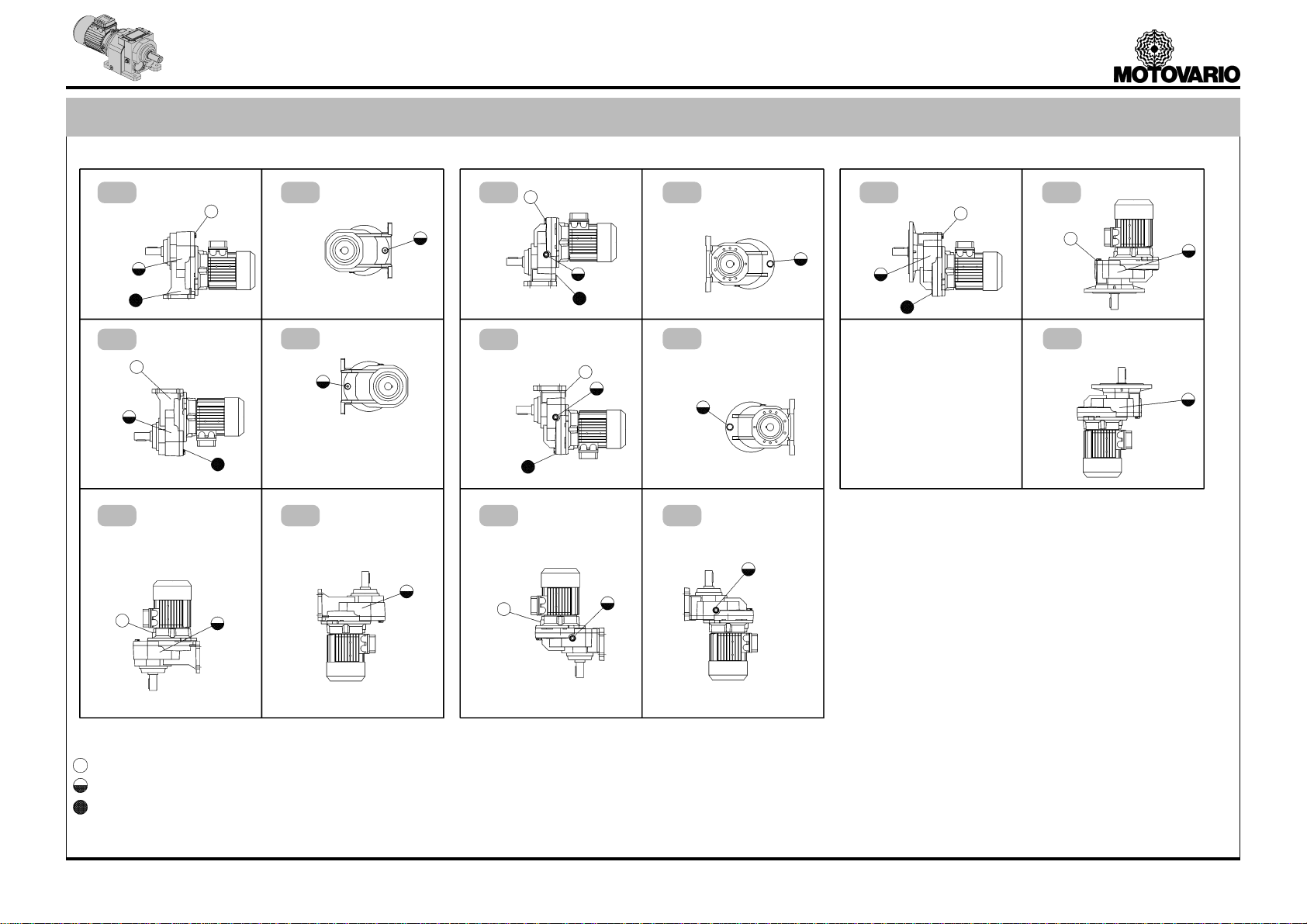

Fig.3

The pulley must be mounted on the main shaft as close as possible to the shoulder so that is

does not cause excessive radial load on the bearings (fig. 2).Great care must be taken when

connecting the couplings to ensure that they are well aligned, so as not to cause excessive

radial load on the bearings (fig.3).When it is applied, paint must never be used on rubber

parts: oil seal, etc. It must never be applied to any breather holes in plugs if they are mounted

on the unit.In the case of assemblies with oil plugs, remove the closed cap used for transport

and fit it with the breather plug that is supplied with the reduction unit.When the assembly is

supplied without a motor, the following precautions must be followed in order to ensure that

connections are properly made

Mounting the motor on the pam B5/B14 flange

Check that the tolerance of the motor shaft and the motor flange comply with at least one

‘normal’ class of quality. Carefully clean off any trace of dirt or paint from the shaft, the centering

diameter and the face of the flange. Carry out mounting operations making sure not to use

force. If this is not possible, check the tolerance of the motor key and ensure that it is correctly

fitted. Apply assembly grease to the shaft in order to prevent oxidation or seizure caused by

contact.

Good quality motors should be used in order to ensure that the unit works correctly, without

vibrations or noise.

Before mounting the unit on the machine, check that the principal shaft of the reduction unit

rotates in the right direction.

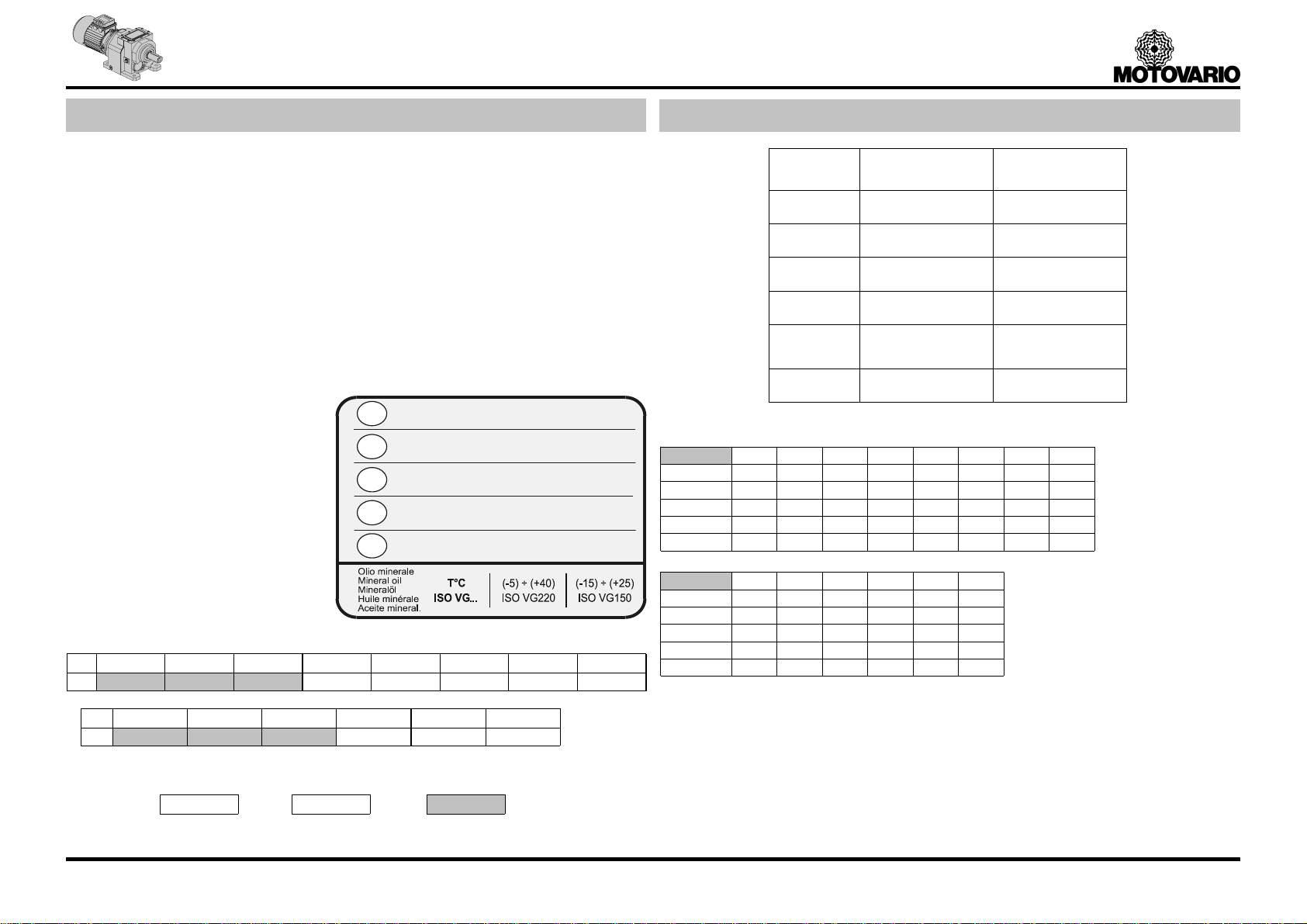

Use the oil window, if present, to check that the lubricant reaches the correct level required for

the mounting position used.